Method for preparing two-phase compact oxygen permeable material with high oxygen permeability

A high oxygen permeability and dense technology, applied in the field of dense ceramic oxygen permeable membrane materials, can solve the problems that the membrane body cannot be dense, the electronic phase cannot be connected, and the oxygen permeability of the material is low, so as to achieve good chemical stability and fine particles , Improve the effect of oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

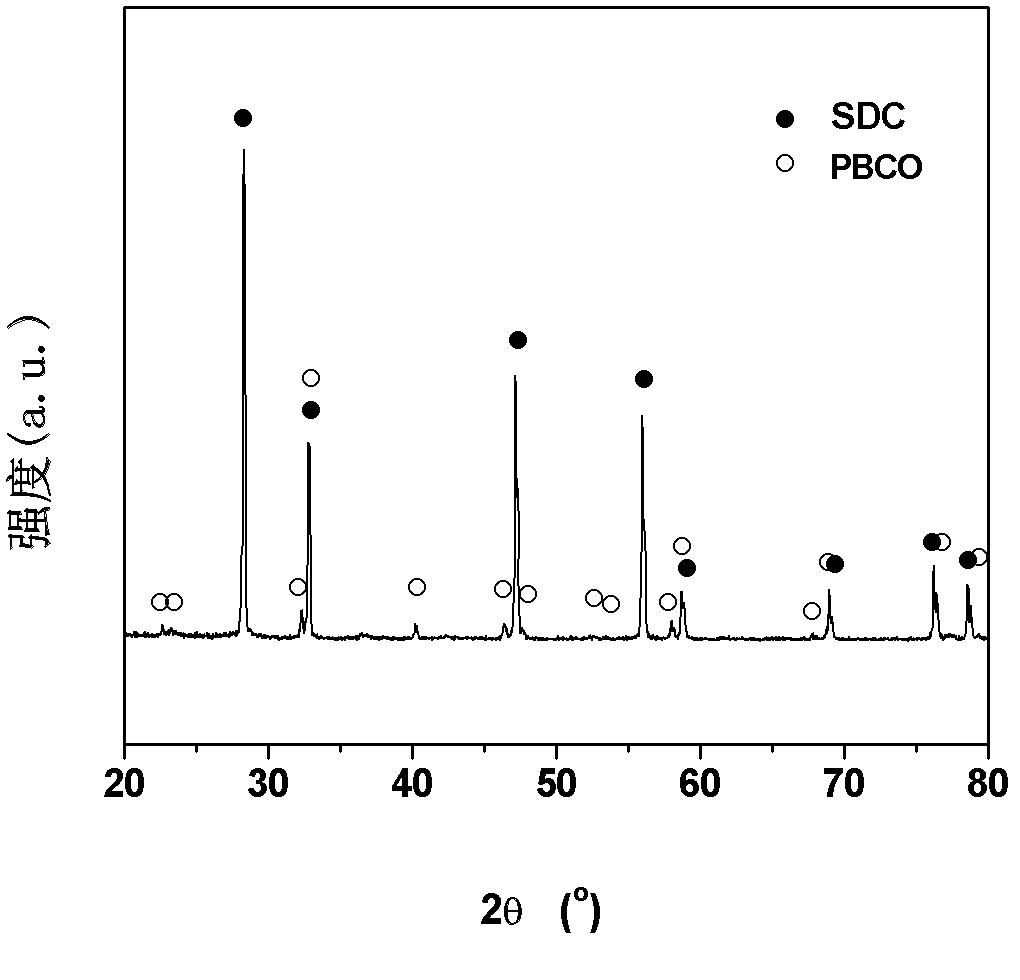

[0017] Ce prepared by coating method with a volume ratio of 8:2 0.8 SM 0.2 o 2-δ –PrBaCo 2 o 5+δ Dual-phase dense oxygen-permeable membrane.

[0018] The fluorite-type oxygen ion conductor Ce used in this example 0.8 SM 0.2 o 2-δ Prepared by surfactant modulation synthesis method: CTAB(CH 3 (CH 2 ) 15 N + (CH 3 ) 3 Br – ) as an organic template was dissolved in deionized water, stirred to completely dissolve to form a solution (0.08 M), and then a certain amount of ammonia was added dropwise. At the same time, according to the proportion of the amount of the substance Ce 3+ :Sm 3+ =8:2 for batching, dissolved in deionized water and stirred evenly (1 mM), then slowly dropped into CTAB solution and stirred for 2 hours to obtain a precipitate. The precipitate was aged at room temperature for 24 hours, then washed by centrifugation and dried at 60°C. The resulting precipitate was sintered in two steps: heating up to 250 °C for 2 hours to remove organic matter; the...

