Catalyst for hydrogenation of ethylene carbonate, preparation method and application

A technology of ethylene carbonate and catalyst, which is applied in the field of catalyst for hydrogenation of ethylene carbonate and its preparation field, can solve the problems of not too long service life and large amount of catalyst, and achieves high product selectivity, good low temperature reaction activity and high product selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

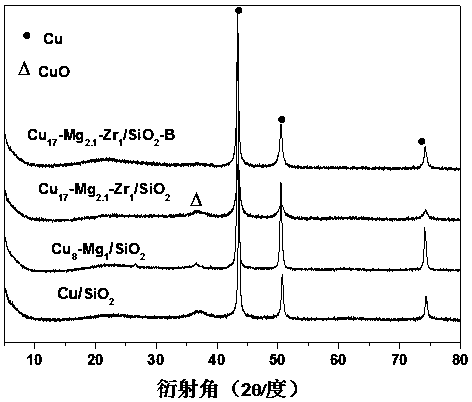

Embodiment 1

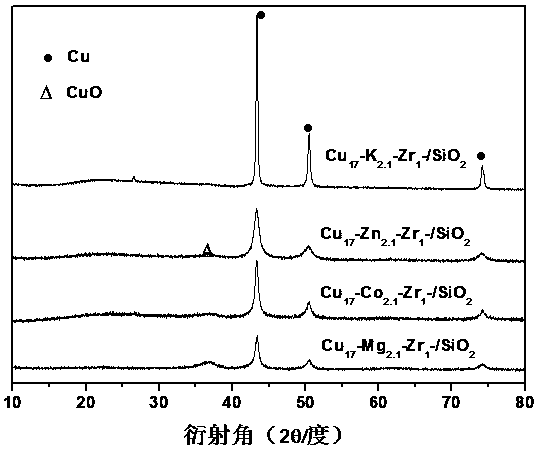

[0029] 10.2 g of Cu(NO 3 ) 2 ·3H 2 O, 1.1 g Zr(NO 3 ) 4 ·5H 2 O and 1.4 g Mg(NO 3 ) 2 ·6H 2 O(x Cu :y Al :z Mg =17:1:2.1) Prepare a mixed solution with deionized water, and transfer it into a round-bottomed flask containing 2 grams of silicon oxide (to make the metal loading 60wt.%). Na 2 C0 3 The aqueous solution and the metal mixed solution are co-precipitated in a water bath at 75°C and continuously stirred, and the pH value of the titration end point is controlled to be 7-8, and the metal ions are co-precipitated into a solid; finally, the solid is dried at 120°C for 10 hours. Roast at 450°C for 5 hours, then impregnate 1% boric acid of the solid mass after roasting by impregnation method, denoted as Cu 17 -Zr 1 -Mg 2.1 / SiO 2-B, to obtain catalyst A, and the catalyst and its composition are shown in Table 1.

[0030] Catalyst reduction and ethylene carbonate hydrogenation:

[0031] Get 1 gram of catalyst A and pack it into a fixed-bed stainless steel rea...

Embodiment 2

[0035] Control the molar ratio of the three metals to be x Cu :y Zr :z Mg The catalyst was prepared under the condition of =17:1:2.1, and other specific operations were the same as in Example 1 except that boric acid was not impregnated.

[0036] The conditions of catalyst reduction and ethylene carbonate hydrogenation are the same as in Example 1, and the reaction results are shown in Table 1.

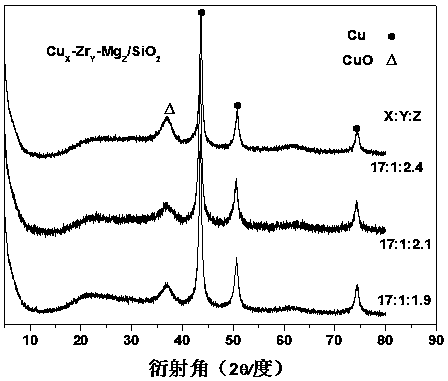

Embodiment 3

[0038] Control the molar ratio of the three metals to be x Cu :y Zr :z Mg Prepare catalyst under the condition of =17:1:2.4, concrete method is with embodiment 2. The conditions of catalyst reduction and ethylene carbonate hydrogenation are the same as in Example 1, and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com