Patents

Literature

64results about How to "Good loadability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coaxial coupling driving system of double planetary gear systems and double motors

ActiveCN106183780AGood loadabilityReduce labor intensityHybrid vehiclesGas pressure propulsion mountingElectric power transmissionVehicle dynamics

The invention provides a coaxial coupling driving system of double planetary gear systems and double motors. The coaxial coupling driving system comprises the double motors, the double planetary gear systems and the like. Each planetary gear system comprises a gear ring, a planetary carrier and a sun wheel. A rotor of the first motor is connected with the gear ring of the first planetary gear system. A rotor of the second motor is connected with the sun wheel of the first planetary gear system and the sun wheel of the second planetary gear system through synchronizers correspondingly. The planetary carriers of the two planetary gear systems are connected with an output shaft. The gear ring of the second planetary gear system is connected with a shell. The output shaft is connected with the input end of a deceleration differential. The output end of the deceleration differential is connected with two wheels through two half shafts. A motor control device is connected with an energy storage device and conducts electric power transmission. The motor control device is further connected with the first motor and the second motor and outputs a control command. The coaxial coupling driving system has the characteristic that the vehicle dynamic property, the energy consumption economical efficiency, the geographical adaptability and the application adaptability are better.

Owner:SHANGHAI JIAO TONG UNIV +1

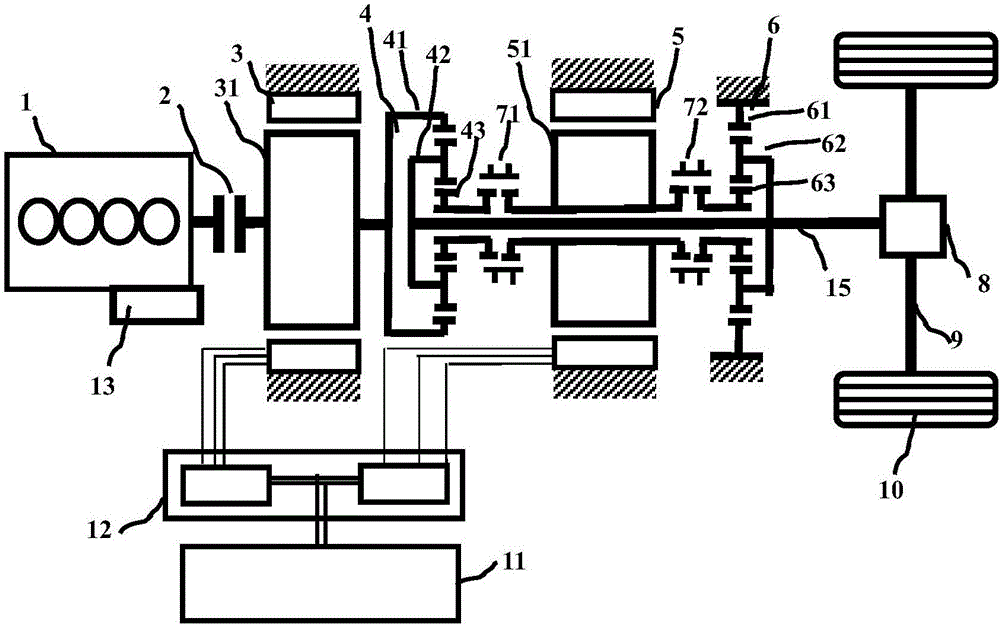

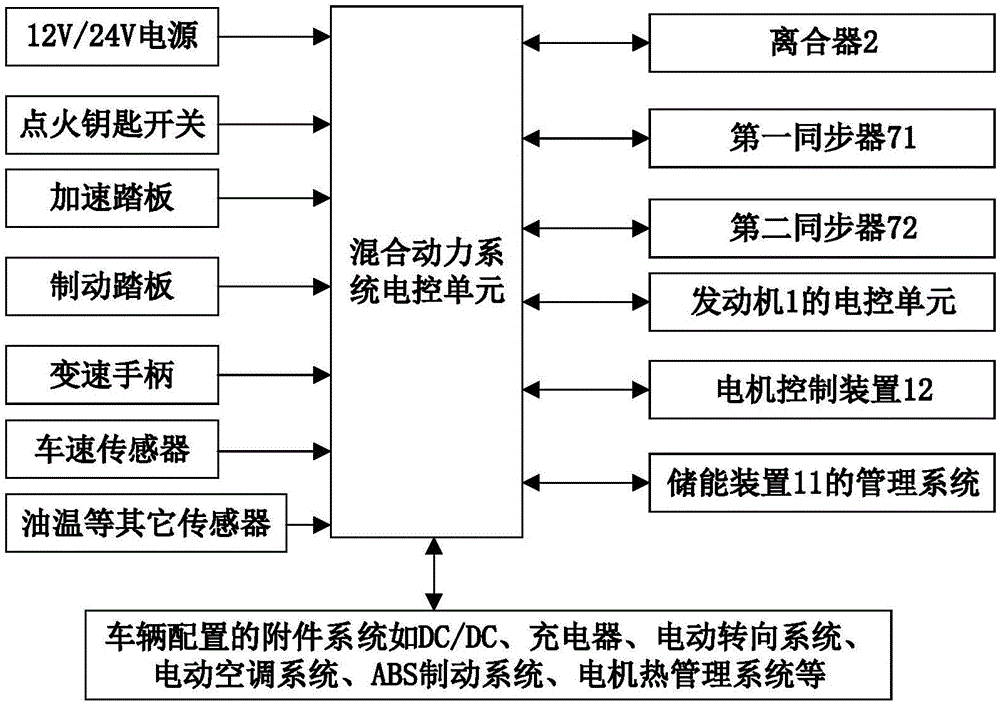

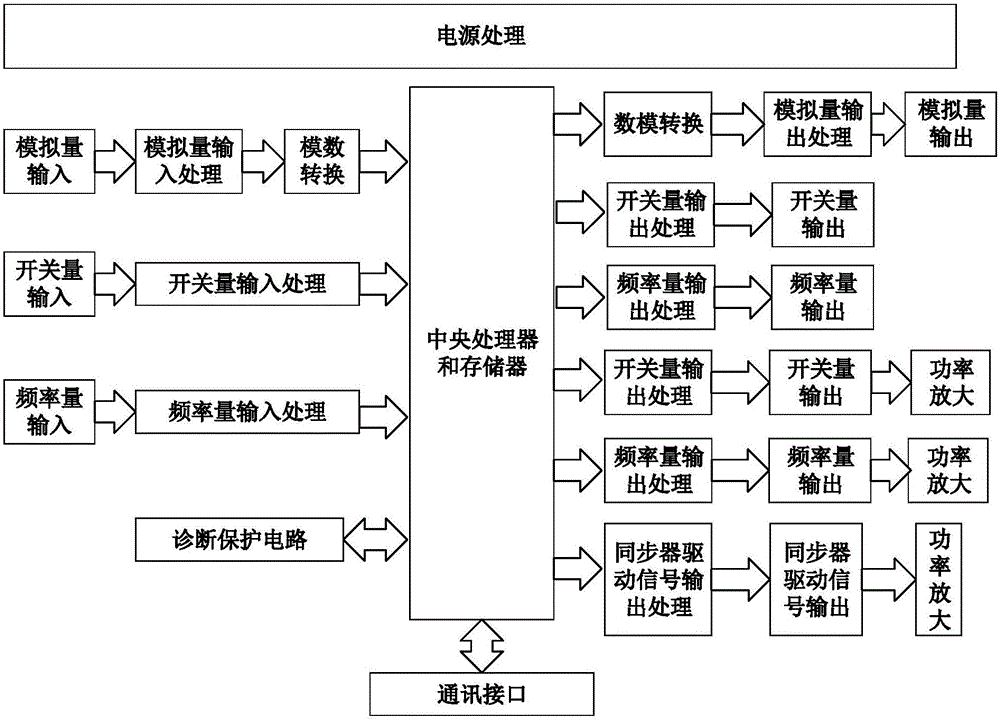

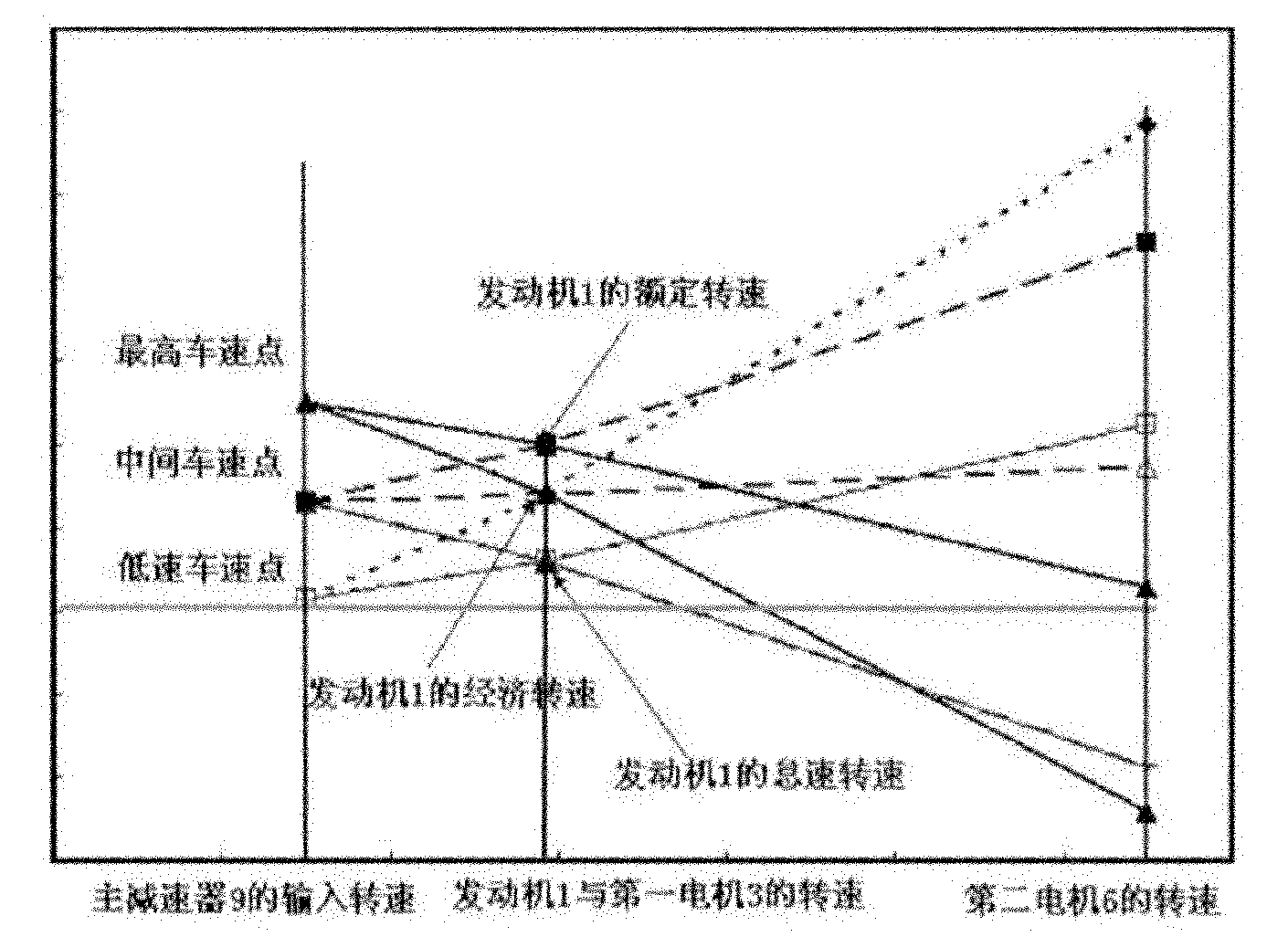

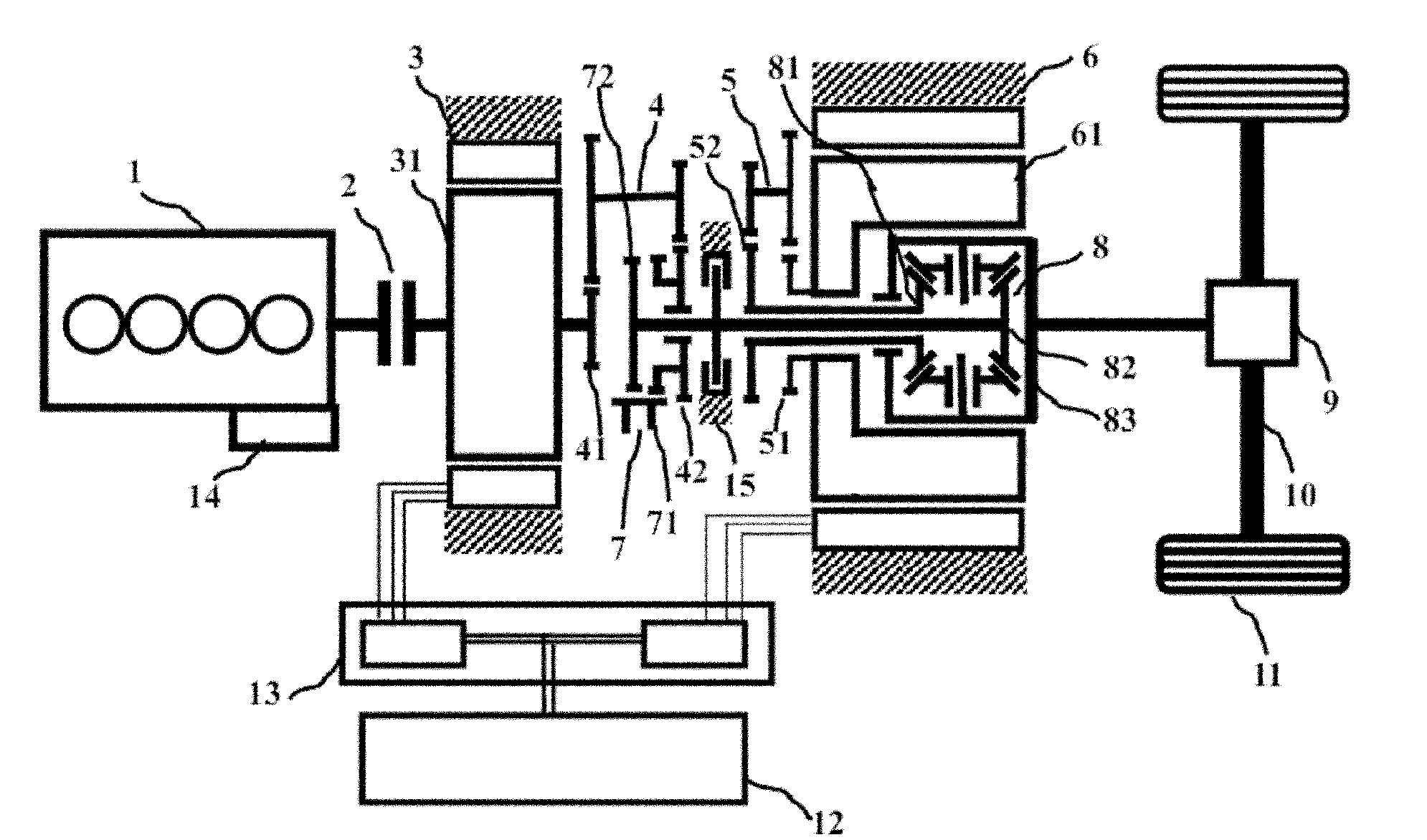

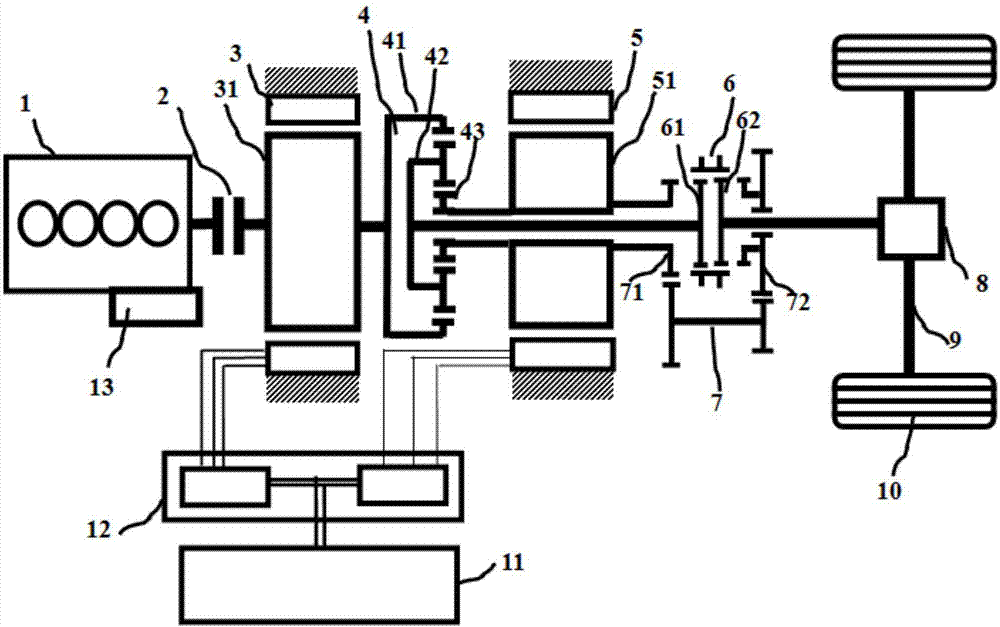

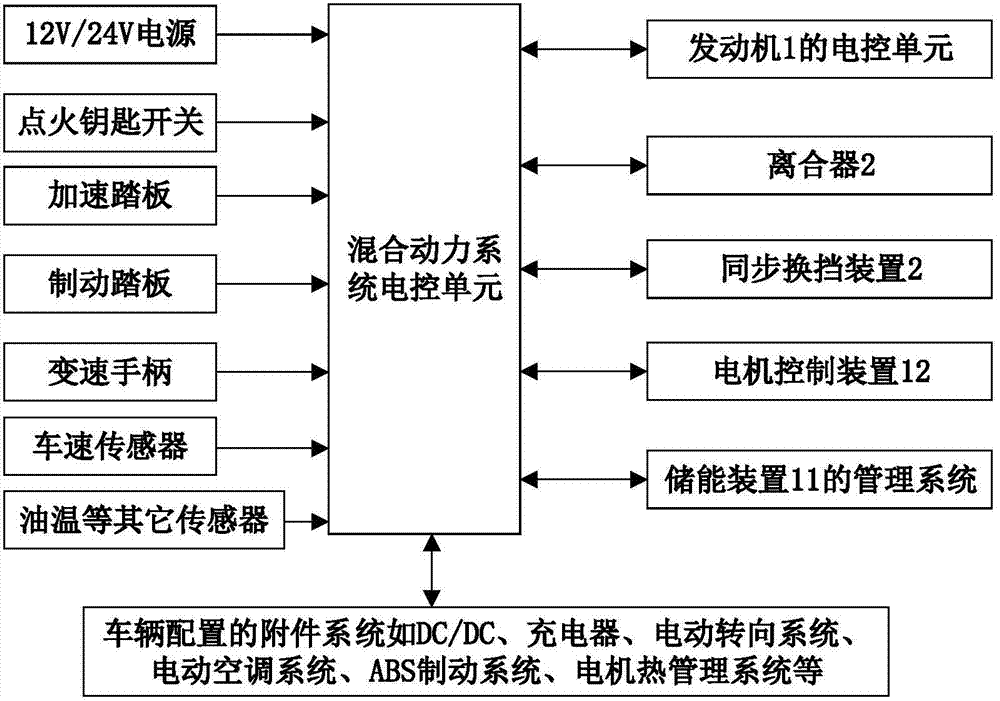

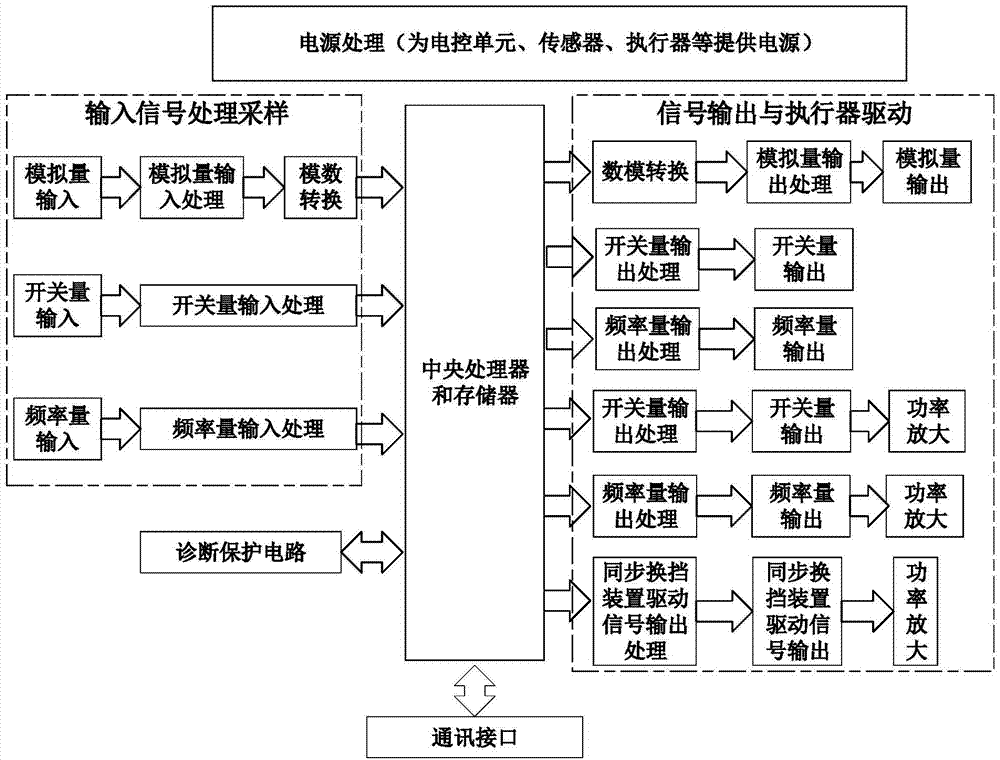

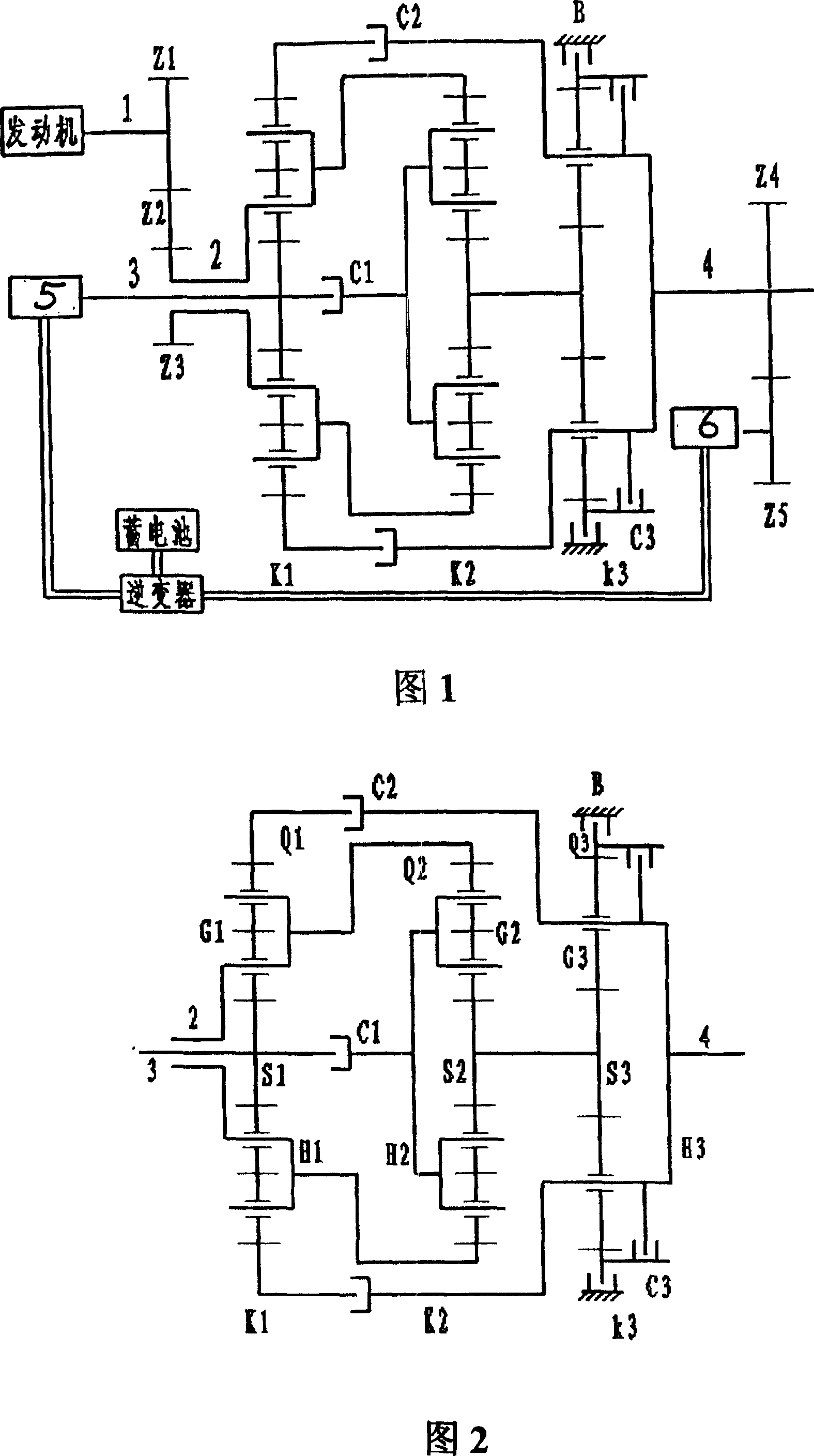

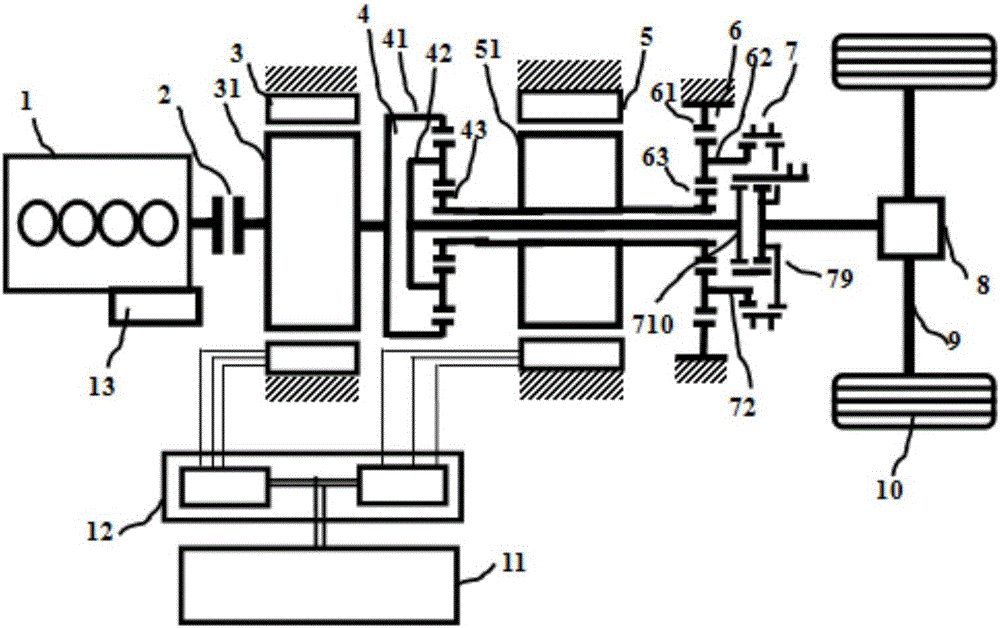

Four-die stepless speed change series-parallel hybrid power driving system

ActiveCN102050001ATight structureEasy to Modular DesignGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchEnergy storage

The invention discloses a four-die stepless speed change series-parallel hybrid power driving system, belonging to the technical field of automobile hybrid driving. The system comprises an engine, a clutch, two motors, corresponding transmission chains of the two motors, a power transfer switching device, a planetary gear differential device, a deceleration differential device, an energy storage device and a motor control device. The system provided by the invention has the characteristics of better technical inheritance with existing vehicles, overall dynamic property, fuel economy and low emission, and has functions of four-die driving, stepless speed change and series-parallel system; the problems of insufficient driving power, lack in ramp starting ability, large system volume and high cost of the existing similar technologies and the problems that the stepless speed regulation of the engine cannot be realized and the batch industrialization is difficult as the electromechanical components are difficult to manufacture are solved, and organic combination of high performance, low development cost, low system cost and easy implementation of scale industrialization is realized.

