Manufacturing device and method of resin transparent concrete block

A technology for making concrete blocks and making devices, which is applied in the field of high light transmittance and high durability resin transparent concrete preparation, and the device field of quickly making resin light guide bodies, can solve the problem of rough molding process, production efficiency and quality of light guide bodies. Unable to guarantee and other problems, to achieve the effect of low cost, high number of repeated use and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

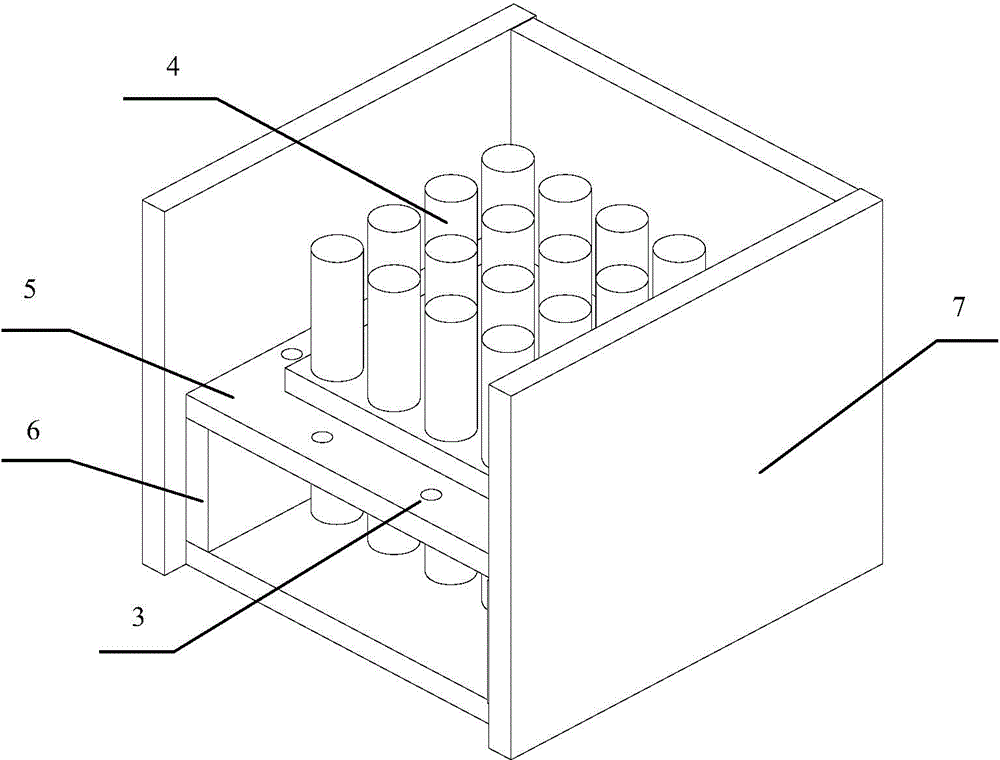

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0033] Figure 6 It is a cubic block with a side length of 100 mm, including a fine stone concrete matrix 13 and a resin light guide 14, wherein the connection part of the light guide is arranged in the middle of the light guide. The method of using this device to produce resin transparent concrete is as follows:

