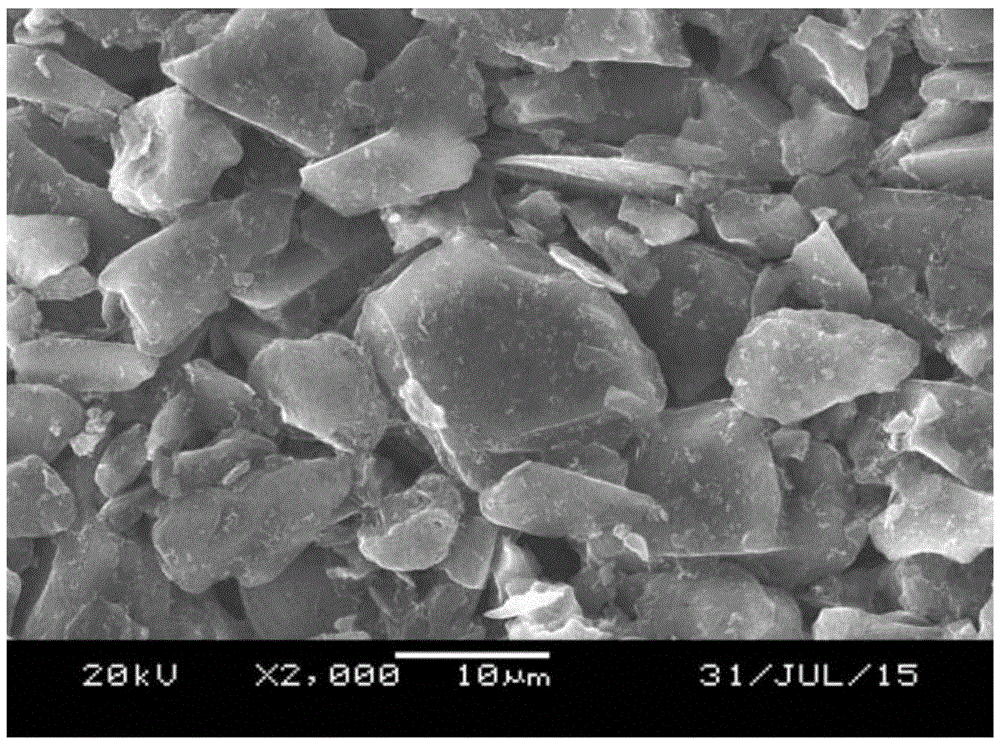

Silicon-carbon composite cathode pole piece of lithium ion battery and preparation method of silicon-carbon composite cathode pole piece

A lithium-ion battery, silicon-carbon composite technology, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of high battery impedance, short cycle life, and inability to improve the conductivity of silicon-based materials, etc., to achieve cycle life long, improve electrical conductivity, and improve the effect of market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In addition, the present invention also provides a method for preparing a silicon-carbon composite negative electrode sheet of a lithium-ion battery, which is used to produce the above-mentioned silicon-carbon composite negative electrode sheet provided by the present invention. The method specifically includes the following steps:

[0051] The first step is to configure carboxymethyl cellulose CMC glue: add carboxymethyl cellulose CMC powder to deionized water, adjust the solid content of the glue solution to 0.1% to 10%, and then stir evenly to obtain CMC glue;

[0052] In the first step, preferably: stirring at a stirring speed of 100 rpm to 800 rpm for 4h to 24h.

[0053] In the first step, on specific realization, the condition that the ratio between the carboxymethyl cellulose CMC powder and the deionized water should meet is: the quality between the carboxymethyl cellulose CMC powder and the deionized water The ratio is 1:(10~1000).

[0054] The second step is t...

