Manufacture method of environment-friendly plywood

A plywood, environmental protection technology, applied in the field of plywood, can solve the problems of slow release, affecting the health of residents, indoor air pollution, etc., to achieve the effect of improving bond strength, no formaldehyde release, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

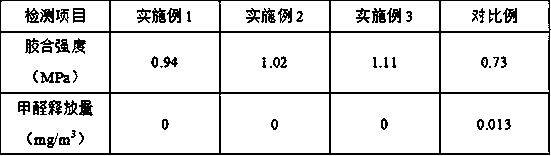

Examples

preparation example Construction

[0019] Preparation of soaking solution: Mix cellulase, pepsin and 0.3mol / L phosphoric acid solution at a mass ratio of 1:1 to 2:7 to obtain the soaking solution.

[0020] Defatted soy flour was purchased from Henan Hetian Food Additive Co., Ltd.

[0021] Water-based polyurethane was purchased from Dongwan City Creed Environmental Protection Material Co., Ltd.

[0022] The preparation method of composite glue comprises the steps:

[0023] A. According to the mass ratio of 1:3, put defatted soybean powder and 0.3mol / L ammonium nitrate solution into a container, and heat at 90°C for 30-35min;

[0024] B. After heating, add water-based polyurethane in an amount of 6-9% of the mass of defatted soybean powder, heat up to 95-100°C, then add lithium iodide, keep warm for 1-3 hours, cool to room temperature, discharge, and spray Drying, collecting dried matter;

[0025] C. In parts by weight, take 70-80 parts of 0.9mol / L sodium hydroxide solution, 30-35 parts of dry matter, 15-18 pa...

Embodiment 1

[0031] Preparation of soaking solution: Mix cellulase, pepsin and 0.3mol / L phosphoric acid solution at a mass ratio of 1:1:7 to obtain the soaking solution.

[0032] Defatted soy flour was purchased from Henan Hetian Food Additive Co., Ltd.

[0033] The preparation method of composite glue comprises the steps:

[0034] A. According to the mass ratio of 1:3, put defatted soybean powder and 0.3mol / L ammonium nitrate solution into a container, and heat at 90°C for 30min;

[0035] B. After heating, add water-based polyurethane in an amount of 6% of the mass of defatted soybean powder, heat up to 95°C, then add lithium iodide, keep warm for 1h, cool to room temperature, discharge, spray dry, and collect dry matter;

[0036] C. In parts by weight, take 70 parts of 0.9mol / L sodium hydroxide solution, 30 parts of dry matter, 15 parts of hexamethyldisilane, 12 parts of methacryloyloxymethyl tri(trimethylsiloxane Base) silane, 6 parts of hydroxyacetamide and 3 parts of platinum oxide,...

Embodiment 2

[0042] Preparation of soaking solution: Mix cellulase, pepsin and 0.3mol / L phosphoric acid solution at a mass ratio of 1:1:7 to obtain the soaking solution.

[0043] Defatted soy flour was purchased from Henan Hetian Food Additive Co., Ltd.

[0044] The preparation method of composite glue comprises the steps:

[0045] A. According to the mass ratio of 1:3, put defatted soybean powder and 0.3mol / L ammonium nitrate solution into a container, and heat at 90°C for 30min;

[0046] B. After heating, add water-based polyurethane in an amount of 6% of the mass of defatted soybean powder, heat up to 95°C, then add lithium iodide, keep warm for 1h, cool to room temperature, discharge, spray dry, and collect dry matter;

[0047]C. In parts by weight, take 70 parts of 0.9mol / L sodium hydroxide solution, 30 parts of dry matter, 15 parts of hexamethyldisilane, 12 parts of methacryloyloxymethyl tri(trimethylsiloxane Base) silane, 6 parts of hydroxyacetamide and 3 parts of platinum oxide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com