Owner:SHANGHAI JIAO TONG UNIV

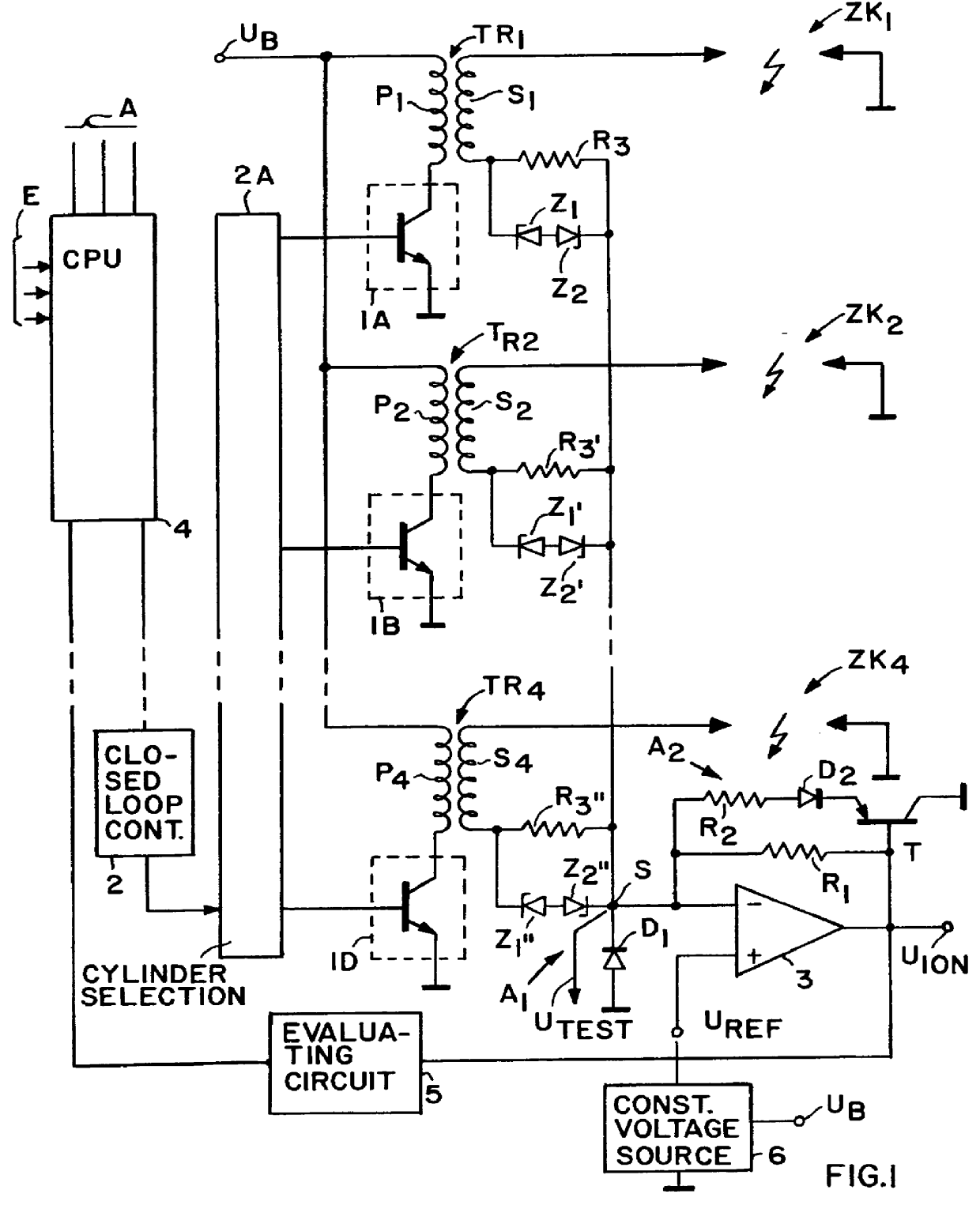

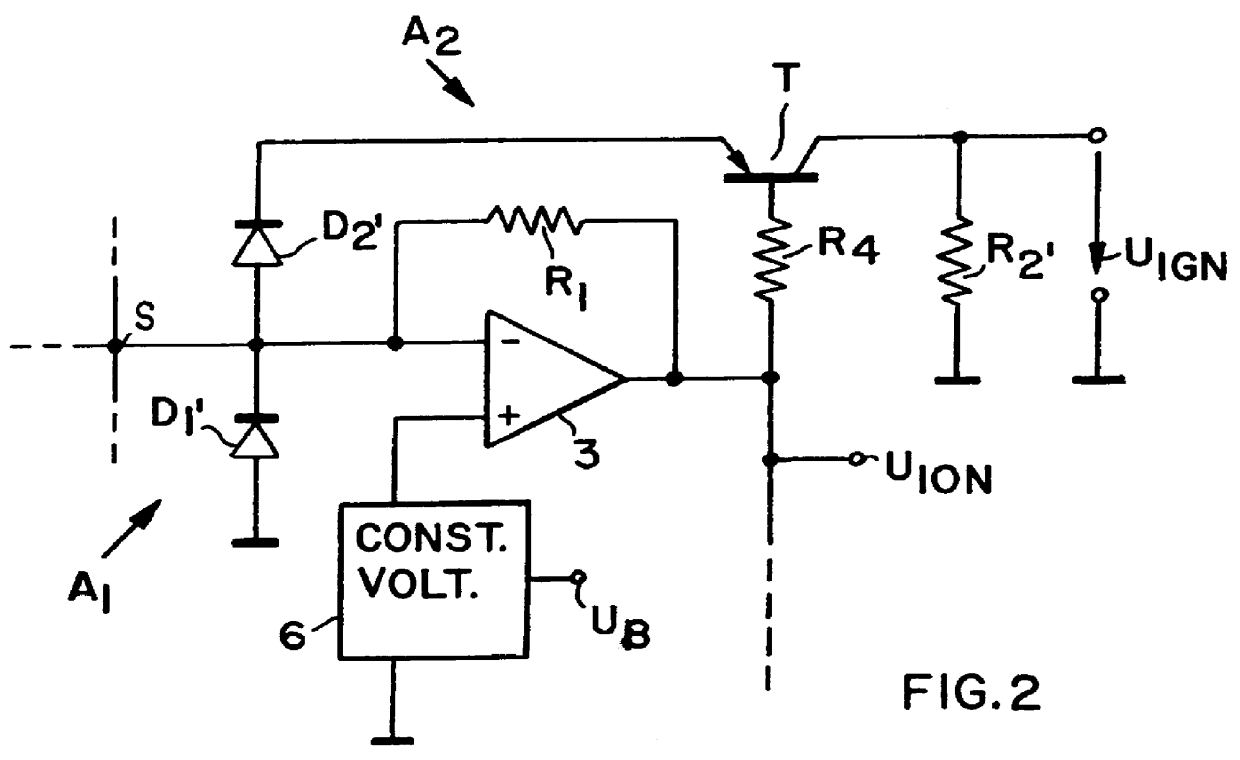

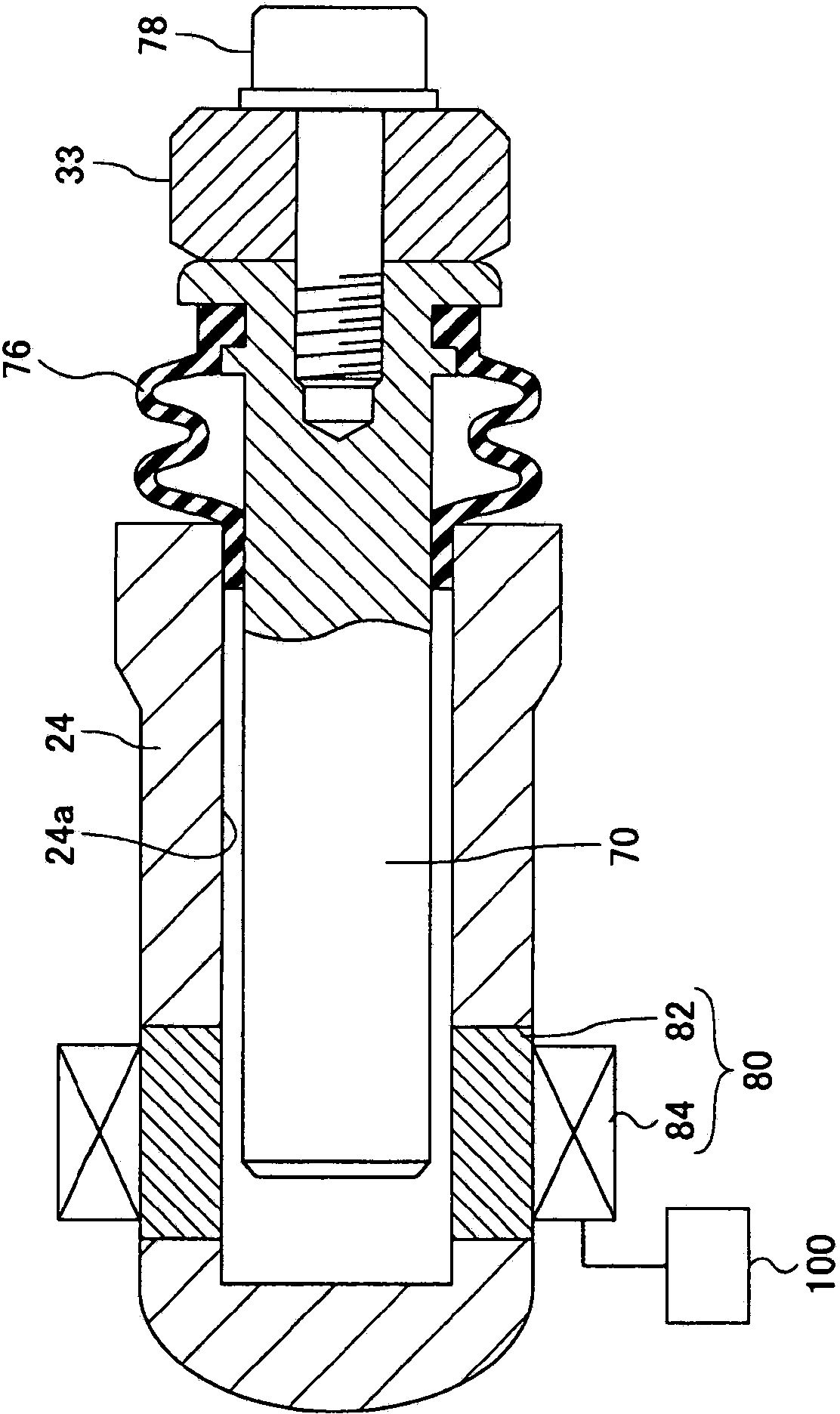

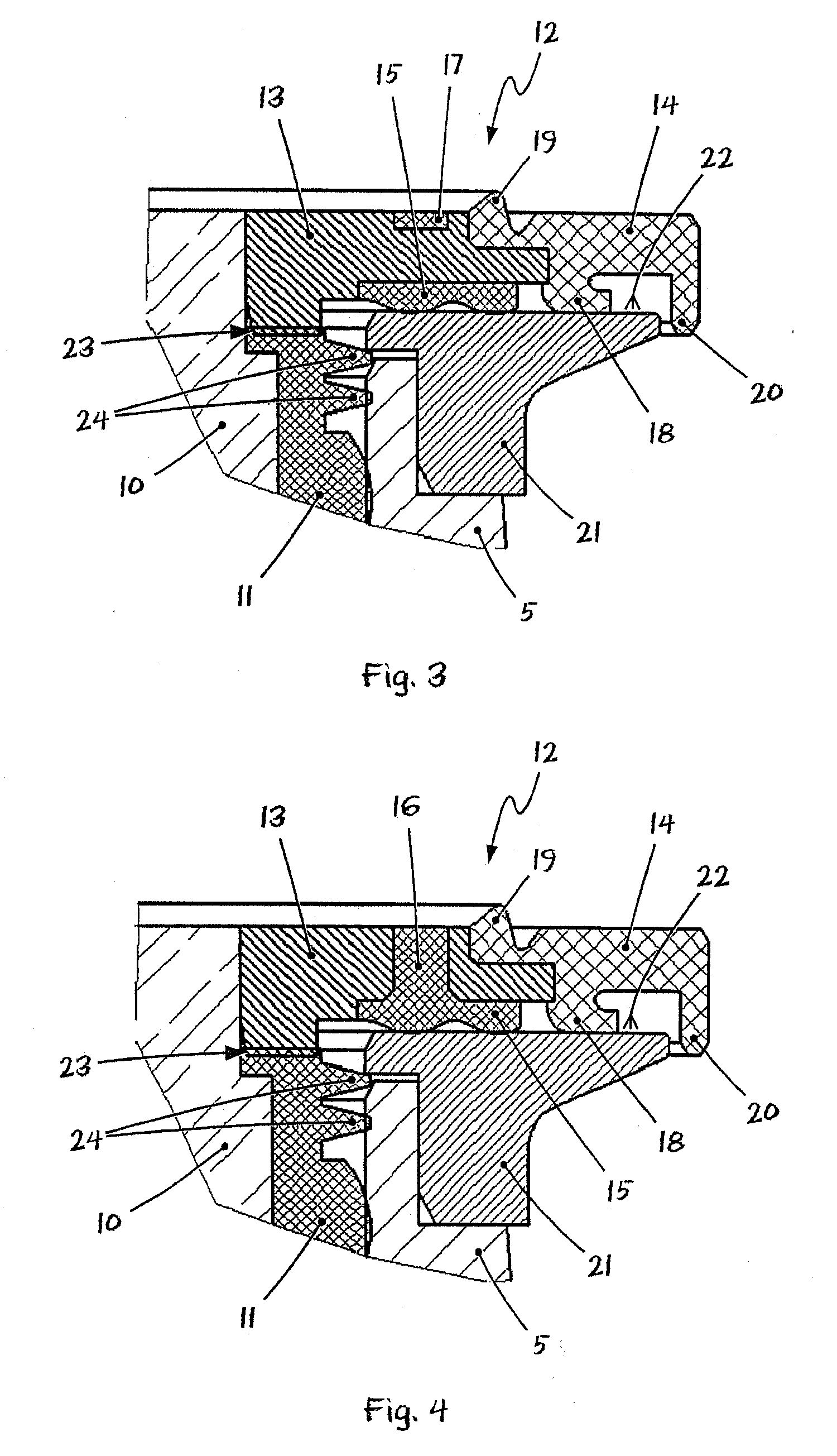

Circuit arrangement for measuring an ion current in a combustion chamber of an internal combustion engine

InactiveUS6043660AHighly accurate measurementShortens decay periodMachines/enginesInstallations with induction energy storageCombustion chamberPower flow

A circuit arrangement measures an ion current generated in the combustion chamber of an internal combustion engine during an iron current flow phase following an ignition phase. A voltage drop across a feedback resistor (R1) connected in parallel to an inverting amplifier is measured since the voltage drop is proportional to the ion current resistance. The amplifier is connected with its inverting input to a low voltage end of a secondary winding of an ignition transformer or coil. The high voltage end of the secondary winding is connected through a spark gap of a spark plug to ground, whereby the spark plug functions as an ion current sensor during the ion current flow phase. Negative voltage peaks flowing during an ignition phase and the ignition current flowing during the ignition phase are diverted through respective first and second circuit branches. The first branch has a first semiconductor diode (D1) grounding the low voltage end of the secondary winding for discharging the negative high voltage peaks while blocking the ignition current. The other diverting branch has a second semiconductor (D2) connected in parallel to the inverting amplifier.

Owner:VOLKSWAGEN AG +1

Multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system

ActiveCN104494415AGood loadabilityReduce labor intensityHybrid vehiclesGas pressure propulsion mountingElectric power transmissionVehicle dynamics

The invention provides a multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system. The multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system comprises a first motor and the like; a planetary gear train comprises a gear ring, a planet carrier and a sun gear; the rotor of the first motor is connected with the gear ring of the planetary gear train; the rotor of the second motor is connected with the sun gear of the planetary gear train and the input end of a transmission chain, respectively; a gear shifting device is connected with the input end of a speed reducing differential mechanism and control on power transfer from the planet carrier of the planetary gear train and the output end of the transmission chain to the speed reducing differential mechanism is realized; the output end of the speed reducing differential mechanism is connected with two wheels by use of two half shafts; a motor control device is connected with an energy storage device to transfer electric energy; the motor control device is further connected with the first motor and the second motor, respectively, and outputs control instructions. The multi-purpose adaptive second-gear multimode stepless speed changing electric transmission integrated power system has the characteristics of better technical inheritance to the existing vehicles, whole vehicle dynamic property, fuel economy and low emission.

Owner:SHANGHAI JIAO TONG UNIV +1

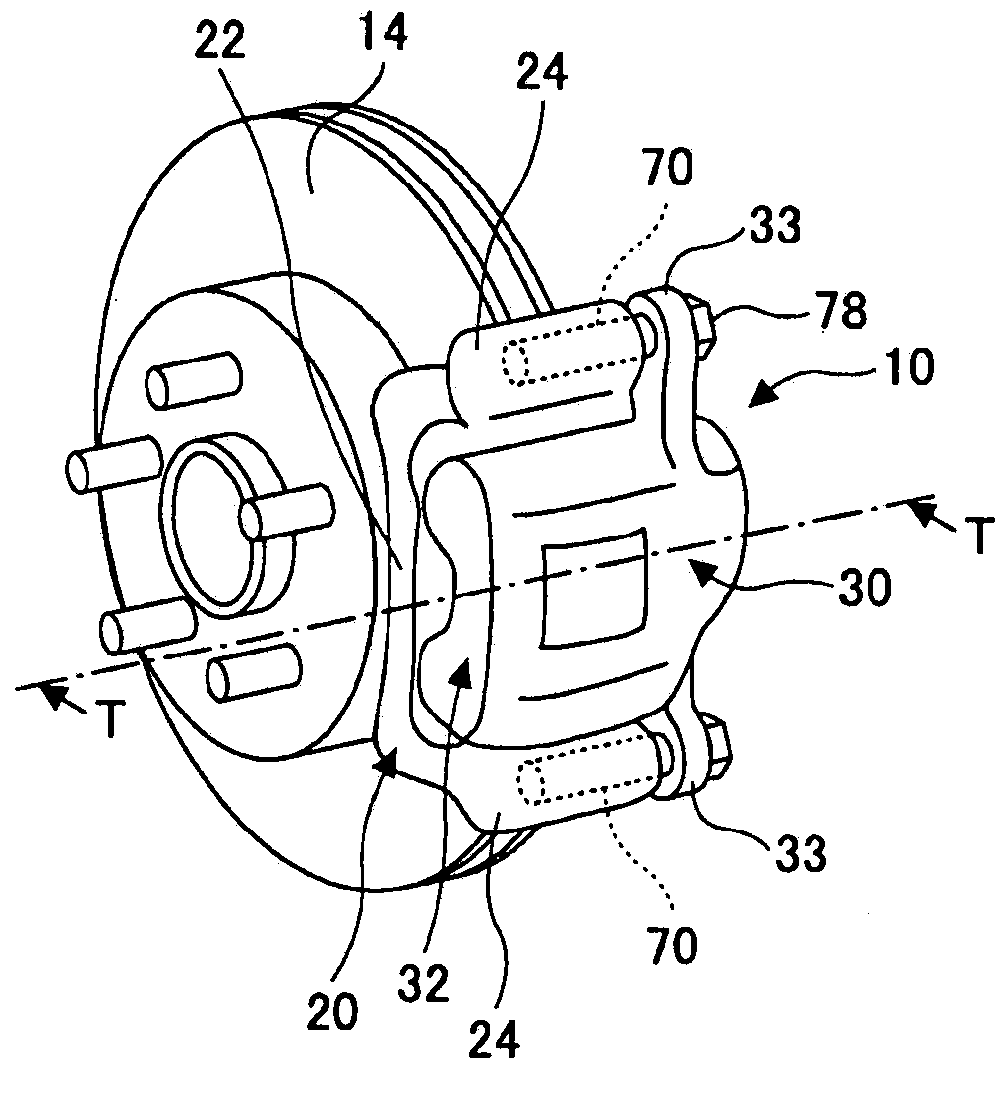

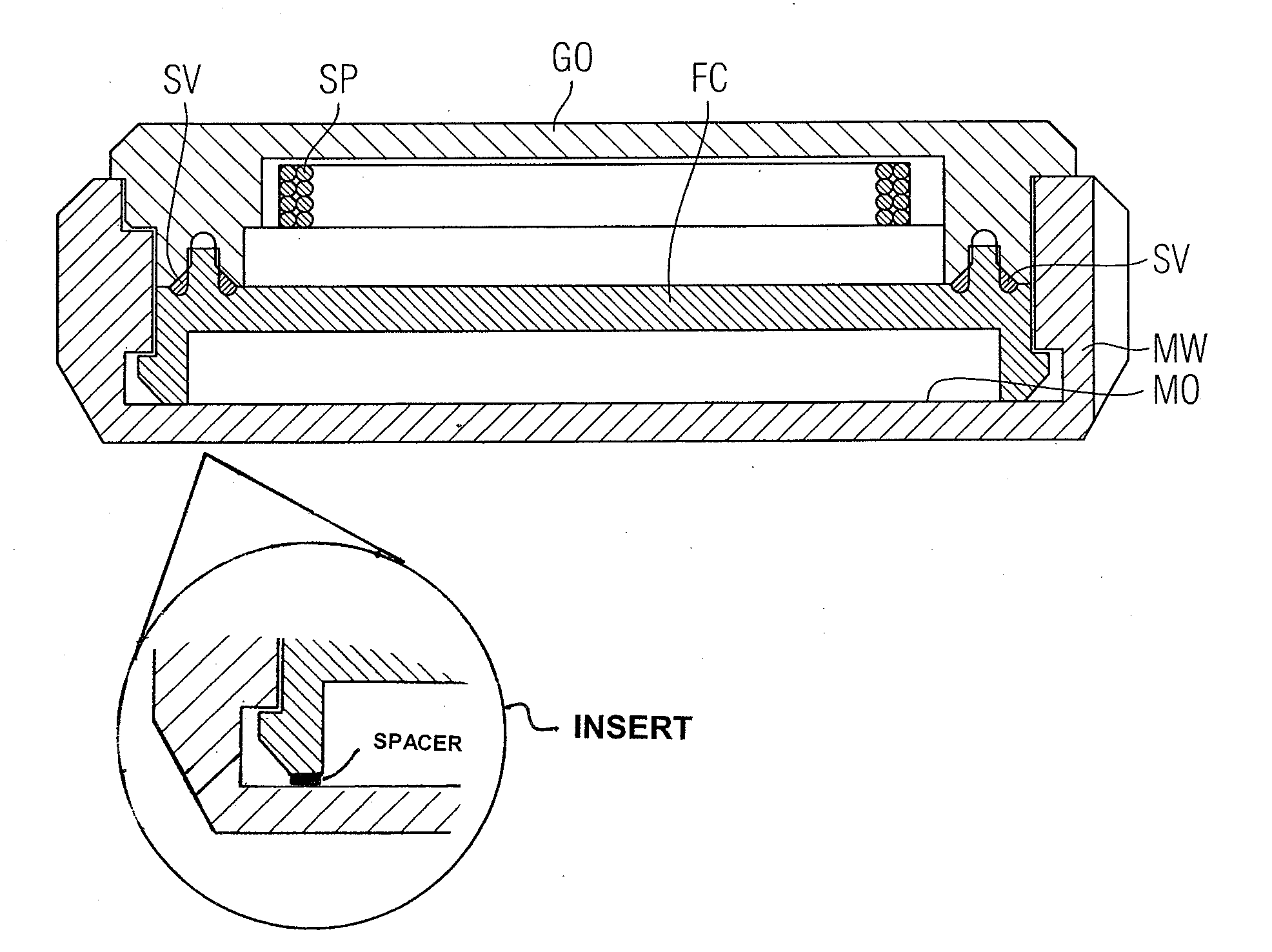

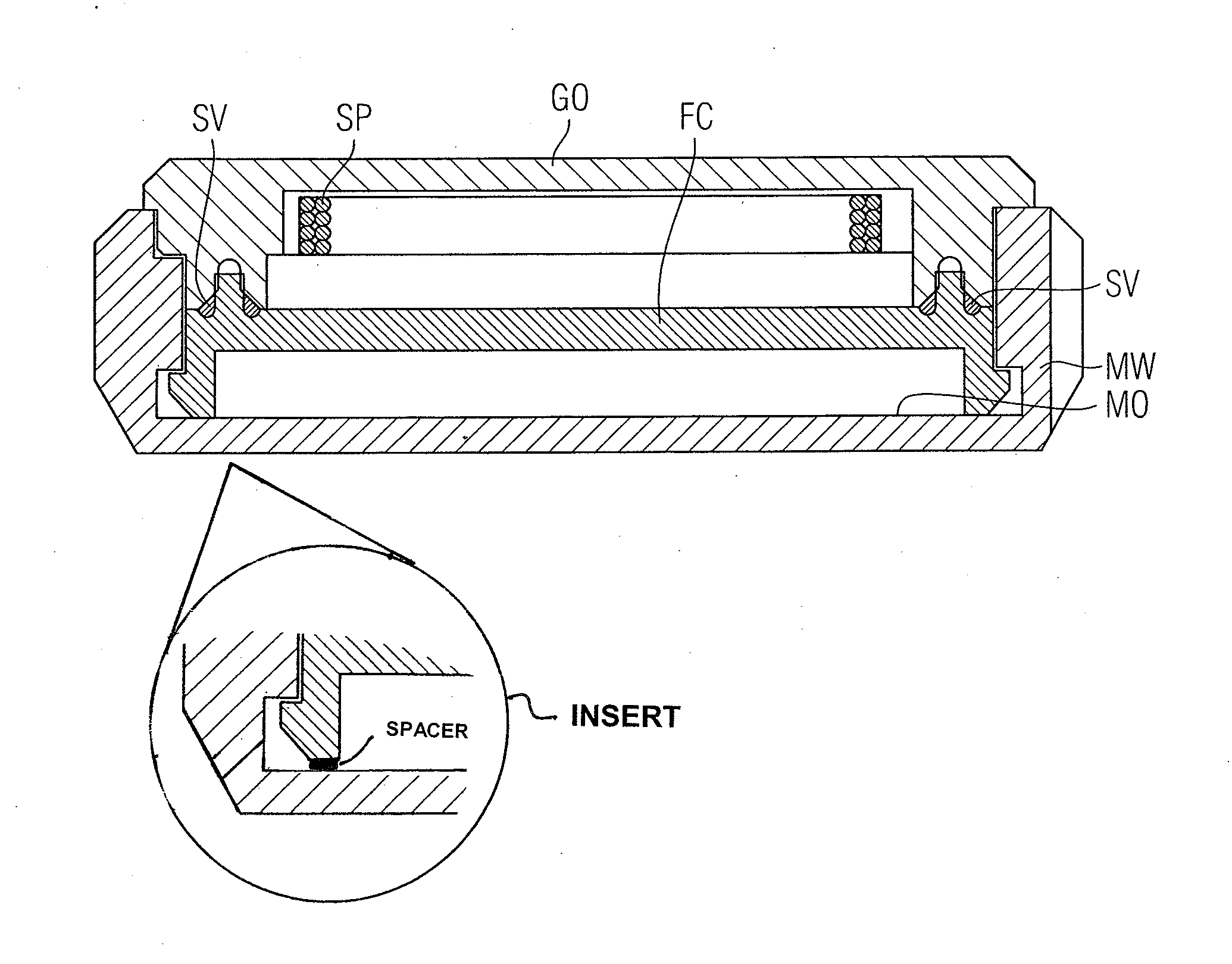

Disc brake

InactiveCN104204598AGood loadabilityPrevent brake dragBraking element arrangementsAxially engaging brakesCalipersBrake pad

In one embodiment, this disc brake, which is such that a caliper is supported with a slide pin therebetween by a mounting bracket affixed to a non-rotating section of a vehicle, is provided with a magnet that is provided to the slide pin and draws the slide pin in the axial direction in a manner so that the a brake pad separates from a disc rotor. In a separate embodiment, the disc brake, which is such that a caliper is supported with a slide pin therebetween by a mounting bracket affixed to a non-rotating section of a vehicle, is provided with: a magnetic body section at the backing plate of the brake pad; and a magnet provided to a position facing the magnetic body section in the direction of vehicle width.

