Semiconductor device and its manufacturing method

A manufacturing method and semiconductor technology, which can be used in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., and can solve problems such as low heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

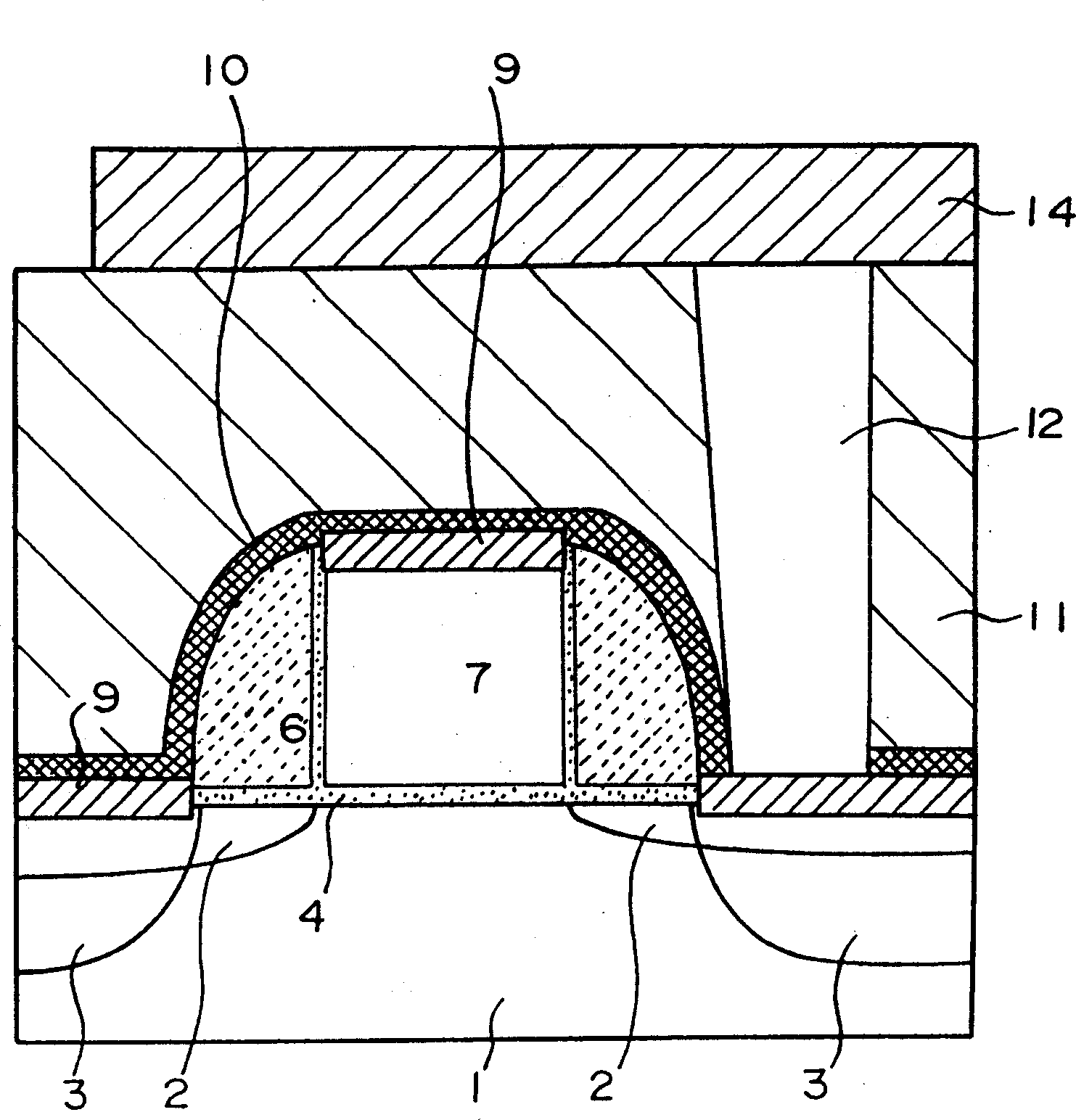

[0041] Embodiments of the present invention will be described below with reference to the drawings.

