A barium titanate doped modified lanthanum zirconate ceramic material and its preparation method

A ceramic material, lanthanum zirconate technology, applied in barium titanate doped modified lanthanum zirconate ceramic material and its preparation field, can solve the problems of low thermal conductivity, high thermal conductivity, low bending strength, etc., and achieve low thermal conductivity The effect of conductivity, simple process, and enhanced bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

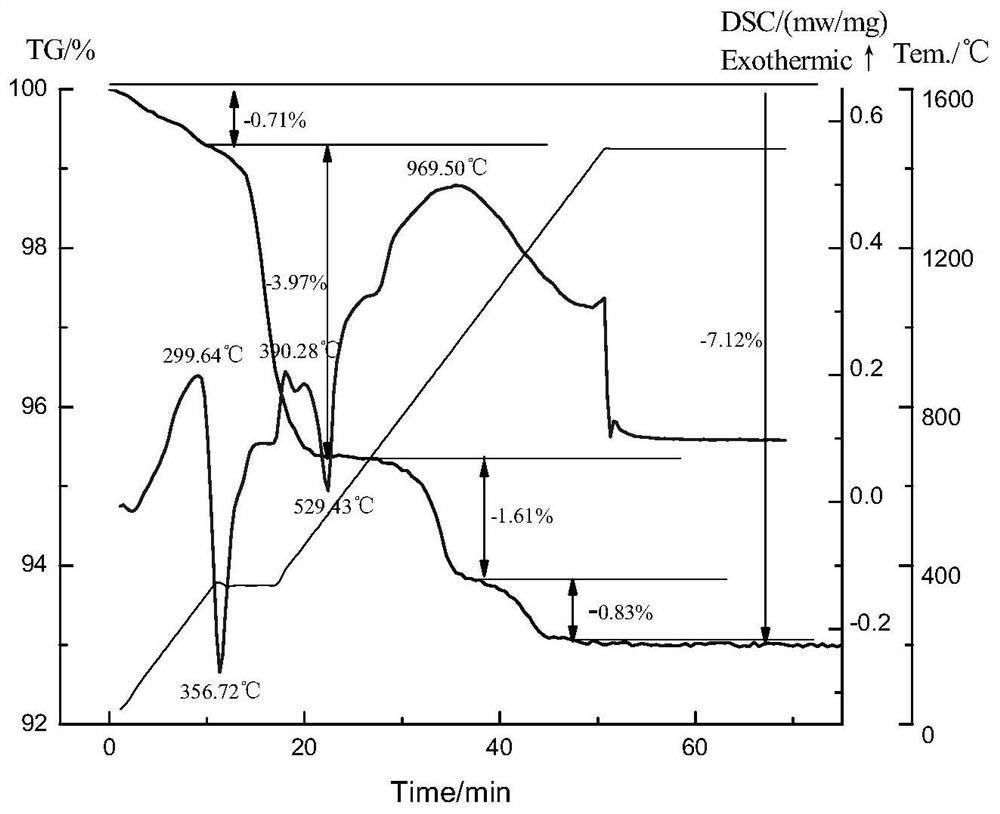

[0046] The preparation method of the described barium titanate doped modified lanthanum zirconate ceramic material, the specific steps are:

[0047] a. Weigh La separately according to the chemical composition ratio 2 o 3 , Y 2 o 3 , ZrO 2 and CeO 2 According to the zirconia ball: the above four raw materials: alcohol = 1: 2: 1 (mass ratio) mixed in a nylon ball mill;

[0048] b. Mix on a ball mill for 6 to 12 hours to obtain a uniformly mixed slurry. At this time, the ball milling medium is alcohol, the ball milling body is a zirconia ball, and the main body is the above four raw materials (La 2 o 3 , Y 2 o 3 , ZrO 2 and CeO 2 );

[0049] c. drying at 60-80°C for 10-16 hours to obtain dry powder;

[0050]d. The dry powder is calcined and synthesized at 1300-1400°C for 2-4 hours, which is the precursor powder obtained by the solid-state reaction method;

[0051] e. Add BaTiO according to the amount added 3 , carry out secondary ball mill drying;

[0052] f. addi...

