Post-repair method of formamidino perovskite thin film

A technology of formamidinyl perovskite and amidinyl perovskite, which is applied in the field of preparation of thin film materials, can solve problems that are difficult to realize and unsuitable for industrial production, and achieve low roughness, simple preparation and repair, and high The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First, 300 cycles of TiO were deposited on cleaned FTO glass using atomic layer deposition equipment. 2 , the deposited FTO glass was heated at 500°C for 30 minutes to obtain dense TiO 2 film. Spin-coating SnO on dense thin films 2 Precursor solution (SnCl 4 aqueous solution), where SnO 2 The size of the micelle is about 12nm, the spin coating condition is 3000rpm, 30s, and then further heat treatment at 200°C for 30min to obtain dense SnO 2 film.

[0042] Secondly, according to the molar percentage 1:0.9:0.1 PbI 2 :FAI:CsI was dissolved in DMF solution to prepare a solution with a mass ratio of 50%, and then spin-coated on SnO 2 On the thin film, the annealing condition is 150°C, 10min, and the solvent in the thin film is volatilized to obtain FA 0.9 Cs 0.1 PB 3 film;

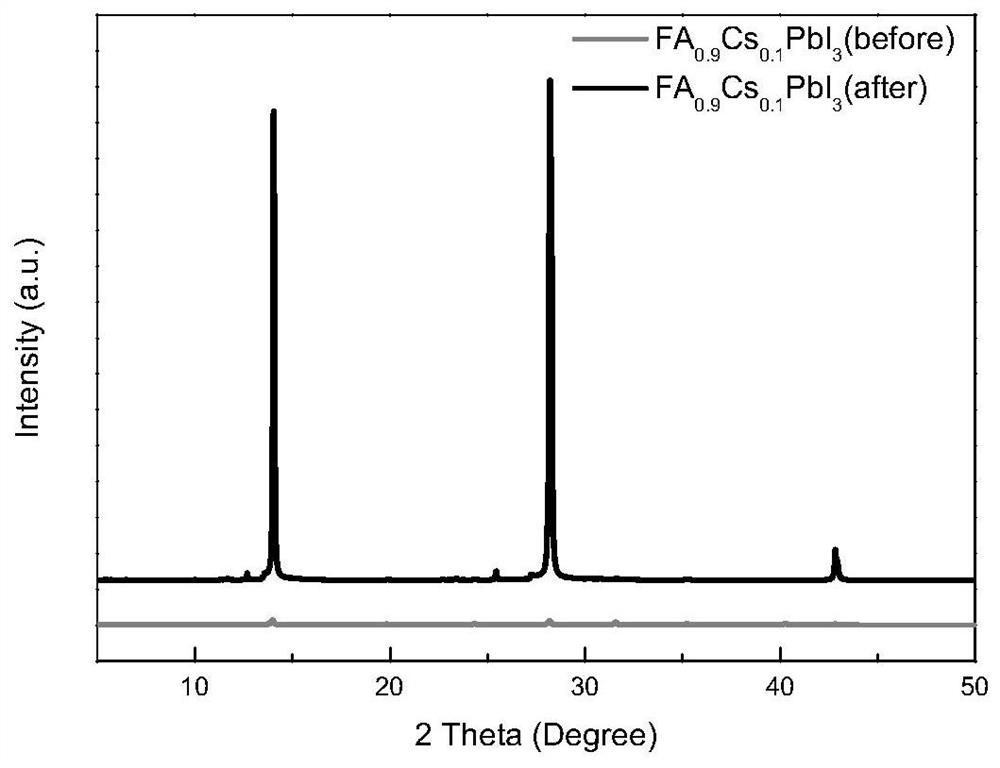

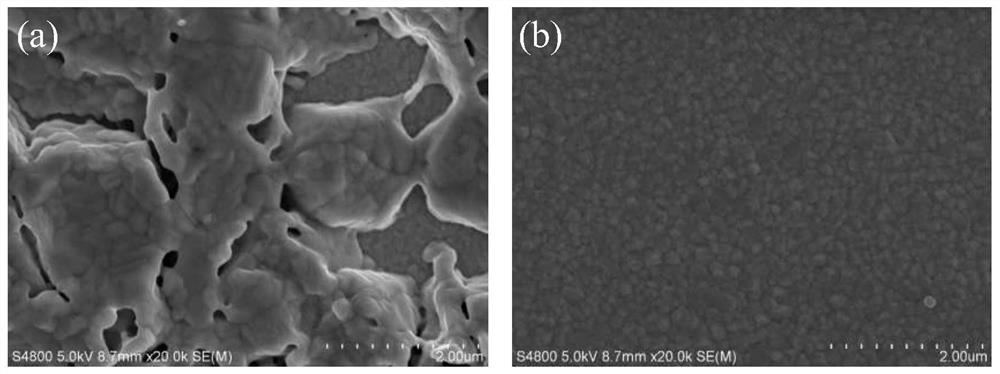

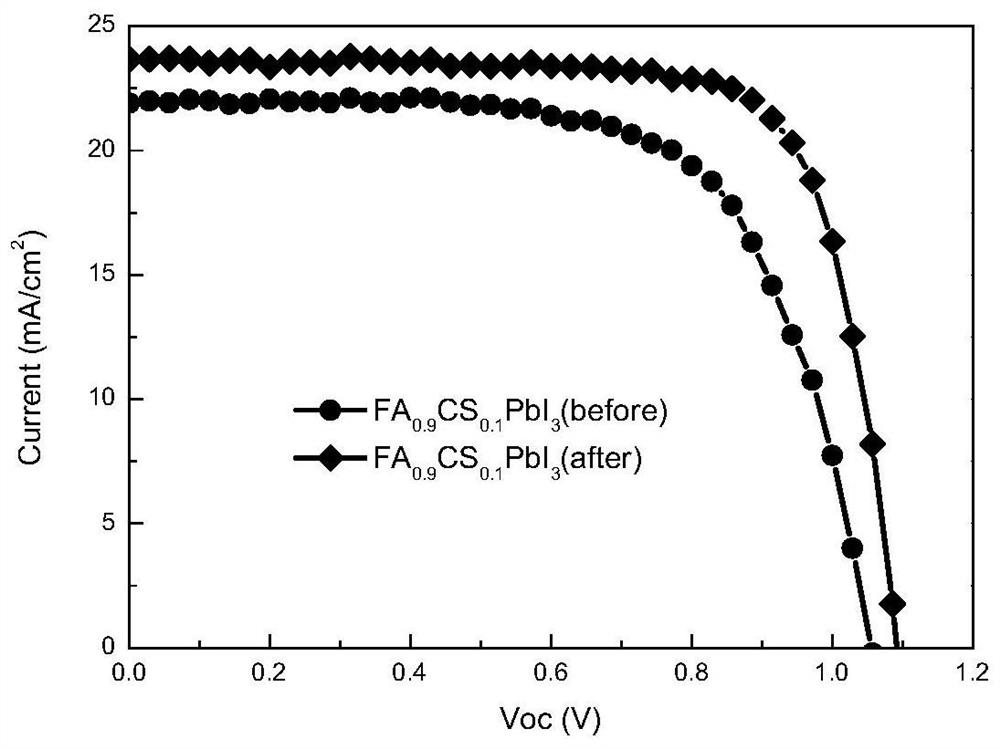

[0043] Then the prepared FA 0.9 Cs 0.1 PB 3 The film is post-treated with ammonia gas, specifically moving it into an atmosphere of ammonia gas (ammonia gas comes from a liquid ammonia cyli...

Embodiment 2

[0047] First, 300 cycles of TiO were deposited on cleaned FTO glass using atomic layer deposition equipment. 2 , the deposited FTO glass was heated at 500°C for 30 minutes to obtain dense TiO 2 film. Spin-coating SnO on dense thin films 2 Precursor solution (SnCl 4 aqueous solution), where SnO 2 The size of the micelle is about 12nm, the spin coating condition is 3000rpm, 30s, and then further heat treatment at 200°C for 30min to obtain dense SnO 2 film.