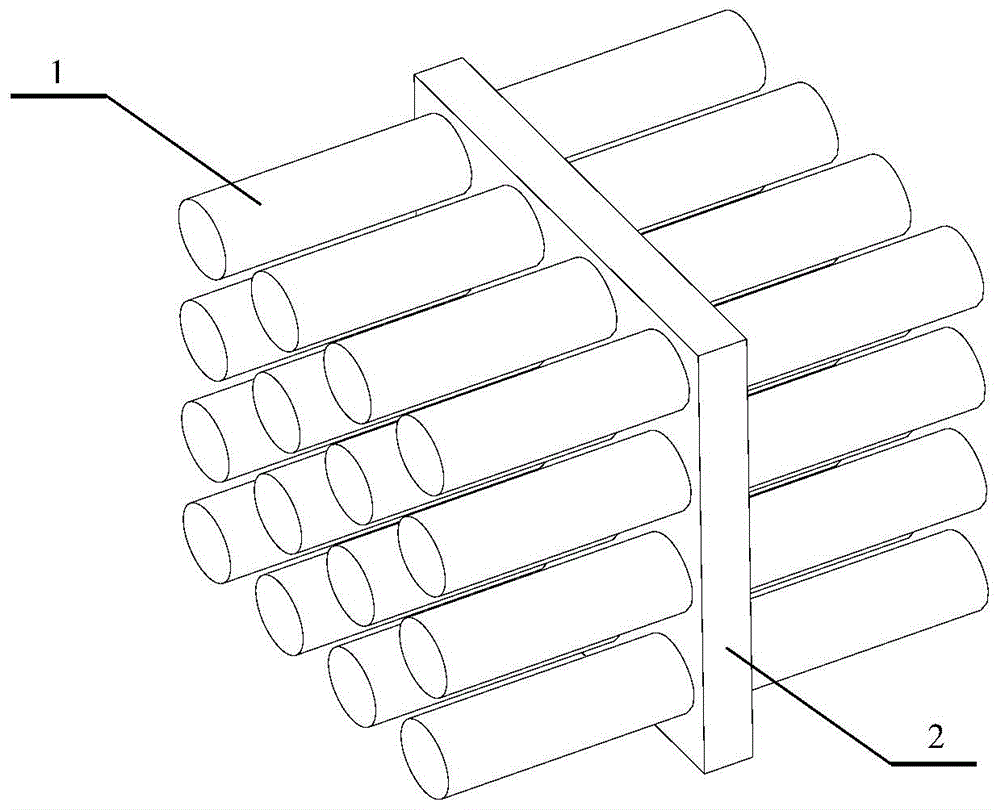

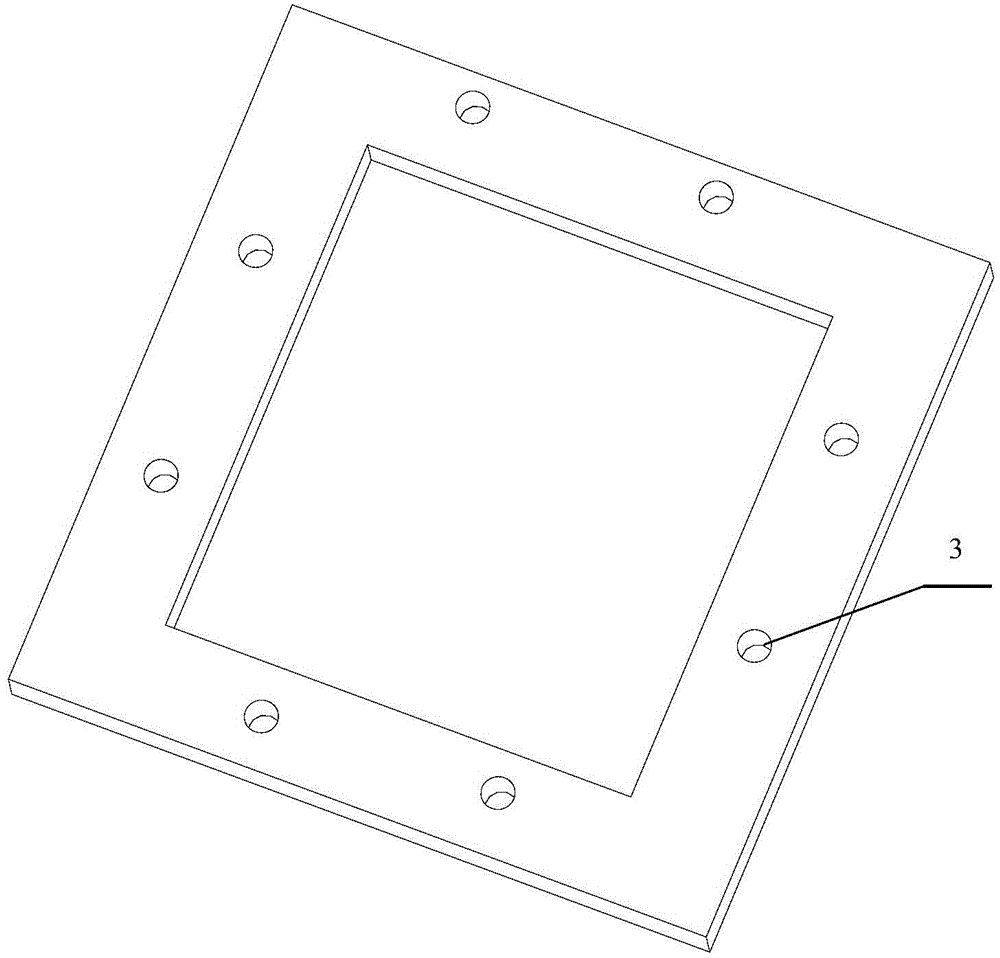

[0034] Make the light guide prototype: such as figure 1 As shown, 16 thin wooden sticks with a diameter of 16mm and a length of 100mm are selected as the light guide branch 1, a square thin wooden board with a side length of 90mm and a thickness of 9mm is used as the connecting part 2, and 16 thin wooden sticks with a diameter of 16mm are evenly drilled on the wooden board. Insert the wooden stick into the round hole, leaving 45.5mm on each side, and finally fix it with fast hard glue.

[0035] Make pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com