Novel methods for producing type A molecular sieve film in current system

A molecular sieve and system technology, which is applied in the field of preparing A-type molecular sieve membranes, can solve the problems of difficulty in forming dense and continuous molecular sieve membranes, uneven crystallization on the surface of molecular sieve membranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

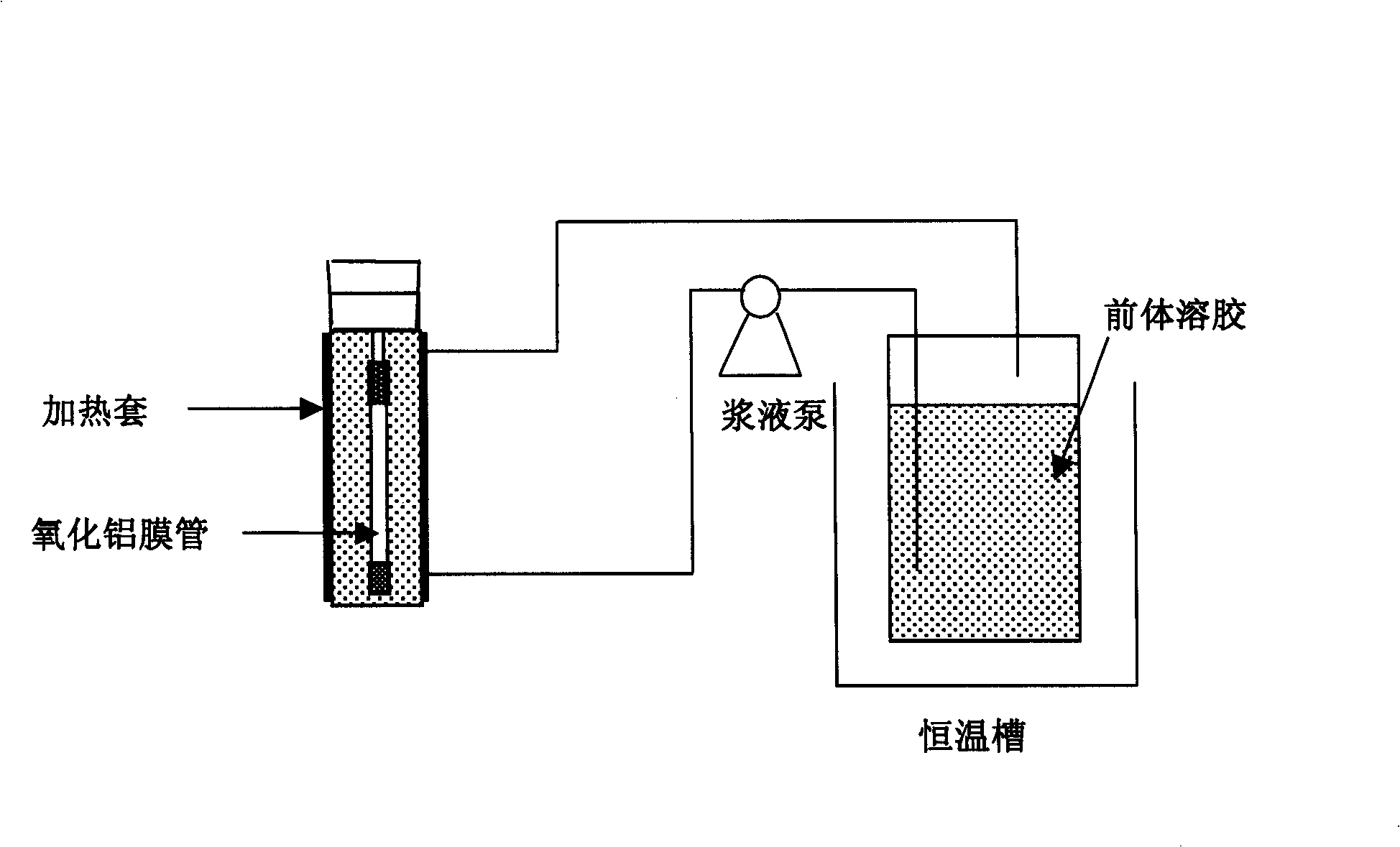

[0017] Embodiment 1: the preparation of NaA type molecular sieve membrane

[0018] Sodium silicate, sodium aluminate, sodium hydroxide and distilled water are used as raw materials to configure the precursor sol of NaA molecular sieve. The molar ratio of each component in the sol is: SiO 2 :Al 2 o 3 :Na 2 O:H 2 O=2:1:2:120, fully stirred and mixed evenly at room temperature. The two ends of the aluminum oxide film tube (commercially available, average pore diameter 1.5 μm, porosity 38%, outer diameter 13 mm, inner diameter 8 mm, length 350 mm) with NaA molecular sieve seed crystallization pre-coated with PTFE rods were fixed on the figure 1 in the synthesis reactor shown. After heating the molecular sieve precursor sol to 100°C in the raw material storage tank, pump it into the synthesis reactor at a speed of 30ml / min with a slurry pump. The outside of the synthesis reactor is wrapped with a heating belt, and the temperature is kept at 100°C. During the whole reaction pr...

