Organic light emission diode, display screen and terminal

An electroluminescence device and electroluminescence technology, which are applied in the field of electric light sources, can solve the problems of reducing the reflectivity of OLEDs, difficult to ensure uniformity, and unsatisfactory reflectivity, and achieve uniform film layers, low driving current, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

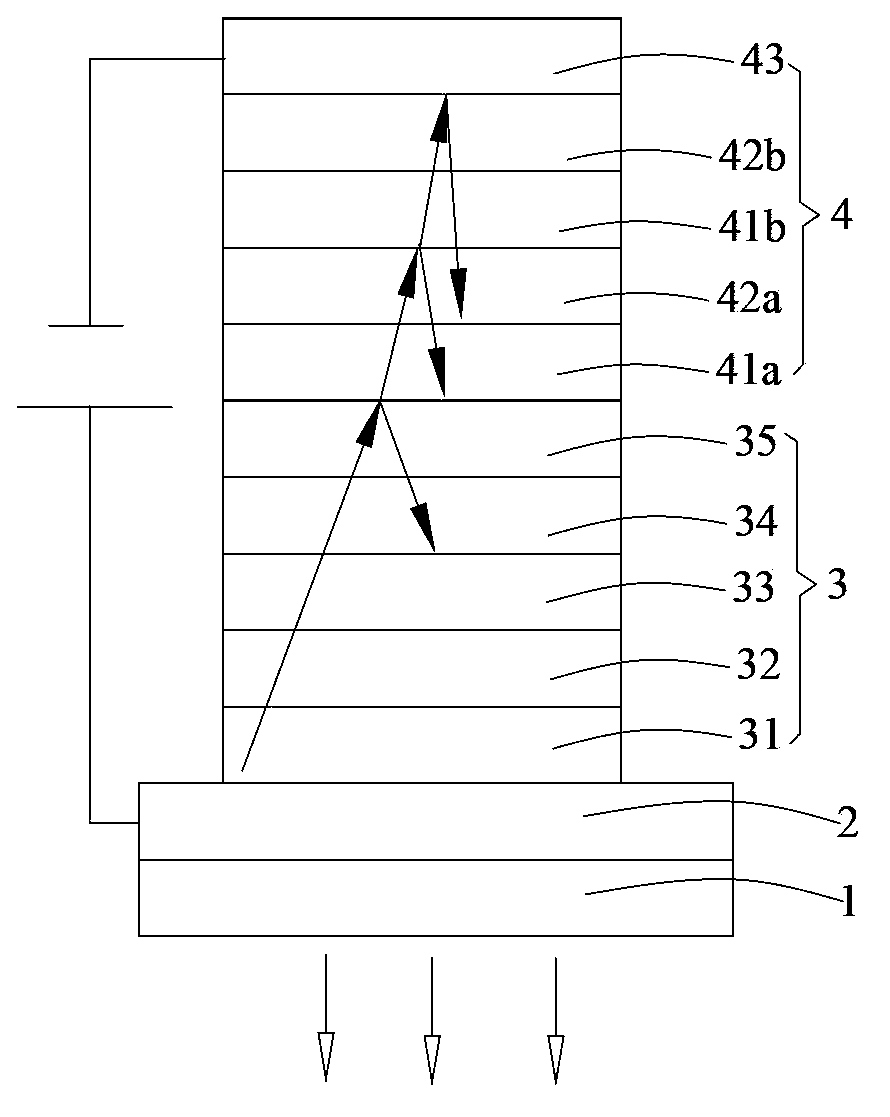

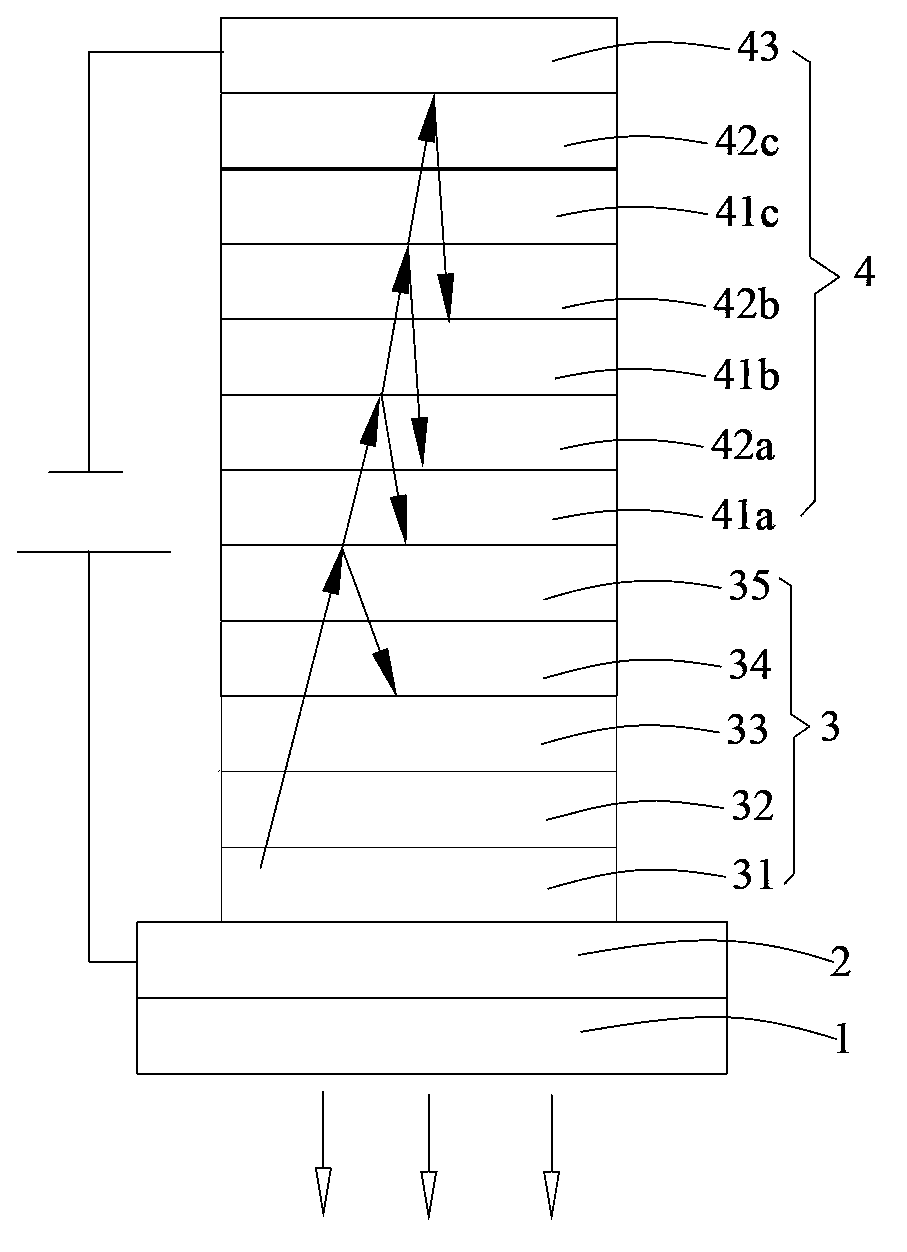

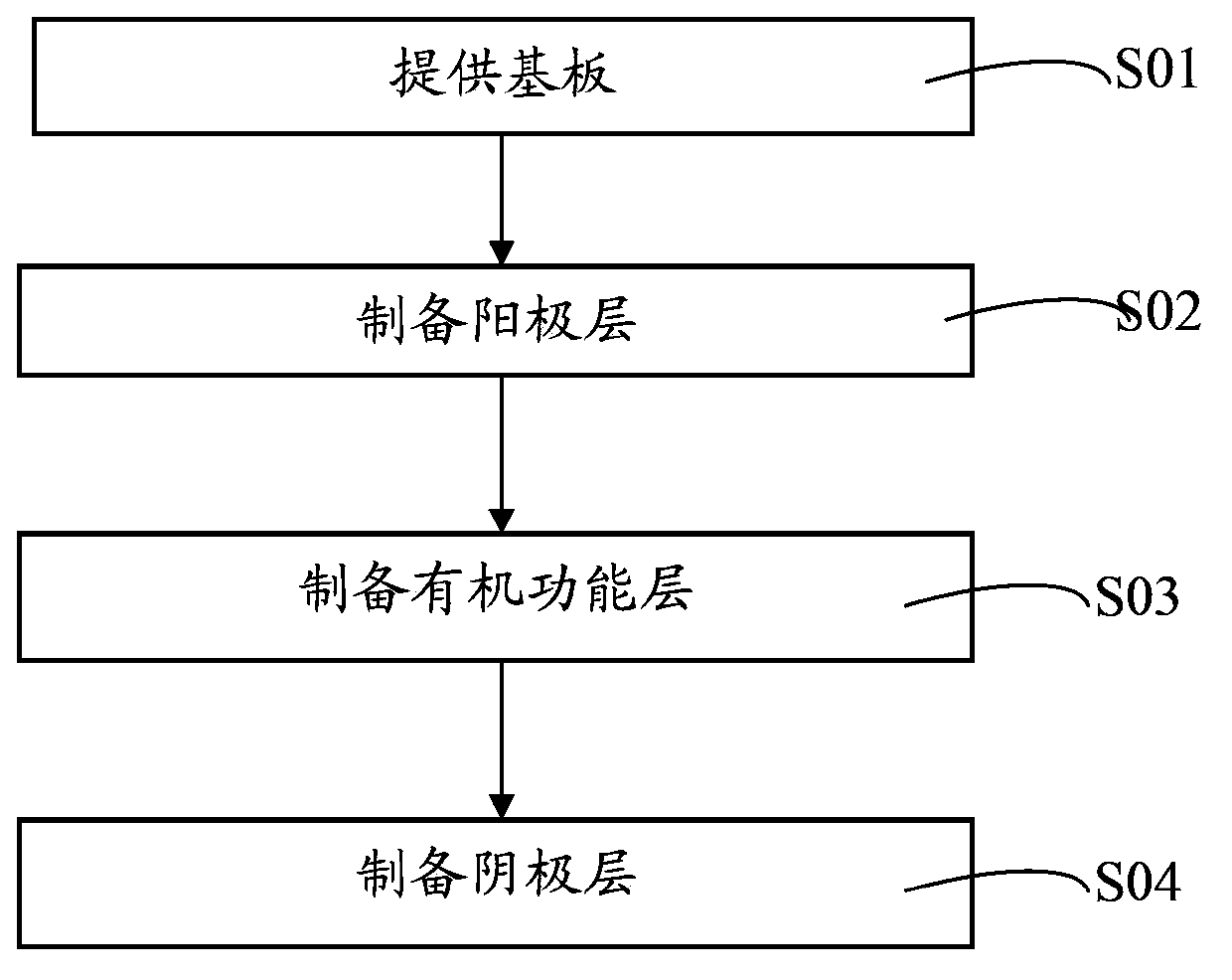

[0048] Correspondingly, the preparation method of the organic electroluminescent device of the above-mentioned embodiment can be as follows image 3 So show. Process preparation, see also Figure 1~2 , Its preparation method includes the following steps:

[0049] S01. Provide a transparent substrate 1;

[0050] S02. Preparation of the anode layer 2: In a vacuum system, the transparent conductive oxide is magnetron sputtered to prepare the anode layer 2 on the surface of the substrate 1 in step S01;