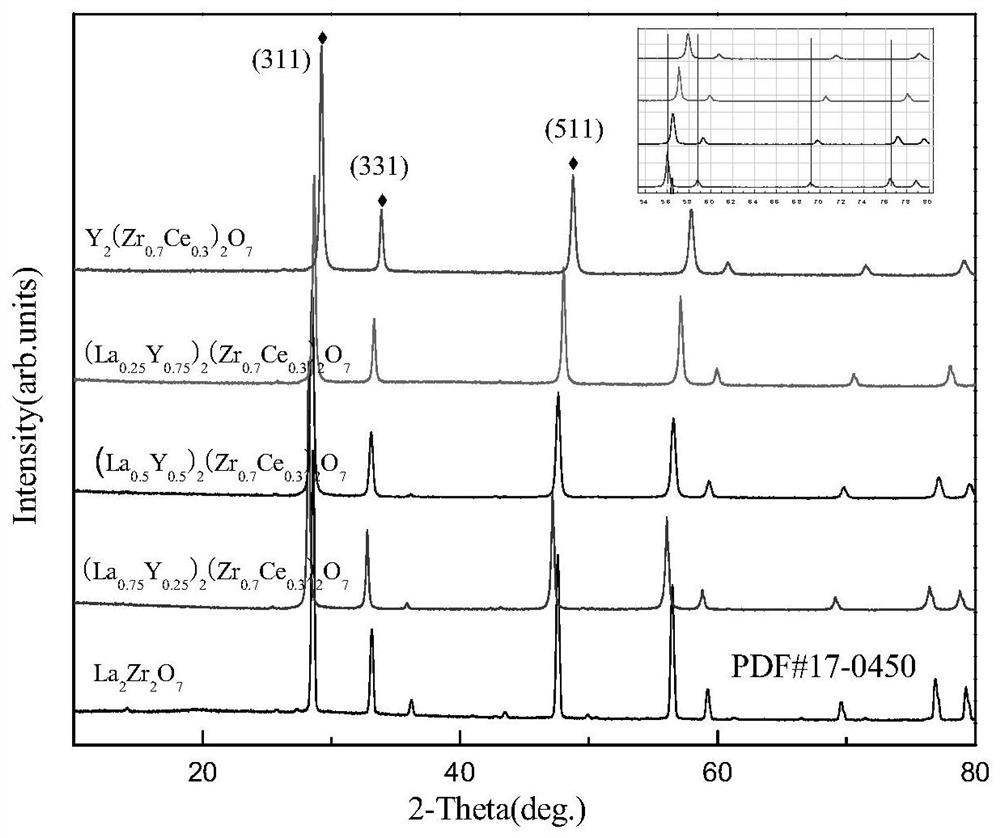

Embodiment 1

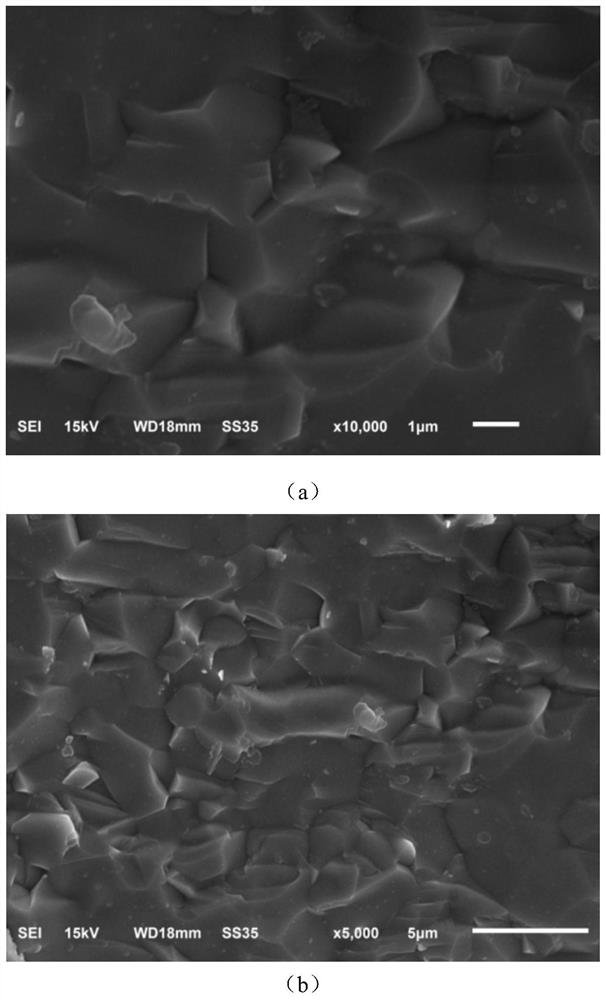

[0056] Preliminary synthesis according to the stoichiometric ratio (La 0.75 Y 0.25 ) 2 (Zr 0.7 Ce 0.3 ) 2 o 7 Precursor, add 5% BaTiO 3 After ball milling, drying, granulation, and molding, it is sintered at 1600°C under normal pressure in an air atmosphere, and the thermal conductivity after sintering is 1.31W·m -1 ·K -1 , the bulk density is 5.76g / cm 3 , The flexural strength is 102.4MPa.

Embodiment 2

[0058] Preliminary synthesis according to the stoichiometric ratio (La 0.75 Y 0.25 ) 2 (Zr 0.7 Ce 0.3 ) 2 o 7 Precursor, add 10% BaTiO 3 After ball milling, drying, granulation, and molding, it is sintered at 1600°C under normal pressure in an air atmosphere, and the thermal conductivity after sintering is 1.14W·m -1 ·K -1 , the bulk density is 5.84g / cm 3 , The flexural strength is 174.7MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com