High-quality ultrathin two-dimensional transition-group metal carbide crystal and preparation method thereof

A technology of transition metals and carbides, which is applied in the field of high-quality ultra-thin two-dimensional transition metal carbide crystals and its preparation, can solve the problems of small size, impure materials, and poor quality, and achieve convenient operation and high material composition. Uniform, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In a specific embodiment, the method for preparing high-quality ultra-thin two-dimensional transition metal carbide crystals of the present invention adopts a bimetallic laminate composed of copper foil (upper layer) / transition metal foil (bottom layer) as a growth substrate. Under high temperature, the carbon source is catalytically cracked by chemical vapor deposition technology to grow ultra-thin two-dimensional transition metal carbide crystals, and then the copper substrate is etched away to obtain ultra-thin two-dimensional transition metal carbide crystals. The specific steps are as follows:

[0046] (1) CVD growth of two-dimensional transition metal carbides: a bimetallic laminate composed of copper foil (upper layer) / transition metal foil (bottom layer) is used as the growth substrate. During the high-temperature chemical vapor deposition process, the transition metal The foil provides transition group metal atoms. After the copper foil is melted, it acts as a d...

Embodiment 1

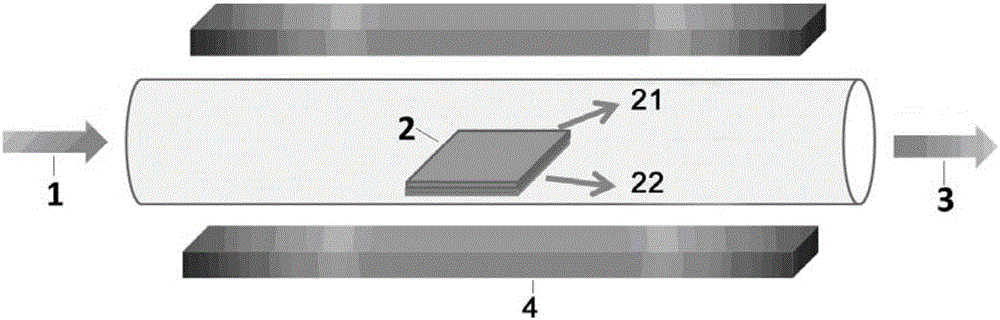

[0056] First, if figure 1 As shown, the present invention uses a horizontal reaction furnace to grow ultra-thin transition metal carbides. The two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 3. The copper foil / molybdenum sheet is placed in the high temperature zone of the horizontal reaction furnace. Copper foil / molybdenum sheet (copper foil 20 millimeters * 20 millimeters * 5 microns, purity is 99.5wt%, molybdenum sheet 20 millimeters * 20 millimeters * 100 microns, purity is 99.95wt%) is placed in horizontal reaction furnace (furnace tube 22 mm in diameter, 20 mm in length of the reaction zone) in the central area; heated to 1110°C in a hydrogen atmosphere (the hydrogen flow rate during the heating process is 200 ml / min, and the heating rate is 20°C / min), after the furnace temperature rises to 1110°C A mixed gas of methane and hydrogen was introduced (the gas flow rates were 0.35 ml / min for methane and 200 ml / min for ...

Embodiment 2

[0060] First, if figure 1 As shown, the present invention uses a horizontal reaction furnace to grow ultra-thin transition metal carbides. The two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 3. The copper foil / molybdenum sheet is placed in the high temperature zone of the horizontal reaction furnace. Copper foil / molybdenum sheet (copper foil 20 millimeters * 20 millimeters * 10 microns, purity is 99.5wt%, molybdenum sheet 20 millimeters * 20 millimeters * 100 microns, purity is 99.95wt%) is placed in horizontal reaction furnace (furnace tube 22 mm in diameter, 20 mm in length of the reaction zone) in the central area; heated to 1086°C in a hydrogen atmosphere (the hydrogen flow rate during the heating process is 200 ml / min, and the heating rate is 20°C / min), after the furnace temperature rises to 1086°C A mixed gas of methane and hydrogen (gas flow rates of 0.35 ml / min for methane and 200 ml / min for hydrogen) was introd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com