[0051] S03. Preparation of organic functional layer 3: In step S02, a hole injection layer 31, a hole transport layer 32, a light emitting layer 33, and an electron transport layer are sequentially evaporated on the surface of the anode layer 2 opposite to the bonding surface of the light-transmitting substrate layer 1 34. The electron injection layer 35 forms the organic functional layer 3;

[0052] S04. Preparation of the cathode layer 4: In the vacuum coating system, the semi-permeab...

Embodiment 1

[0068] An organic electroluminescence device with a low reflectivity cathode and an anode as the light-emitting surface. Its structure is: glass substrate / ITO (70nm) / hole injection layer (CuPc, 20nm) / hole transport layer (NPB, 40nm) ) / Luminescent layer (Alq 3 :C545T(10%),10nm) / electron transport layer (TPBi,40nm) / electron injection layer (LiF,1nm) / Cr(10nm) / Alq 3 :Li 2 CO 3 (60nm) / Cr(10nm) / Alq 3 :Li 2 CO 3 (80nm) / Ag(100nm). Among them, Cr(10nm) / Alq 3 :Li 2 CO 3 (60nm) / Cr(10nm) / Alq 3 :Li 2 CO 3 (80nm) / Ag(100nm) constitutes the anode, and the Cr layer is a semi-permeable metal layer, Alq 3 :Li 2 CO 3 The layer is an interference layer, and Ag (100nm) is a metal reflective layer.

[0069] The preparation method is as follows:

[0070] (1) When the vacuum degree is 10 -4 Prepared in the Pa vacuum coating system, the glass substrate is cleaned with a cleaning agent, then with distilled water, acetone, followed by ultrasonic cleaning, and then in the coating system;