Embodiment 2

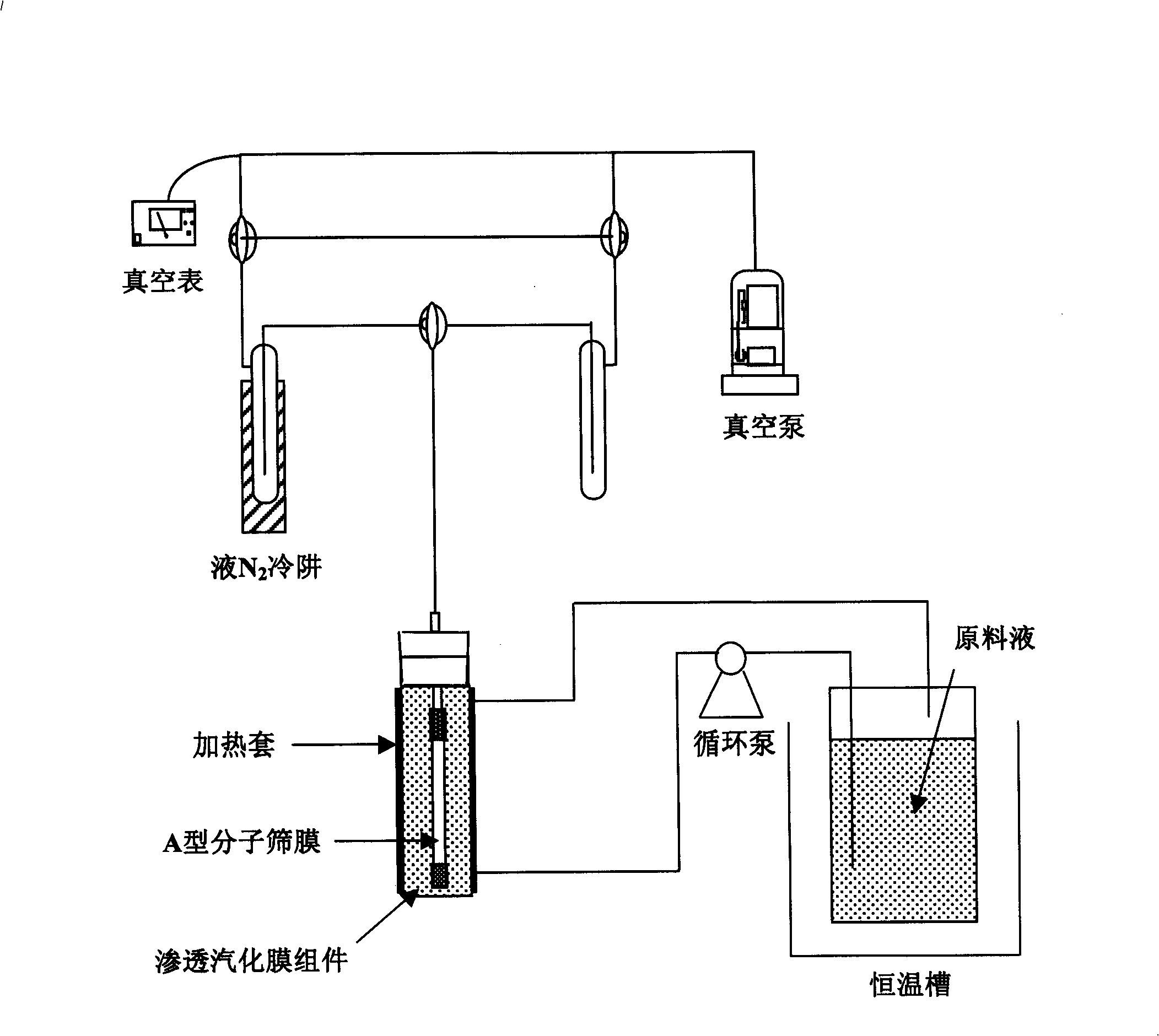

[0019] Embodiment 2: Pervaporation separation performance of NaA molecular sieve membrane

[0020] figure 2 It is a schematic diagram of the molecular sieve membrane pervaporation separation device in the present invention. The molecular sieve membrane tube is placed in a stainless steel assembly, one end is connected to a small section of polytetrafluoroethylene rod, the other end is connected to a vacuum system, and the two ends are respectively sealed with a silicone rubber tube and a thermoplastic tube in turn, and the outside of the assembly is wrapped with a heating tape. The raw material liquid heated to a certain temperature in the constant temperature tank is circulated and supplied in the module through the liquid pump, and liquid N is used for permeating steam. 2 Condensation is recovered, and two cold traps are switched to ensure continuous measurement. The permeate collected by condensation is weighed with an electronic balance, and the concentrations of the ra...

