Foamy carbon/copper matrix or aluminum matrix composite material and preparation method thereof

An aluminum-based composite material and carbon foam technology, which is applied in the field of electronic packaging materials to achieve the effects of low density, low thermal expansion coefficient and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

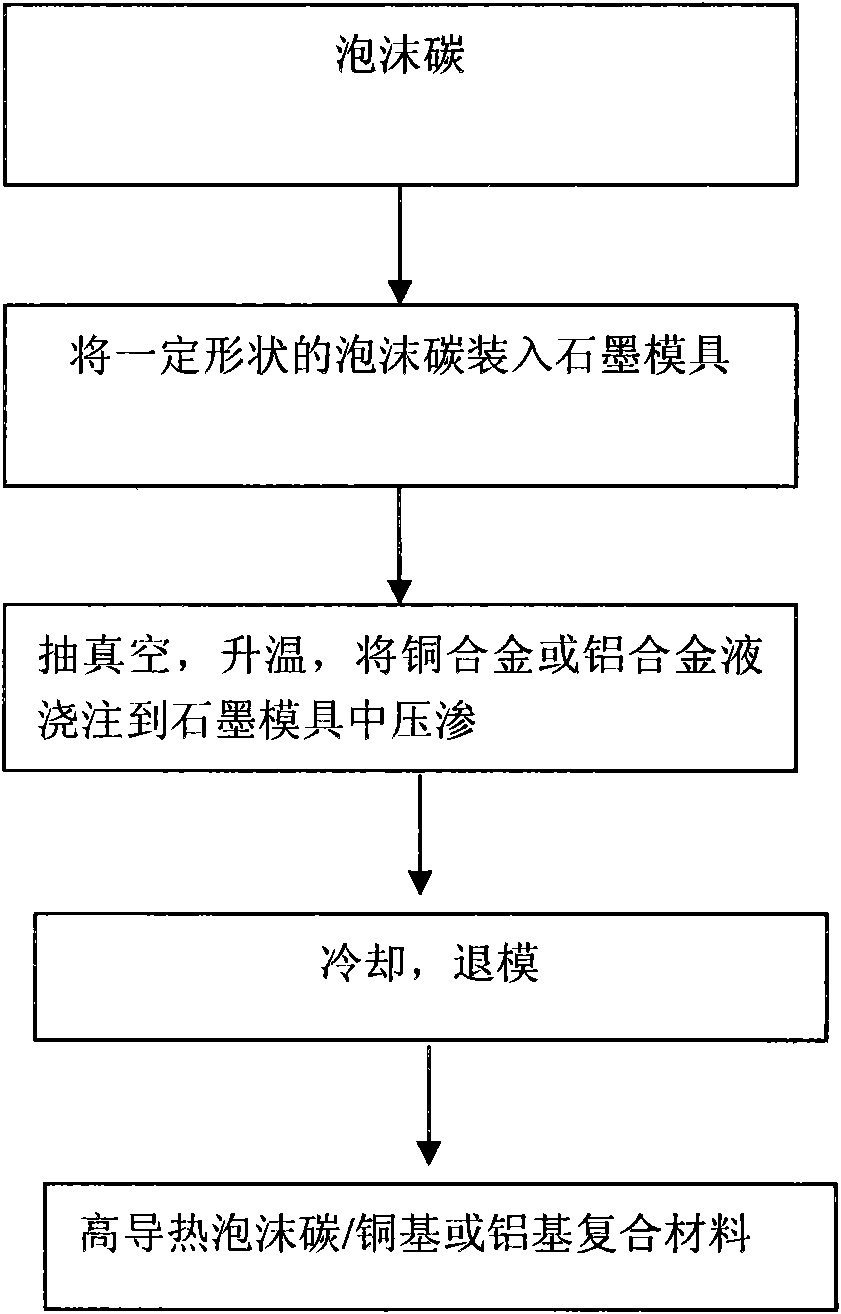

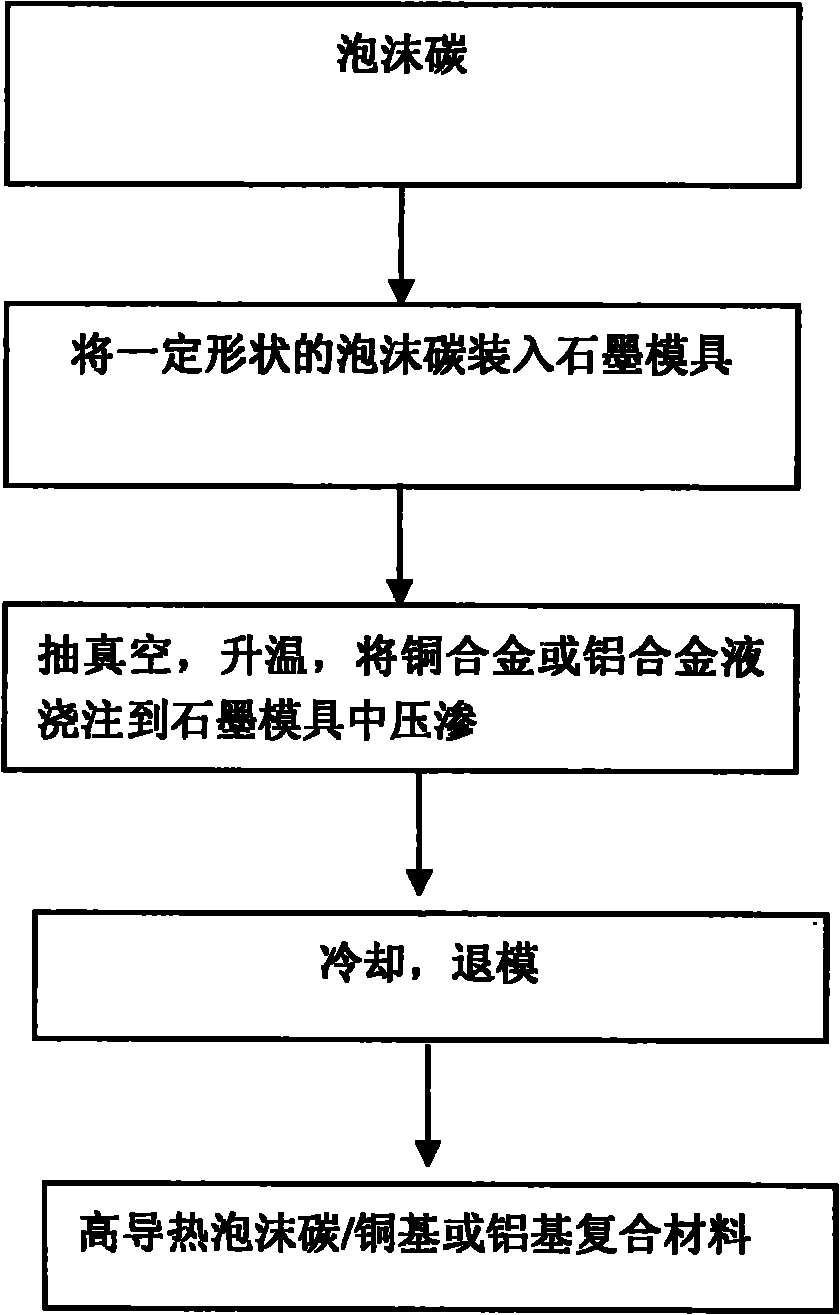

Method used

Image

Examples

Embodiment 1

[0029] Raw materials: carbon foam with a porosity of 50%, carbon foam is a graphitized structure, and the thermal conductivity is about 150W / mK (the specific thermal conductivity of copper and aluminum is 45W / mK and 54W / mK respectively); Cu-0.5Cr alloy.

[0030] Put the foamed carbon with a porosity of 50% into the graphite mold, put the Cu-0.5Cr alloy into the intermediate frequency induction furnace of the vacuum pressure infiltration furnace, the volume percentage of the foamed carbon is 50%, and the copper-chromium alloy is 50% ;The graphite mold that foam carbon is housed is put into vacuum pressure infiltration furnace, vacuumizes, heats up simultaneously, when vacuum pressure infiltration furnace vacuum degree reaches 0.05Pa, temperature rises to 1200 ℃ (the melting point of copper-chromium alloy is 1080 ℃) began to pour the molten copper-chromium alloy liquid from the intermediate frequency induction furnace into the graphite mold for pressure infiltration, furnace coo...

Embodiment 2

[0032] Raw materials: carbon foam with a porosity of 60%, the carbon foam is a graphitized structure, and the thermal conductivity is about 140W / mK; Cu-0.1Ti alloy.

