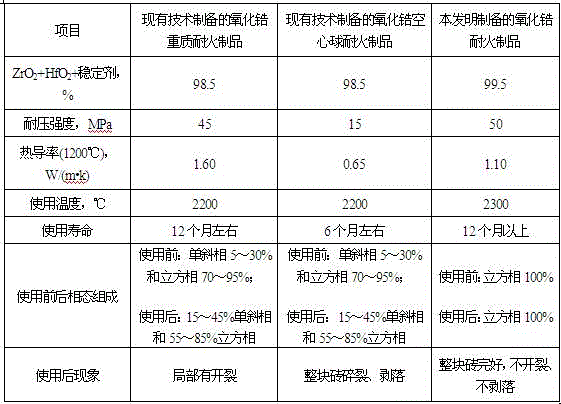

A functional composite zirconia refractory product and preparation method thereof

A technology for refractory products and zirconia, applied in the field of refractory materials, can solve the problems of reducing the purity and service temperature of the products, polluting the furnace body and crystals of the crystal growth furnace, etc., and achieves good structural stability, long service life and thermal conductivity of products. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

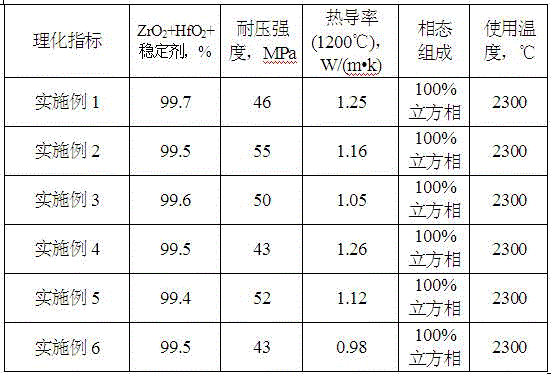

Examples

Embodiment 1

[0033] Embodiment 1: Using the process and scheme described in the present invention, the electrofusion Y with a particle size of 0.15 to 3.5 mm 2 o 3 Stabilized zirconia particles 60%; fused Y with a particle size of 1-50 μm 2 o 3 Stabilized zirconia fine powder 35%; fused Y 2 o 3 5% of granulated material prepared by stabilized zirconia micropowder; water-based resin solution is used as binder, and the binder is 3.0% of the total mass of the whole raw material (additional); the above raw materials are mixed and sieved and put into a closed trough for trapping After 12 hours, put it into a mold and press it into an embryo body, dry it at 120°C, and fire it at a high temperature of 1900°C to get a functional composite zirconia refractory product.

Embodiment 2

[0034] Embodiment 2: Using the process and scheme described in the present invention, the electrofusion Y with a particle size of 0.15 to 3.5 mm 2 o 3 Stabilized zirconia particles 54%; fused Y with a particle size of 1-50 μm 2 o 3 Stabilized zirconia fine powder 33%; fused Y 2 o 3 13% of granulated material prepared by stabilized zirconia micropowder; polyvinyl alcohol solution is used as a binder, and the binder is 4.5% of the total mass of the raw materials (additional); the above raw materials are mixed and sieved and put into a closed trough Made for 24 hours, put into the mold to vibrate and press to form an embryo body, dry at 60°C, and fire at a high temperature of 1850°C to obtain a functional composite zirconia refractory product.

Embodiment 3

[0035] Embodiment 3: Using the process and scheme described in the present invention, the electrofusion Y with a particle size of 0.15 to 3.5 mm 2 o 3 Stabilized zirconia particles account for 45% of the total mass of the raw materials; fused Y with a particle size of 1-50 μm 2 o 3 Stabilized zirconia fine powder accounts for 35% of the total mass of the raw materials; electrofusion Y 2 o 3 The granulated material prepared by stabilized zirconia micropowder accounts for 20% of the total mass of the raw materials; the phenolic resin solution is used as the binder, and the binder is 5% of the total mass of the raw materials (additional); the above raw materials are mixed and sieved and placed in a closed Trapped in the trough for 18 hours, put into the mold to vibrate and press to form an embryo body, dry at 180°C, and fire at a high temperature of 2000°C to obtain a functional composite zirconia refractory product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com