Copper-based mosaic structure interface diamond coating and preparation method and application thereof

A diamond coating and mosaic structure technology, applied in metal material coating process, coating, electrolytic coating and other directions, can solve the problems of insignificant increase in thermal conductivity, increase in interface thermal resistance, etc., and achieve increased bonding force and interface contact. The effect of increased area and good bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

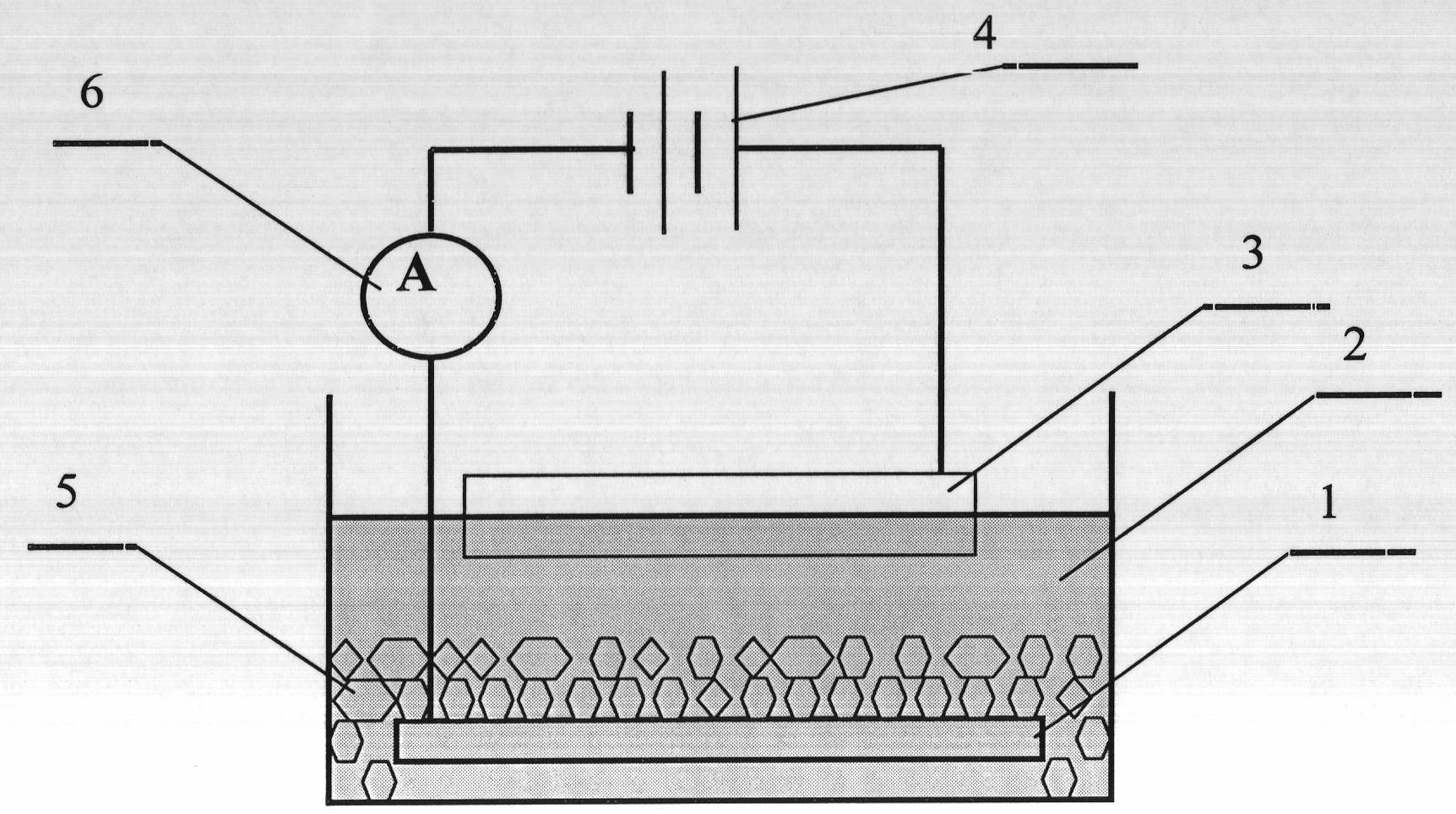

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Prepare coarse sand + Cu reinforcement + fine sand composite coating:

[0041] (1) Prepare sand-coated copper plating solution: take 27 grams of citric acid and 6 grams of basic copper carbonate and dissolve them in a beaker A containing 80 ml of distilled water in turn, take 3.6 grams of ammonium bicarbonate and 3.0 grams of ethylenediaminetetraacetic acid in turn Dissolve in beaker B filled with 40ml of distilled water. After the dissolution is complete, slowly add the solution in beaker B to beaker A. Take 9.0 grams of potassium sodium tartrate and add it to beaker A. Measure 30 ml of formamide and add it to beaker A. Adjust the pH value to 8.3 to 9.5 with sodium, prepare 200ml of sanded copper plating solution, and divide the prepared sanded copper plating solution into A beaker and B beaker, each of which is 100ml, and set aside;

[0042] (2) Configure the coarse and sandy composite plating solution: boil diamond particles with a particle size of W10 (9-10 ...

Embodiment 2

[0057] Step 1: Prepare coarse sand + Cu reinforcement + fine sand composite coating:

[0058] (1) Prepare sand-coated copper plating solution: take 27 grams of citric acid and 6 grams of basic copper carbonate and dissolve them in a beaker A containing 80 ml of distilled water in turn, take 3.6 grams of ammonium bicarbonate and 3.0 grams of ethylenediaminetetraacetic acid in turn Dissolve in beaker B filled with 40ml of distilled water. After the dissolution is complete, slowly add the solution in beaker B to beaker A. Take 9.0 grams of potassium sodium tartrate and add it to beaker A. Measure 30 ml of formamide and add it to beaker A. Adjust the pH value to 8.3 to 9.5 with sodium, prepare 200ml of sanded copper plating solution, and divide the prepared sanded copper plating solution into A beaker and B beaker, each of which is 100ml, and set aside;

[0059] (2) Configure the coarse and sandy composite plating solution: boil diamond particles with a particle size of W15 (14-15...

Embodiment 3

[0071] Step 1: Prepare coarse sand + Cu reinforcement + fine sand composite coating:

[0072] (1) Prepare sand-coated copper plating solution: take 27 grams of citric acid and 6 grams of basic copper carbonate and dissolve them in a beaker A containing 80 ml of distilled water in turn, take 3.6 grams of ammonium bicarbonate and 3.0 grams of ethylenediaminetetraacetic acid in turn Dissolve in beaker B filled with 40ml of distilled water. After the dissolution is complete, slowly add the solution in beaker B to beaker A. Take 9.0 grams of potassium sodium tartrate and add it to beaker A. Measure 30 ml of formamide and add it to beaker A. Adjust the pH value to 8.3 to 9.5 with sodium, prepare 200ml of sanded copper plating solution, and divide the prepared sanded copper plating solution into A beaker and B beaker, each of which is 100ml, and set aside;

[0073] (2) Configure the coarse and sandy composite plating solution: boil diamond particles with a particle size of W10 (9-10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com