High-conductivity high-strength copper-iron alloy and preparation method thereof

A copper-iron alloy, high electrical conductivity technology, applied in the field of copper-iron alloy, can solve the problems of large size, uneven distribution and insufficient mechanical properties of iron precipitates, and achieve the effect of improving alloy strength, tensile strength and high lifting amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

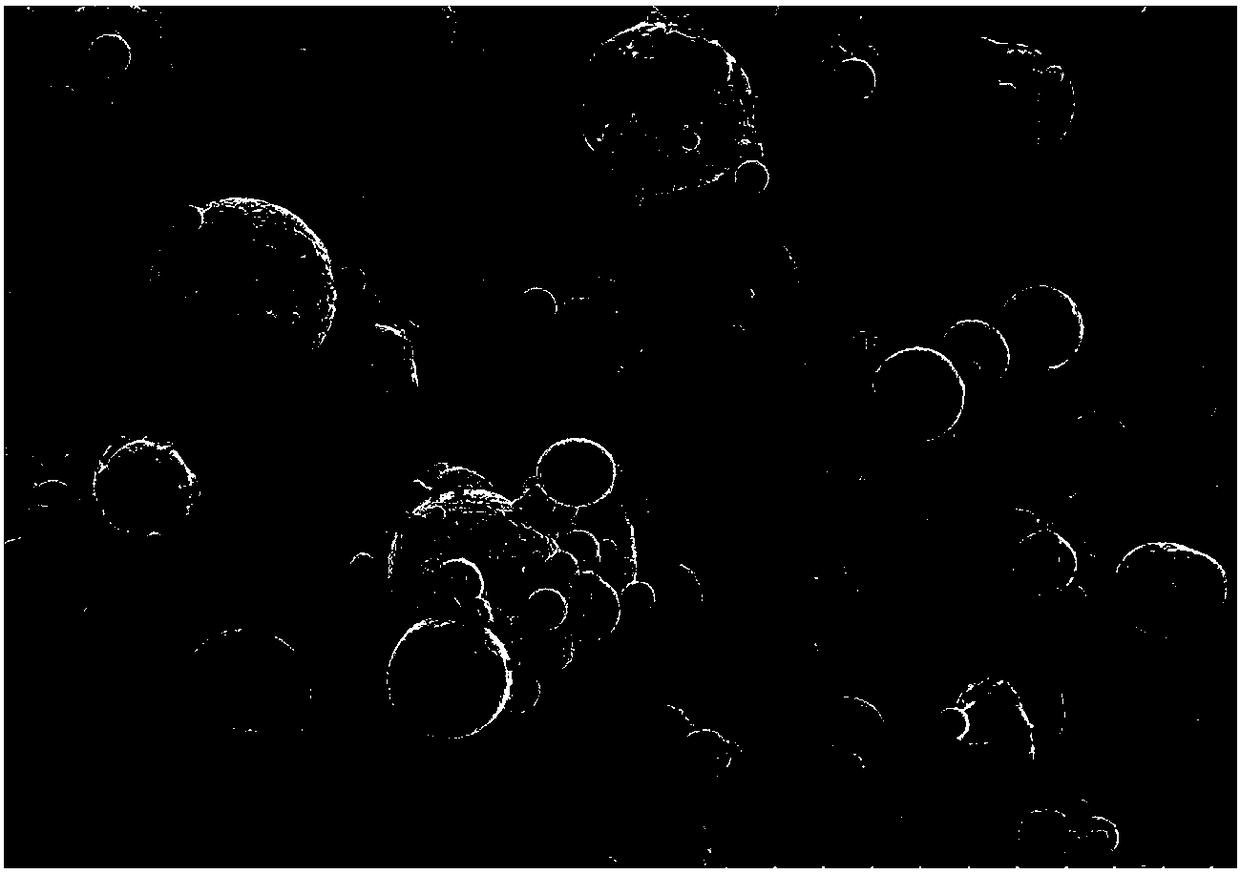

Image

Examples

Embodiment 1

[0025] A high-conductivity and high-strength copper-iron alloy of the present invention, the Fe content of the copper-iron alloy is 5wt%, the electrical conductivity is 58% IACS, and the tensile strength is 670MPa.

[0026] The preparation method of the high-conductivity high-strength copper-iron alloy of the present embodiment comprises the following steps:

[0027] (1) The mass percentage of Fe / (Cu+Fe) in the alloy composition is 5%, that is, the iron content in the required copper-iron alloy is 5% and the ratio of copper powder and iron powder; under nitrogen atmosphere, adopt gas atomization method Preparation of alloy powder, the pressure of the gas atomization process is 0.5-0.7MPa, and the gas flow rate is 0.15m 3 / s, the melting temperature is 1200°C; (2) Press the alloy powder under a pressure of 200MPa to obtain a powder compact; the powder compact is sintered for 1 hour under a hydrogen atmosphere at a temperature of 1050°C to obtain a sintered compact; ( 3) The si...

Embodiment 2

[0029] A high-conductivity and high-strength copper-iron alloy of the present invention, the Fe content of the copper-iron alloy is 5wt%, the electrical conductivity is 57% IACS, and the tensile strength is 730MPa.

[0030] The preparation method of Example 2 is the same as that of Example 1, except that the deformation strain in step (3) is 6.

Embodiment 3

[0032] A high-conductivity and high-strength copper-iron alloy of the present invention, the iron content of the copper-iron alloy is 5wt%, the electrical conductivity is 55% IACS, and the tensile strength is 680MPa.

[0033] The preparation method of the high-conductivity high-strength copper-iron alloy of the present embodiment comprises the following steps:

[0034] (1) The mass percentage of Fe / (Cu+Fe) in the alloy composition is 5%, that is, the iron content in the required copper-iron alloy is 5% proportioning copper powder and iron powder; adopt water atomization method to prepare alloy powder, water The flow rate is 200kg / min, the water pressure is 7MPa, and the atomized melt temperature is 1200°C; (2) The alloy powder is pressed under a pressure of 200MPa to obtain a powder compact; the powder compact is in a hydrogen atmosphere and the temperature is 1050°C , sintered for 1 hour to obtain a sintered billet; (3) the sintered billet was subjected to wire drawing treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com