Embodiment 2

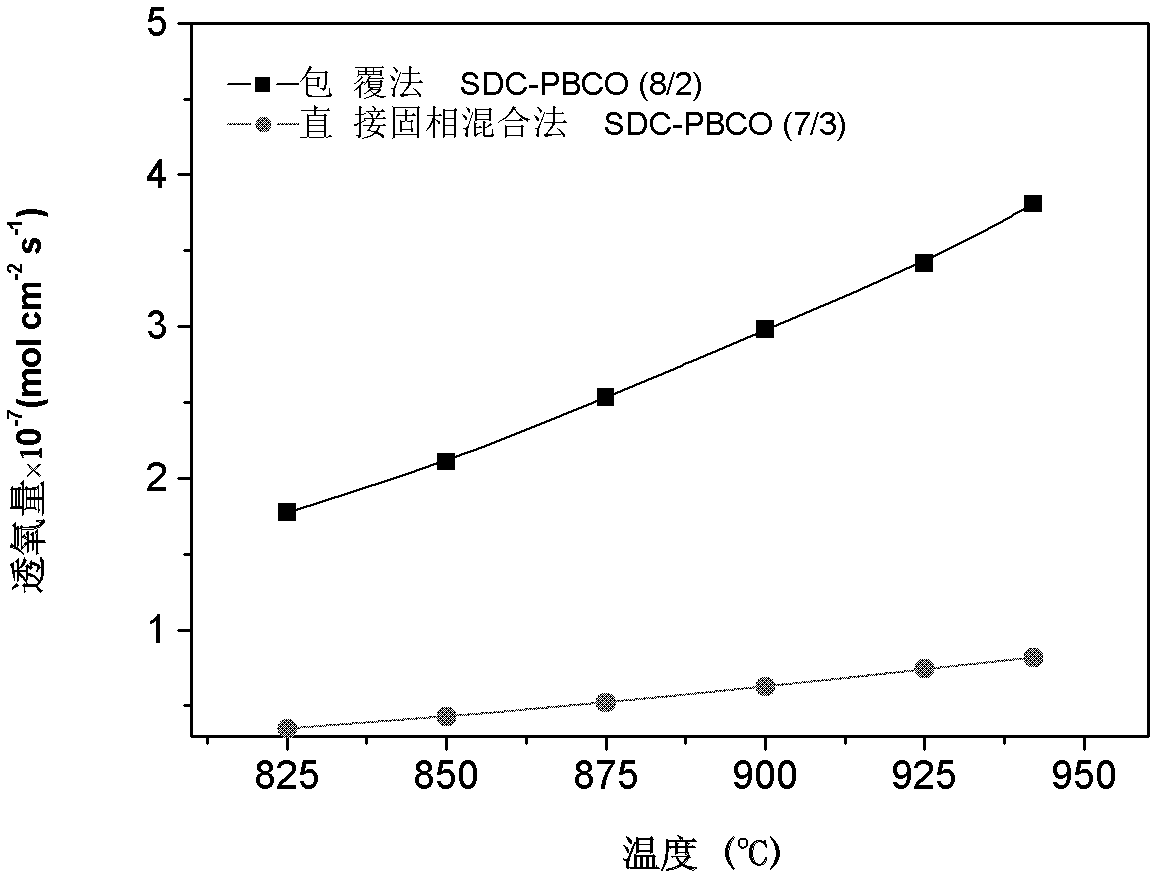

[0024] The preparation method and preparation conditions of this example and the above-mentioned Example 1 are the same, the difference is that the Ce with a volume ratio of 7:3 is prepared by the liquid phase coating method. 0.8 SM 0.2 o 2-δ –PrBaCo 2 o 5+δ Dual-phase dense oxygen-permeable membrane. According to Ce 0.8 SM 0.2 o 2-δ :PrBaCo 2 o 5+δ The volume ratio is 7:3 preparation, the Ce 0.8 SM 0.2 o 2-δ The powder is ultrasonically dispersed in the PrBaCo described in Example 1 2 o 5+δ in the precursor solution.

