Method for preparing silicon carbide tube by adopting chemical vapor deposition process

A technology of chemical vapor deposition and silicon carbide tubes, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of low density of silicon carbide tubes and easy detachment of silicon carbide tubes, and achieve improved crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the method for preparing a silicon carbide tube on a graphite tube substrate using a chemical vapor deposition process is as follows:

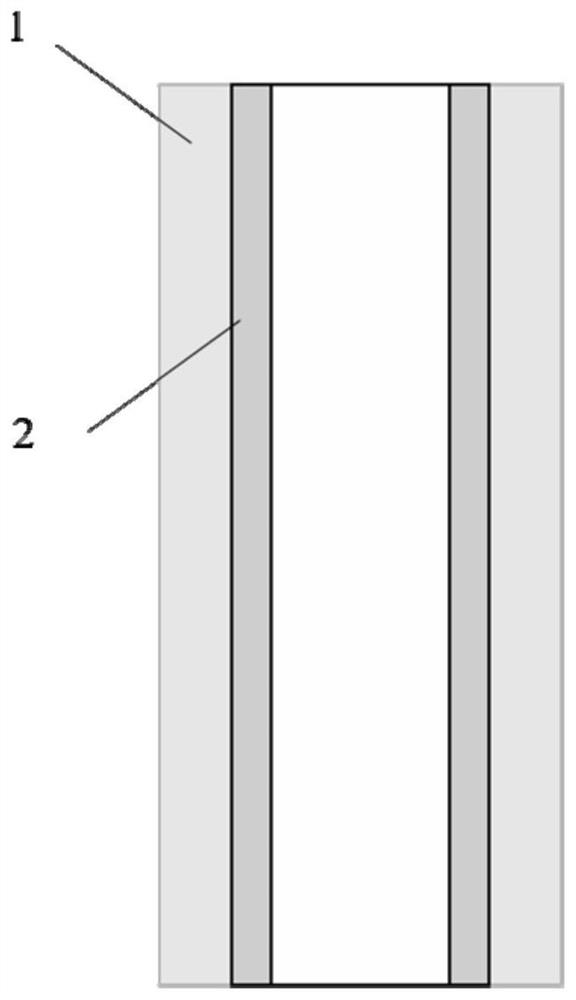

[0026] (1) Select a graphite tube with an outer diameter of 10 mm and an inner diameter of 6 mm (the shape of the inner hole is cylindrical) as the substrate, and ultrasonically clean the graphite tube in alcohol for 15 minutes;

[0027] (2) The graphite tube is vertically placed in the deposition chamber, and the gas system only passes through the central hole of the graphite tube during deposition;

[0028] (3) Start to deposit SiC, the liquid flow rate of hexamethyldisilane is 0.3g / min, H 2 The flow rate is 600sccm, the Ar flow rate is 4000sccm, the deposition temperature is 1100°C, the working pressure is 300Pa, the deposition time is 5h, and the obtained tube is a silicon carbide tube;

[0029] During the heating process, H was first introduced into the 2 and Ar, after the temperature rises to the deposition t...

Embodiment 2

[0033] In this embodiment, the method for preparing a silicon carbide tube on an alumina ceramic tube substrate by a chemical vapor deposition process is as follows:

