Fluorine-containing polyarylether-based anion exchange membrane with low surface resistivity and high oxidation stability and preparation method of fluorine-containing polyarylether-based anion exchange membrane

An anion exchange membrane, high oxidation stability technology, applied in electrochemical generators, circuits, fuel cells, etc., to achieve the effect of low surface resistivity, simple reaction method, and improved ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 fluorine-containing polyarylether compound FPAE-10

[0041] Add 0.2315 g (0.40 mmol) tetraamine bisphenol fluorene, 1.2615 g (3.60 mmol) bisphenol fluorene, 1.3500 g (4.00 mmol) decafluorobiphenyl and 8.50 mL N -Methylpyrrolidone, stir until the solid is completely dissolved, add 0.1250 g (3 mmol) of calcium hydride and 2.50 g (17 mmol) of cesium fluoride, and stir at room temperature for 24 hours under the protection of argon. After the reaction, the viscous mixture was poured into 500 mL of deionized water and stirred while pouring to precipitate the polymer, and the resulting white strip polymer was collected and dried in a vacuum oven at 60 °C for 12 hours, and then Dissolve 2.50 g of the obtained polymer in 30 mL of dichloromethane, then pour it into 500 mL of methanol, collect the precipitated flocculent polymer, and dry it in a vacuum oven at 60 °C for 12 hours to obtain tetraamine-based fluoropolymer Aryl ether compound FPAE-10, ...

Embodiment 2

[0042] Example 2 Preparation of fluorine-containing polyarylether compound FPAE-20

[0043] In Example 1, the feeding amount of tetraamine-based bisphenol fluorene was replaced by 0.4630 g (0.8 mmol), and the feeding amount of bisphenol fluorene was replaced by 1.1213 g (3.2 mmol). The rest of the steps were the same as in Example 1 to obtain tetraamine-based Fluorine-containing polyarylether compound FPAE-20, its yield is 95%.

Embodiment 3

[0044] Example 3 Preparation of dense diquaternary ammonium salt ion side chain type fluorine-containing polyarylether compound DQA-6C-FPAE-10

[0045] Dissolve 1.00 g (0.6 mmol) of the fluorine-containing polyarylether compound FPAE-10 obtained in Example 1 in 20 mL N- In methylpyrrolidone, make 5 wt.% solution A; then dissolve 2.73g (0.9 mmol) QA-6C in 30 mL N- Methylpyrrolidone, make 9 wt.% solution B; slowly drop solution B into solution A, stir the mixture at room temperature for 24 hours, then slowly pour it into deionized water to precipitate a precipitate, then filter and pour it on the surface In a dish, dry at 80°C for 12 hours to obtain the dense bisquaternary ammonium salt ion side chain type fluorine-containing polyarylether compound DQA-6C-FPAE-10, the yield rate is 96%, and the chemical structural formula is:

[0046] , where n is 1~400; m is 10~400.

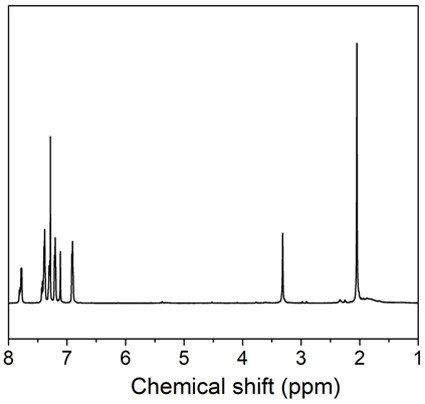

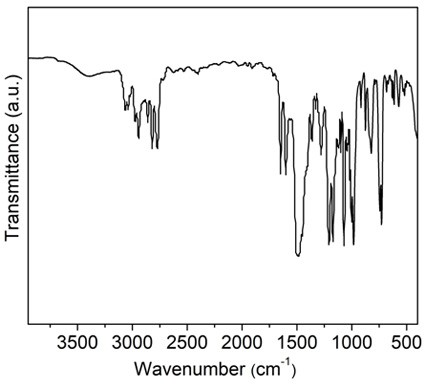

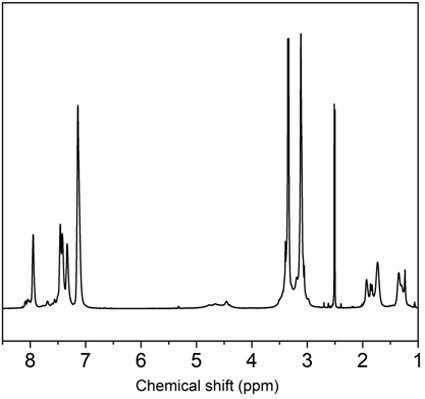

[0047] The data of the proton nuclear magnetic resonance spectrum of this compound are: 1 HNMR (600MHz, DM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com