[0071] (2) First, pre...

Embodiment 2

[0076] An organic electroluminescence device with a low reflectivity cathode and an anode as the light-emitting surface. Its structure is: glass substrate / ITO (100nm) / hole injection layer (CuPc, 20nm) / hole transport layer (NPB, 40nm) ) / Luminescent layer (Alq 3 :C545T(10%),10nm) / electron transport layer (TPBi,40nm) / electron injection layer (LiF,1nm) / Al(7nm) / TPBi:Cs 2 CO 3 (20nm) / Al(7nm) / TPBi:Cs 2 CO 3 (30nm) / Al(7nm) / TPBi:Cs 2 CO 3 (40nm) / Mg-Al(70nm). Among them, Al(7nm) / TPBi:Cs 2 CO 3 (20nm) / Al(7nm) / TPBi:Cs 2 CO 3 (30nm) / Al(7nm) / TPBi:Cs 2 CO 3 (40nm) / Mg-Al (70nm) constitutes the anode, and the Al layer is a semi-permeable metal layer, TPBi:Cs 2 CO 3 The layer is an interference layer, and Mg-Al (70nm) is a metal reflective layer.

[0077] The preparation method is as follows:

[0078] (1) When the vacuum degree is 10 -4 Prepared in the Pa vacuum coating system, the glass substrate is cleaned with a cleaning agent, then with distilled water, acetone, followed by ultrasonic cleaning, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com