Treatment method for tunnel local collapse

A tunnel and partial technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems that threaten the personal safety of construction personnel, equipment safety, block falling, and complicated processes, etc., to overcome the complexity of construction procedures, prevent continued collapse, The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

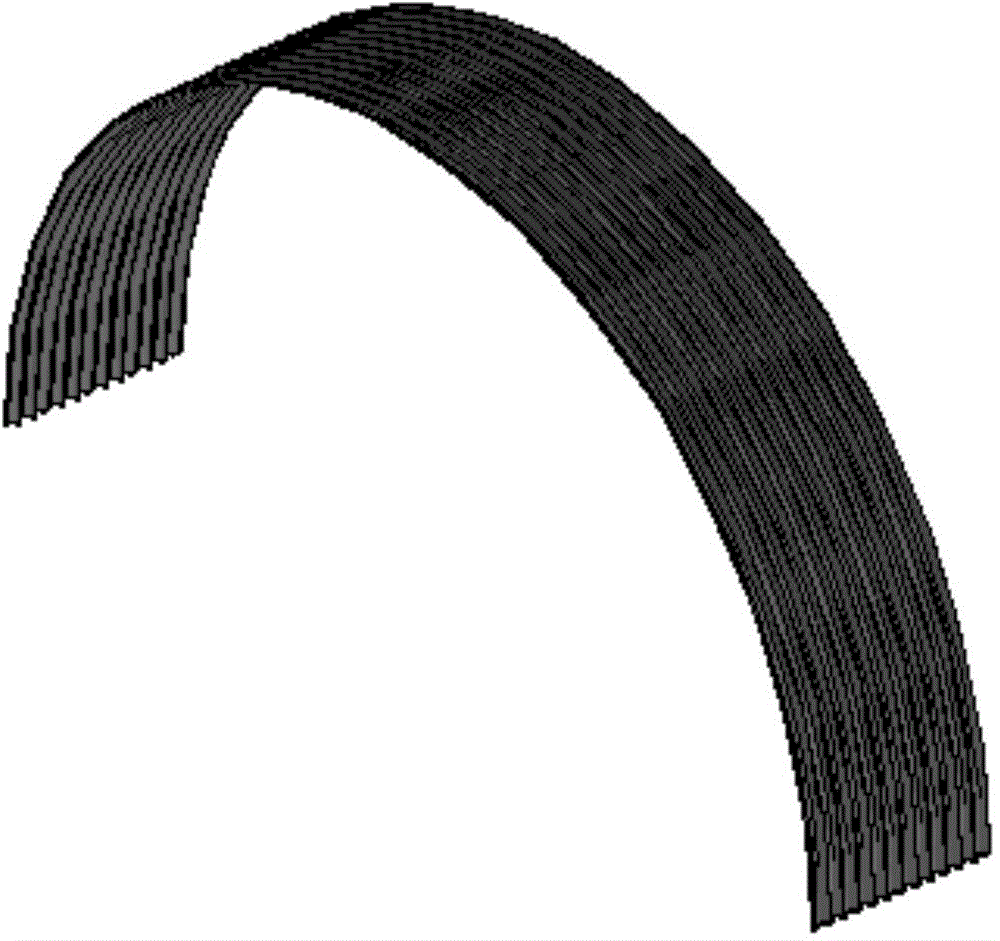

Image

Examples

Embodiment 1

[0035] Embodiment 1: Steel bellows method construction

[0036] Step 1, outside the landslide-affected section on one side of the tunnel collapse position, make a plurality of support bodies with steel plates, the cross-section of each support body is the same as the tunnel profile shape; the length of each support body along the tunnel axis direction is 1.25 meters; In the present embodiment, it is considered that the section affected by the landslide is within 8 meters from one side of the tunnel landslide position;

[0037] Step 2. Use heavy machinery, such as excavators, bulldozers, forklifts, etc., to push the first support body to the section affected by the collapse of the tunnel, and then connect the second support body and the first support body with the same axis And advance to the section affected by the tunnel collapse, repeat the above steps until the multiple supports are connected with the same axis and advanced to the collapse section of the tunnel, after the e...

Embodiment 2

[0042] Embodiment 2: Steel bellows grouting method construction

[0043] Step 1. Begin grouting and consolidation of the tunnel surrounding rock from the collapse-affected section on the side of the tunnel collapse position 8m away from the edge of the collapse section, and the grouting position gradually advances to the tunnel collapse position; adjacent grouting points on the same cross section The circumferential spacing is 1 meter, the length of the small conduit is not less than 4m, and the overlapping distance is not less than 1m;

[0044] Step 2. On the side of the tunnel collapse position, make multiple supports with steel plates. The cross-section of each support is the same as the shape of the tunnel outline. The length of each support along the axis of the tunnel is 1.25 meters. The coaxial connection between the bodies is integrated, and the bolts are used to fasten the connection, and the nut pre-tightening torque is 340N.m±70N.m; when a grouting position reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com