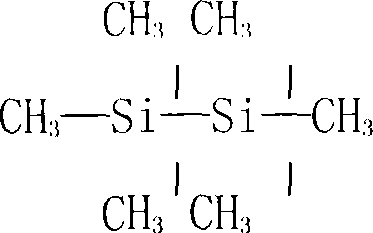

Method for preparing hexamethyldisilane

A technology of hexamethyldisilane and trimethylchlorosilane is applied in the field of preparation of organosilicon materials, and can solve the problems that hexamethyldisilane and hexamethyldisilane are not disclosed, and the reaction is not easy to control, and the like, Achieve the effect of short reaction time and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First fill nitrogen into a 1500ml reactor, pump in 2.0mol (246.5ml) of solvent o-xylene, put in 1.2mol (46.8g) of potassium metal, raise the temperature to about 80 degrees, and slowly add 1.5 mol of trimethylchlorosilane dropwise. mol (191.5ml), while raising the temperature to reflux for about 9 hours, the reaction was completed, cooled to normal temperature, added 500ml of water, stirred and separated, and then collected 113 degree fractions, the yield was 81.2%, and the conversion rate of the material was 92.17%.

Embodiment 2

[0028] According to the steps of Example 1, first fill nitrogen into a 1500ml reactor, pump in 2.0mol (246.5ml) of solvent m-xylene, put in 1.2mol (46.8g) of potassium metal, raise the temperature to about 75 degrees, and slowly drop Add 1.4 mol (178.7 ml) of trimethylchlorosilane, and raise the temperature and reflux for about 10 hours at the same time. After the reaction is completed, cool to room temperature, add 600 ml of water, stir and separate, and then collect the 113-degree fraction with a yield of 81.9%. The conversion of the material The rate is 93.0%.

Embodiment 3

[0030] According to the steps of Example 1, first fill nitrogen into a 1500ml reactor, pump in 2.0mol of trimethylbenzene as a solvent, put in 1.1mol (42.9g) of metal potassium, raise the temperature to about 65 degrees, and slowly add trimethyl chloride dropwise Silane 1.6mol (204.2ml), while raising the temperature and refluxing for about 9 hours, the reaction was completed, cooled to normal temperature, added 500ml of water, stirred and separated, and then collected the 113 degree fraction, the yield was 80.1%, and the conversion rate of the material was 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com