Release agent, its preparation method and release paper prepared from the same

A technology of release agent and release coating, which is applied in the direction of special paper, textiles, papermaking, paper, etc., can solve the problem that it is not suitable for large-scale industrial production of release paper, high production cost of release paper, and lack of market competitiveness. problems, to achieve the effect of short heat curing treatment time, low requirements for equipment and operators, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

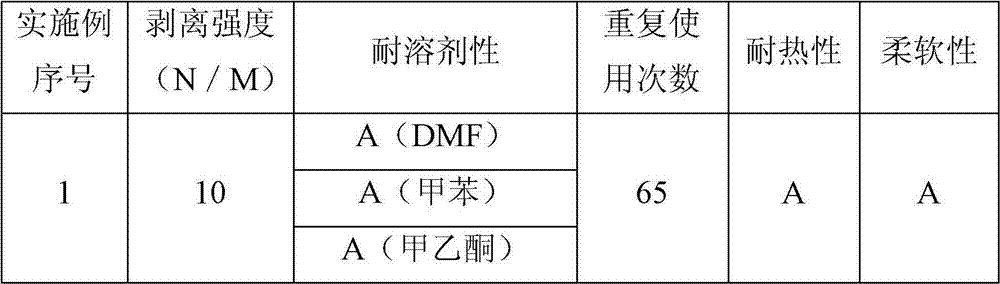

Embodiment 1

[0049] The preparation of release agent: get 200g stearic acid, 100g ammonium zirconium carbonate aqueous solution (the mass percentage concentration of ammonium zirconium carbonate aqueous solution is 30%), 700g mass fraction is the polyvinyl alcohol aqueous solution of 8% (the degree of polymerization of polyvinyl alcohol is 1700, degree of alcoholysis 98% to 100%), after mixing evenly, heat to 70°C to 75°C, keep warm for 1h, cool to room temperature and discharge to obtain a white emulsion-like release agent.

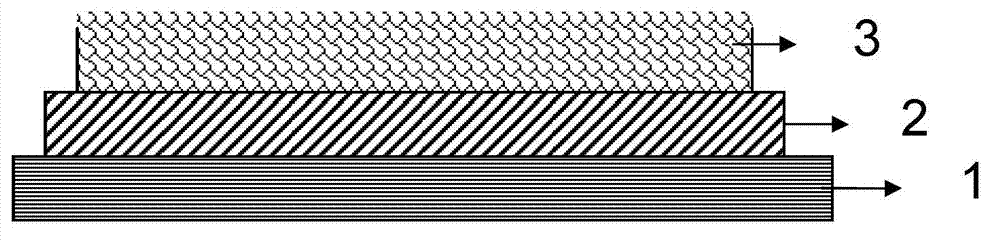

[0050] Preparation of release paper: uniformly coat conventional styrene-acrylic latex (Shanghai Zhenzhou Chemical Group Coating Co., Ltd., model A-62), calcium carbonate dispersion (Shunde District, Foshan City) Coating Co., Ltd.), lubricant (Zhejiang Hexin Technology Co., Ltd., model CH / RH346K), dispersant (Zhejiang Hexin Technology Co., Ltd., model CH / FS218M). After drying, complete the release base paper 1 primer treatment, forming a primer layer 2 on one side of...

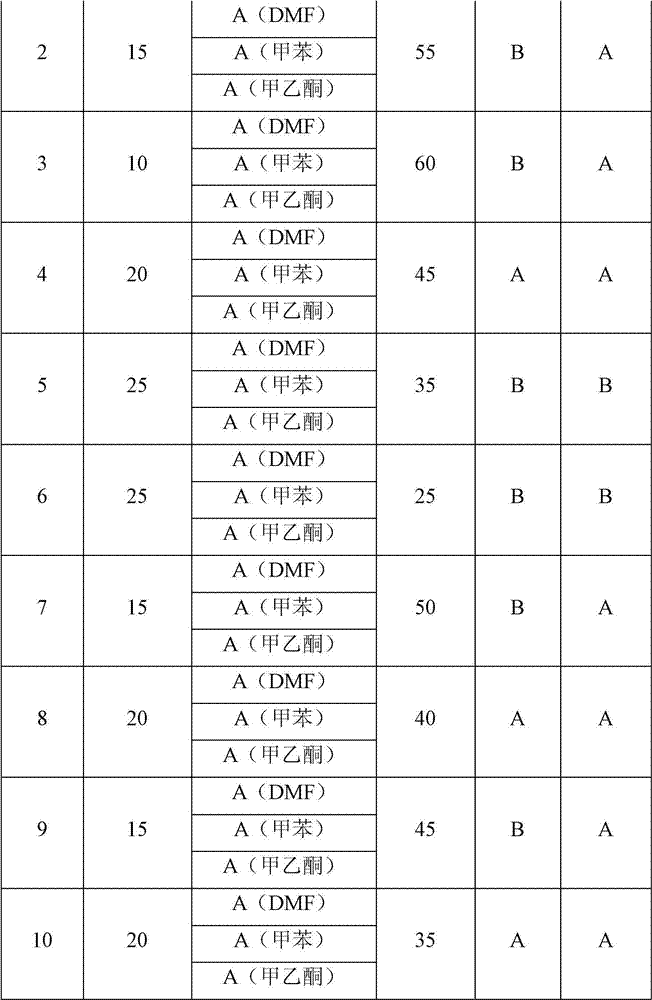

Embodiment 2

[0052] The preparation of release agent: get 300g stearic acid, 150g ammonium zirconium carbonate aqueous solution (the mass percentage concentration of ammonium zirconium carbonate aqueous solution is 30%), 550g mass fraction is the polyvinyl alcohol aqueous solution of 8% (the degree of polymerization of polyvinyl alcohol is 1700, degree of alcoholysis 98% to 100%), after mixing evenly, heat to 70°C to 75°C, keep warm for 1h, cool to room temperature and discharge to obtain a white emulsion-like release agent.

[0053] The release paper was prepared according to the method of Example 1, except that the heat curing treatment temperature was 120° C., and the heat curing treatment time was 2.5 minutes.

Embodiment 3

[0055] The preparation of release agent: get 300g stearic acid, 150g aqueous solution of potassium zirconium carbonate (the mass percent concentration of aqueous solution of potassium zirconium carbonate is 30%), 550g mass fraction is the polyvinyl alcohol aqueous solution of 8% (the degree of polymerization of polyvinyl alcohol is 1700, degree of alcoholysis 98% to 100%), after mixing evenly, heat to 70°C to 75°C, keep warm for 1h, cool to room temperature and discharge to obtain a white emulsion-like release agent.

[0056] The release paper was prepared according to the method of Example 1, except that the heat curing treatment temperature was 120° C., and the heat curing treatment time was 2.5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com