Owner:TOYOTA JIDOSHA KK

Electrical machinery planetary mechanism stepless gear system

ActiveCN101082365AWide variation range of speed ratioLow powerToothed gearingsGearing controlElectric machineryHigh ability

The invention relates to a electric horn machinery planetary mechanism step-less variable speed transmission system, it belongs to vehicle transmission technology field. The system is make up of mutual meshing gear (Z1), idle gear (Z2) and gear (Z3), planetary mechanism, input axis (1), axle sleeve (2), input axis (3), output axis (4), mutual meshing gear (Z4) and (Z5), motor (6), inverter and battery. The biggest advantage of invention is using a lower power speed control motor to realize the speed ratio continuous step-less change of whole system. To compare with mainstream step-less variable speed transmission system, the speed ratio change range of invention is larger, transmission efficiency is higher and has lower cost, simple and compact structure, stable transmission, high ability of transfer power and torque and easy application of advanced control strategy. The invention has widely prospect on common automobile especially the electric vehicle transmission system.

Owner:HUNAN JIANGLU & RONGDA VEHICLE TRANSMISSION LIMITED

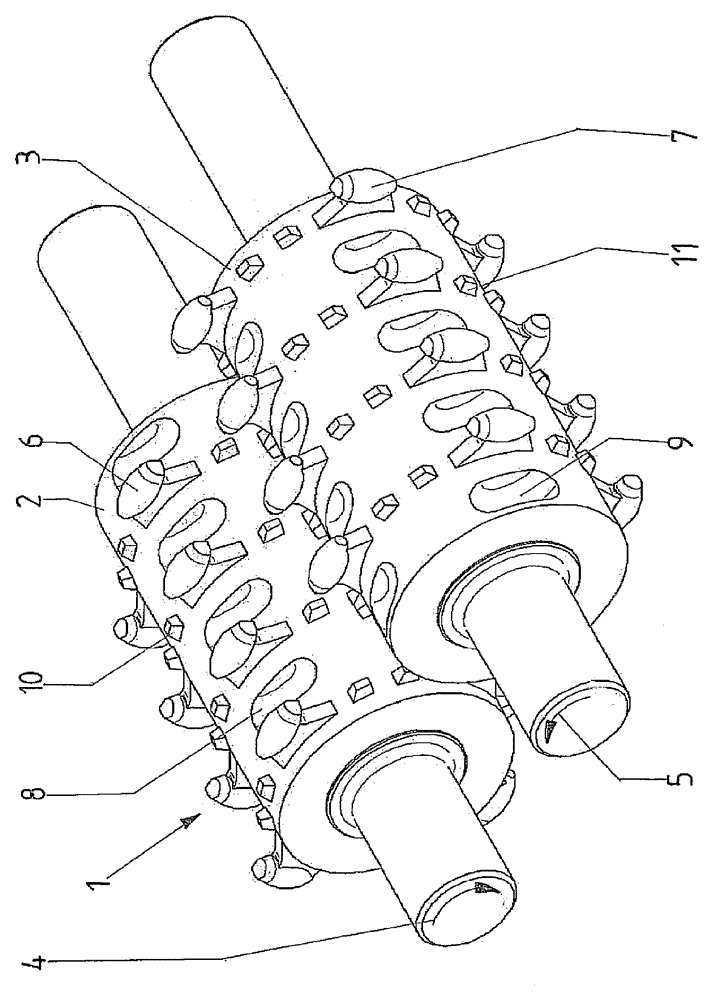

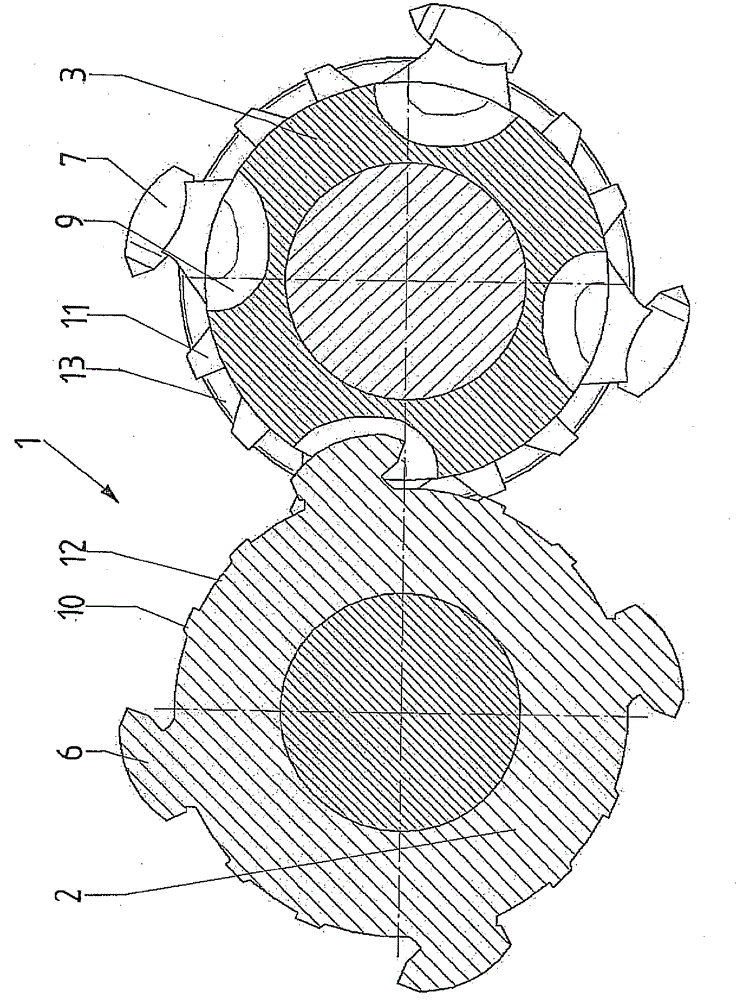

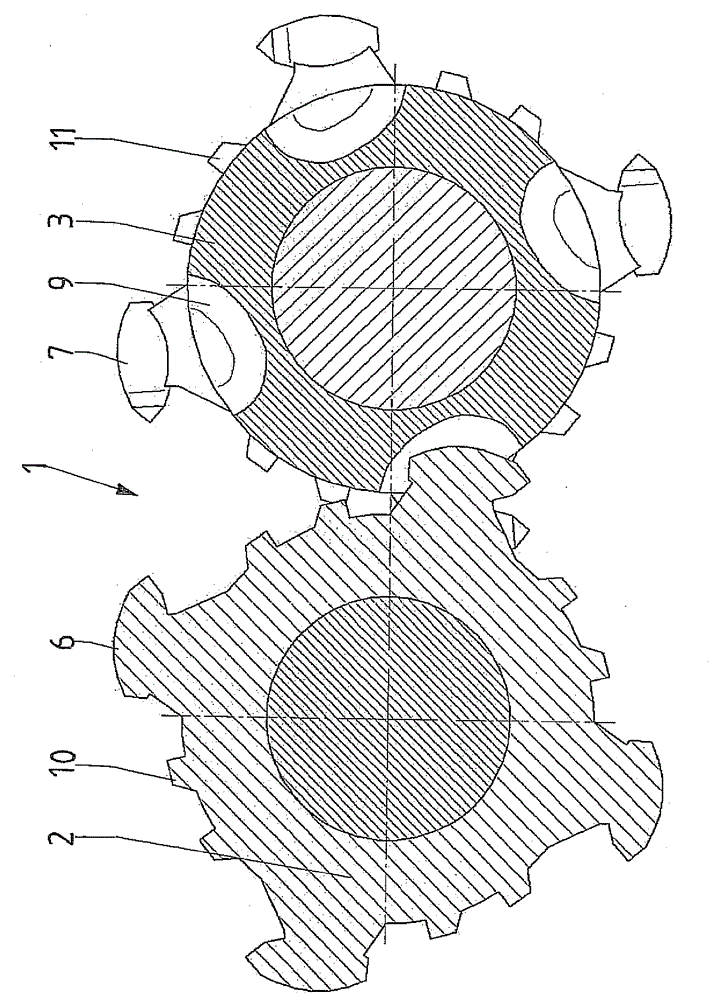

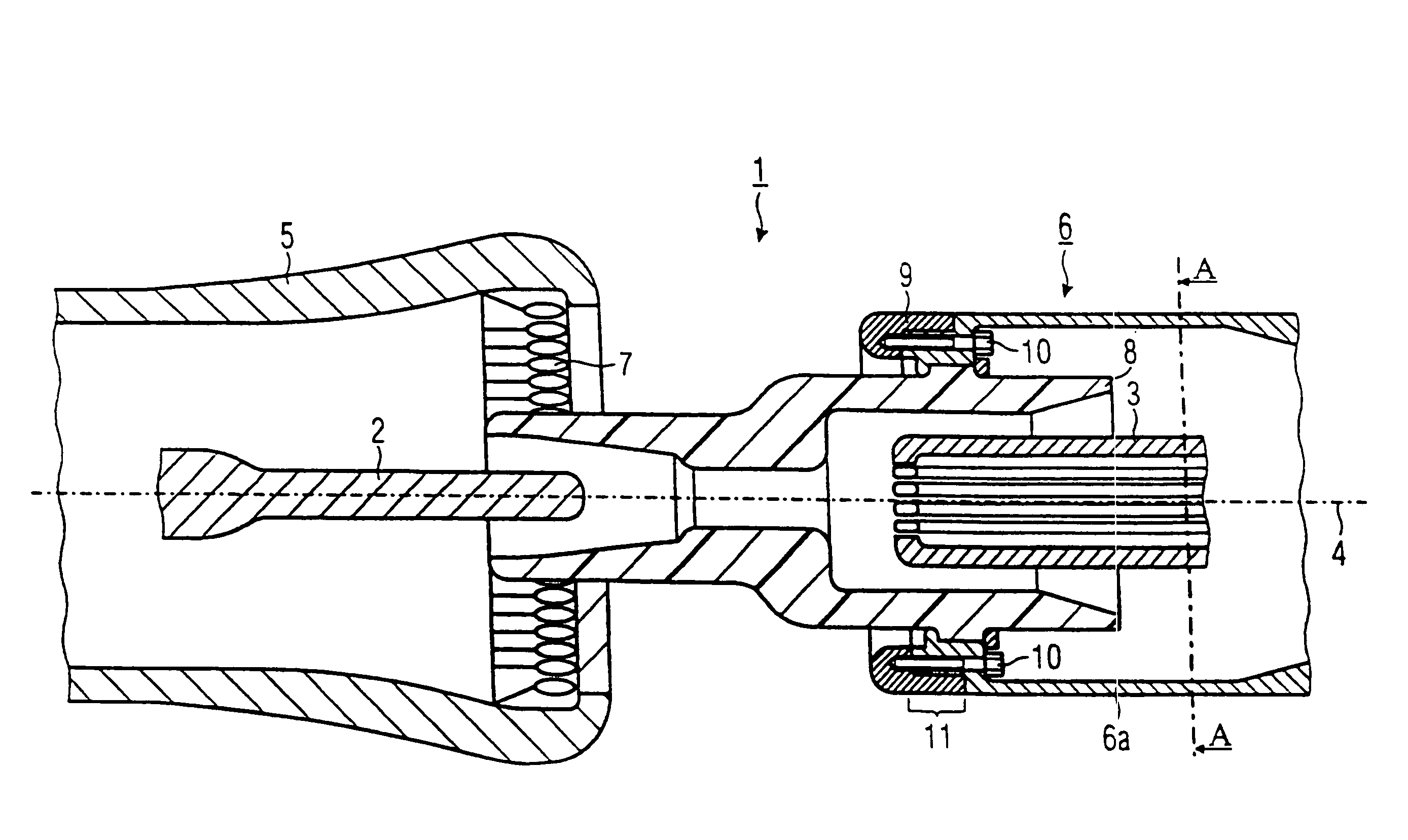

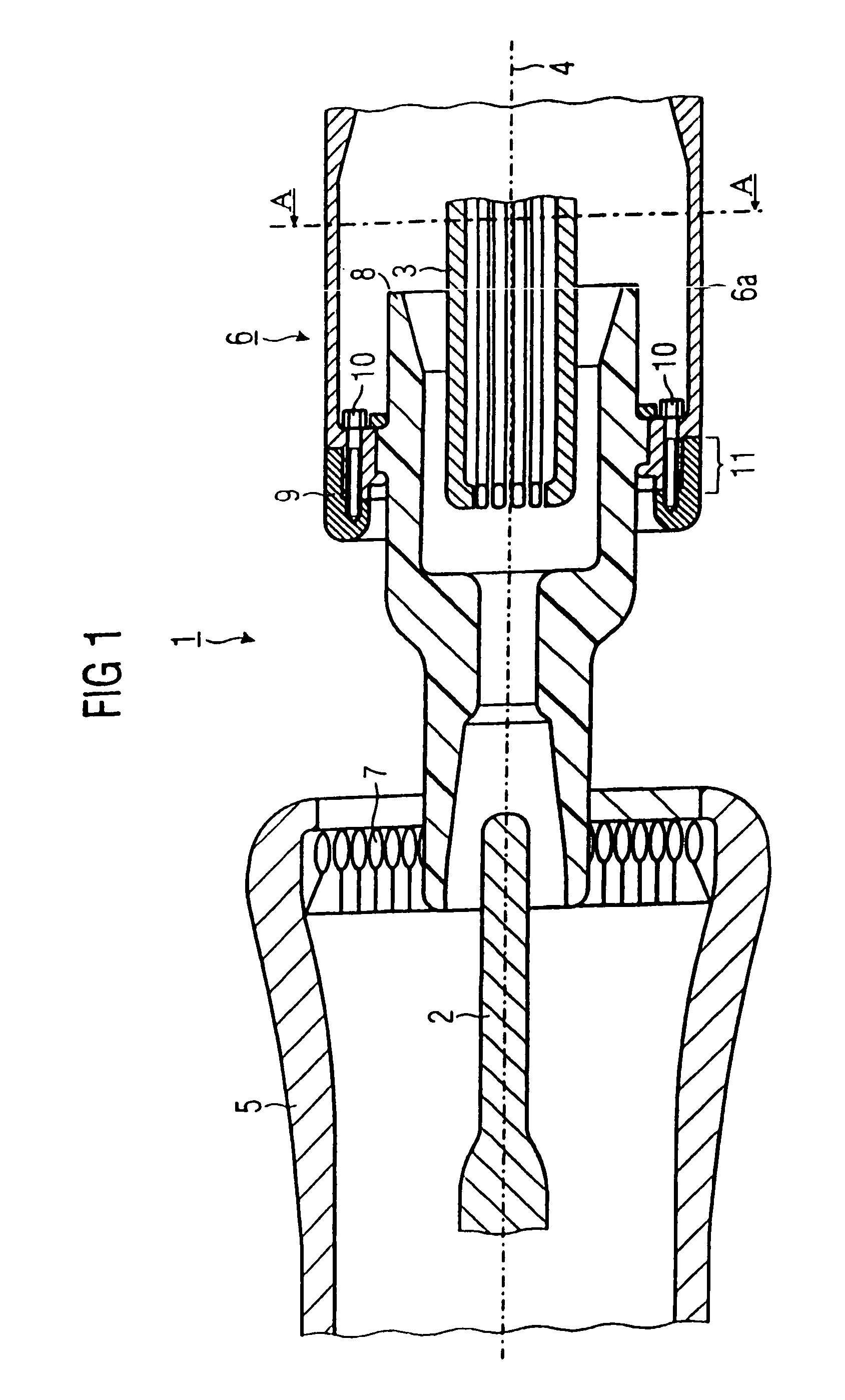

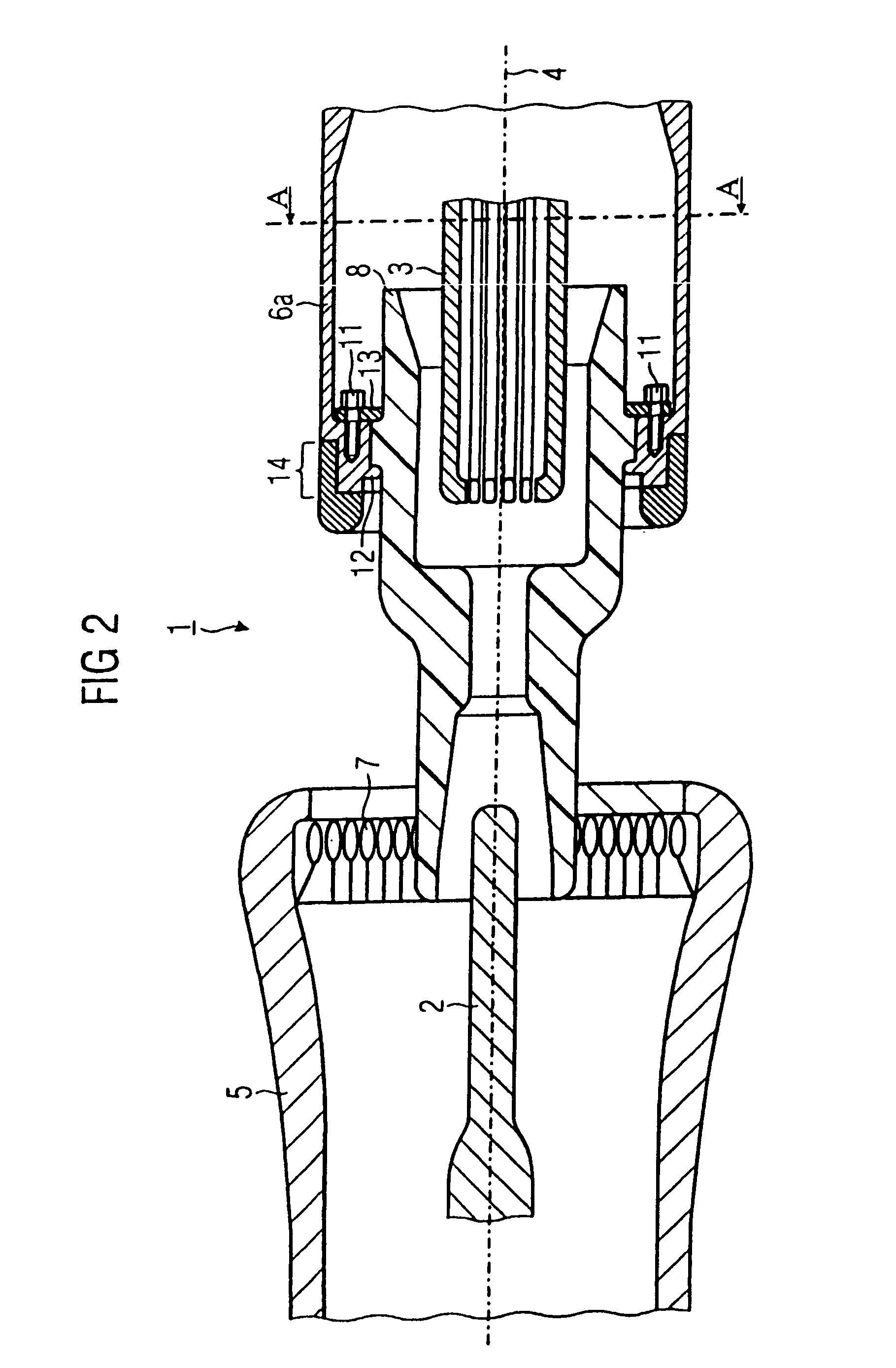

Twin roller crusher

The invention relates to a twin roller crusher (1) with rollers (2, 3) that are rotatably mounted in a crusher housing and are motor-driven so as to turn synchronously in opposite directions, the center axes thereof being aligned in parallel to each other. Crusher teeth (6, 7) are arranged on the outer face of the crushers (2, 3), said teeth projecting beyond the lateral surfaces, every crusher tooth (6, 7) of a roller (2, 3) of the pair of rollers being associated with a pocket (8, 9) in the lateral surface of the other roller (2, 3) of the pair of rollers such that when the rollers (2, 3) rotate the crusher tooth (6, 7) is inserted into the pocket (8, 9).

