A large hollow cylinder sample maker for coarse-grained soil and its use method

A technology of hollow cylinder and coarse-grained soil, which is applied in the field of large-scale hollow cylindrical sample preparation for coarse-grained soil, can solve the problems of time-consuming, increased friction, and low energy, so as to avoid uneven force, not easy to collapse, and reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

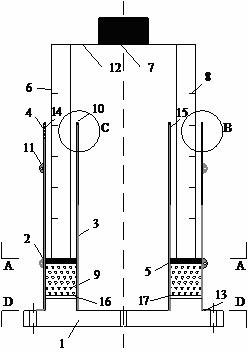

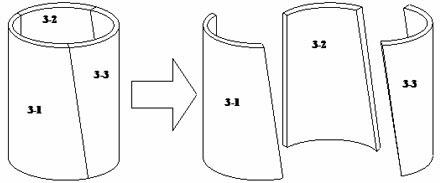

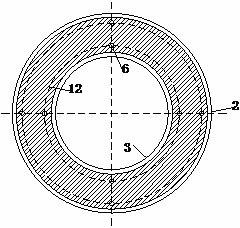

[0037] Such as Figure 1~Figure 6 Shown is a large hollow cylindrical sampler for coarse-grained soil. The outer diameter and inner diameter of the sample of the large-scale hollow cylinder sample maker for coarse-grained soil are determined according to the maximum particle diameter of the test material, the difference between the outer diameter and the inner diameter should be greater than 10 times the maximum particle diameter, and the inner diameter and The ratio of the outer diameter should be greater than 0.5; the height of the sample should be greater than 1 times the difference between the outer diameter and the inner diameter. It mainly consists of an annular base (1), an annular outer sleeve (2), an annular inner sleeve (3), an annular extension tube (4), a vibration motor (7), a circular iron plate (12), and a dowel rod (6 ), a locator (8) and an annular iron plate (5).

[0038] The ring-shaped outer sleeve (2) is composed of split molds, made of aluminum alloy ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com