Method for manufacturing silver nanowires using ionic liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Silver Nanowires Using Ionic Liquid Containing Chlorine Ion (Cl−) as Additive in Polyol Reaction

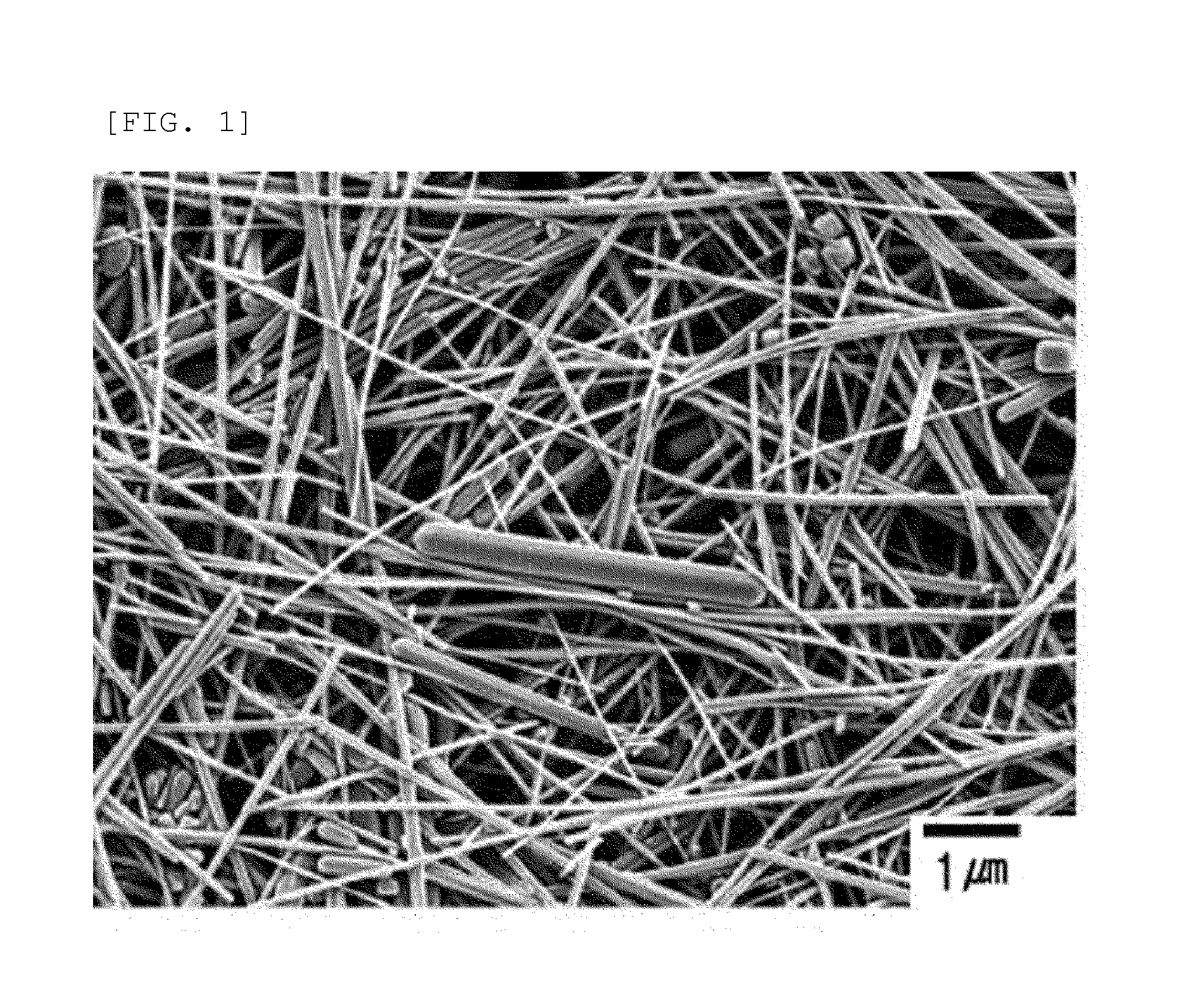

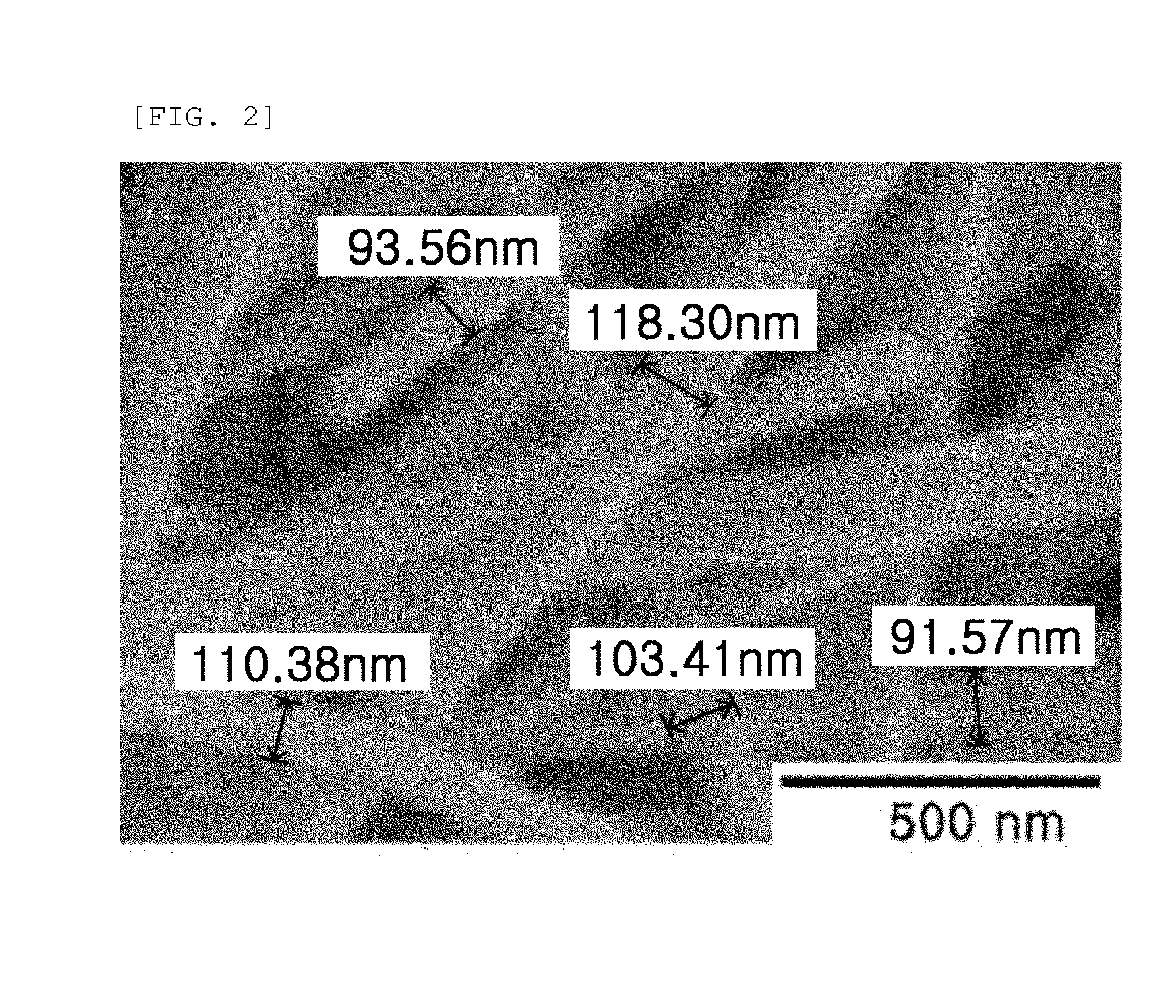

[0041]0.1 mol of AgNO3, 0.15 mol of PVP and 0.001 mol of 1-ethyl-3-methylimidazolium chloride (EMIM-Cl) were dissolved in 1 L of ethyleneglycol (EG), and were then stirred at room temperature for 10 minutes to obtain a transparent mixed solution. The color of the mixed solution became gray as soon as the mixed solution was reacted at 150° C. for about 30 minutes. Subsequently, the mixed solution was cooled to room temperature, filtered by a filter having a pore size of 1 μm, dried, and then observed using a scanning electron microscope. As shown in the photograph of FIG. 3, it was observed that silver nanowires having a diameter of 55˜65 nm and a length of 10˜30 μm were uniformly formed. Further, it was observed that, differently from the results of Comparative Example 1 in which an ionic liquid was not used, silver nanoparticles having different shapes from the silver nano...

example 2

Preparation of Silver Nanowires Using Ionic Liquid Containing Chlorine Ion (Cl−) as Additive in Polyol Reaction