Owner:CRUSH SIZE TECH

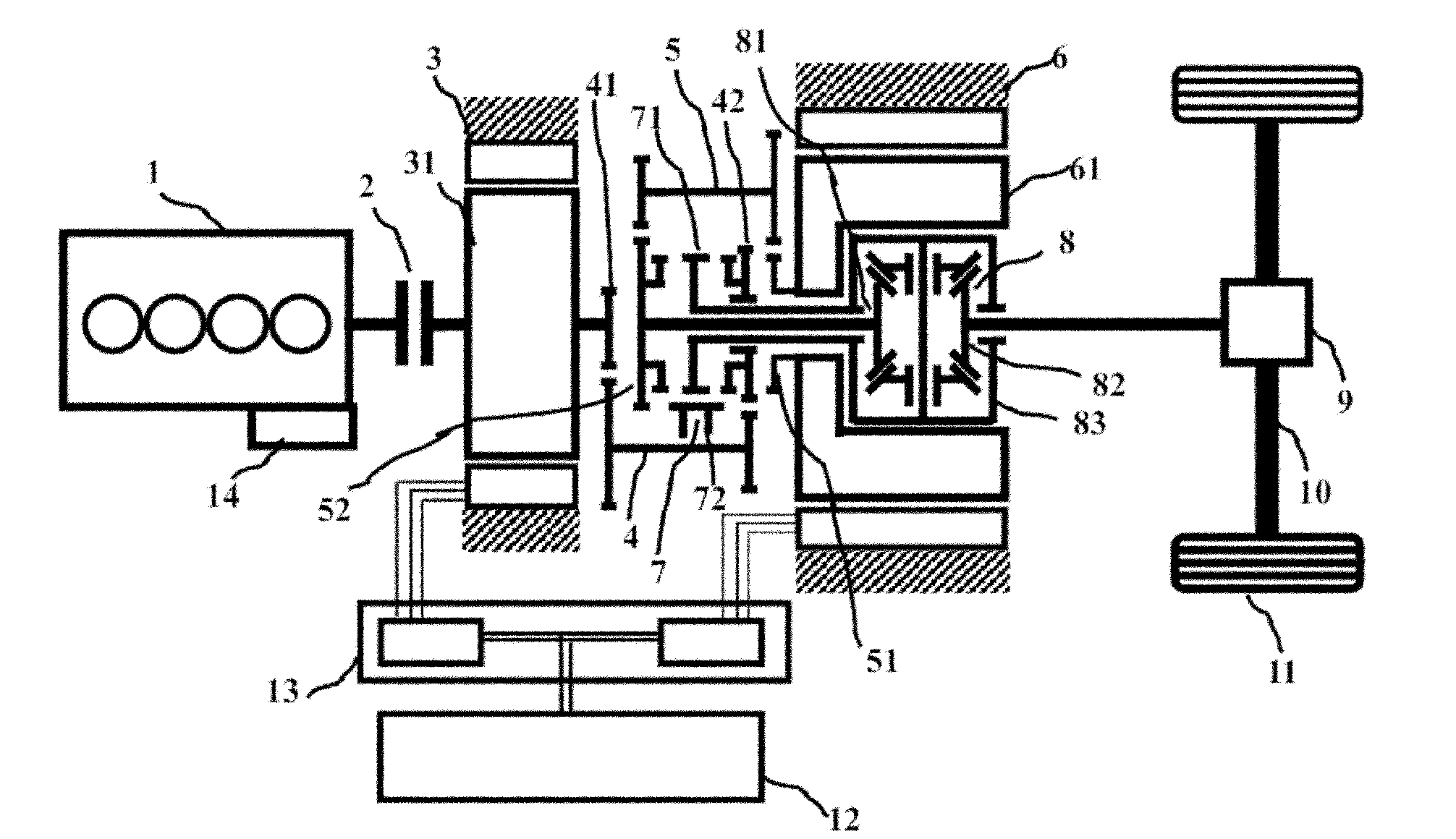

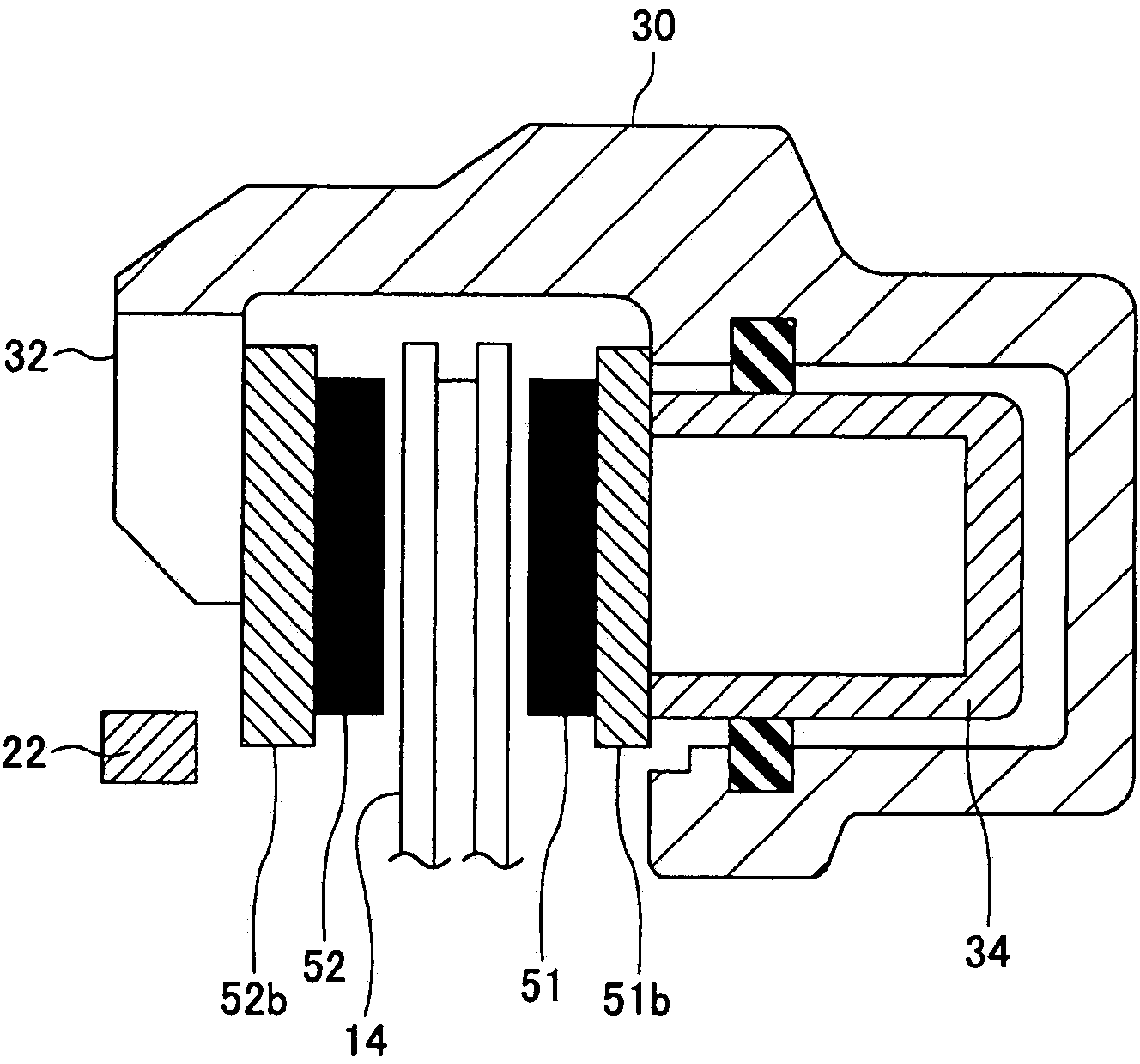

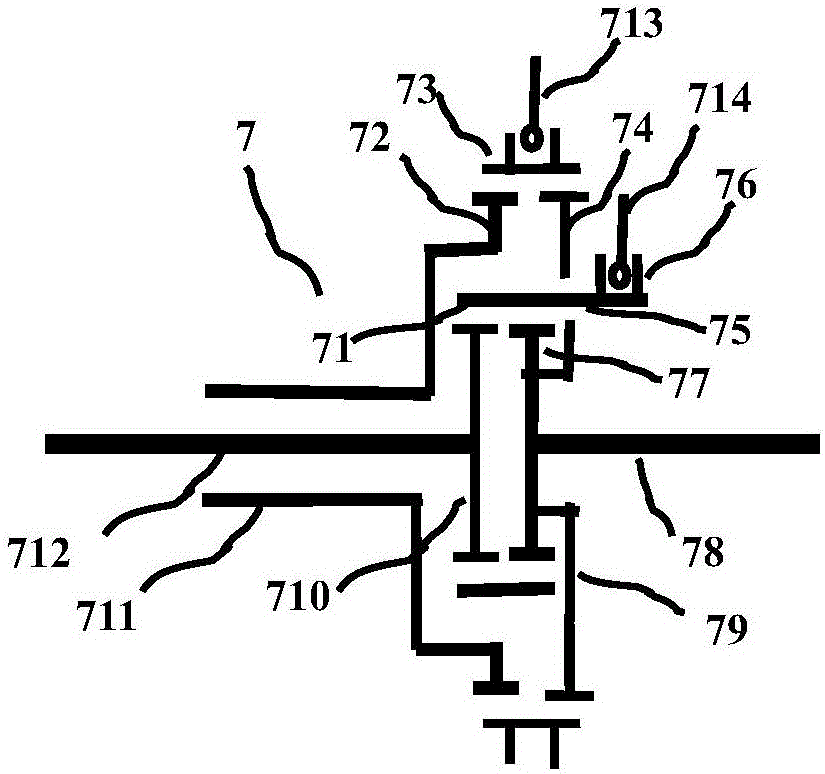

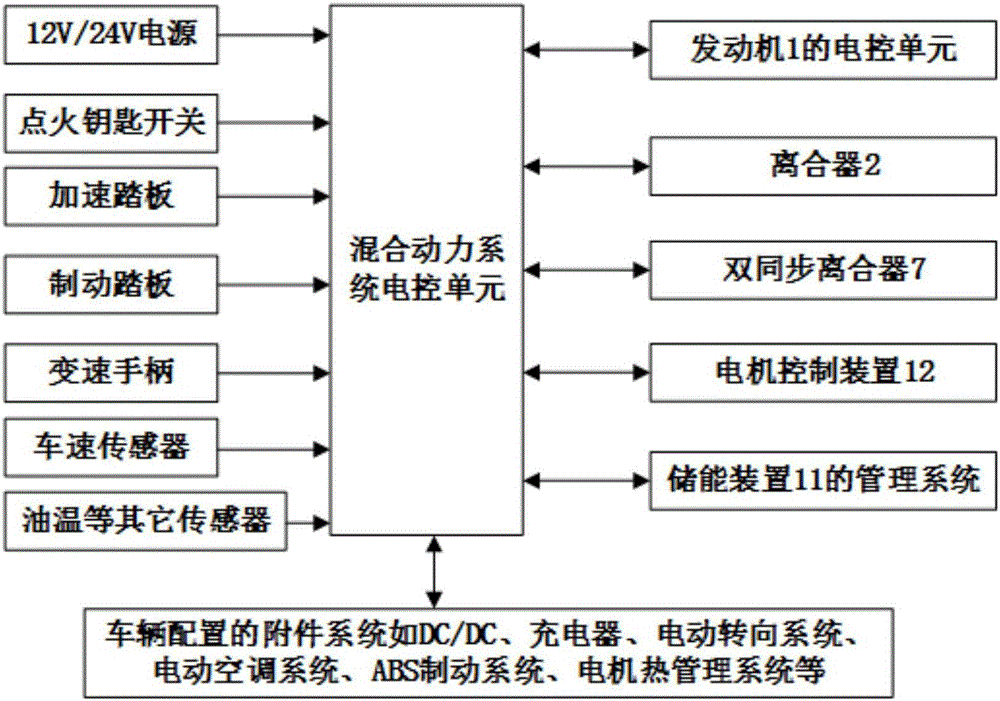

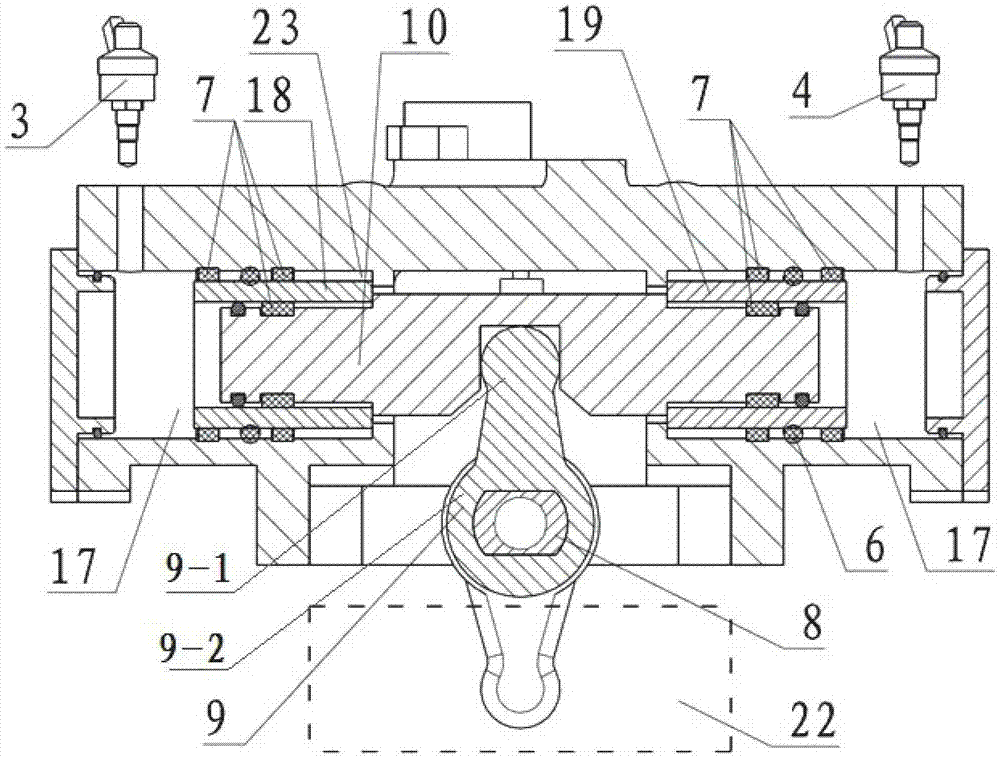

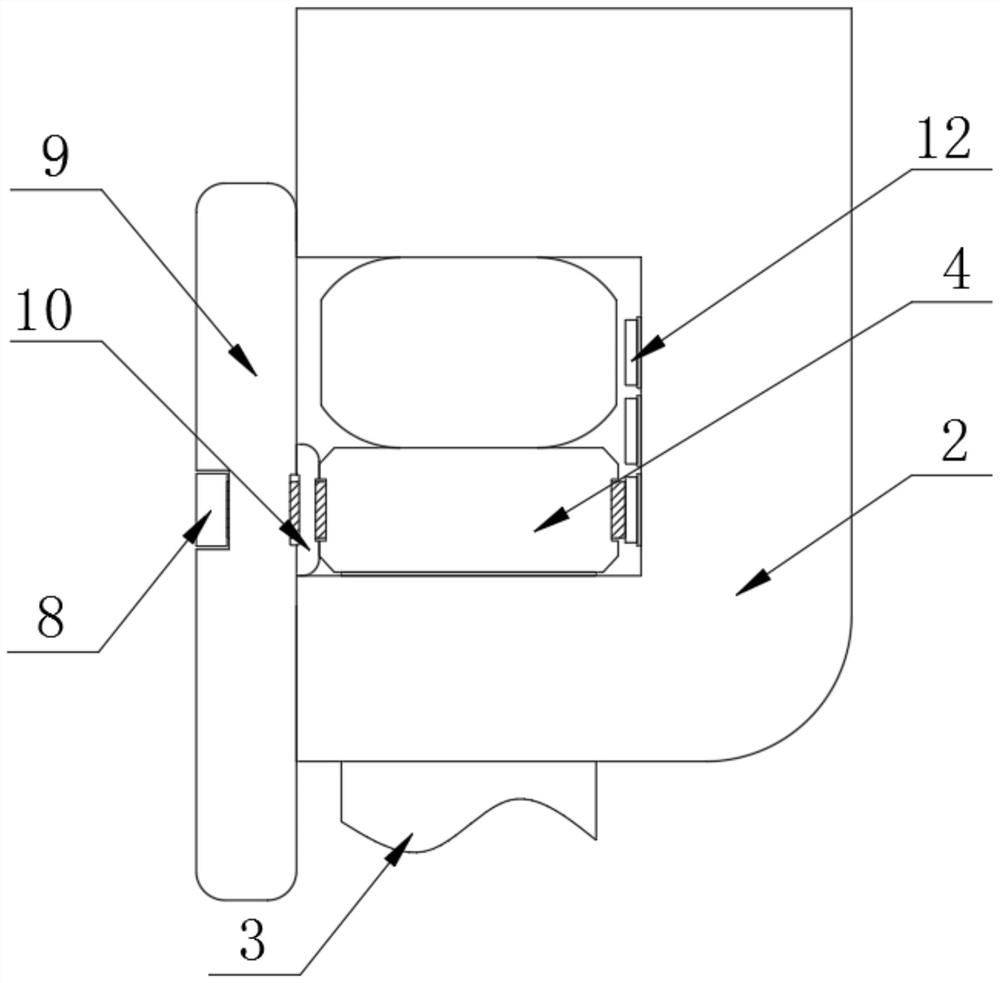

Double synchronizing clutch and planetary gear coupling double-motor power system

ActiveCN106274443AGood loadabilityReduce labor intensityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machine

The invention provides a double synchronizing clutch and a planetary gear coupling double-motor power system. The double synchronizing clutch comprises an inner synchronizer and an outer synchronizer which are arranged inside and outside in the radial direction, a first spline hub of the outer synchronizer and a second spline hub of the inner synchronizer are mechanically connected into a spline hub of an integrated structure, a channel is formed in the spline hub, an axial protrusion is arranged on a combining sleeve of the inner synchronizer, penetrates through the channel in the spline hub and is connected with a shifting fork ring groove of the inner synchronizer, an operation mechanism of the inner synchronizer is movably connected with the shifting fork ring groove of the inner synchronizer, an operation mechanism of the outer synchronizer is movably connected with a combining sleeve of the outer synchronizer, a combination tooth ring of the inner synchronizer is connected with a first input / output end, a combination tooth ring of the outer synchronizer is connected with a second input / output end, and the spline hub is connected with a third output / input end. The double synchronizing clutch and the planetary gear coupling double-motor power system have the stepless speed change function and the like, and have the advantage of meeting all-region and multipurpose application requirements.

Owner:SHANGHAI JIAO TONG UNIV +1

Switching device

InactiveUS7679021B2Reduce contact resistanceGood loadabilityHigh-tension/heavy-dress switchesAir-break switchesEngineeringElectrical switching

An electrical switching device, especially a high-voltage circuit breaker, contains arcing contacts and nominal current contacts. At least one of the nominal current contacts has a surface formed of an arc-resistant material provided with a galvanic coating. In this configuration, the contact points can withstand high mechanical and thermal loads and at the same time maintain a high current carrying capacity.