[0033] Put the foamed carbon with a porosity of 60% into the graphite mold, put the Cu-0.1Ti alloy into the intermediate frequency induction furnace of the vacuum pressure infiltration furnace, the volume percentage of the foamed carbon is 40%, and the copper-titanium alloy is 60% ;The graphite mold that foam carbon is housed is put into the vacuum pressure infiltration furnace, vacuumizes, heats up simultaneously, when the vacuum degree of vacuum pressure infiltration furnace reaches 0.01Pa, temperature rises to 1200 ℃ (the melting point of copper-titanium alloy is 1080 ℃) began to pour the molten copper-titanium alloy liquid from the intermediate frequency induction furnace into the graphite mold for pressure infiltration, furnace cooling, and ejection of the mold. The density of the prepared foamed carbon / coppe...

Embodiment 3

[0035] Raw materials: carbon foam with a porosity of 70%, the carbon foam is a graphitized structure, and the thermal conductivity is about 130W / mK; Al-0.2B alloy.

[0036] Put the foamed carbon with a porosity of 70% into the graphite mold, put the Al-0.2B alloy into the medium frequency induction furnace of the vacuum pressure infiltration furnace, the volume percentage of the foamed carbon is 30%, and the aluminum-boron alloy is 70% ;The graphite mold that foam carbon is housed is put into vacuum pressure infiltration furnace, vacuumizes, and heats up simultaneously, when vacuum pressure infiltration furnace vacuum degree reaches 1Pa, temperature rises to 850 ℃ (the fusing point of aluminum-boron alloy is 660 ℃ ) began to pour the molten aluminum-boron alloy liquid from the intermediate frequency induction furnace into the graphite mold for pressure infiltration, furnace cooling, and demoulding, and the density of the prepared carbon foam / aluminum matrix composite material w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com