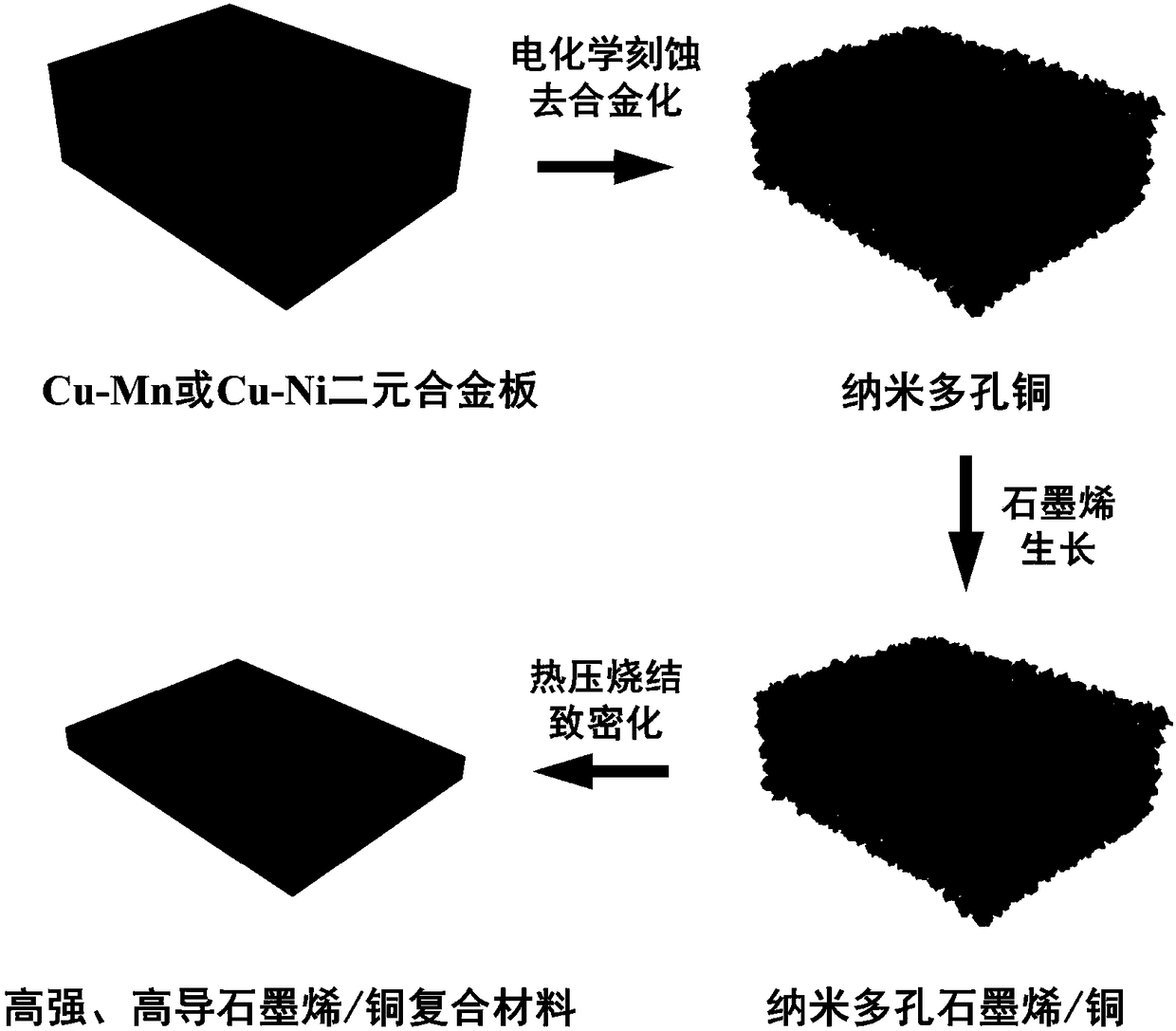

High strength, high conductivity graphene/copper nanocomposite material and preparation method and application thereof

A composite material, graphene technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem of not meeting the requirements of use, to increase the hindering effect, improve the carrier migration speed, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment provides a kind of preparation of graphene / copper composite material, comprising:

[0031] (1) A Cu-Mn binary alloy plate with a thickness of 100 μm and a mass fraction of Mn of 70% is electrochemically etched and dealloyed, and the electrolyte is 0.25mol / L HCl aqueous solution; the potential difference is 0.10V; the electrochemical etching The time is 4 hours; the obtained nanoporous copper has a pore size of 30 nm.

[0032] (2) A 2.5 g / L polymethyl methacrylate anisole solution was introduced into the nanoporous copper structure by vacuum impregnation, and then dried at 80° C. to obtain nanoporous PMMA / copper. The nanoporous PMMA / copper is placed in a tube furnace, the flow rate of hydrogen gas is adjusted to 10 sccm, the flow rate of argon gas is 150 sccm, and the pressure in the tube is kept <1 Torr. Graphene growth is performed at a temperature of 900° C. for 1 hour. Keep the pressure in the tube < 200mTorr until the furnace temperature is ...

Embodiment 2

[0036] The present embodiment provides a kind of preparation of graphene / copper composite material, comprising:

[0037] (1) A Cu-Ni binary alloy plate with a thickness of 500 μm and a mass fraction of Ni of 80% is electrochemically etched and dealloyed, and the electrolyte is 0.05Mol / L of H 2 SO 4 aqueous solution; the potential difference is 0.20V; the electrochemical etching time is 12 hours; the obtained nanoporous copper has a pore diameter of 50nm.

[0038] (2) A 0.50 g / L polymethyl methacrylate chloroform solution was introduced into the nanoporous copper structure by vacuum impregnation, and then dried at 80° C. to obtain nanoporous PMMA / copper. The nanoporous PMMA / copper is placed in a tube furnace, the flow rate of hydrogen gas is adjusted to 15 sccm, the flow rate of argon gas is 200 sccm, and the pressure in the tube is kept <1 Torr. Graphene growth is performed at a temperature of 1000° C. for 1 hour. Keep the pressure in the tube < 200mTorr until the furnace t...

Embodiment 3

[0042] The present embodiment provides a kind of preparation of graphene / copper composite material, comprising:

[0043] (1) A Cu-Mn binary alloy plate with a thickness of 1000 μm and a mass fraction of Mn of 90% is electrochemically etched and dealloyed, and the electrolyte is an aqueous HCl solution of 0.50Mol / L; the potential difference is 0.30V; the electrochemical etching The time is 20 hours; the pore diameter of the obtained nanoporous copper is 75nm.

[0044] (2) A 5.0 g / L polystyrene anisole solution was introduced into the nanoporous copper structure by vacuum impregnation, and then dried at 80°C to obtain nanoporous PS / copper. The nanoporous PS / copper is placed in a tube furnace, the flow rate of hydrogen gas is adjusted to 5 sccm, the flow rate of argon gas is 100 sccm, and the pressure in the tube is kept <1 Torr. Graphene growth was performed at a temperature of 800° C. for 2 hours. Keep the pressure in the tube <200mTorr until the furnace temperature is cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com