Method for preparing interactive laminar modeling material test piece

A technology of model material and interactive layer, applied in the field of rock mechanics test, can solve the problem of undiscovered preparation method, and achieve the effect of shortening the production cycle, high reliability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

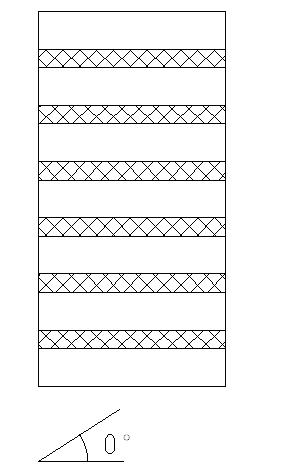

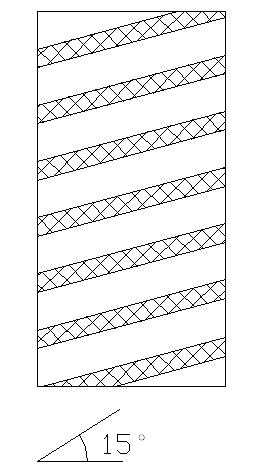

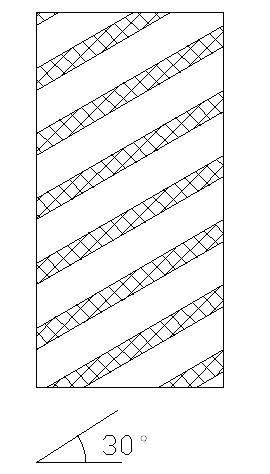

Image

Examples

Embodiment 1

[0044]The invention is used in cooperation with a thin-layer cutting device for multi-interlayer model materials and a soft thin-layer adsorption and translation device for model materials. According to the physical and mechanical properties of each layer of the multi-interlayer composite rock mass, the present invention mixes a variety of similar model materials; uses a thin-layer cutting device for multi-interlayer model materials to slice various model material blocks to obtain Model material thin layer; then use a model material soft thin layer adsorption translation device to alternately superimpose the thin layers of different materials obtained by cutting, and lay bonding materials on the interface when superimposing according to the test requirements; then, superimpose The final model material block is placed on a pressure testing machine, and it is pressurized to make it consolidate until it meets the test requirements, and an interactive layered model material block i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com