Electron vibratory measurement system for measuring mass flow rate

A measurement system, mass flow rate technology, applied in the direction of measuring flow/mass flow, mass flow measurement device, direct mass flowmeter, etc., can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

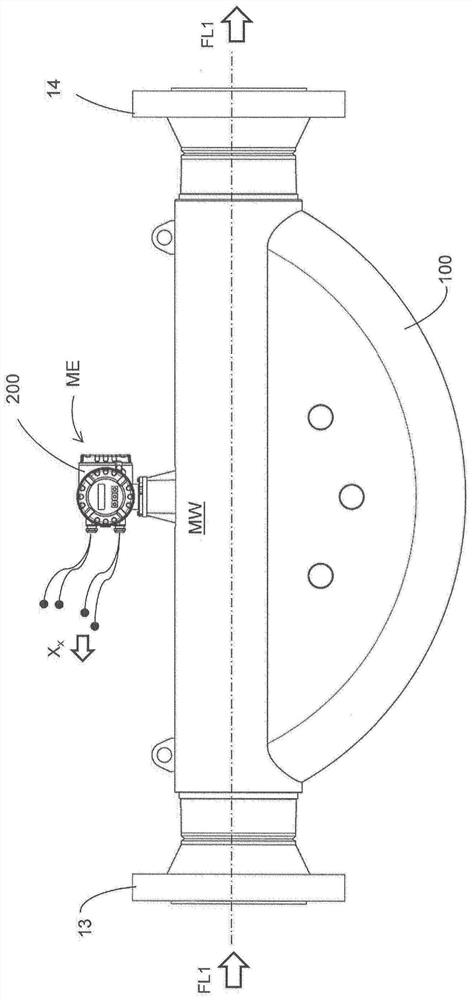

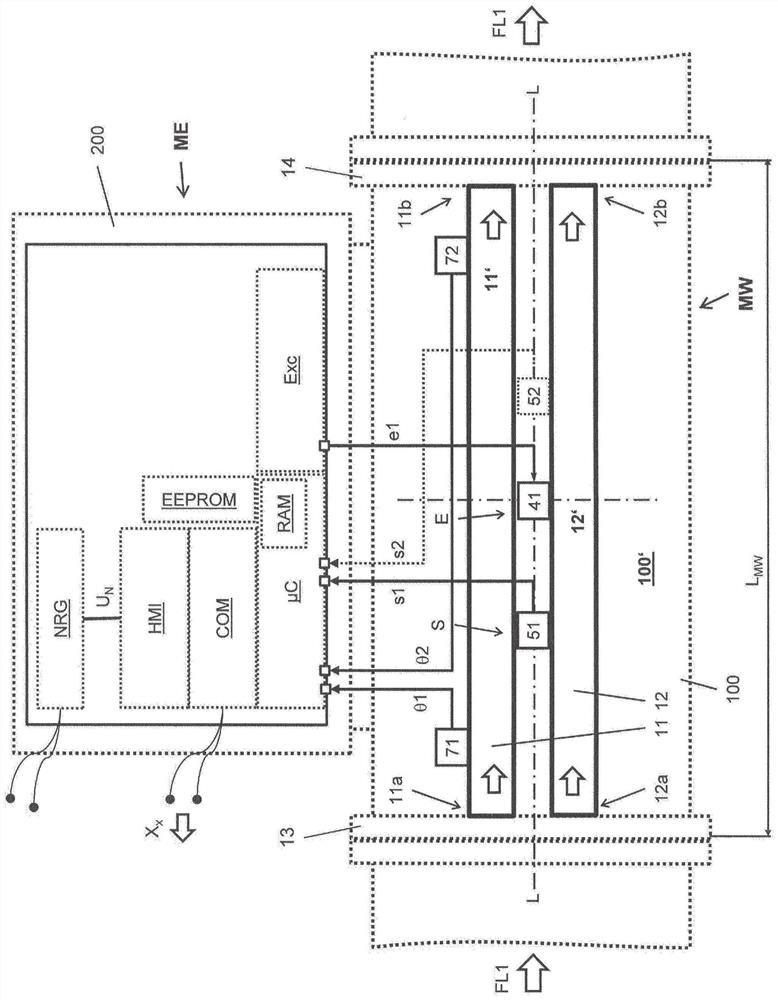

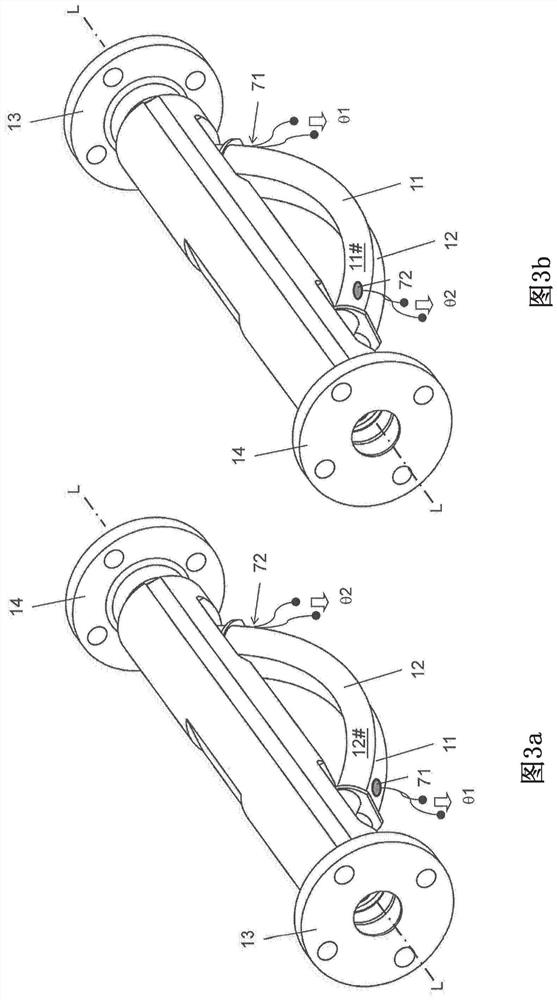

[0082] figure 1 A schematic diagram showing an electro-vibratory measurement system for measuring the mass flow rate m of a flowing fluid FL1 (measurement fluid), optionally with a temporally and / or spatially varying measurement fluid temperature For example gases, liquids or flowable dispersions, the electro-vibratory measuring system is either used to repeatedly determine a mass flow measurement x representing the mass flow rate m instantaneously m . The measuring system can also be designed for determining at least one further measured variable of the fluid FL, namely, for example, a material parameter. The further measured variable may be, for example, density p, viscosity η or, for example, the measured fluid temperature of the fluid flowing through the pipeline

[0083] For this purpose, the measuring system comprises: a transducer device MW for generating a measurement signal at least for measuring the mass flow rate; and a measuring and operating electronics unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com