Embodiment 3

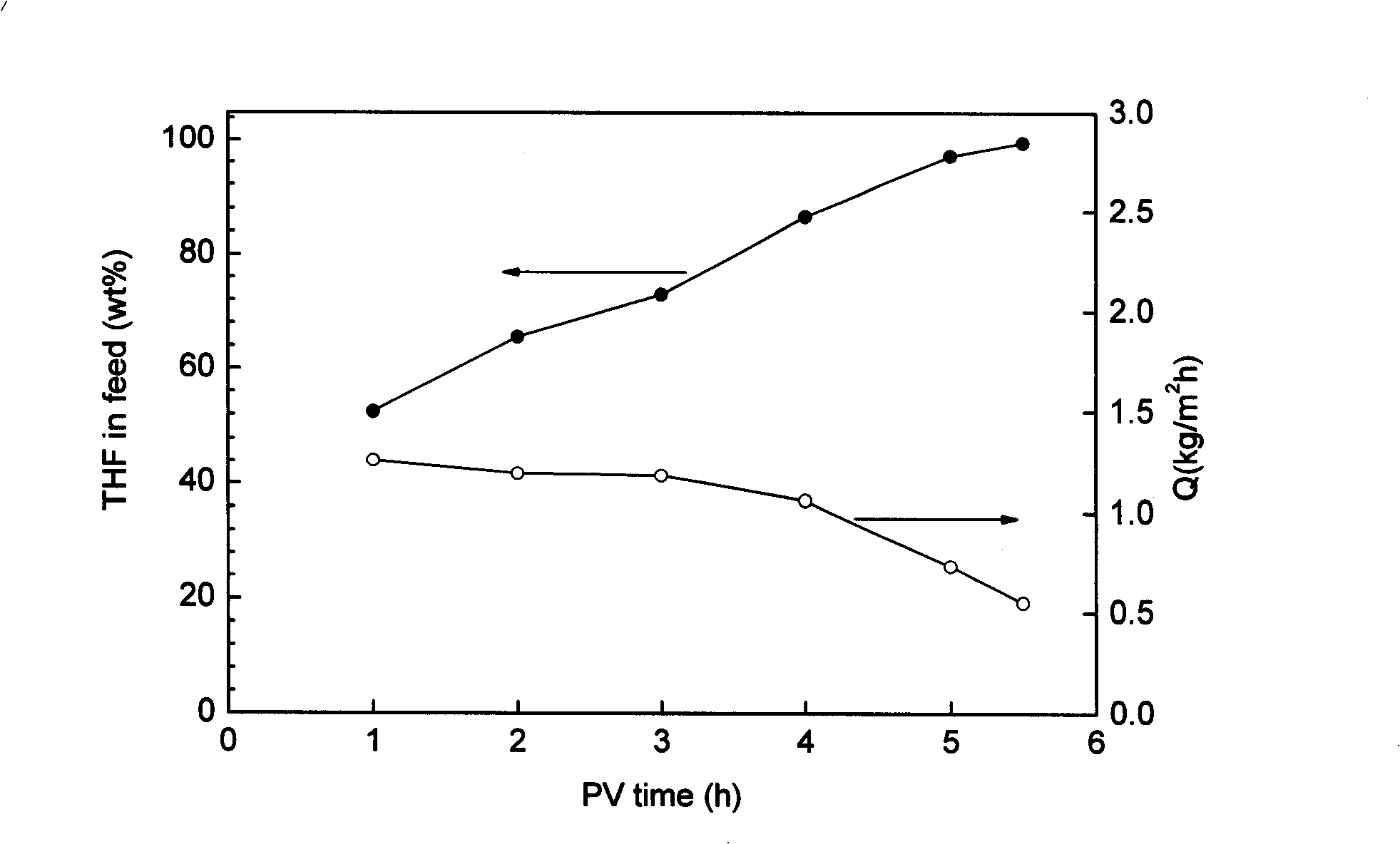

[0022] Embodiment 3: NaA molecular sieve membrane is to THF / H 2 Pervaporation Separation of O System

[0023] THF is a very important organic solvent widely used in pharmaceutical, chemical, electronic and other industries. Due to the high price of THF, its separation and recovery are very important for the effective utilization of resources and environmental protection. THF and H 2 O forms an azeotropic composition when the content is 95 wt%, and the azeotropic point is 63.4°C. At present, the commonly used separation methods are azeotropic distillation and extractive distillation with salt addition, etc., which have high energy consumption, and the addition of entrainer and extractant will cause serious pollution to the environment and products. With 200ml of mixed solution containing THF 50wt% as raw material, the A-type molecular sieve membrane pervaporation method prepared in Example 1 is used to separate THF / H 2 O mixture, pervaporation separation results see image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com