Light high-conductivity coating as well as preparation method and application thereof

A high-conductivity, lightweight technology, applied in the direction of conductive coatings, epoxy resin coatings, coatings, etc., can solve problems such as weight increase, coatings that do not meet the minimum requirements for aviation flight, and the impact of composite materials on lightweight effects, etc., to achieve Avoid the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

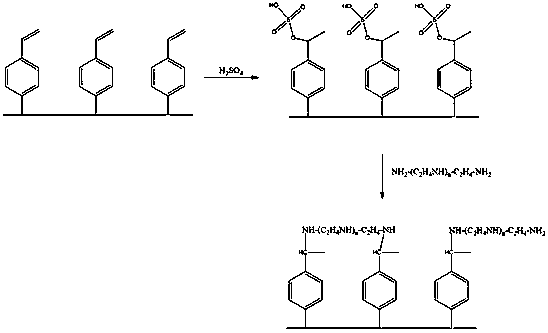

[0058] (1) Polyamine surface modification

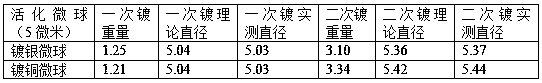

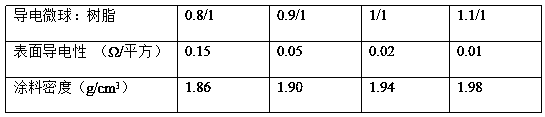

[0059] 25% chloromethyl styrene and 75% divinylbenzene copolymerized 5-micron microspheres as the starting microspheres (the microspheres are TS005CI microspheres provided by Taizhou Tianshu New Material Technology Co., Ltd., the coefficient of variation of the particle size distribution of the microspheres 2.8%).

[0060] 20 g of TS005CL and 2.5 g of tris(2-aminoethyl)amine were added to a 500 ml round bottom flask containing 250 ml of DMF. Under electromagnetic stirring, the solution was heated to 105° C., and the reaction was continued for 5 hours. After cooling, filter and rinse thoroughly with deionized water. After vacuum drying at 100°C for two hours, polyamine-modified microspheres were obtained. The microspheres are analyzed by infrared spectroscopy, and the benzyl chloride groups on the surface of the microspheres are completely converted into amine groups.

[0061] (2) The surface support of the microspheres is activat...

Embodiment 2

[0073] Other steps are with embodiment 1, difference is:

[0074] (1) Polyamine surface modification

[0075] The 4.5-micron microspheres polymerized with 65% divinylbenzene were used as the starting microspheres (the No. TS0045-Y microspheres were provided by Taizhou Tianshu New Material Technology Co., Ltd., and the coefficient of variation of the particle size distribution of the microspheres was 3.0%).

[0076] Add 50g of TS0045-Y microspheres into a 1000ml round bottom flask containing 500g of acetonitrile, slowly add 3ml of 98% concentrated sulfuric acid dropwise, and stir electromagnetically at room temperature for 5 hours. Then slowly add 10ml of anhydrous polyethyleneimine (PEI) with a molecular weight of 800 dropwise. After the dropwise addition was completed, the temperature was slowly raised to reflux of acetonitrile. Continue to react for three hours. After cooling, filter and rinse thoroughly with deionized water. After vacuum drying at 100°C for two hours, p...

Embodiment 3

[0084] Other steps are with embodiment 1, difference is:

[0085] (1) Polyamine surface modification

[0086] 3.05 micron microspheres copolymerized with 25% maleic anhydride and 75% divinylbenzene as the starting microspheres (No. TS00305-AN microspheres are provided by Taizhou Tianshu New Material Technology Co., Ltd., the coefficient of variation of particle size distribution of microspheres 5.5%).

[0087] Add 50g of TS00305-AN microspheres into a 1000ml round bottom flask containing 500ml of acetonitrile, slowly add 5g of triethylenetetramine dropwise, and slowly raise the temperature to reflux of acetonitrile. Continue to react for three hours. After cooling, filter and rinse thoroughly with deionized water. Dry under vacuum at 100°C for two hours. Then, under nitrogen condition, heat to 205°C for two hours. polyamine-modified microspheres. The microspheres are analyzed by infrared spectroscopy, and the maleic anhydride groups on the surface of the microspheres are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com