[0048] Secondly, according to the mole percentage of 0.94:0.06:1 PbI 2 :BiI 3 : FAI was dissolved in DMF solution to prepare a solution with a mass ratio of 50%, and then spin-coated on SnO 2 On the film, the annealing condition is 150°C, 10min, the solvent in the film is evaporated, and FABi is obtained 0.06 Pb 0.94 I 3 film;

[0049] Then the prepared FABi 0.06 Pb 0.94 I 3 The film is post-treated with ammonia gas, specifically, it is moved into an atmosphere of ammonia gas (ammonia gas comes from a liquid am...

Embodiment 3

[0053] First, 300 cycles of TiO were deposited on cleaned FTO glass using atomic layer deposition equipment. 2 , the deposited FTO glass was heated at 500°C for 30 minutes to obtain dense TiO 2 film. Spin-coating SnO on dense thin films 2 Precursor solution (SnCl 4 aqueous solution), where SnO 2 The size of the micelle is about 12nm, the spin coating condition is 3000rpm, 30s, and then further heat treatment at 200°C for 30min to obtain dense SnO 2 film.

[0054] Secondly, according to the molar percentage of 0.94:0.06:0.9:0.1 PbI 2 :BiI 3 :FAI:CsI was dissolved in DMF solution to prepare a solution with a mass ratio of 50%, and then spin-coated on SnO 2 On the thin film, the annealing condition is 150°C, 10min, and the solvent is evaporated to obtain FA 0.9 Cs 0.1 Bi 0.06 Pb 0.94 I 3 film;

[0055] Then the prepared FA 0.9 Cs 0.1 Bi 0.06 Pb 0.94 I 3 The film is post-treated with ammonia gas, specifically, it is moved into an atmosphere of ammonia gas (ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com