Owner:SIEMENS AG

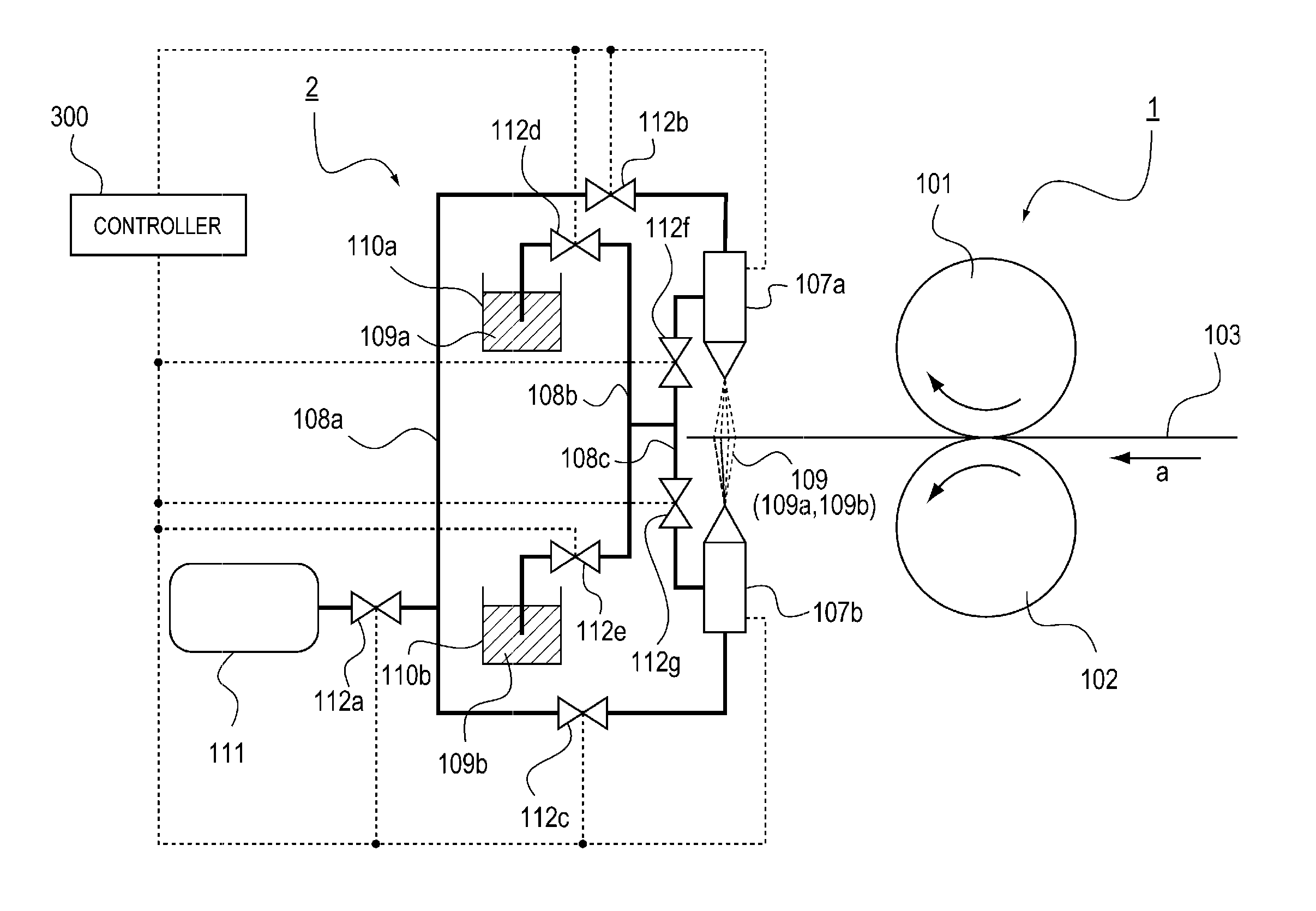

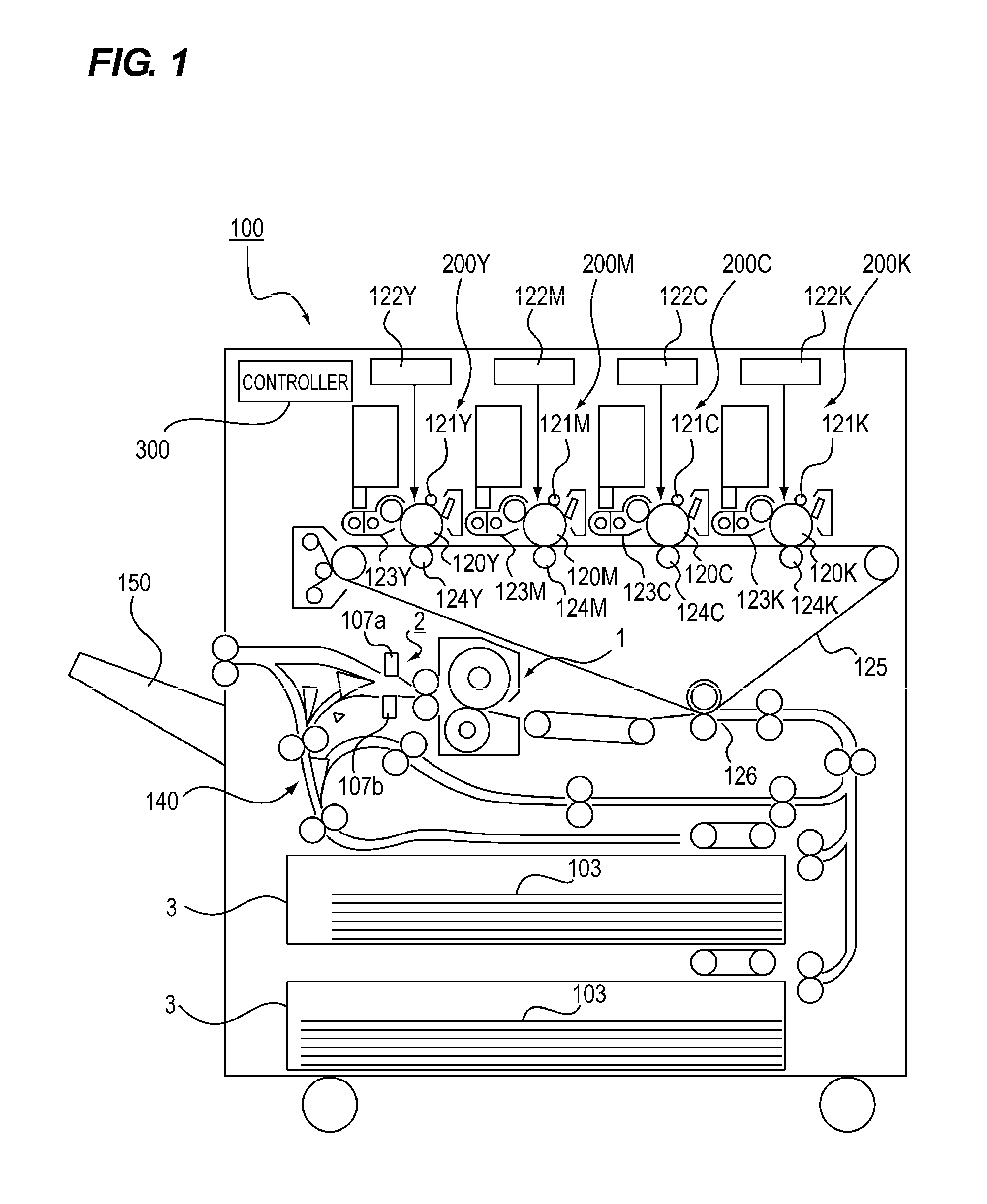

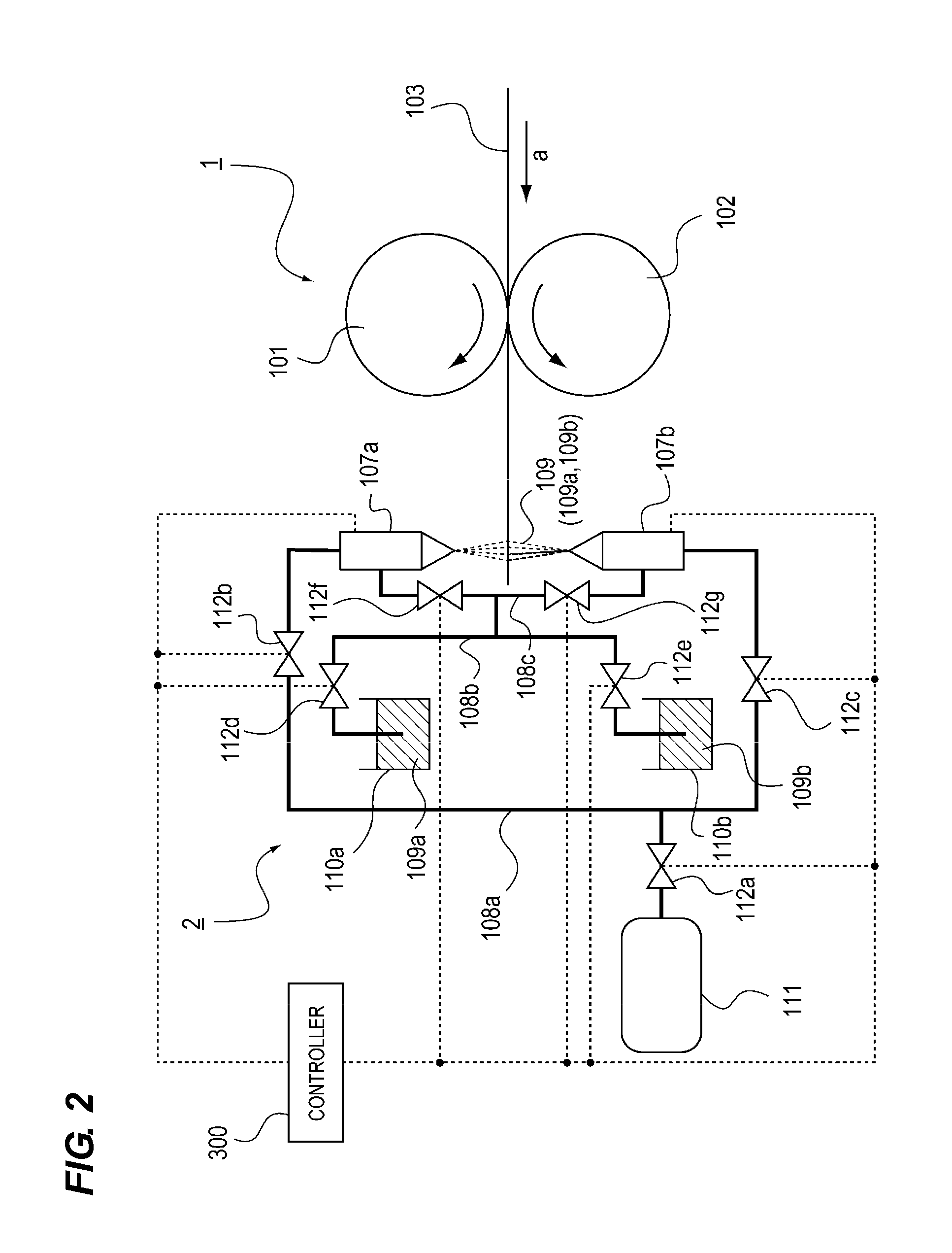

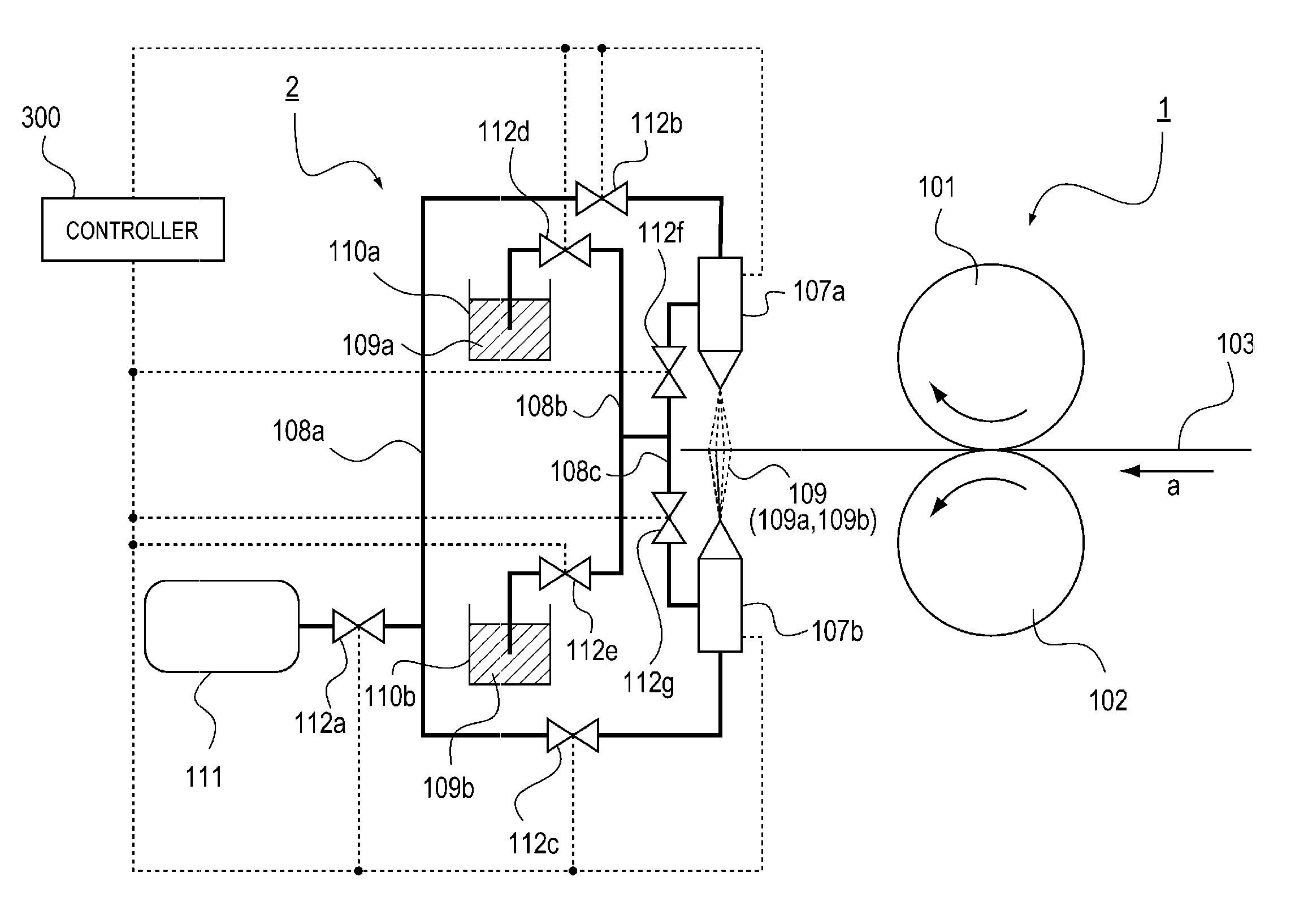

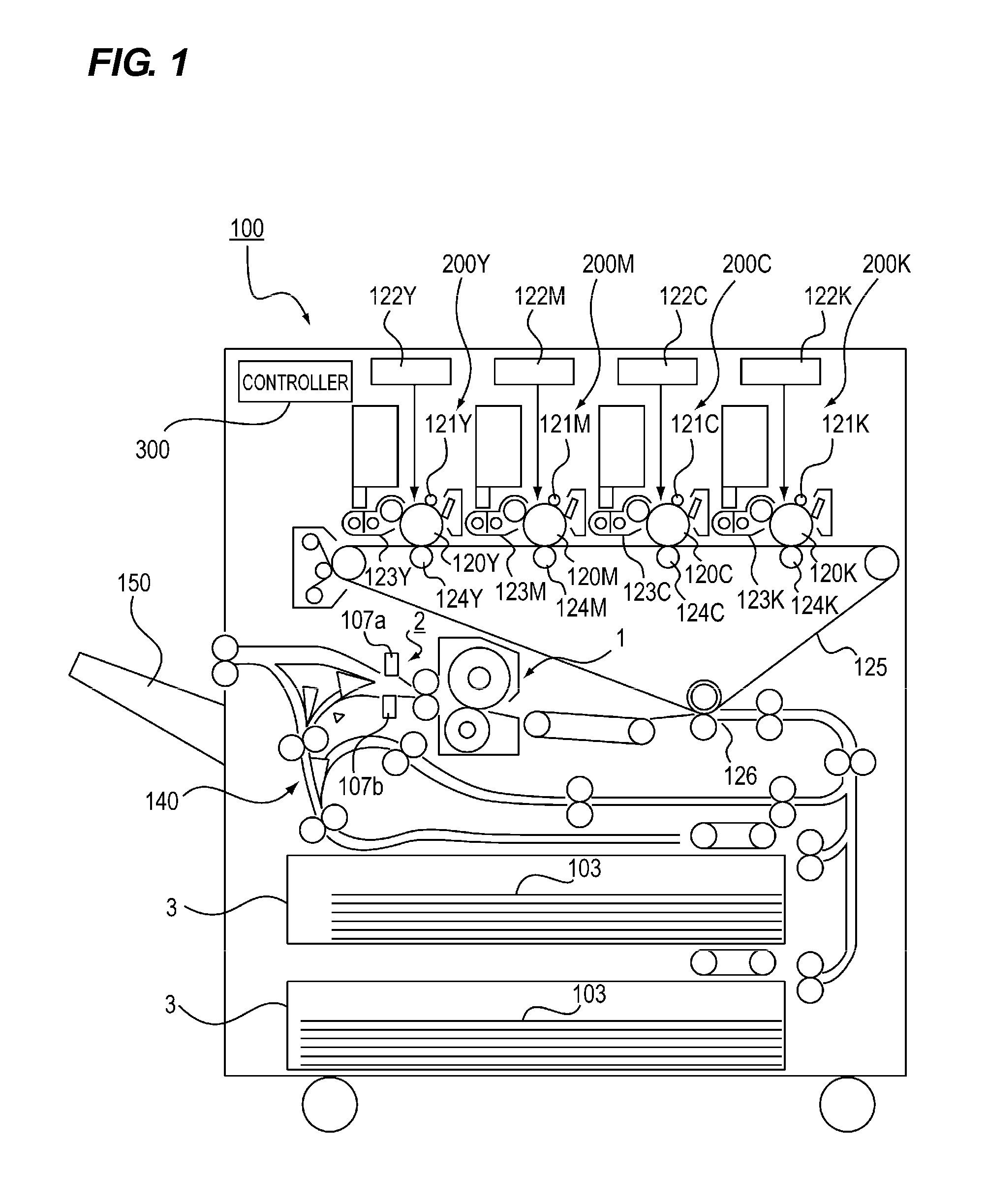

Image forming apparatus

InactiveUS20120114402A1Prevent evaporationImprove feedabilityElectrographic process apparatusEvaporationImage formation

The invention provides an image forming apparatus capable of preventing a ripple or curling of the sheet and stabilizing feedability or loadability of the sheet. The image forming apparatus includes an aqueous solution applying portion that applies the aqueous solution containing the deliquescent material for hindering evaporation of moisture to the sheet where the toner image has been thermally fixed by the fixing portion, and a controller that controls so that a concentration of the deliquescent material of the aqueous solution applied to the sheet using the aqueous solution applying portion is changed depending on the basis weight of the sheet.

Owner:CANON KK

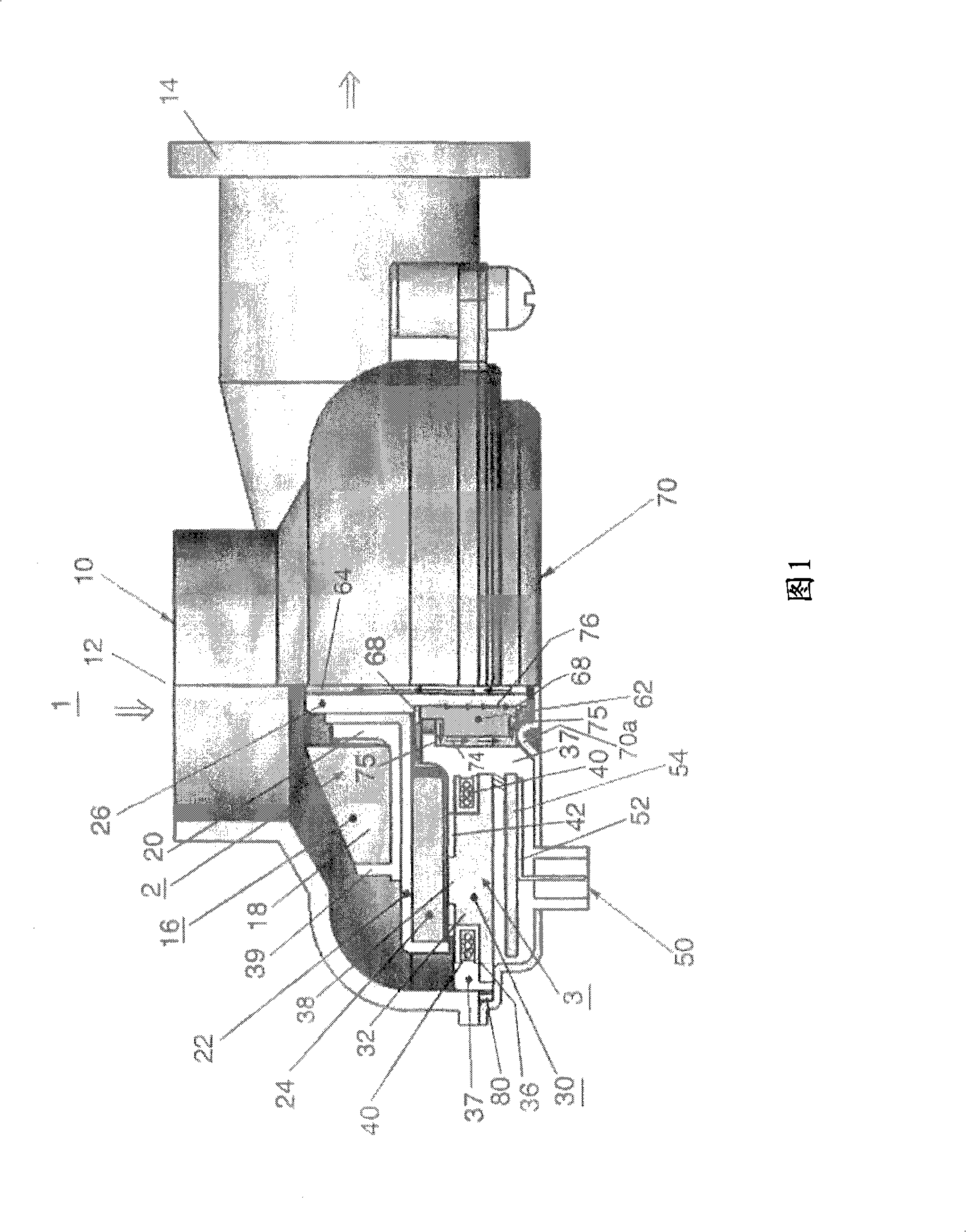

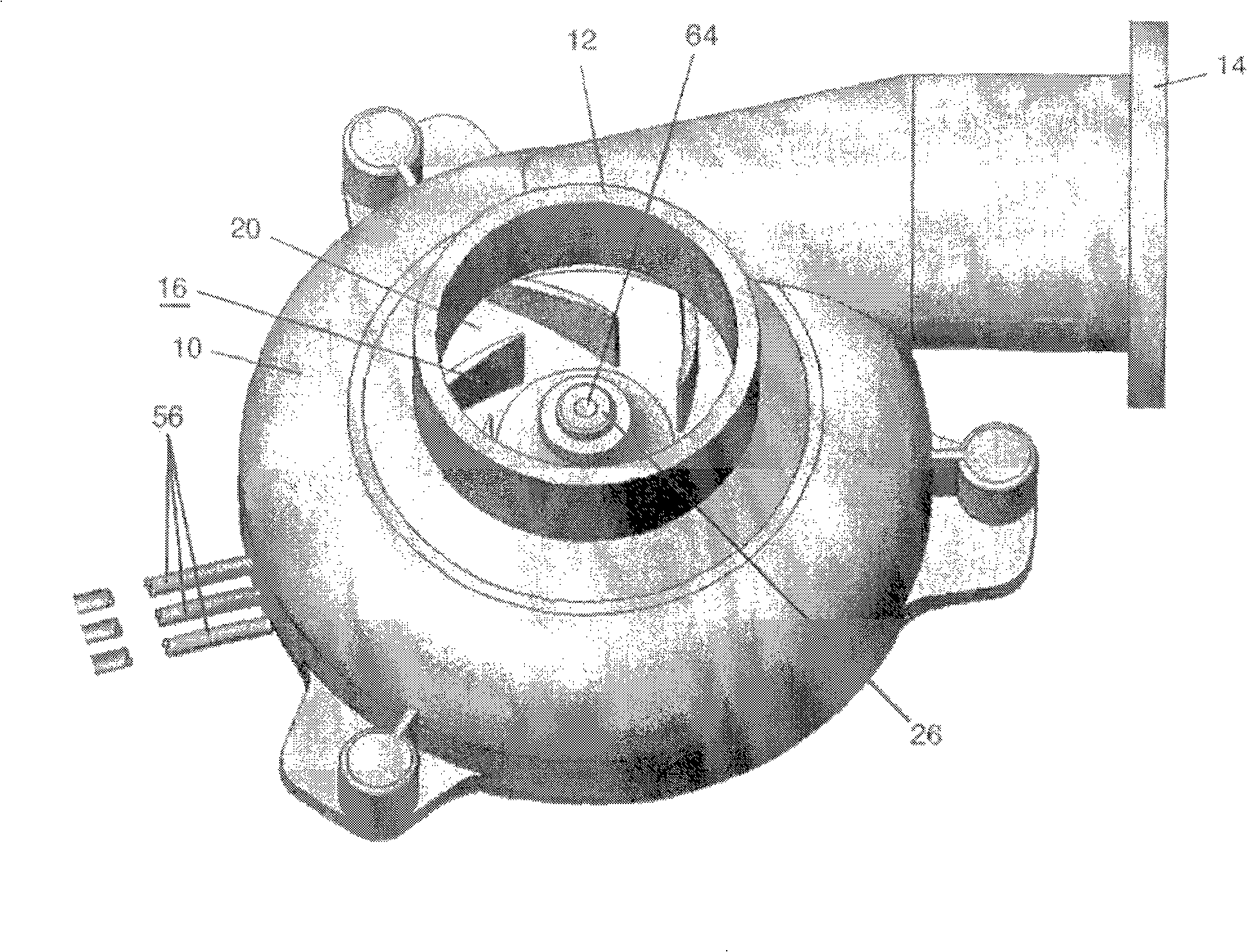

Flat type brushless electric pump and electric water pump group for vehicle using the same

InactiveCN101341340AImprove featuresReduce resistancePump componentsMechanical energy handlingImpellerBrushless motors

A flat brushless motor pump comprising a flat brushless motor, an impeller coupled with the rotating shaft of the flat brushless motor, a pump casing for containing the flat brushless motor and the impeller and having a suction opening for sucking fluid and a delivery opening for delivering fluid, and a motor cover constituting a part of the pump casing and holding the bearing of the flat brushless motor which bears the rotating shaft rotatably wherein the fluid is sucked from the suction opening by the rotation of the rotting shaft and delivered from the delivery opening.; The flat brushless motor comprises a stator section having a core around which a plurality of armature coils are wound and a terminal connected electrically with the armature coils and formed by resin molding the core and the terminal watertightly, and a rotor section formed of a magnet arranged oppositely to the core through an air gap, the rotating shaft and a yoke secured to the rotating shaft and holding the magnet, wherein the bearing is an underwater bearing for sliding the rotating shaft by a water membrane.

Owner:YAMAMOTO ELECTRIC

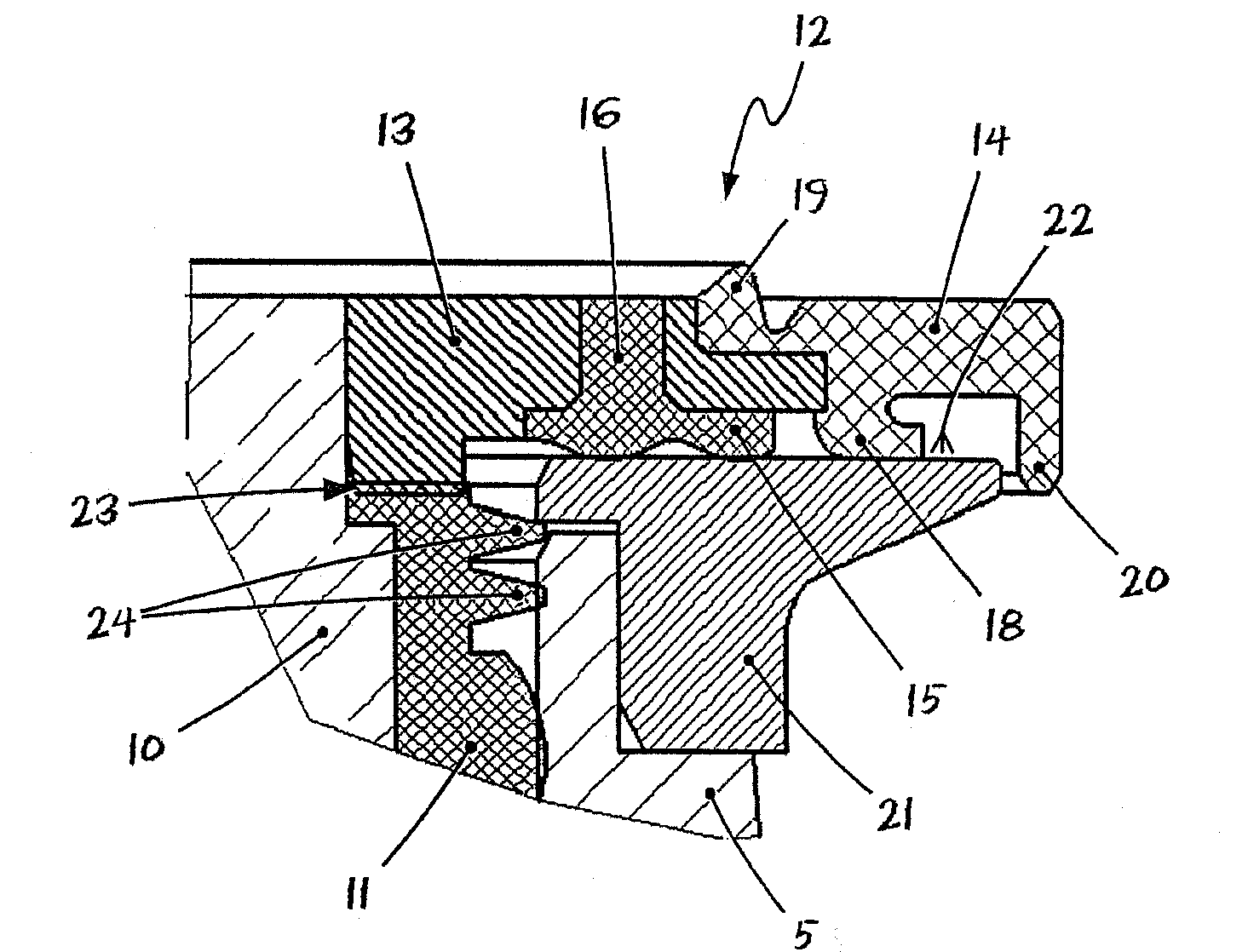

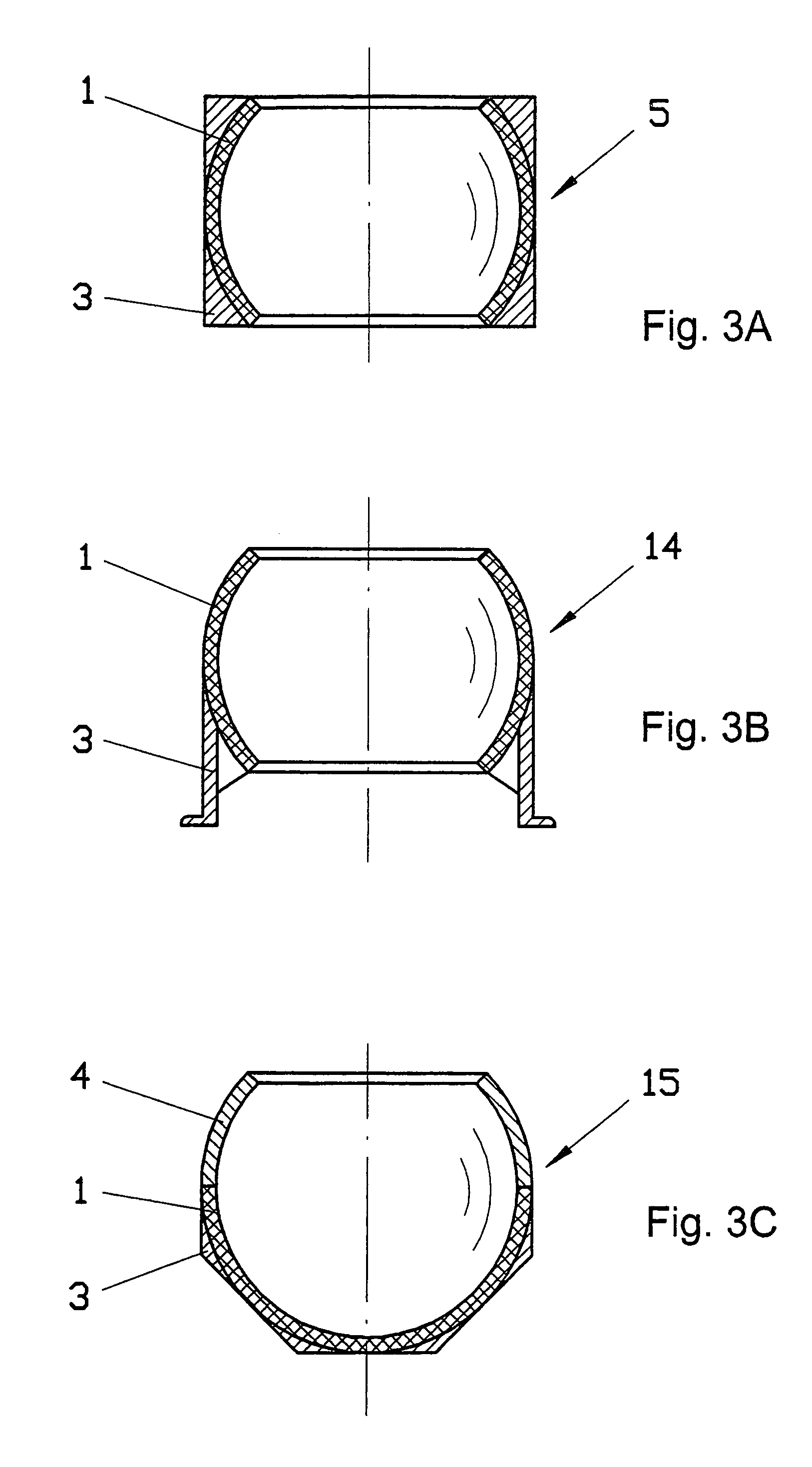

Bearing Arrangement

InactiveUS20080317394A1Small possibleReduce assemblyBearing componentsSliding contact bearingsEnvironmental effectMechanical engineering

A bearing arrangement (4) is provided with a bearing inner bush (10) and an outer bush (5), especially for the central joint (1) of a Watt's linkage. The bearing arrangement (4) is provided with a sealing arrangement (12) surrounding the front-side bearing gap between the inner bush (10) and the outer bush (5). The sealing arrangement (12) comprises an elastic sealing element (14) with static as well as dynamic sealing surfaces. The bearing arrangement (4) has a sealing arrangement (12) designed as a sealing module (12), which can be connected to the bearing inner bush (10), the sealing module (12) also comprising a running surface (15) for the axial bearing of the outer bush (5). The arrangement makes possible the especially economical production of modularly designed, highly loadable bush bearings. Furthermore, undivided, continuous bearing bushes can be used, which improves the ability to be mounted and the precision and the service life of the bearing arrangement. It is also possible, especially in case of highly stressed bush bearings, to dimension the axial rigidity as well as the radial rigidity of the bearing arrangement independently from one another, and especially good sealing is obtained against environmental effects.

