Device for mixing powder and liquid and method thereof

A mixing device and liquid technology, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve problems such as centralized supply of polymers

Inactive Publication Date: 2003-12-03

MITSUBISHI CHEM CORP

View PDF4 Cites 46 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, with the structure of the mixing device, the polymer injected into the mixing chamber flies upward, and the polymer scatters to the outside of the mixing chamber, or it is difficult to concentrate and supply the polymer dropped after being charged to the area where the central part of the mixing chamber is located. Make it difficult for the liquid sprayed from the nozzle to mix uniformly with the polymer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

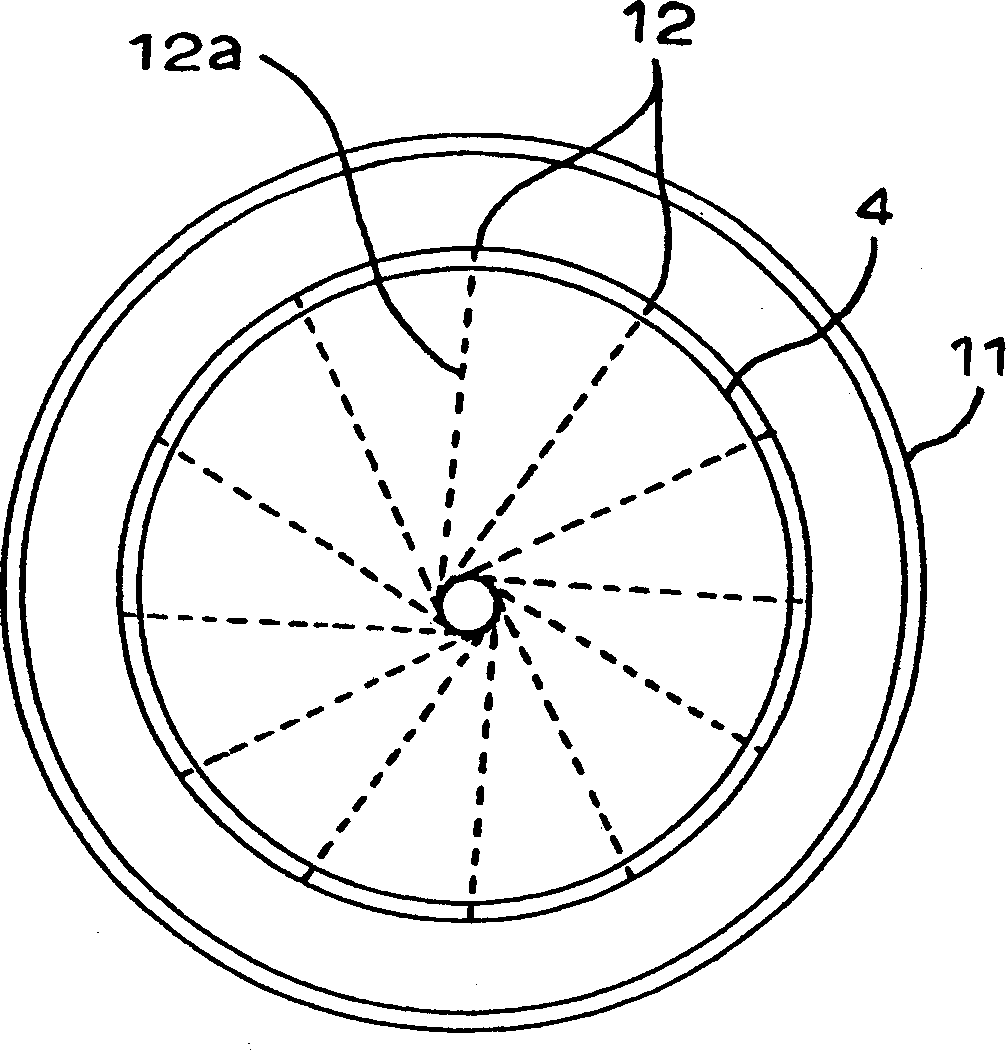

[0058] With a flow rate of 50kg / min, the polymer powder for polyacrylonitrile fibers falls freely from the pipeline 5, and dimethylacetamide at 35°C is sprayed out from the spray hole 12 at a flow rate of 200kg / min for mixing . The result is the absence of "clumps" in the slurry.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

