A kind of preparation method of alumina-coated transesterification catalyst

A catalyst and hydroxide technology, applied in the chemical industry, can solve the problems of difficult separation of homogeneous catalysts, increase the difficulty of promotion, difficult separation and recovery, etc., so as to improve the low temperature reaction activity and thermodynamic stability, and improve the chemical stability and thermodynamics. Stability, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

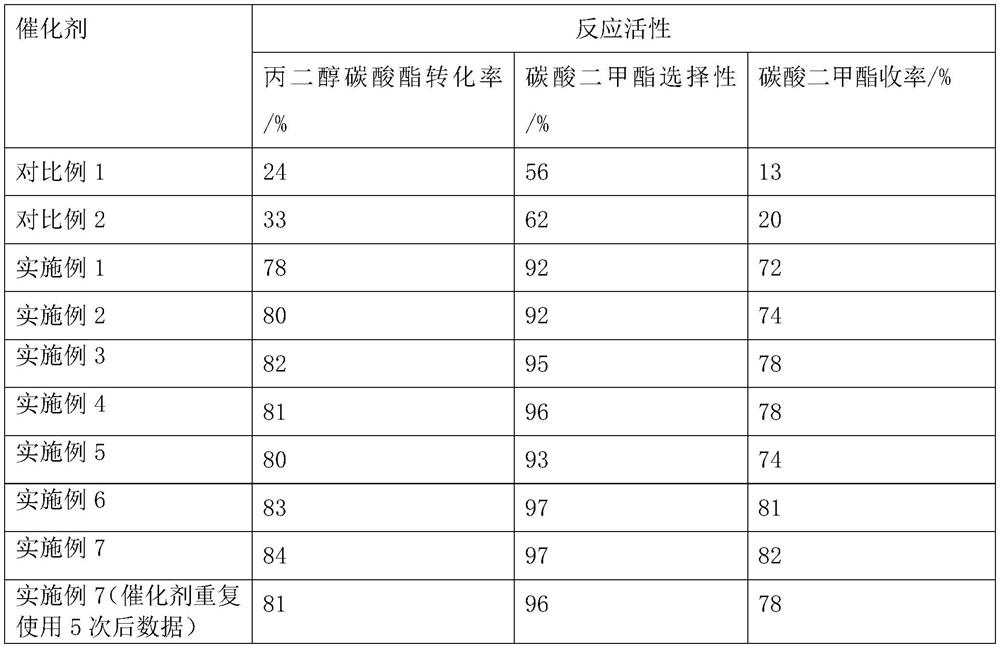

Examples

preparation example Construction

[0033] one for Al 2 O 3 Coated K 2 O / Na 2 O-WO 3 The preparation method of catalyst comprises the following steps:

[0034] Step A: mix by weighing the soluble alkali metal salt solution or hydroxide solution, soluble tungsten source solution and ethylene glycol in a metered ratio to obtain a mixed solution;

[0035] Step B: carry out a flux thermal reaction at 160-190°C, the reaction time is 12-20h, and then put it into a muffle furnace and calcinate at 450-600°C for 3-8h to obtain nano-K 2 O-WO 3 or Na 2 O-WO 3 particles;

[0036] Step C: The nano-K obtained in step B 2 O / Na 2 O-WO 3 The granules are mixed with 0.2mol / L glucose aqueous solution in a metered ratio, and subjected to a hydrothermal reaction at 160-190°C for 12-20h to obtain K 2 O / Na 2 O-WO 3 @C Granule mother liquor ;

[0037] Step D: Convert the K obtained in Step C to 2 O / Na 2 O-WO 3 @C particle mother liquor is added to the ammonia solution with a pH value of 13, and the addition amount of...

Embodiment 1

[0077] This example A1 2 O 3 Coated K 2 O / Na 2 O-WO 3 The preparation method of the catalyst is as follows:

[0078] Step A:

[0079] First, take the mass as WO 3 Mass 15% potassium nitrate, 3000% ethylene glycol and 100% (in WO 3 meter) of ammonium metatungstate, then add WO 3 Dissolve 5000% deionized water by mass, stir and mix well.

[0080] Step B:

[0081] The above solution was put into a high pressure reactor at 160°C for solvothermal reaction for 20h, and then put into a muffle furnace for calcination at 450°C for 8h to obtain nano-K 2 O-WO 3 particles.

[0082] Step C:

[0083] The resulting nanoK 2 O-WO 3 Granules, mixed with 0.2mol / L glucose aqueous solution in metered ratio, K 2 O-WO 3 The mass ratio of particles to glucose solution was 1:200. After ultrasonic dispersion, it was placed in an autoclave and hydrothermally reacted at 160 °C for 20 h to obtain K. 2 O-WO 3 @C mother liquor.

[0084] Step D:

[0085] The K obtained in step C 2 O-WO ...

Embodiment 2

[0090] This example A1 2 O 3 Coated K 2 O / Na 2 O-WO 3 The preparation method of the catalyst is as follows:

[0091] Step A:

[0092] First, take the mass as WO 3 5% by mass potassium hydroxide, 15% sodium nitrate, 10000% ethylene glycol and 100% (with WO 3 meter) of sodium metatungstate, then add WO 3 Dissolve 5000% deionized water by mass, stir and mix well.

[0093] Step B:

[0094] Put the above solution into a high pressure reactor at 190°C for 12h solvothermal reaction, and then put it into a muffle furnace and calcinate at 600°C for 3h to obtain nano-K 2 O / Na 2 O-WO 3 particles.

[0095] Step C:

[0096] The resulting nanoK 2 O / Na 2 O-WO 3 Granules, mixed with 0.2mol / L glucose aqueous solution in metered ratio, K 2 O / Na 2 O-WO 3 The mass ratio of particles to glucose solution was 1:500. After ultrasonic dispersion, it was placed in an autoclave and hydrothermally reacted at 190 °C for 12 h to obtain K. 2 O / Na 2 O-WO 3 @C mother liquor.

[0097] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com