Owner:ZF FRIEDRICHSHAFEN AG

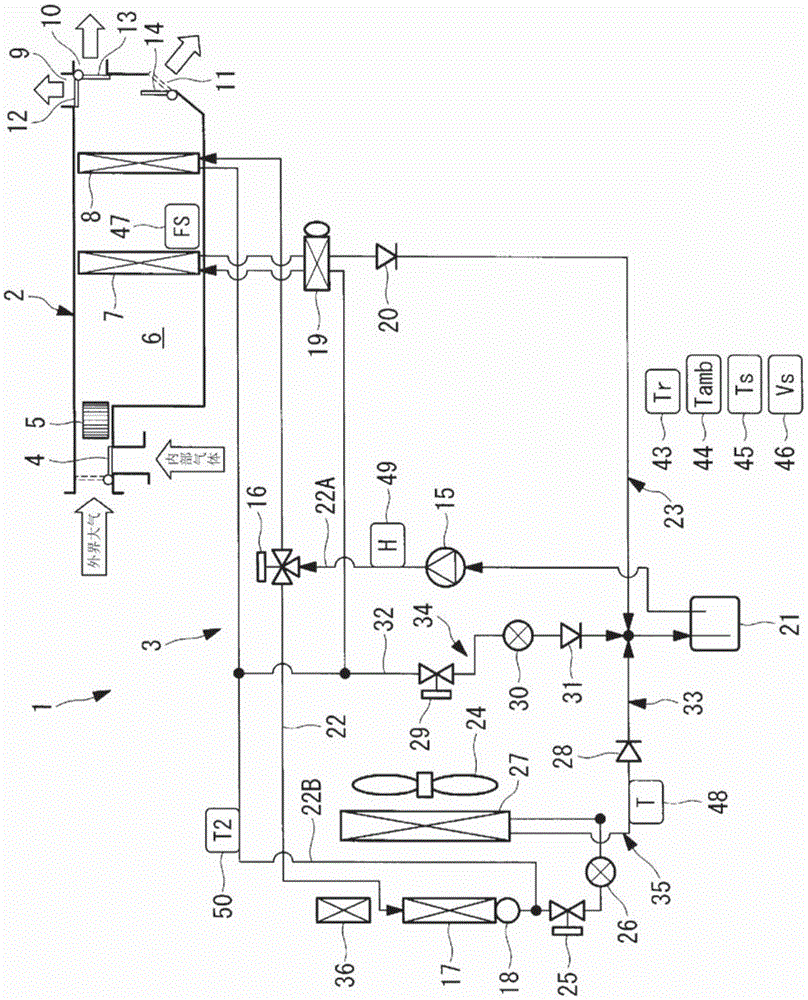

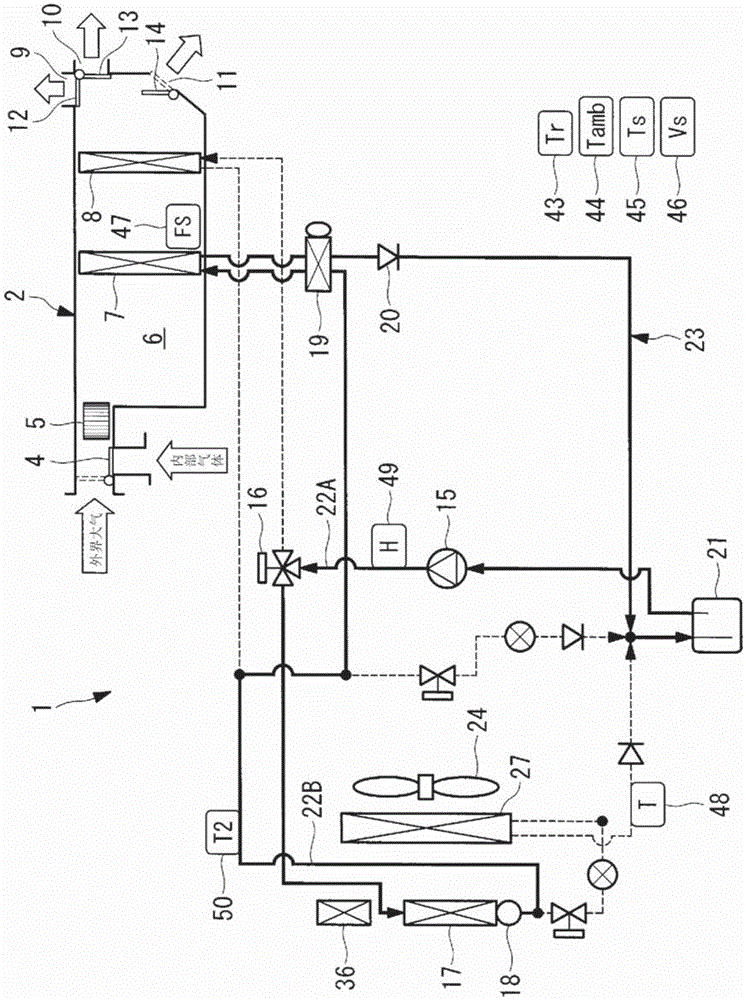

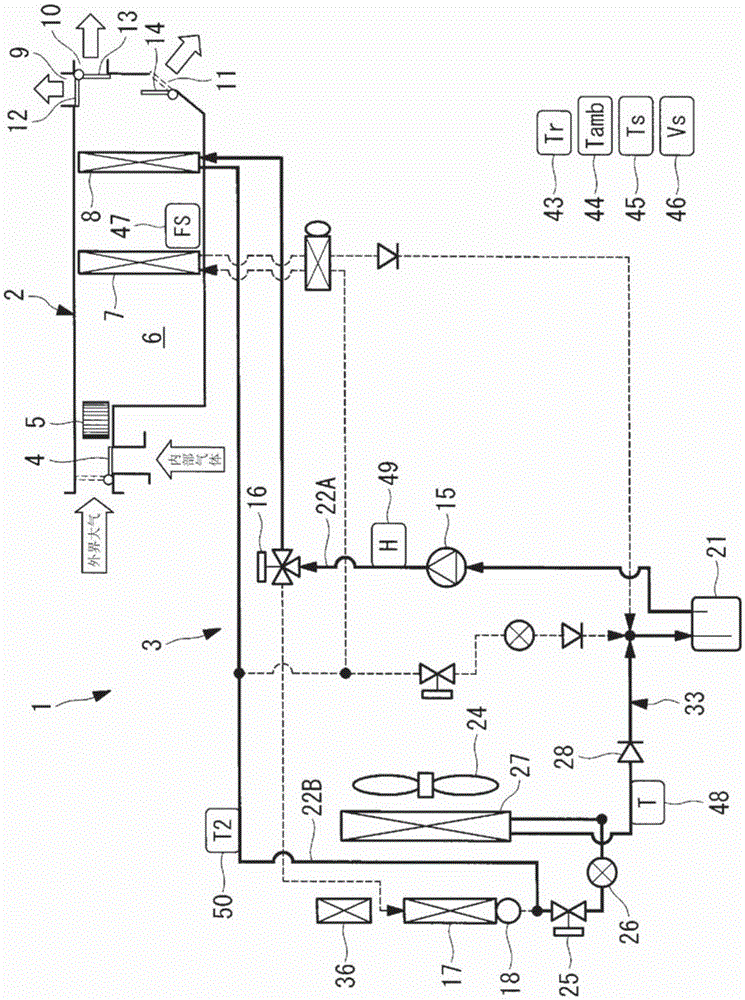

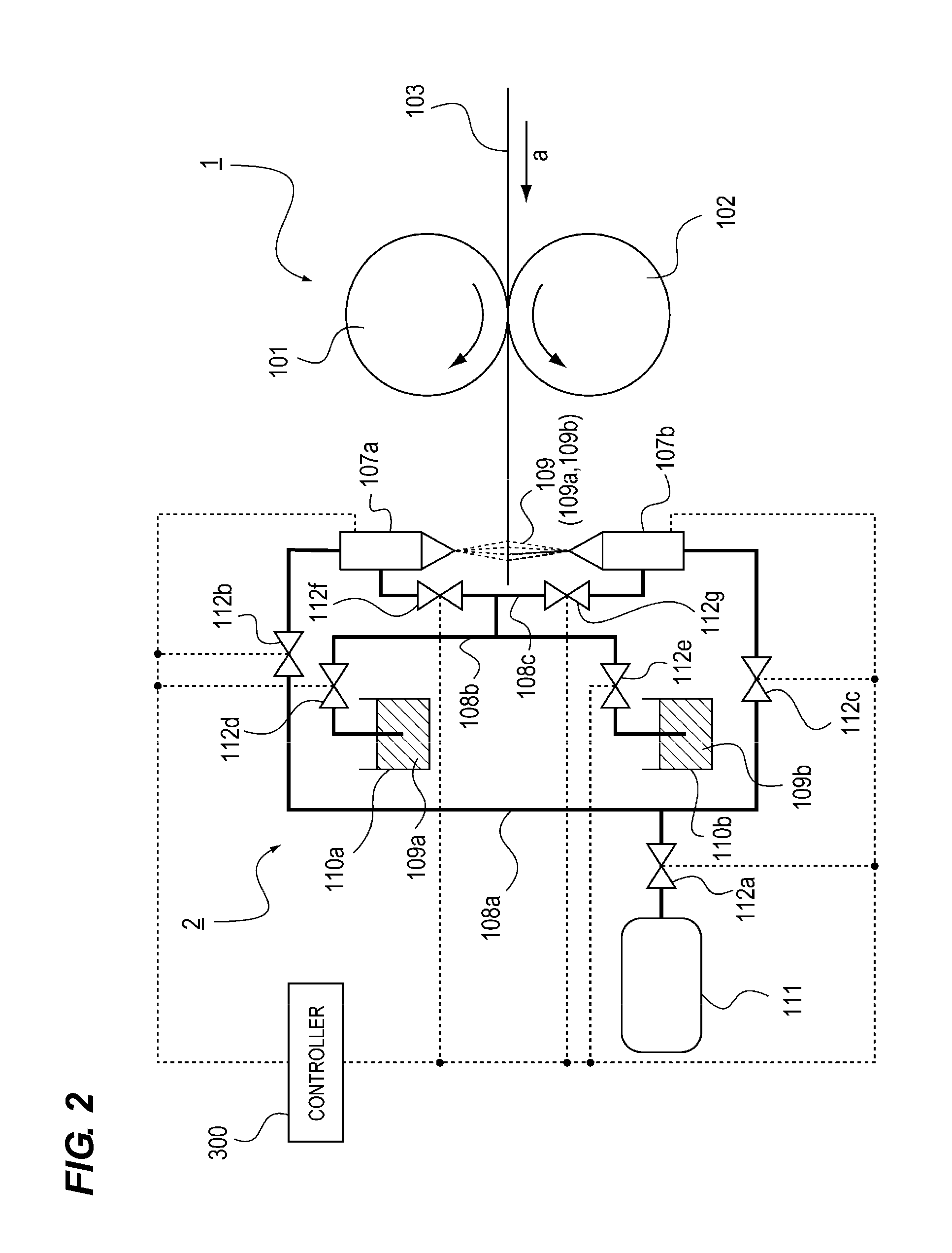

Heat-pump-type vehicle air conditioning system and defrosting method thereof

InactiveCN105555564AImprove reliabilityLow costMechanical apparatusAir-treating devicesRefrigerantAir temperature

Provided is a heat-pump-type vehicle air conditioning system that flows hot gas to both an vehicle-cabin-exterior condenser and a vehicle-cabin-exterior vaporizer during a defrosting operation, and that, even during times of low outside air temperatures, can efficiently defrost in a short period of time and can use in a commoditized manner the cooling cycle of an existing system as-is. In the heat-pump-type vehicle air conditioning system (1): a vehicle-cabin-interior condenser (8) disposed downstream of a vehicle-cabin-interior vaporizer (7) within an HVAC unit (2) is connected, with a coolant switching means (16) therebetween, to a cycle (23) for cooling comprising an electric compressor (15), a vehicle-cabin-exterior condenser (17), a first decompression means (19) to which an on-off valve functionality is provided, the vehicle-cabin-interior vaporizer (7), and an accumulator (21); the vehicle-cabin-exterior vaporizer (27) disposed at the outside of the vehicle cabin is connected, with a second decompression means (26) to which an on-off valve functionality is provided therebetwen, to the exit-side liquid coolant tubing (22B) of the vehicle-cabin-exterior condenser (17); and furthermore a bypass circuit (32) having a third decompression means (30) to which an on-off functionality is provided is connected between the accumulator (21) and the exit exit-side liquid coolant tubing (22B) of the vehicle-cabin-exterior condenser (17).

Owner:MITSUBISHI HEAVY IND THERMAL SYST

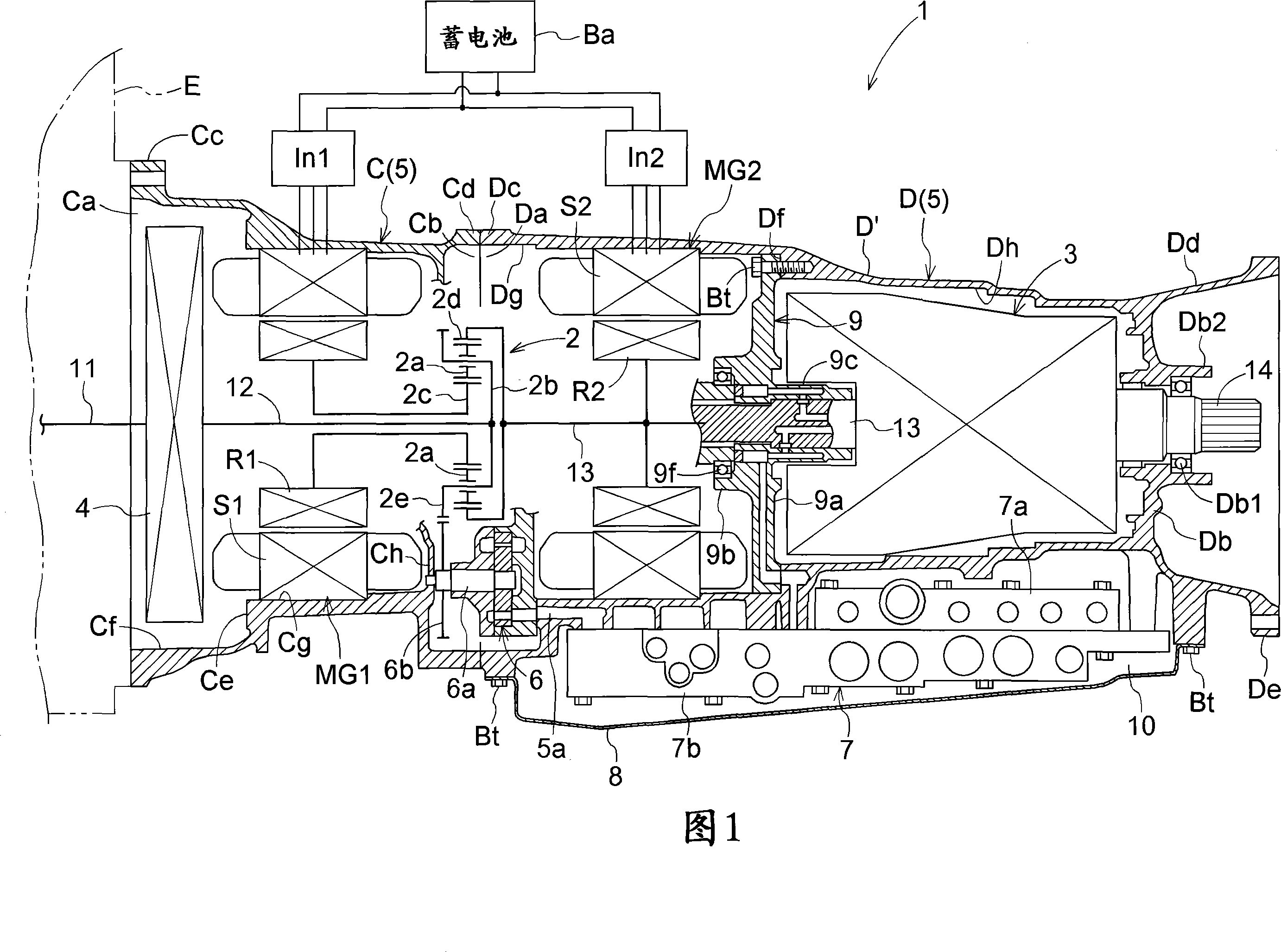

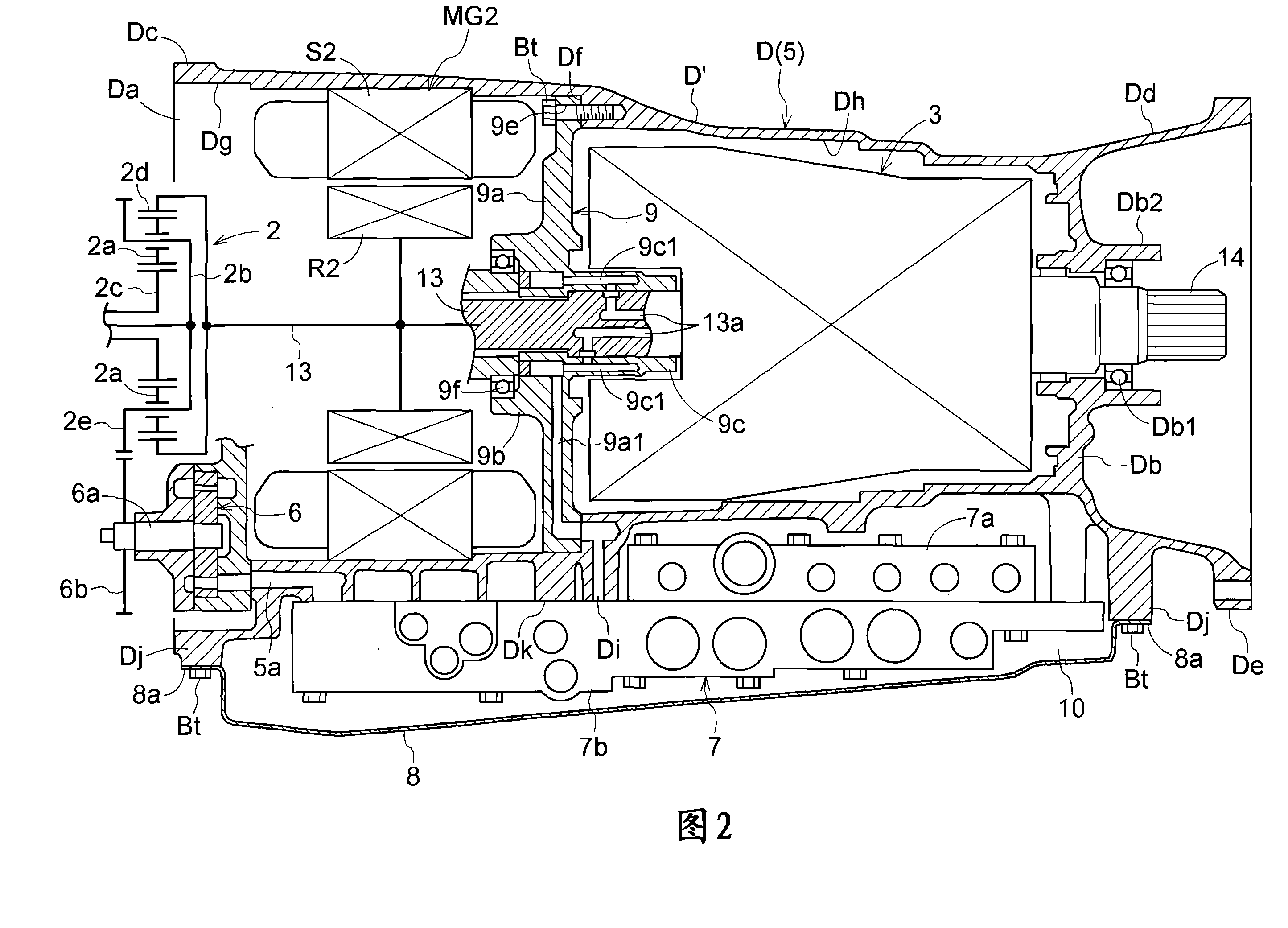

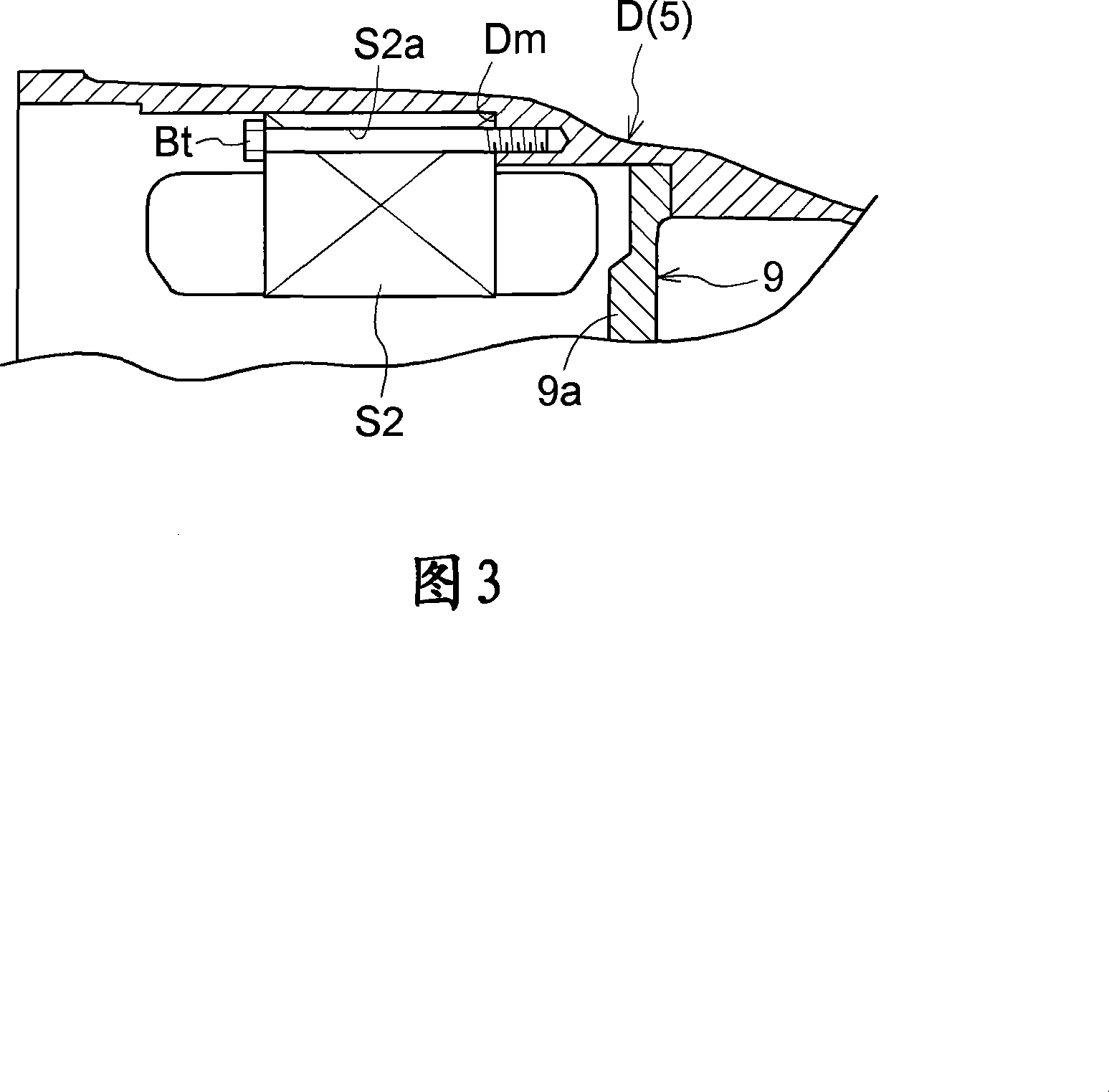

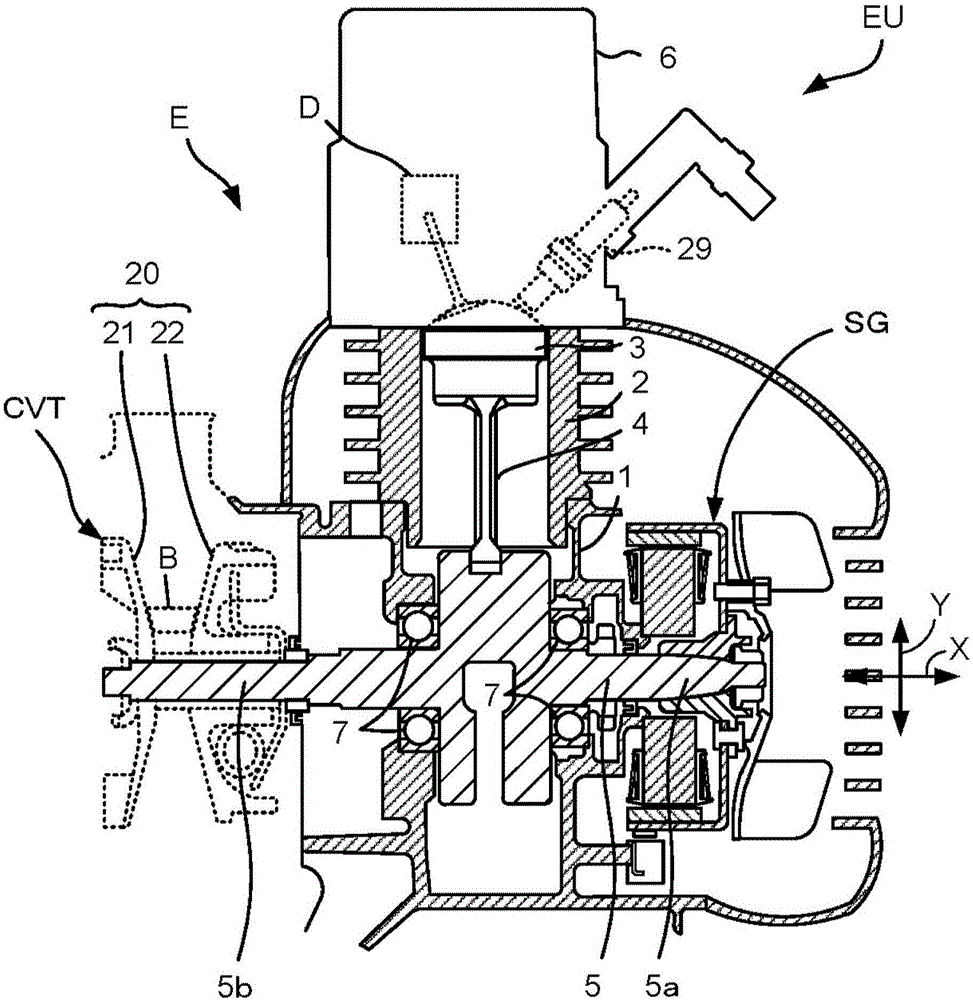

Vehicle driving device

The present invention provides a vehicle drive device capable of ensuring sufficient installation space for a hydraulic control device and a capacity of an oil pan. The drive device (1) for a vehicle is configured by accommodating a speed change mechanism (3) and an electric motor (MG2) in a case (D), and disposing a hydraulic control device (7) on the outer wall of the case (D), wherein the case (D), there is an opening (Da) at one end of the case main body (D') into which the speed change mechanism (3) and the motor (MG2) can be inserted, and the other end side of the case main body (D') is connected to the case main body (D') integrally has the other end wall portion (Db) provided with a shaft support portion (Db1) for supporting the output shaft (14) of the speed change mechanism (3).

