Sec-butyl acetate hydrogenation catalyst and preparation method and application thereof

A technology of sec-butyl acetate and hydrogenation catalyst, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc. It can solve the problems that no relevant reports have been seen in the hydrogenation process, and achieve good low-temperature reaction activity and high product quality. The effect of high selectivity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

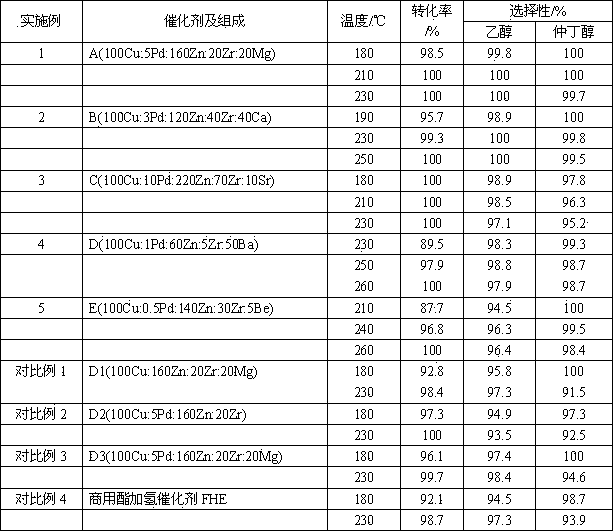

Examples

Embodiment 1

[0027] Preparation of catalyst:

[0028] 189.0 g of Zn(NO 3 ) 2 , 20.8 g ZrCl 4 and 50.1 g Mg(NO 3 ) 2 Mix metal solution 1 with deionized water, mix (NH 4 ) 2 CO 3 The aqueous solution and the metal mixed solution 1 were co-precipitated in a water bath at 80°C under constant stirring conditions, and the pH value at the end point was controlled to be 7-8, and the metal ions were co-precipitated into solid 1; 119.3 grams of Cu(NO 3 ) 2 With 4.4 g Pd(NO 3 ) 2 Mix metal solution 2 with deionized water, mix (NH 4 ) 2 CO 3 The aqueous solution and the metal mixed solution 2 are co-precipitated under the conditions of 80°C water bath, constant stirring and the presence of the solid 1, and the pH value of the end point is controlled to be 7-8, and finally all the metal ions are co-precipitated into the solid 2; finally the solid 2 Dry at 120°C for 10 hours and then bake at 450°C for 5 hours to obtain catalyst A. See Table 1 for the catalyst and its composition.

[0029]...

Embodiment 2

[0034] Preparation of catalyst:

[0035] 80.5 g ZnSO 4 , 40.4 g Zr(NO 3 ) 4 and 30.1 g CaCl 2 Make metal mixed solution 1 with deionized water, carry out co-precipitation with NaOH aqueous solution and metal mixed solution 1 in a 60°C water bath with constant stirring, control the end point pH value to 7-8, and metal ions are co-precipitated into solids 1 ; 68.0 g of CuSO 4 with 1.4 g PdCl2 Use deionized water to make metal mixed solution 2, carry out co-precipitation with NaOH aqueous solution and metal mixed solution 2 in a 60°C water bath, constant stirring and the presence of solid matter 1, control the end point pH value to 7-8, and finally all the metal Ions were co-precipitated into solid 2; finally, solid 2 was dried at 100°C for 15 hours and then calcined at 480°C for 6 hours to obtain catalyst B. The catalyst and its composition are shown in Table 1.

[0036] Catalyst reduction and hydrogenation of sec-butyl acetate:

[0037] Get 10.0 grams of catalyst B and pa...

Embodiment 3

[0041] Preparation of catalyst:

[0042] 136.0 g ZnCl 2 , 64.3 grams of Zr(SO 4 ) 2 and 5.3 g SrCl 2 Make metal mixed solution 1 with deionized water, carry out co-precipitation with KOH aqueous solution and metal mixed solution 1 in a 40°C water bath with constant stirring, control the end point pH value to 7-8, and metal ions are co-precipitated into solid matter 1 ; 62.3 grams of CuCl 2 with 4.9 g PdCl 2 Use deionized water to make metal mixed solution 2, and carry out co-precipitation with KOH aqueous solution and metal mixed solution 2 in a 60°C water bath, constant stirring and the presence of solid matter 1, and control the end point pH value to 7-8, and finally all the metal Ions were co-precipitated into solid 2; finally, solid 2 was dried at 80°C for 20 hours and then calcined at 550°C for 4 hours to obtain catalyst C. The catalyst and its composition are shown in Table 1.

[0043] Catalyst reduction and hydrogenation of sec-butyl acetate:

[0044] Get 10.0 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com