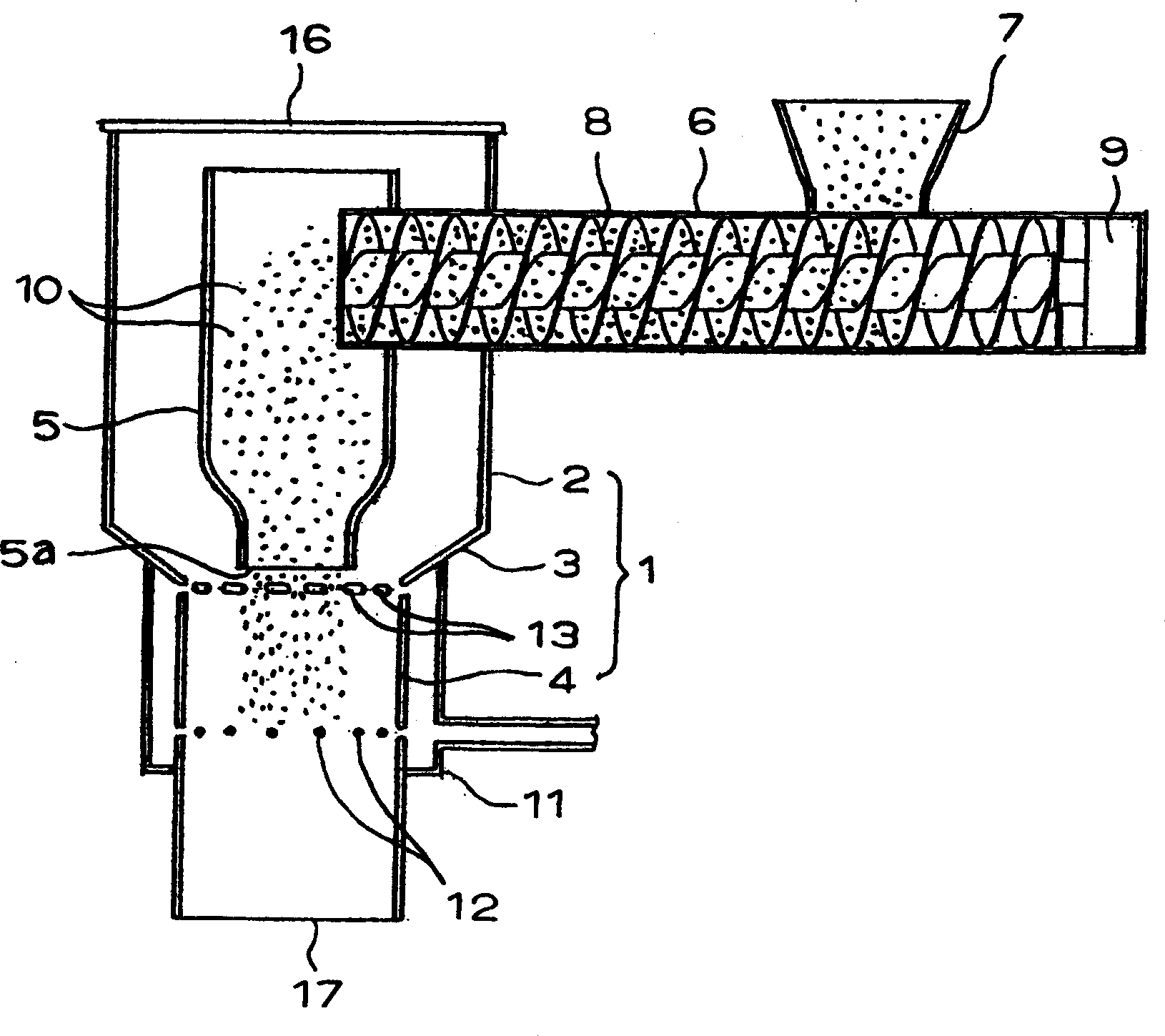

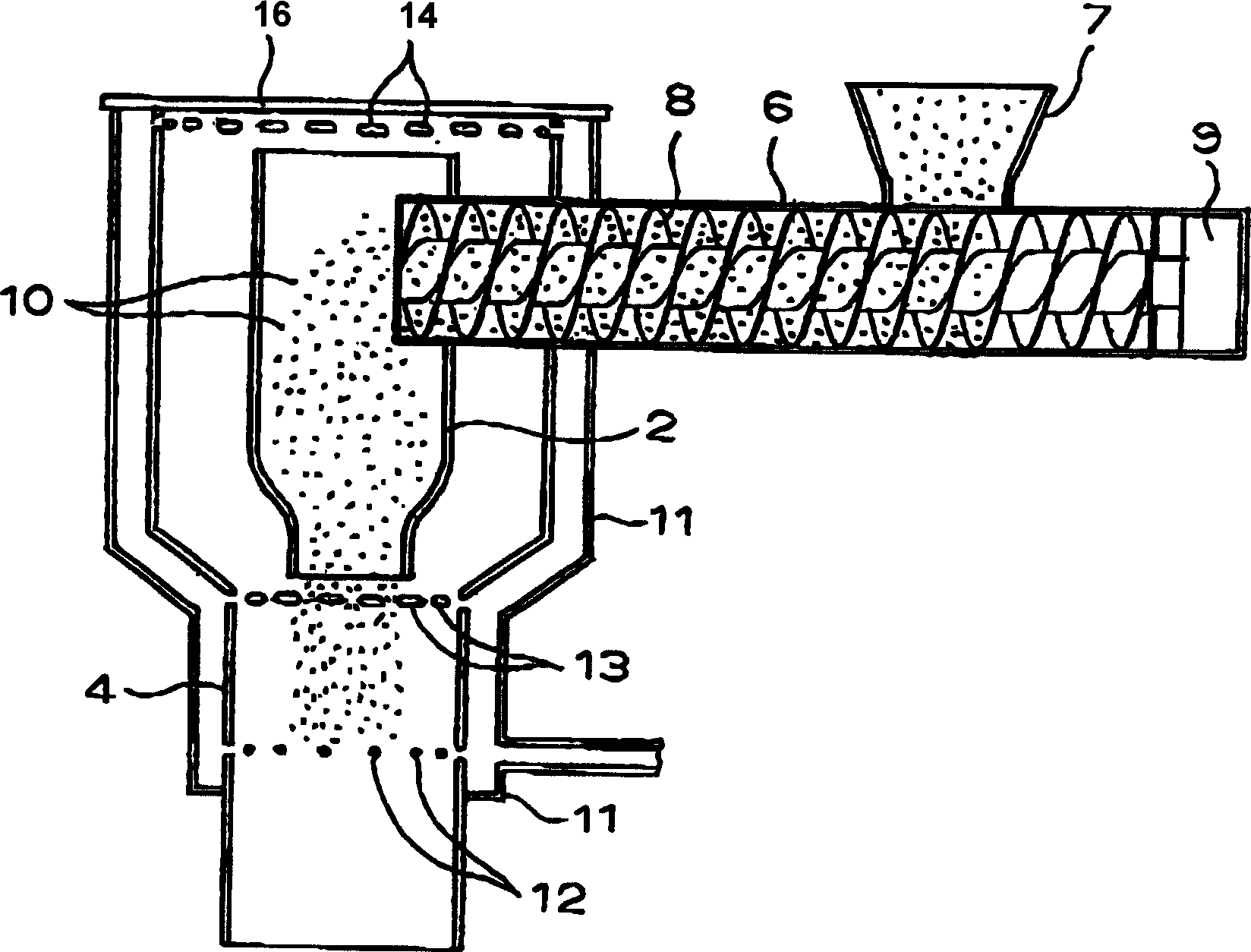

To provide a mixing device which prevents generation of lumps and undissolved powder in mixing the powder and liquid, and can continuously mix them and uniformly at a desired concentration, and to provide a method therefor. The constant quantity of powder 10 is fallen continuously by gravity into the central part of a cylindrical vessel 1 and the falling powder is mixed with the injection-flow liquid by injecting the liquid from an injection opening 12 installed along the peripheral direction of the lower cylindrical part 4 of the cylindrical vessel 1.

Description

technical field [0001] The present invention relates to a powder and liquid mixing device and method thereof, which can prevent the powder from being The liquid cannot penetrate into the inside of the aggregate formed by the powder and becomes an undissolved substance such as "powder lump" or "powder lump", so that the powder is uniformly and continuously mixed with the liquid. Background technique [0002] According to the conventional technology, it is possible to carry out the operation of continuously mixing the powder with respect to the liquid. However, especially in the case where the liquid is a solvent, only the surroundings of the powder lumps will be dissolved, and the liquid cannot penetrate into the inside of the powder, thus forming Undissolved substances such as "powder lumps" or "powder lumps" cannot be mixed uniformly with respect to the liquid. Therefore, due to the presence of undissolved substances, the mixing accuracy can...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F25/90

Inventor 中村辉男大西宏明

Owner MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com