A kind of cobalt base catalyst and application for carbon dioxide methanation

A technology based on cobalt-based catalysts and carbon dioxide, which is applied in physical/chemical process catalysts, catalyst activation/preparation, and hydrocarbon production from carbon oxides, etc. It can solve the problems of high thermal conductivity, low conversion rate, and large heat release. , to achieve good low-temperature reactivity, good mechanical strength, good thermal conductivity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

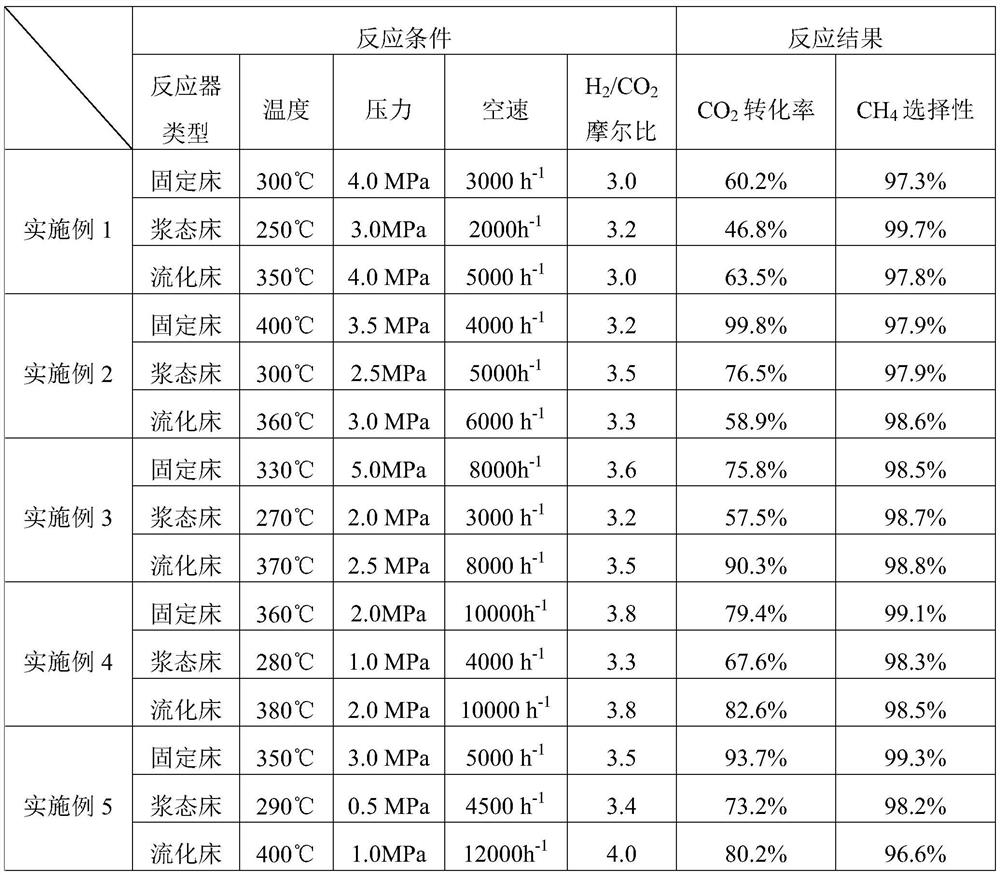

Examples

Embodiment 1

[0029] (1) Prepare titanium carbide according to the method disclosed in Example 1 of patent CN102674350B, the average particle diameter of the prepared titanium carbide nanoparticles is 16nm, and the specific surface area is 197m 2 / g;

[0030] (2) According to the content of silicon dioxide and titanium carbide on the modified carrier in the final catalyst, weigh 1.72g of dimethylethoxysilane to prepare an ethanol solution and impregnate an equal volume in 100g of the above-mentioned titanium carbide, and then rotate at 100°C Evaporate until there is no volatile matter, and then roast at 400°C for 8 hours to obtain a modified titanium carbide carrier, the weight composition of which is silicon dioxide:titanium carbide=0.01:1;

[0031] (3) According to the content of cobalt carbide in the final catalyst, weigh 90.47g of cobalt nitrate hexahydrate, dissolve and impregnate the above-mentioned modified titanium carbide carrier in equal volume, then dry at 100°C for 24h, and then...

Embodiment 2

[0036] (1) Prepare titanium carbide according to the method disclosed in Example 2 of the patent CN102674350B, the average particle diameter of the prepared titanium carbide nanoparticles is 23nm, and the specific surface area is 136m 2 / g;

[0037] (2) According to the content of silicon dioxide and titanium carbide of the modified carrier in the final catalyst, take 4.51g of trimethylsilanol to prepare an ethanol solution and impregnate an equal volume in 100g of the above-mentioned titanium carbide, and then rotate evaporate at 120°C to No volatile matter, then calcined at 500°C for 6 hours to obtain a modified titanium carbide carrier, the weight composition of which is silicon dioxide:titanium carbide=0.03:1;

[0038] (3) According to the content of cobalt carbide in the final catalyst, weigh 115.32g of cobalt nitrate hexahydrate, dissolve and impregnate the above-mentioned modified titanium carbide carrier in equal volume, then dry at 110°C for 16h, and then roast at 300...

Embodiment 3

[0043] (1) Prepare titanium carbide according to the method disclosed in Example 3 of the patent CN102674350B, the average particle diameter of the prepared titanium carbide nanoparticles is 25nm, and the specific surface area is 121m 2 / g;

[0044] (2) According to the content of silicon dioxide and titanium carbide on the modified carrier in the final catalyst, weigh 9.86g of trimethylethoxysilane to prepare an ethanol solution and impregnate an equal volume in 100g of the above-mentioned titanium carbide, then rotate at 130°C Evaporate until there is no volatile matter, and then bake at 600°C for 5 hours to obtain a modified titanium carbide carrier, the weight composition of which is silicon dioxide:titanium carbide=0.05:1;

[0045] (3) According to the content of cobalt carbide in the final catalyst, weigh 120.72g of cobalt acetate tetrahydrate, dissolve and impregnate the above-mentioned modified titanium carbide carrier in equal volume, then dry at 120°C for 12h, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com