Owner:AISIN AW CO LTD

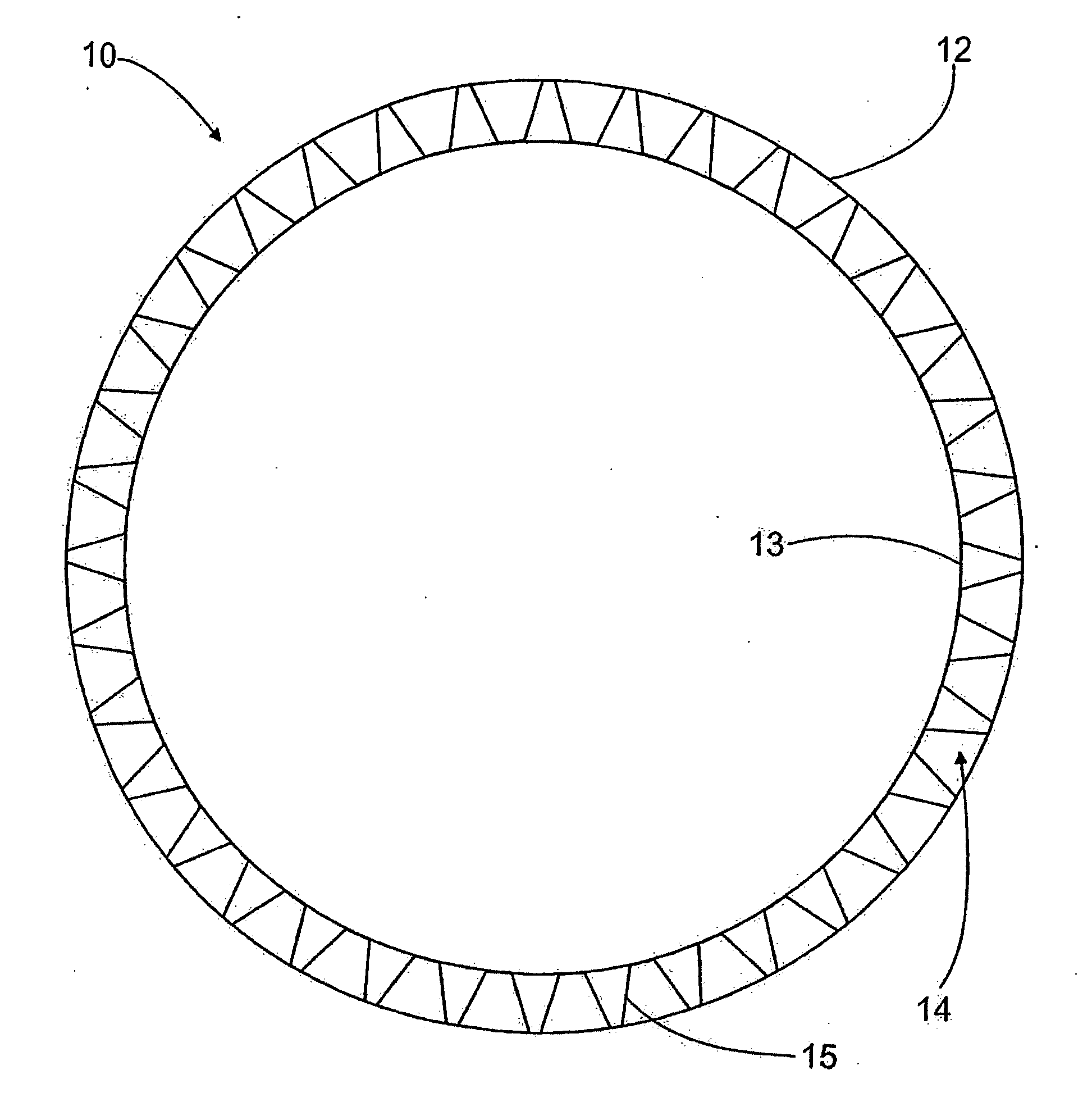

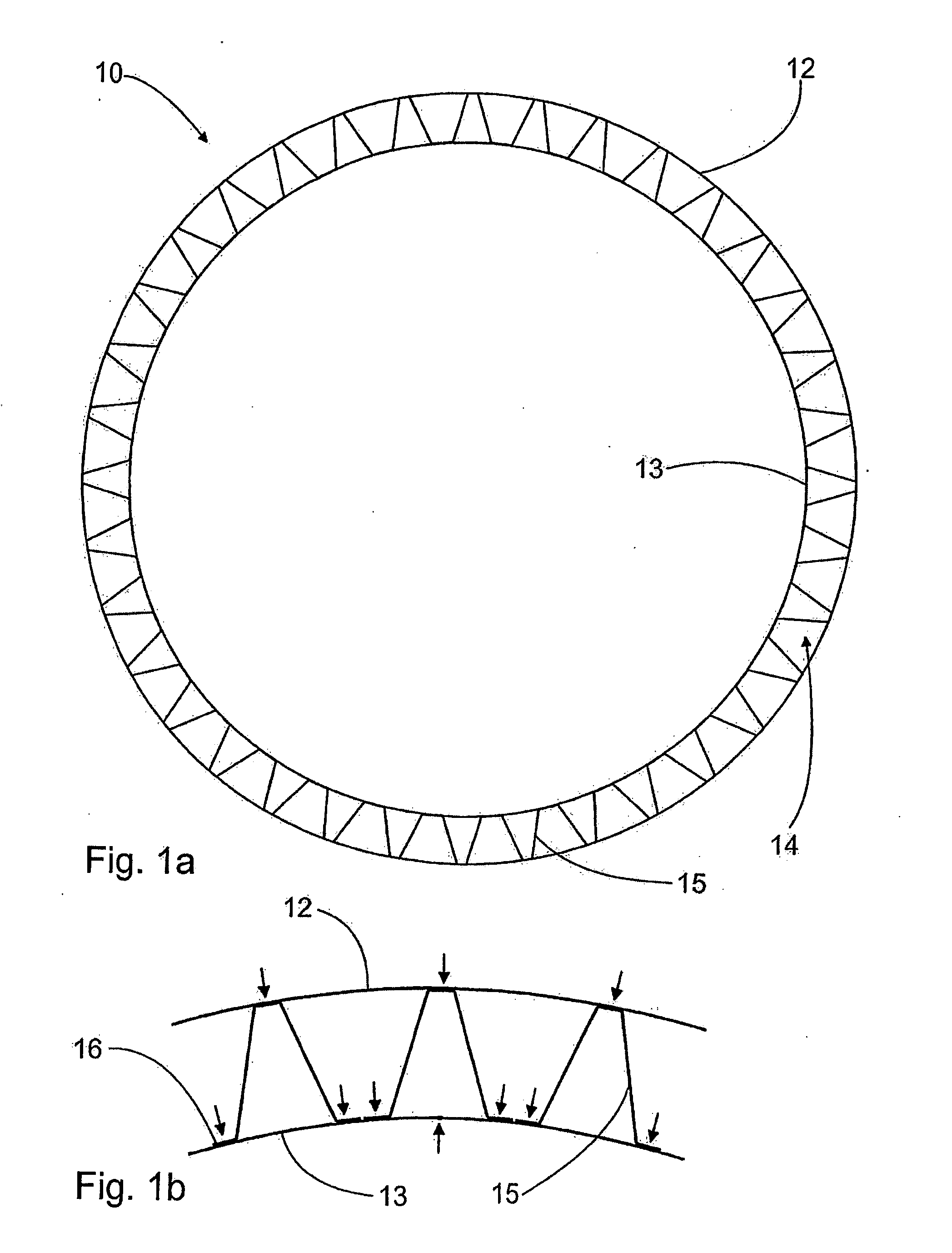

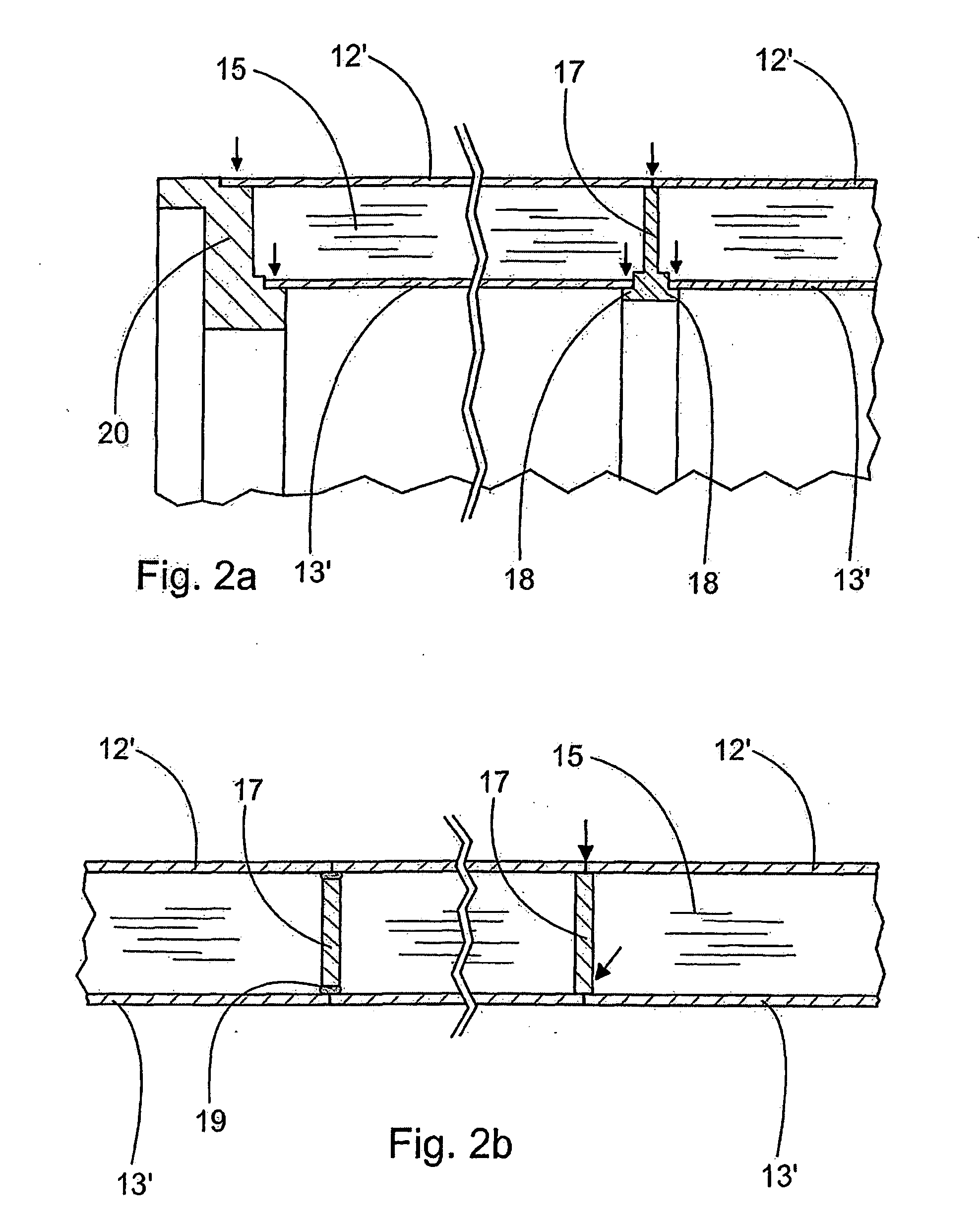

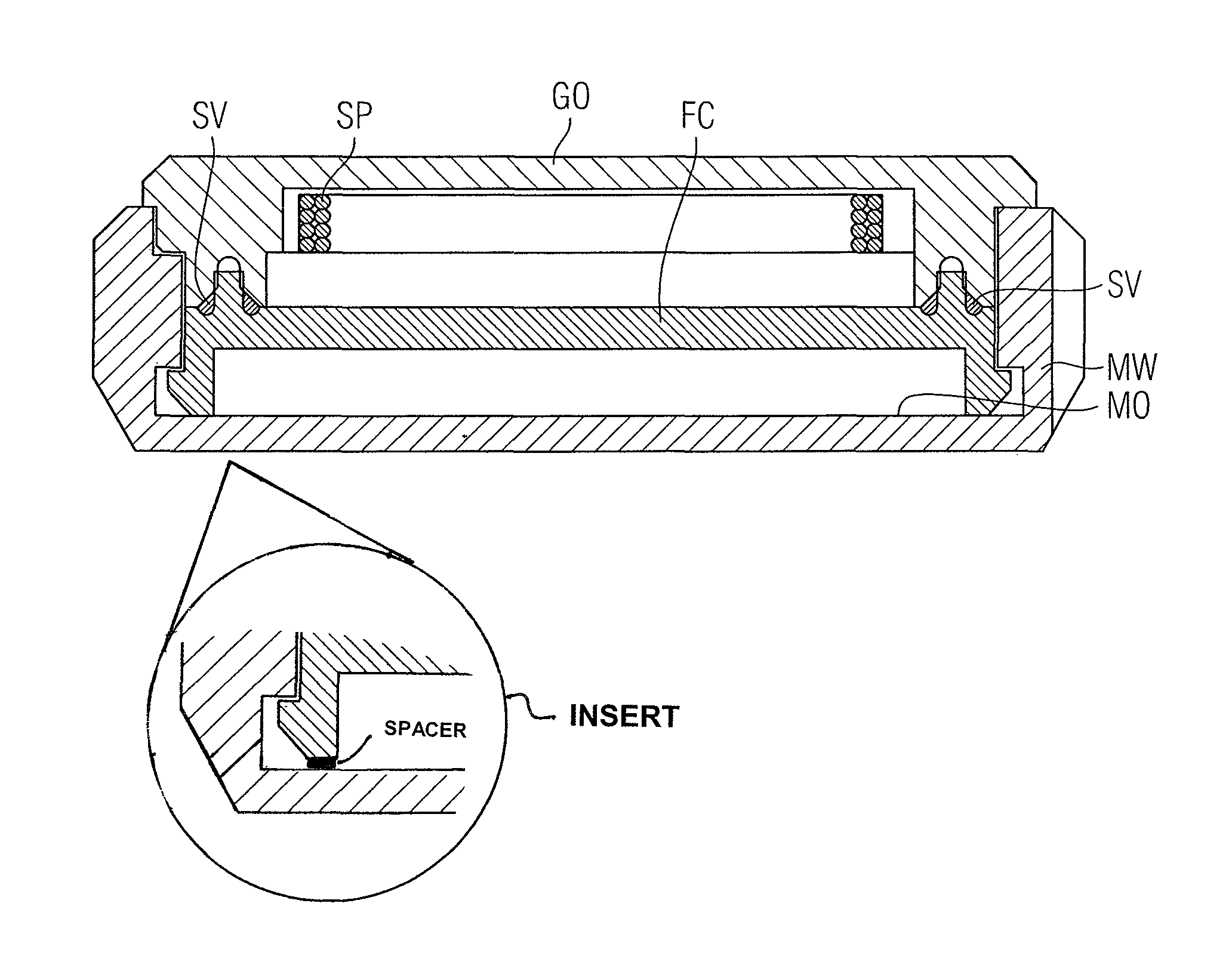

Tube roll for a paper machine and a method for manufacturing a tube roll

InactiveUS20060096098A1Light weightGood loadabilityShaft and bearingsMetal-working apparatusMetalMetal cylinder

A tube roll for a paper machine has a shell (10) and roll heads (11) for supporting the tube roll rotably to the paper machine. The shell (10) has two metal cylinders (12, 13) adapted coaxially at an interval of each other. Between the cylinders (12, 13) there is additionally a core construction (14) attached to both of the cylinders (12, 13). Each roll head (11) is attached to both of the cylinders, of which at least the inner cylinder (13) is made of a sheet metal material. The invention also relates to a method for manufacturing a tube roll.

Owner:VALMET TECH INC

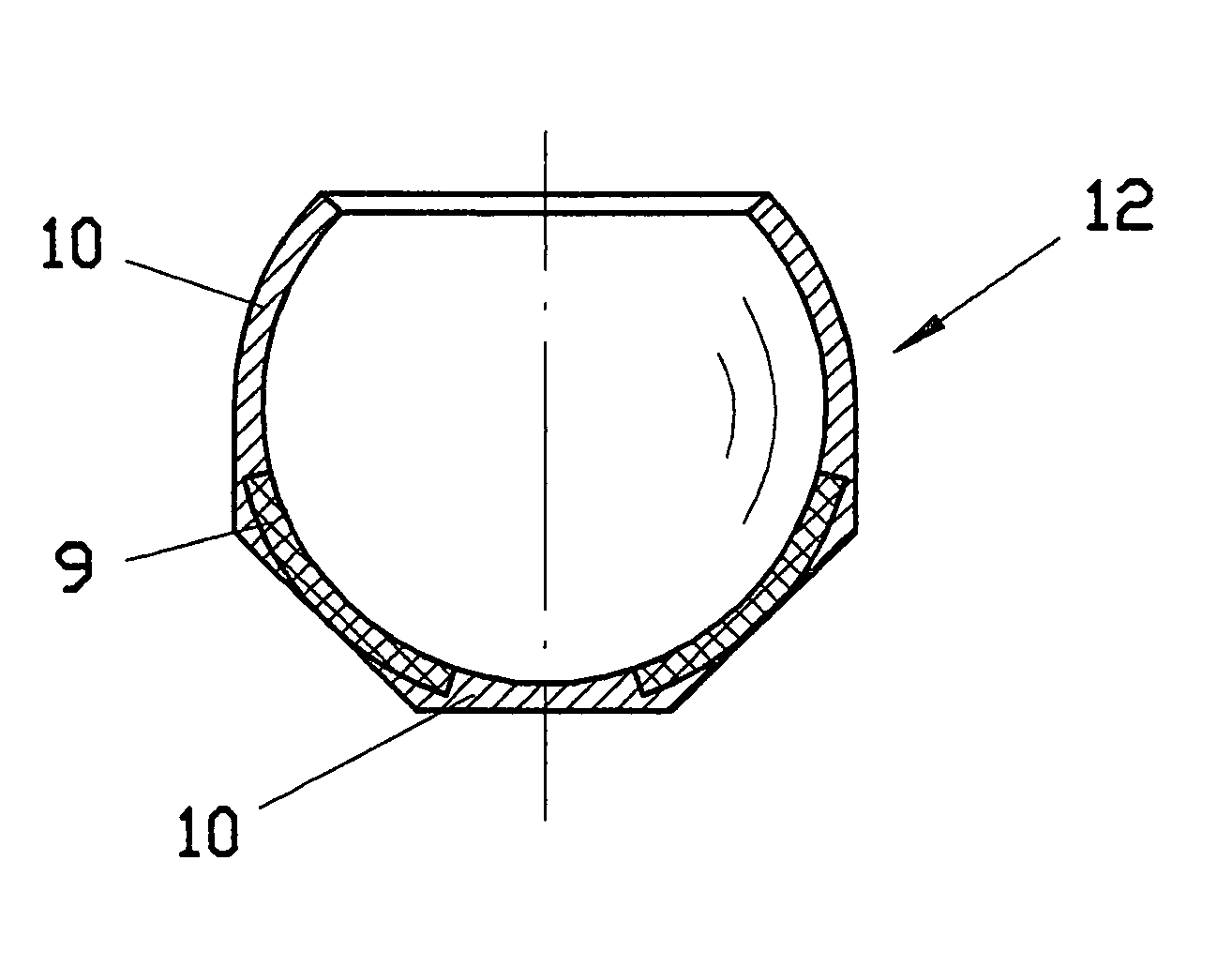

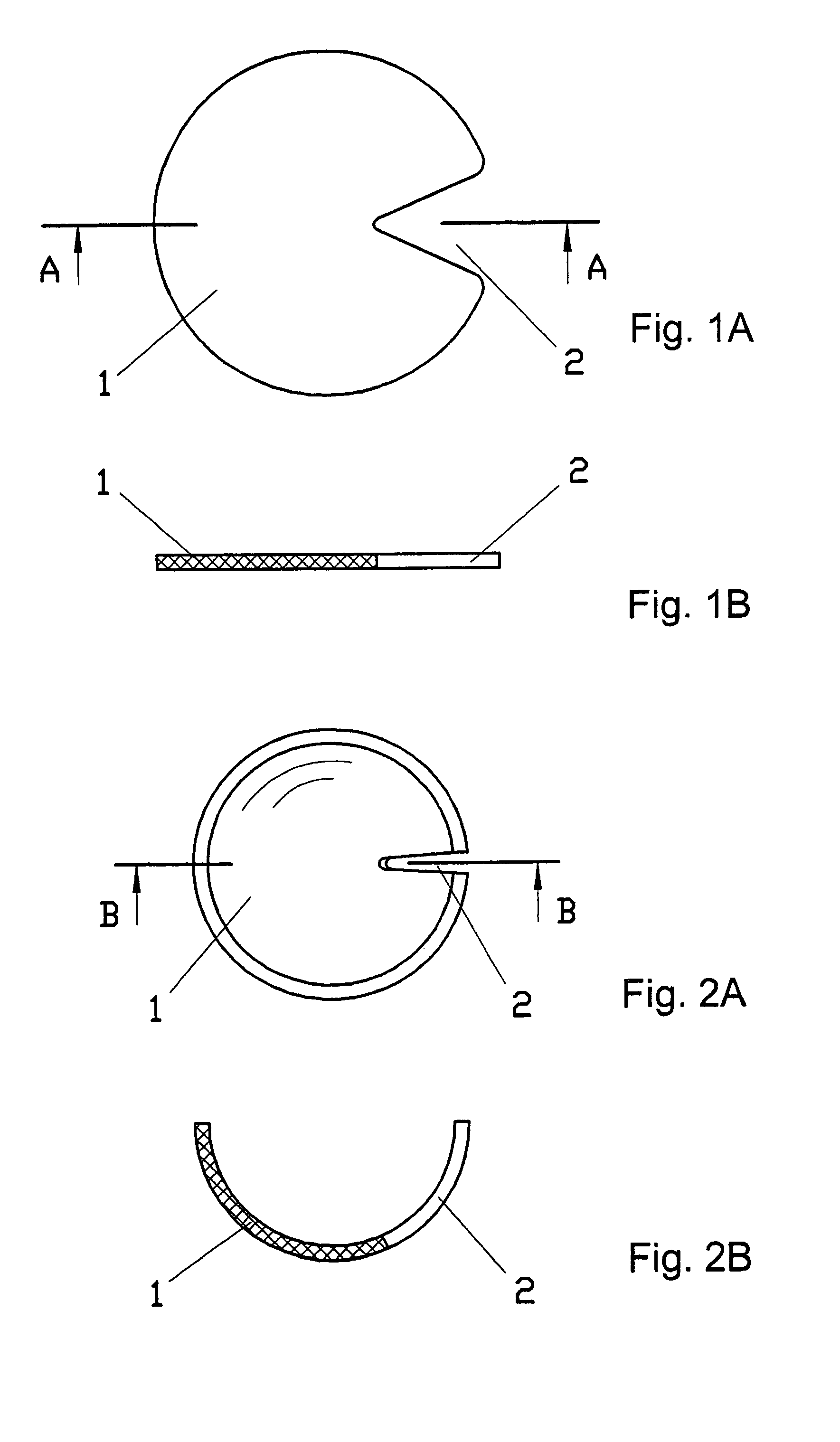

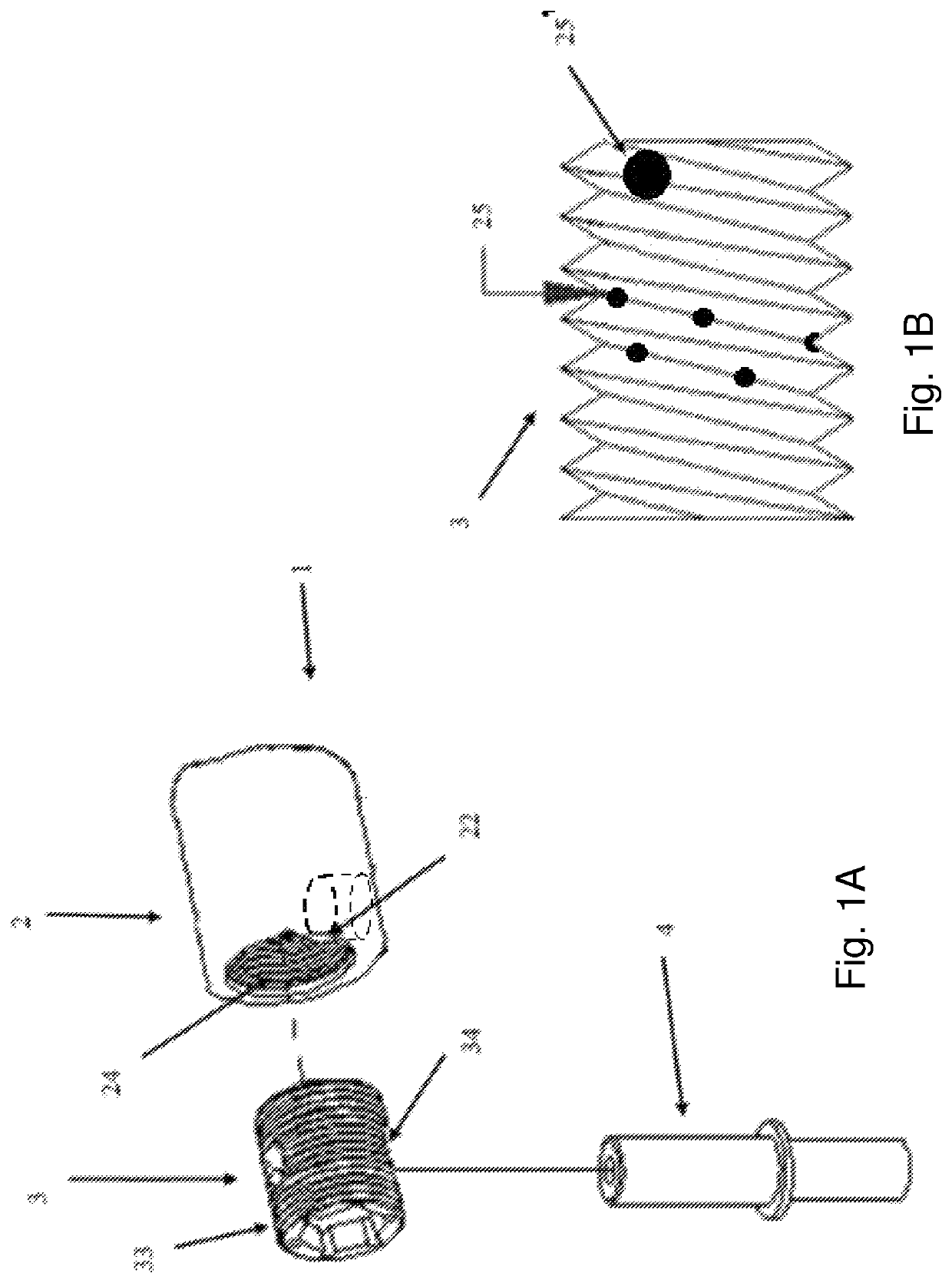

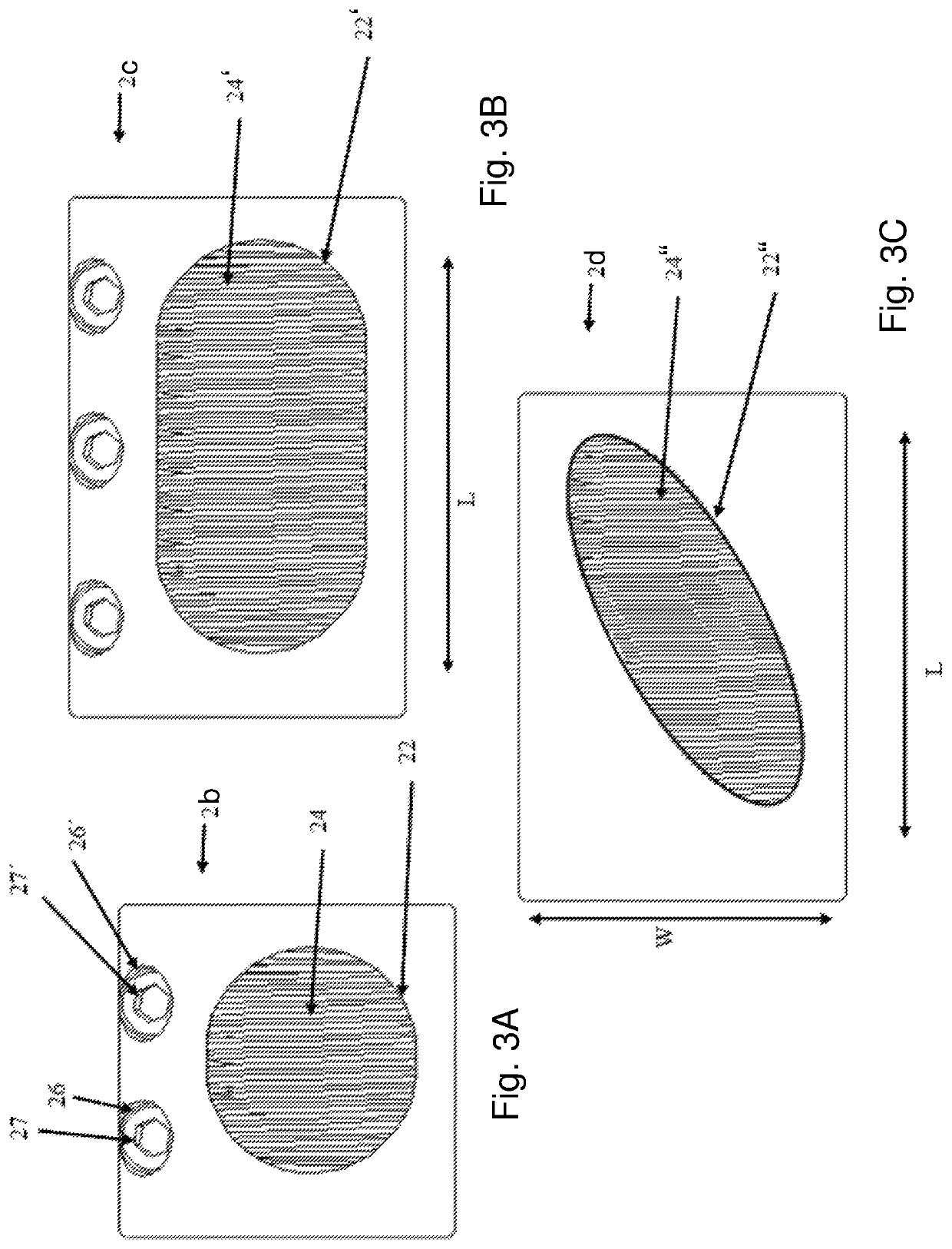

Bearing shell for a ball and socket joint

InactiveUS7320548B2Reduce manufacturing costHigh standardSuspensionsRolling contact bearingsSpherical bearingWork in process

A bearing shell with a spherical bearing surface for a ball and socket joint preferably for use in chassis suspensions or steering mechanisms of motor vehicles, which has essentially a joint housing and a bearing journal, which comprises a spherical surface and a pivot part and which is mounted with the spherical surface rotatably and deflectably in the spherical bearing surface of the bearing shell fixed in the joint housing, is presented, in which a filament fabric is embedded according to the present invention in the thermoplastic of the bearing shell (5, 11, 12, 13, 14, 15) at least in a partial area. In addition, the present invention pertains to a process for manufacturing an above-described bearing shell from thermoplastic, in which a bearing shell blank (1, 9) provided with an essentially circular outer contour is fashioned out of a sheet-shaped thermoplastic semifinished product, in which a filament fabric had been embedded, and in which the final shape of the bearing shell (5, 11, 12, 13, 14, 15) with spherical bearing surface is brought about in a subsequent processing operation by heating the thermoplastic material above its melting point and subsequent mechanical deformation of the bearing shell blank (1, 9).