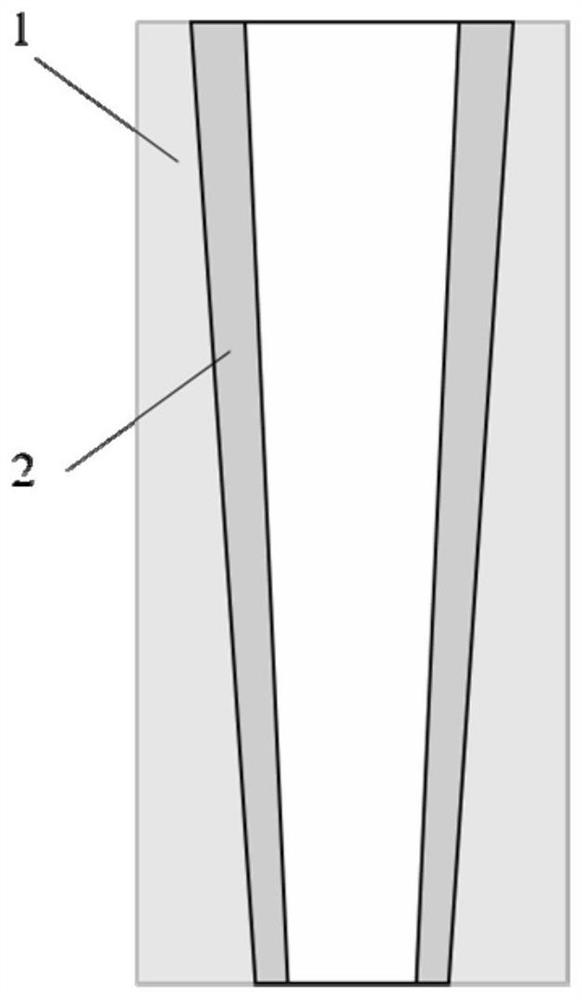

[0034] (1) Select an alumina ceramic tube with an outer diameter of 12mm and an inner diameter of 6mm (the cross-sectional shape of the inner hole is trapezoidal) as the substrate, and ultrasonically clean the alumina ceramic tube in acetone for 10 minutes;

[0035] (2) The alumina ceramic tube is vertically placed in the deposition chamber, and the gas system only passes through the central hole of the alumina ceramic tube during deposition;

[0036] (3) Start to deposit SiC, the liquid flow rate of hexamethyldisilane is 0.5g / min, H 2 The flow rate is 300sccm, the Ar flow rate is 2000sccm, the deposition temperature is 1100°C, the working pressure is 600Pa, the deposition time is 5h, and the obtained tube is a silicon carbide tube;

[0037] During the heating process, H was first introduced into the 2 and Ar,...

Embodiment 3

[0040] In this embodiment, the method for preparing a silicon carbide tube on an alumina ceramic tube substrate by a chemical vapor deposition process is as follows:

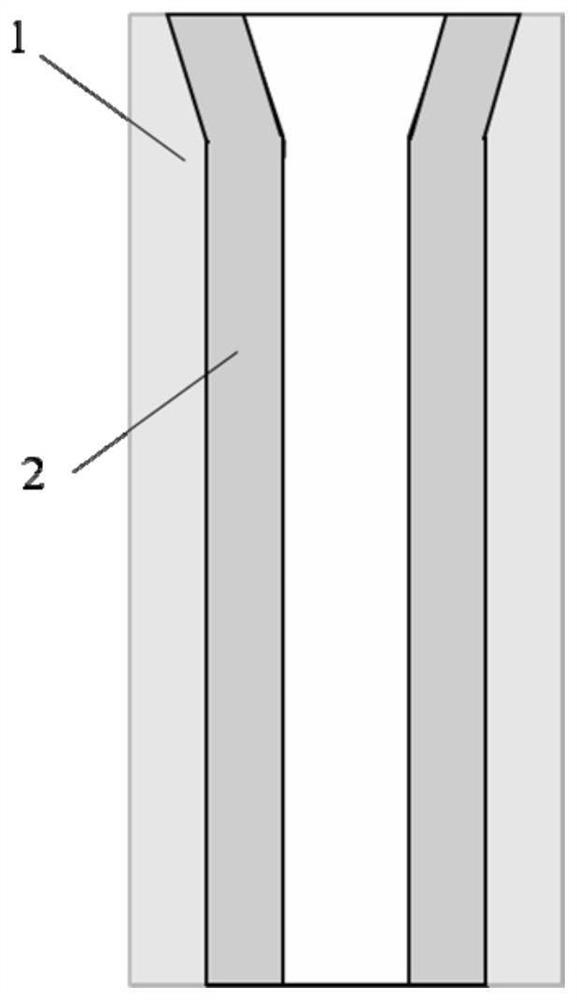

[0041] (1) Select an alumina ceramic tube with an outer diameter of 12 mm and an inner diameter of 6 mm (the shape of the inner hole is a combination of a truncated cone and a cylinder) as the substrate, and ultrasonically clean the alumina ceramic tube in acetone for 5 minutes;

[0042] (2) The alumina ceramic tube is vertically placed in the deposition chamber, and the gas system only passes through the central hole of the alumina ceramic tube during deposition;

[0043] (3) Start to deposit SiC, the liquid flow rate of hexamethyldisilane is 1.2g / min, H 2 The flow rate is 900sccm, the Ar flow rate is 6000sccm, the deposition temperature is 1000°C, the working pressure is 900Pa, the deposition time is 10h, and the obtained tube is a silicon carbide tube;

[0044] During the heating process, H was first introdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com