Continuous casting heat composite apparatus and method for preparing copper lead alloy-steel shaft bushing material

A copper-lead alloy and thermal compounding technology, applied in metal rolling and other directions, can solve the problems of structure segregation, poor quality stability, short service life, etc., and achieve the effect of dense structure, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

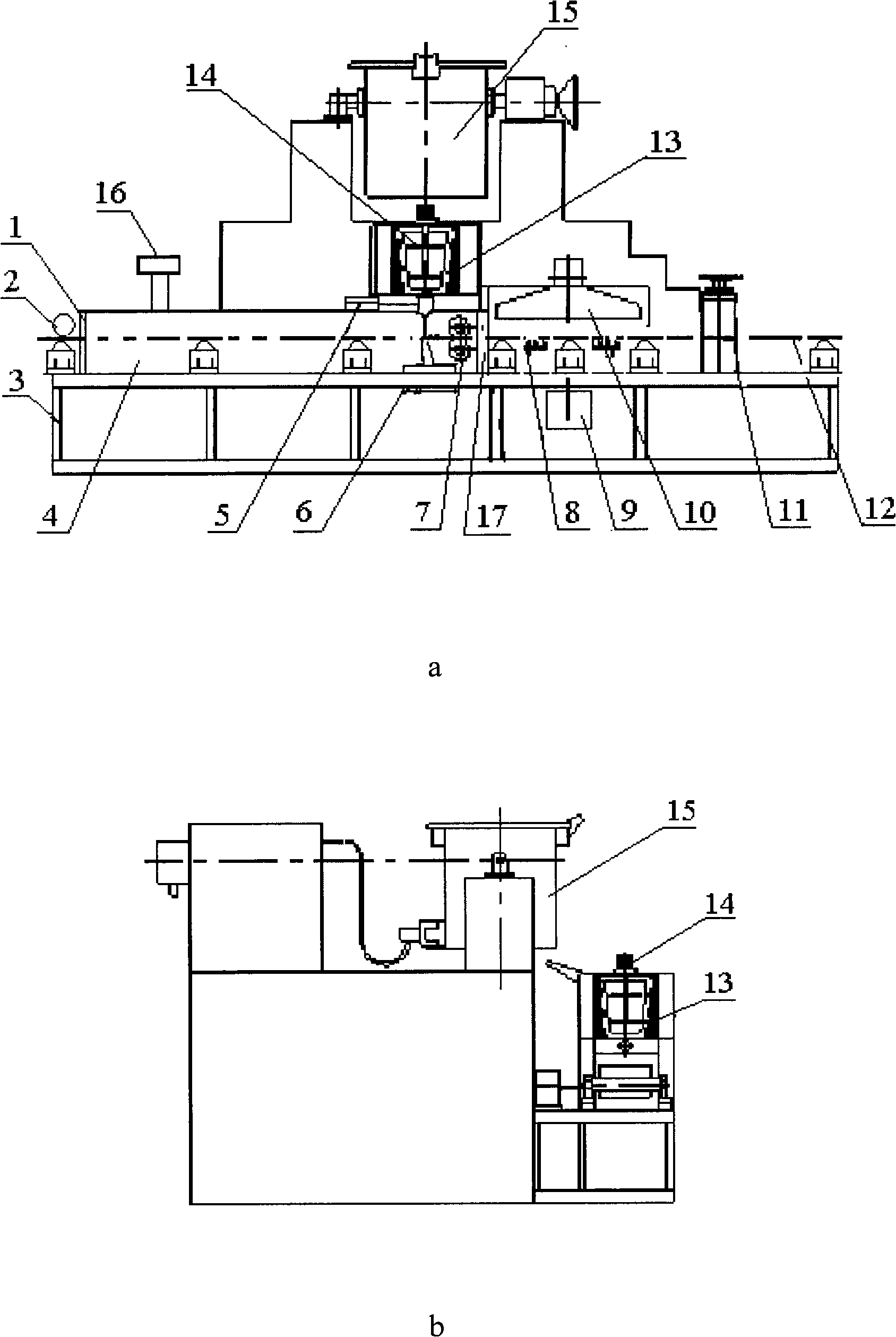

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The structure of an embodiment of the thermal compound device of the present invention, such as figure 1 shown. It includes a bracket 3 fixed on the foundation. On the top of the bracket 3, along the feeding direction of the steel plate 12, a steel plate conveying device 2, a fire curtain sealing device A1, a sealed heating channel, a fire curtain sealing device B17, a cooling device 8 and a rolling Rolling device 11.

[0032] The fire curtain sealing device A1, the sealed heating channel and the fire curtain sealing device B17 constitute a preheating system for the sealed steel plate 12. The fire curtain sealing device A1 is located at the entrance of the sealed heating passage, and the fire curtain sealing device B17 and an infrared thermometer are arranged at the exit of the sealed heating passage.

[0033]A gas protection device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com