A kind of preparation method of pitch-based carbon fiber self-adhesive network material

A pitch-based carbon fiber, pitch fiber technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc., can solve the problems of increasing the propagation path, affecting high thermal conductivity and electrical conductivity, and achieves uniform fiber dispersion and improvement. The effect of specific thermal conductivity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

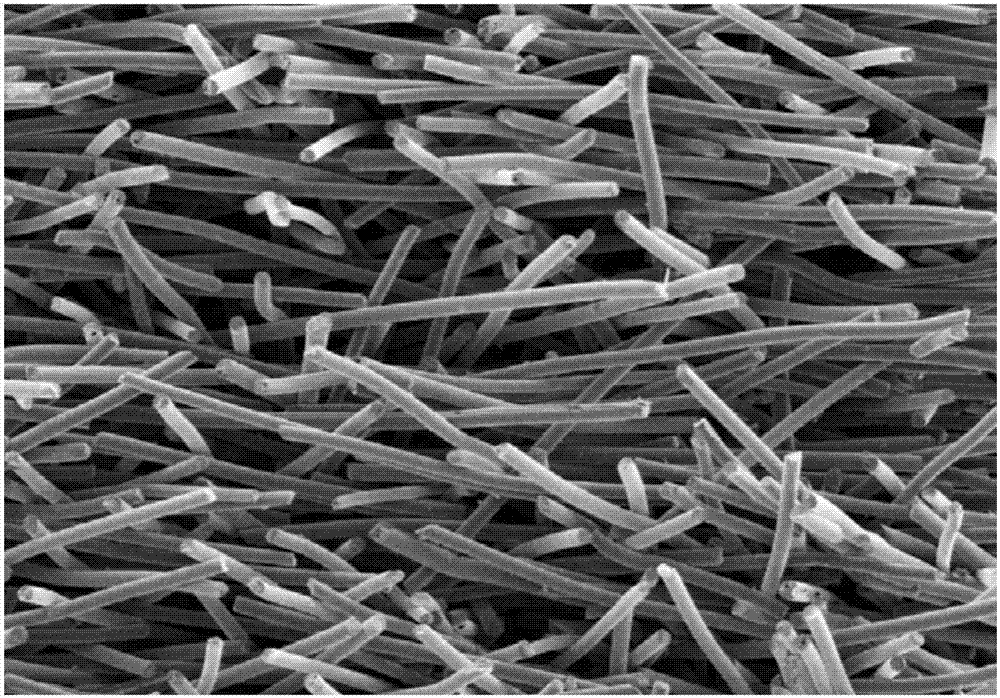

[0037] 1. Pre-oxidize 100% mesophase pitch fiber under an oxygen atmosphere until its oxidation weight gain is 4.04% (complete pre-oxidation weight gain is 5.20%), take 0.4g and chop it to a length of 1mm, mix it with deionized water and stir 2h to obtain a uniformly dispersed aqueous solution.

[0038] 2. Inject the aqueous solution obtained in step 1 into a mold with an inner diameter of 13 mm. The bottom of the mold is covered with filter cloth and a filter plate, and the filter plate has a pore size of 100 mesh. The bottom end is connected with a vacuum machine to speed up the water filtration process.

[0039] 3. After the mold is pressurized, place it in a drying oven and dry it at 100°C for 5 hours, and apply a pressure of 5KPa.

[0040] 4. After taking out the mold, put it into the carbonization furnace under nitrogen protection and raise the temperature to 550°C at 1°C / min.

[0041] 5. Cool naturally to room temperature and demould.

[0042] 6. Carbonize the self-a...

Embodiment 2

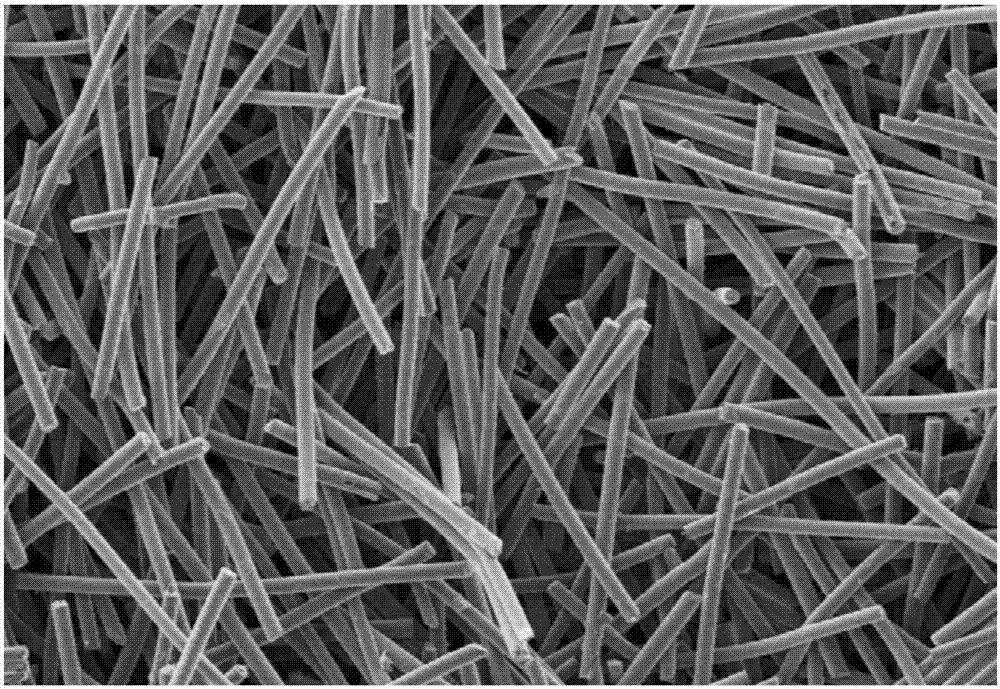

[0048] The difference between this example and example 1 is that after step 6, the self-adhesive carbon fiber network material obtained in step 6 is subjected to graphitization treatment under argon gas condition, and the heating rate during graphitization is 10°C / min graphitization temperature It is 2800°C.

[0049] The density of the pitch-based carbon fiber self-adhesive network material prepared in this example is 0.37 g cm -3 , the density of the pitch-based carbon fiber self-adhesive network reinforced epoxy resin composite material obtained by the composite material preparation method described in Example 1 is 1.35g cm -3 , the thermal conductivity measured by the carbon material thermal conductivity testing machine is 45.4w m in the direction perpendicular to the pressure -1 ·K -1 , 7.5w·m parallel to the direction of pressure -1 ·K -1 .

Embodiment 3

[0051] The difference between this embodiment and Example 2 is that the oxidation weight gain in step 1 is 3.97% (the complete pre-oxidation weight gain is 5.20%).

[0052] The density of the pitch-based carbon fiber self-adhesive network material prepared in this example is 0.42gcm -3 , the obtained pitch-based carbon fiber self-adhesive network reinforced epoxy resin composite material has a density of 1.40 g cm -3 , The compressive strength parallel to the pressing direction is 163MPa, which is 25% higher than the 130MPa of the pure epoxy resin sample. The thermal conductivity measured by the carbon material thermal conductivity testing machine is 49.5w m in the direction perpendicular to the pressure -1 ·K -1 , 7.8w·m parallel to the direction of pressure -1 ·K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com