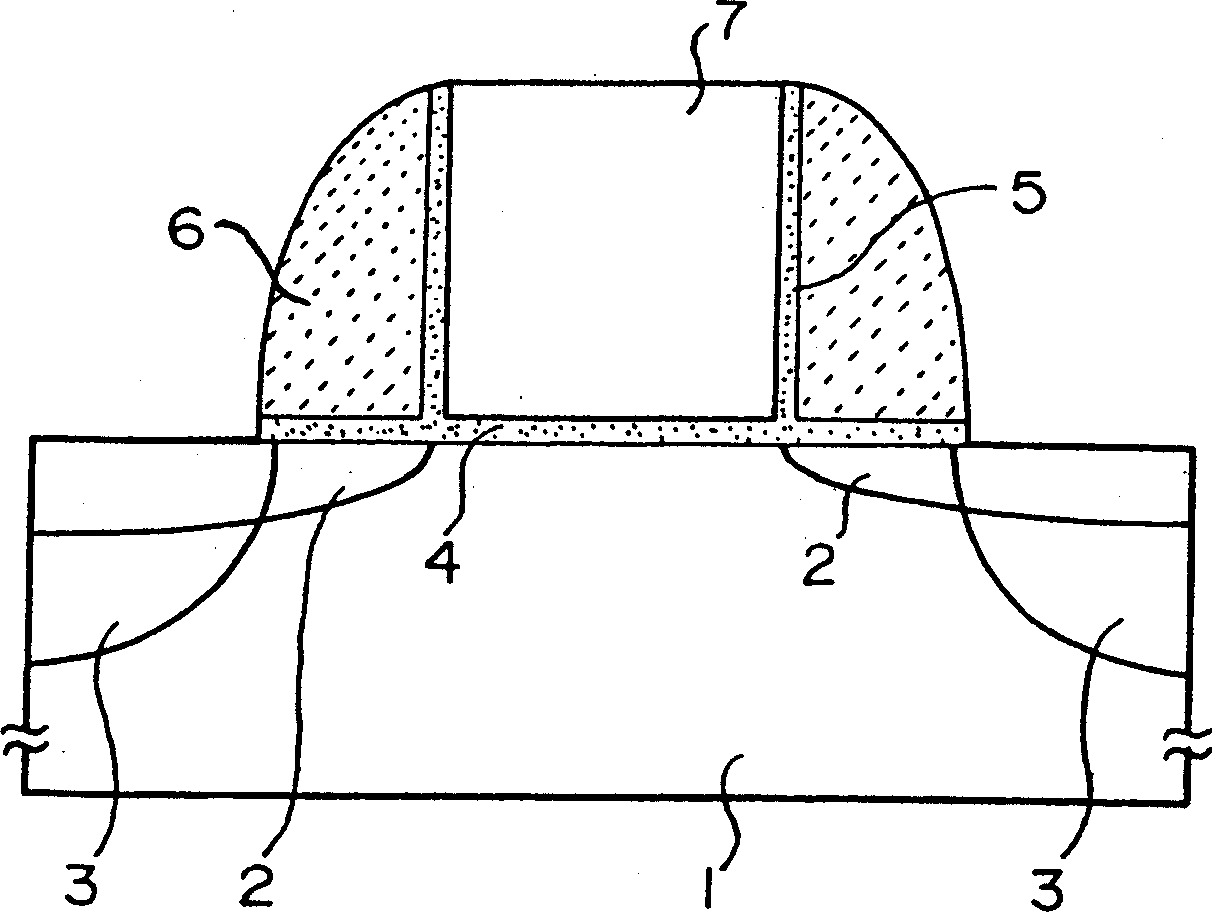

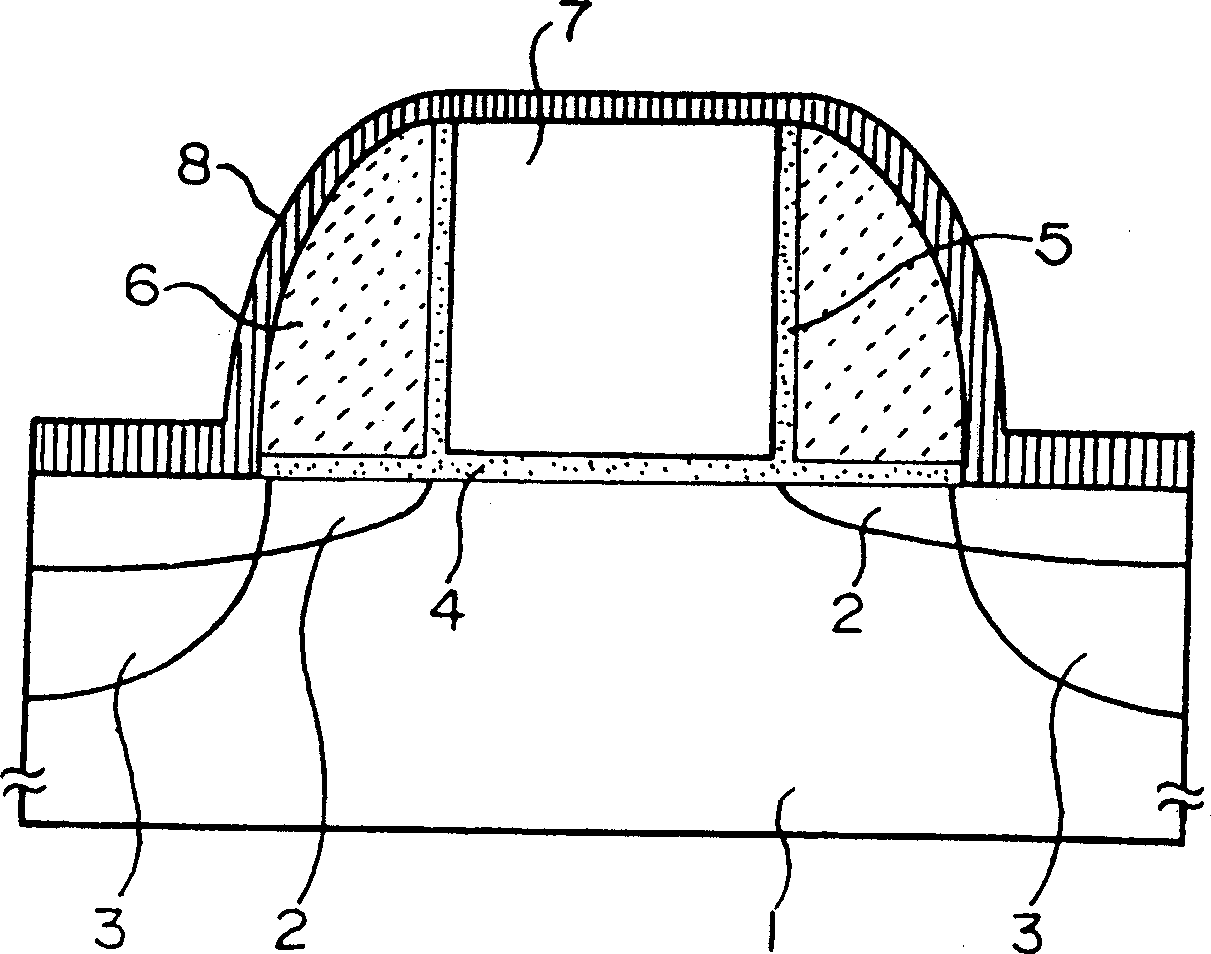

[0042] First refer to Figure 1 to Figure 6 The first embodiment will be described.

[0043] figure 1 is a cross-sectional view of a semiconductor device, Figure 2 to Figure 5 is a cross-sectional view of the manufacturing process of a semiconductor device, Image 6 is a characteristic diagram showing the results of SIMS analysis of impurities in a silicon nitride film (SiN) film formed by the method of this example.

[0044] The silicon semiconductor substrate 1 is, for example, P-type, and this figure is a cross-sectional view of the structure of an NMOSFET formed on the substrate. figure 1 The MOSFET shown in is used, for example, in a CMOS structure in which both NMOS and PMOS are formed within the same chip. and Figure 8 Likewise, on the semiconductor substrate 1, MOSFETs are formed in element regions divided by element isolation regions (not shown) such as STI. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com