[0042]Example 2 is the same as Example 1, except that 0.001 mol of 1-butyl-3-methylimidazolium chloride (BMIM-Cl) was used as an ionic liquid. As shown in the photograph of FIG. 4, it was observed that silver nanowires having a diameter of 55˜65 nm were uniformly formed. Further, it was observed that, similarly to the results of Example 1, silver nanoparticles having different shapes from the silver nanowires were not discovered. Comparing the results of Example 2 with the results of Example 1, it was observed that the shapes of silver nanowires were not changed or were only slightly changed depending on the length of an alkyl group of an imidazolium-based ionic liquid having a cation.

example 3

Preparation of Silver Nanowires Using Ionic Liquid Containing Bromine Ion (Br−) as Additive in Polyol Reaction

[0043]Example 3 is the same as Example 2, except that 0.001 mol of 1-butyl-3-methylimidazolium bromide (BMIM-Br) was used as an ionic liquid. As shown in the photograph of FIG. 5, it was observed that silver nanowires having a diameter of about 30 nm were uniformly formed. Further, it was observed that, similarly to the results of Example 1, silver nanoparticles having different shapes from the silver nanowires were not discovered. Comparing the results of Example 3 with the results of Example 2, it was observed that the shapes and diameters of silver nanowires were changed depending on the anion of the ionic liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com