[0025] Using the four-terminal lead method to measure Ce in the air atmosphere within the temperature range of 200~900℃ 0.8 SM 0.2 o 2-δ –PrBaCo 2 o 5+δ Conductivity of biphasic dense oxygen-permeable membranes. The experimentally measured conductivity reaches 6.67 S cm at 900 °C -1 . The oxygen permeability of the material is tested by a high temperature oxygen permeability test system. High-purity helium and synthetic air were blown into...

Embodiment 3

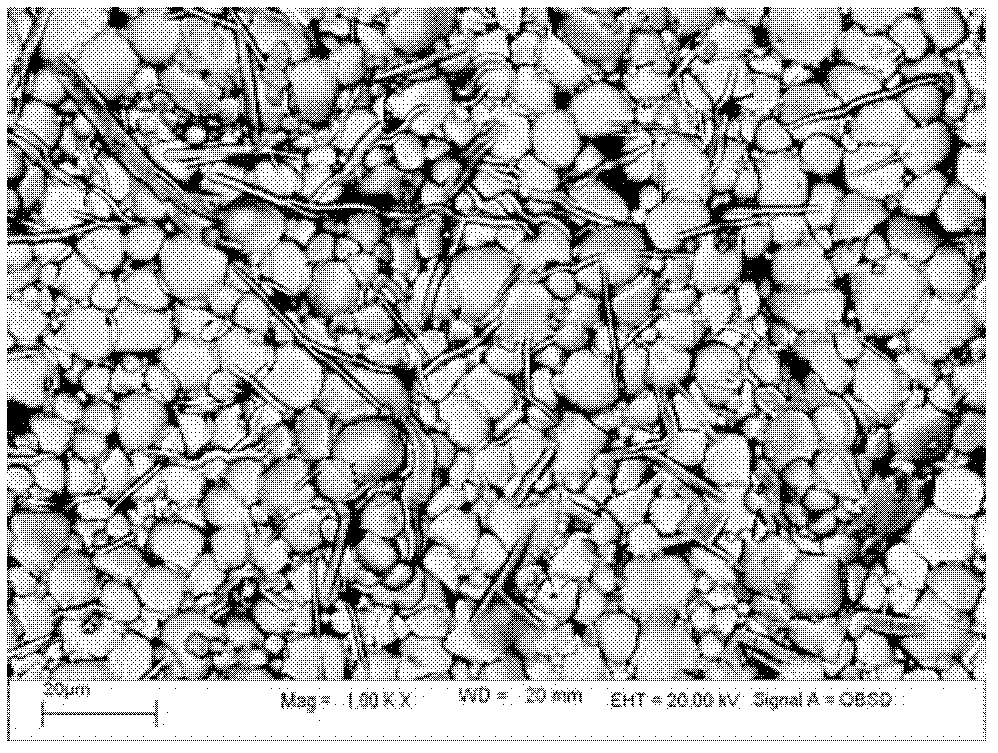

[0027] Preparation of Ce with a particle size of about 10 mm by solid-state method 0.8 SM 0.2 o 2-δ Ionically conductive phase powder according to Ce 0.8 SM 0.2 o 2-δ :PrBaCo 2 o5+δ The volume ratio is 8:2 preparation, the Ce 0.8 SM 0.2 o 2-δ Ultrasonic dispersion of the PrBaCo described in Example 1 2 o 5+δ in the precursor solution. Use a rotary evaporator to dry at 90° C. under reflux to form a gel, bake at 950° C. for 8 hours, and cool in the furnace to obtain a mixture of an electronically conductive phase coated with an ionically conductive phase.

[0028] The resulting mixture was ground in a mortar until homogeneous, (binder) polyvinyl alcohol was added, and then dry-pressed into discs in a stainless steel mold with a uniaxial pressure of 110 MPa, followed by sintering at 1193 °C for 10 h.

[0029] Measure Ce by four-terminal lead method in air atmosphere at a temperature of 200~900°C 0.8 SM 0.2 o 2-δ –PrBaCo 2 o 5+δ Conductivity of biphasic dense oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com