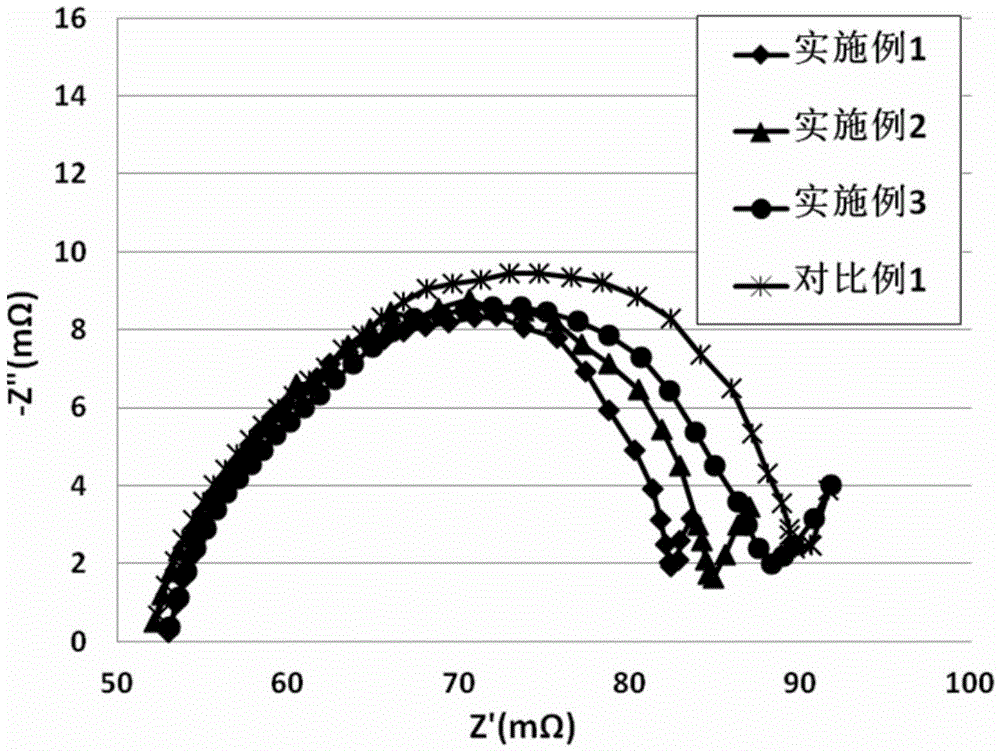

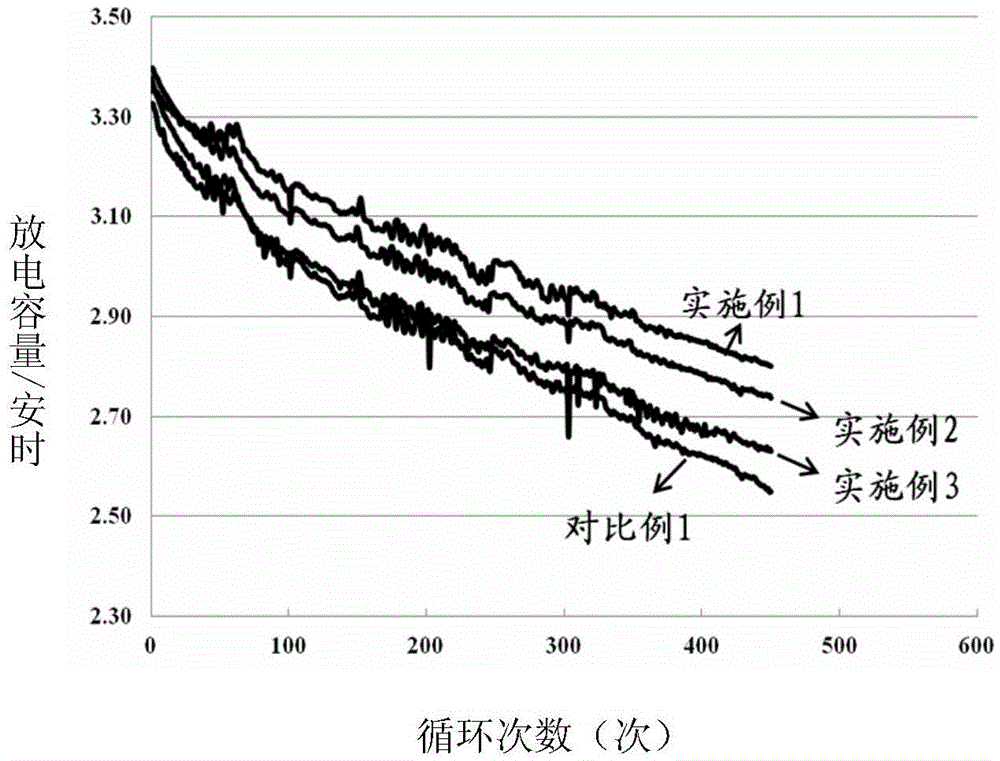

specific Embodiment 1

[0073] In specific embodiment 1, the present invention makes highly conductive lithium-ion battery silicon-carbon composite negative pole sheet, comprising the following steps:

[0074] The first step is to configure carboxymethylcellulose CMC glue: add 30g of CMC powder into deionized water, adjust the solid content of the glue solution to 1.6%, stir at a slow speed of 500rpm for 12h, and stir evenly to obtain CMC glue;

[0075] The second step is to configure conductive glue: add 80g graphene conductive agent, 185g carbon nanotube conductive agent, and 10g SuperP conductive agent to the CMC glue, and stir rapidly at a speed of 3000rpm for 1 hour to obtain conductive glue;

[0076] The third step is to add silicon carbon material: add 2.3kg of artificial graphite and 0.2kg of silicon oxide to the conductive adhesive obtained in the second step at the same time, stir at a slow speed of 500rpm for 30min, and then quickly at a speed of 2000rpm Stir for 4 hours, add deionized wat...

specific Embodiment 2

[0086] In specific embodiment 2, the present invention makes highly conductive lithium-ion battery silicon-carbon composite negative pole sheet, comprising the following steps:

[0087]The first step is to configure carboxymethylcellulose CMC glue: add 30g of CMC powder into deionized water, adjust the solid content of the glue solution to 1.2%, stir at a slow speed of 400rpm for 12h, and stir evenly to obtain CMC glue;

[0088] The second step is to configure conductive adhesive: add 160g graphene conductive agent, 100g carbon nanotube conductive agent, and 10g SuperP conductive agent to the CMC adhesive, and stir rapidly at a speed of 3000rpm for 1 hour to obtain conductive adhesive;

[0089] The third step is to add silicon carbon materials: add 2.3kg of artificial graphite and 0.2kg of silicon oxide to the conductive adhesive obtained in the second step, stir at a slow speed of 600rpm for 30min, and then quickly at a speed of 2000rpm Stir for 4 hours, add deionized water t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com