Owner:ZF LEMFOERDER METALLWAREN AG

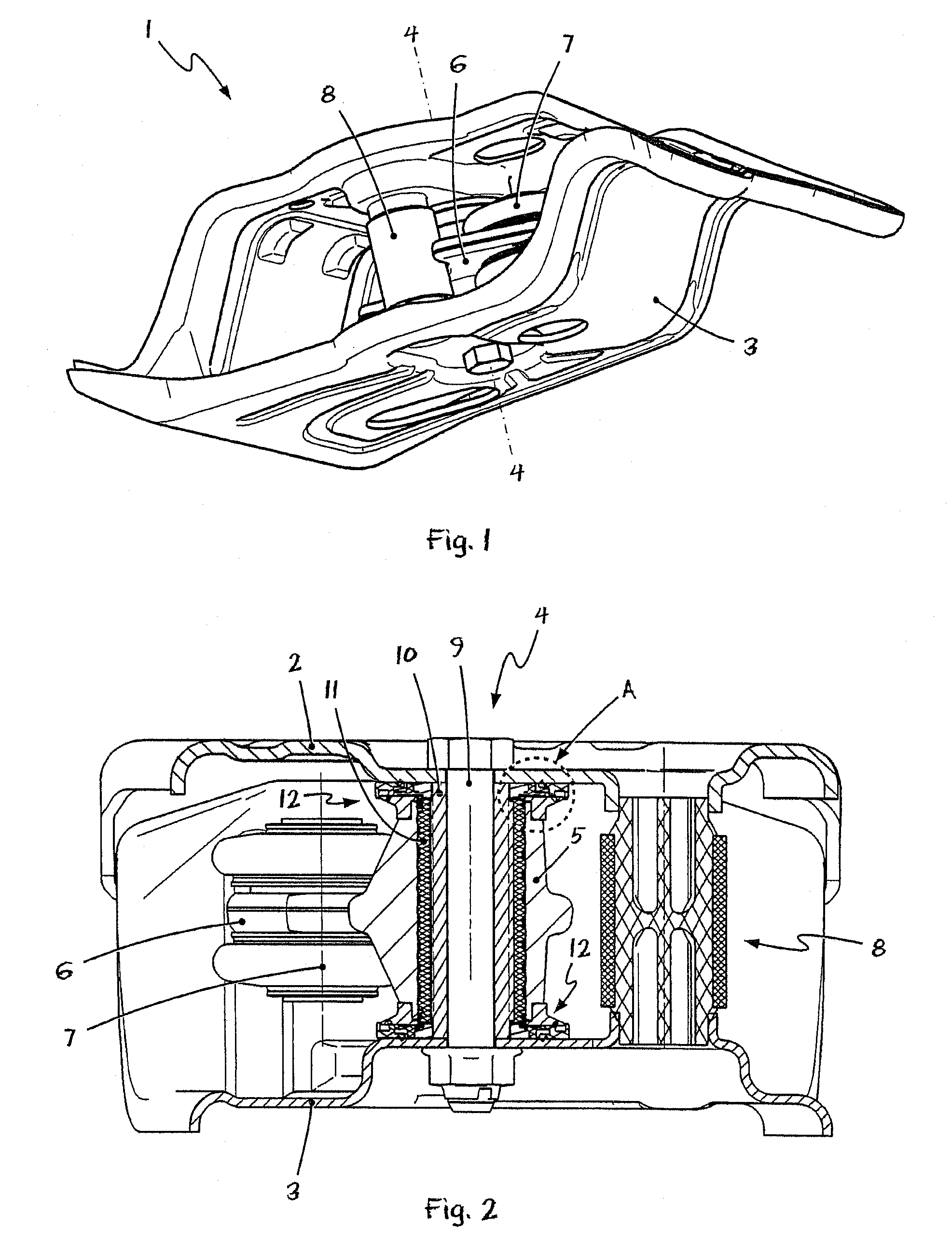

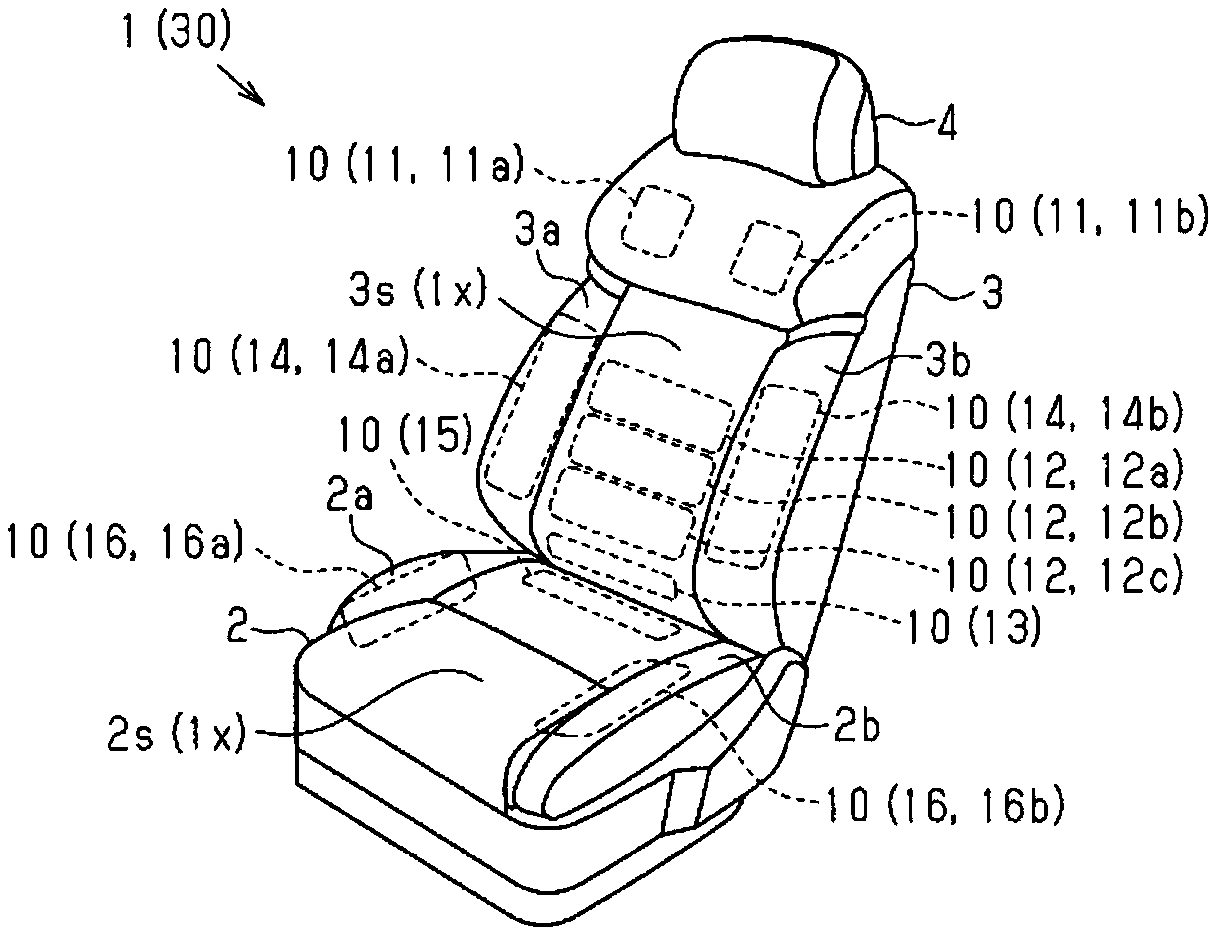

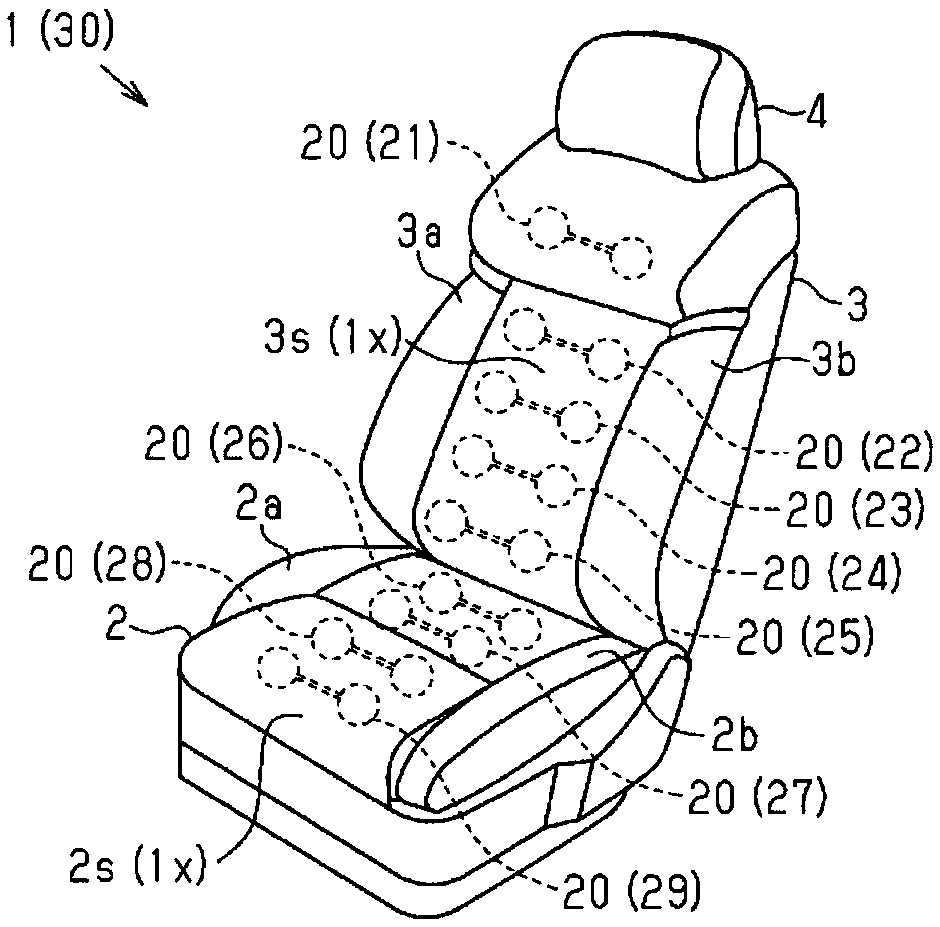

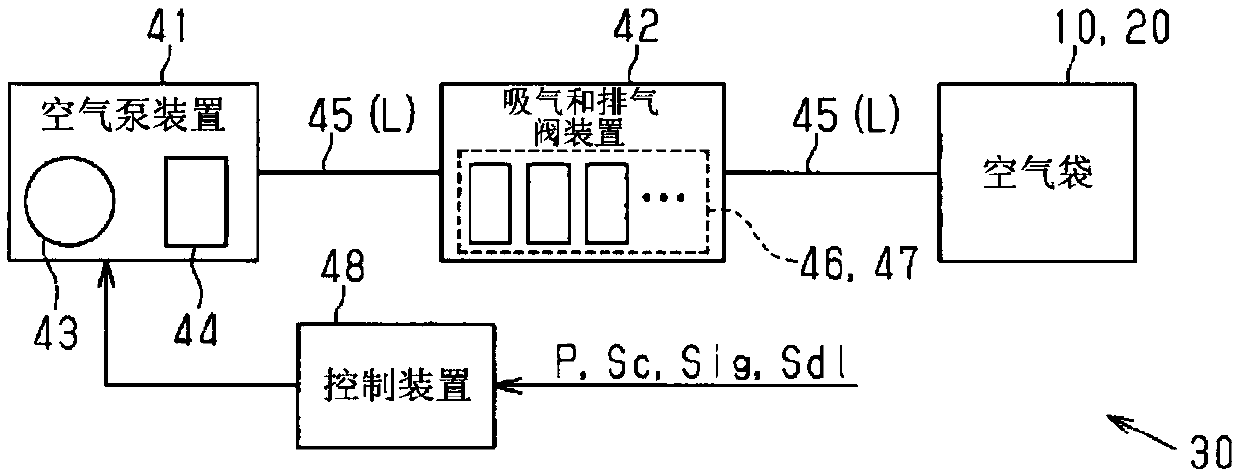

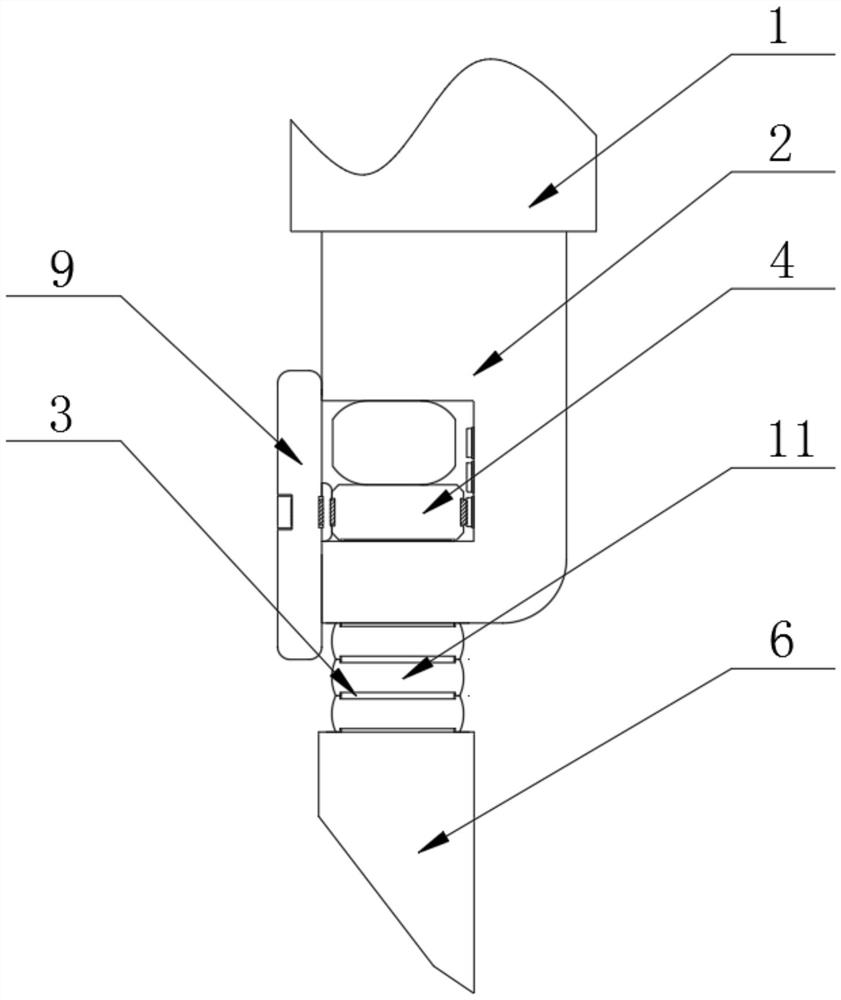

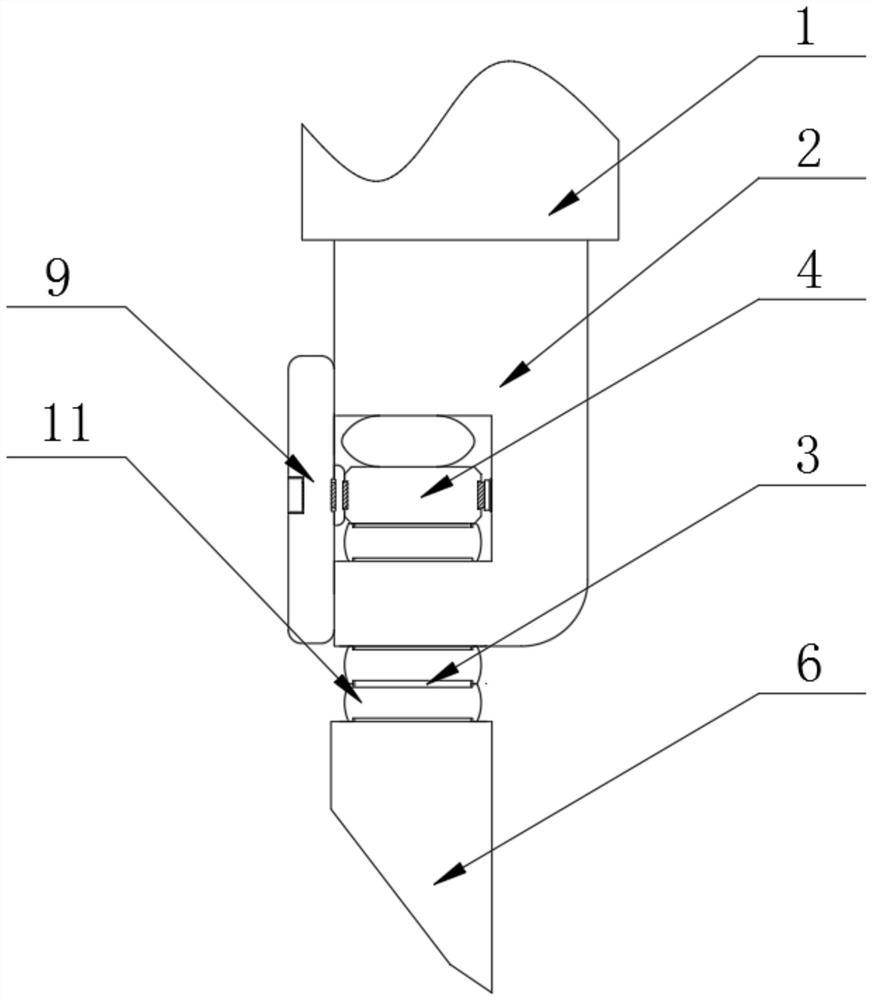

Air pump device and seat device

InactiveCN109563823AGood loadabilityImprove mute effectVehicle seatsPositive displacement pump componentsAir pumpEngineering

This air pump device is provided with: an electric pump unit including a pump mechanism and a motor; a case; and a vibration-proof member. The pump mechanism and the motor are arranged side by side inthe axial direction of the motor. The pump mechanism has an inlet and an outlet at an end in the axial direction on the opposite side of the motor. The case has a first wall and a second wall which are located on opposite sides in the axial direction of the motor and which face the electric pump unit. The vibration-proof member is provided with: a first axial vibration-proof unit interposed between the electric pump unit and the first wall; and a second axial vibration-proof unit interposed between the electric pump unit and the second wall. The first axial vibration-proof unit covers the inlet.

Owner:AISIN SEIKI KK +1

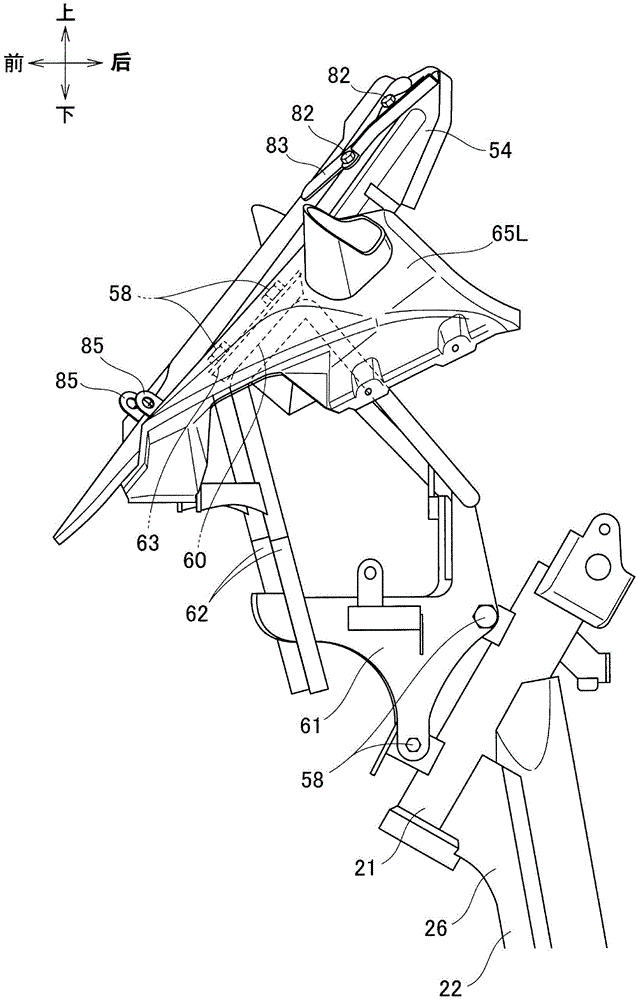

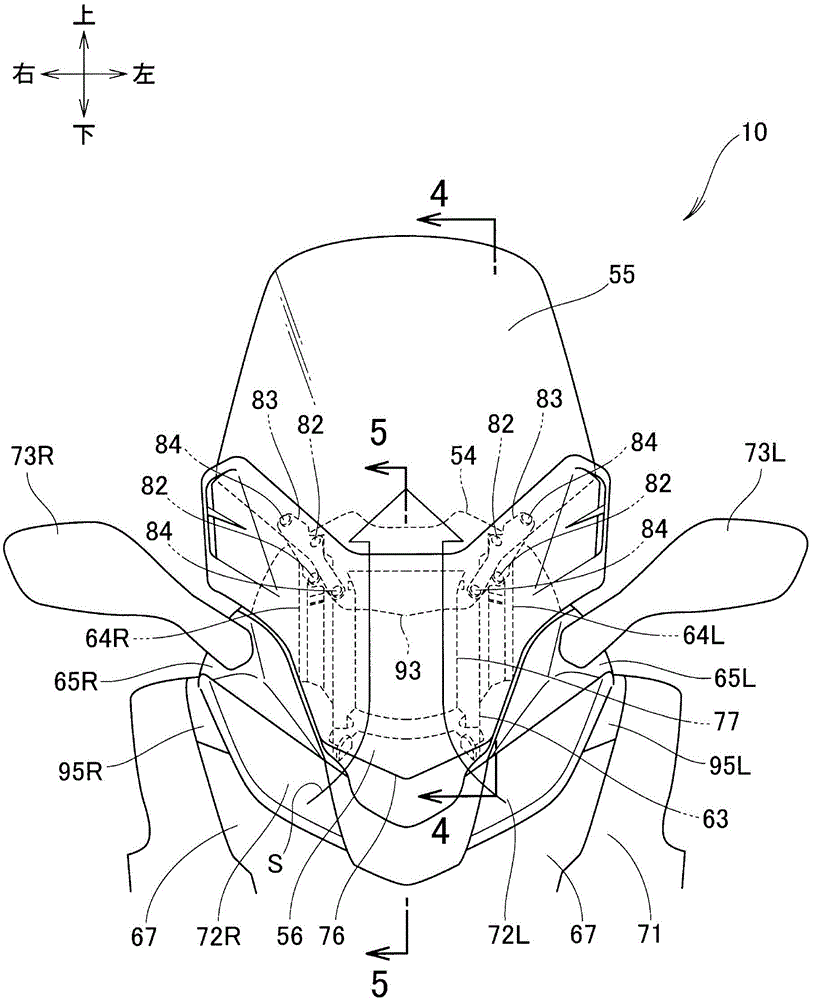

Brake control apparatus for bar-handle-type vehicle

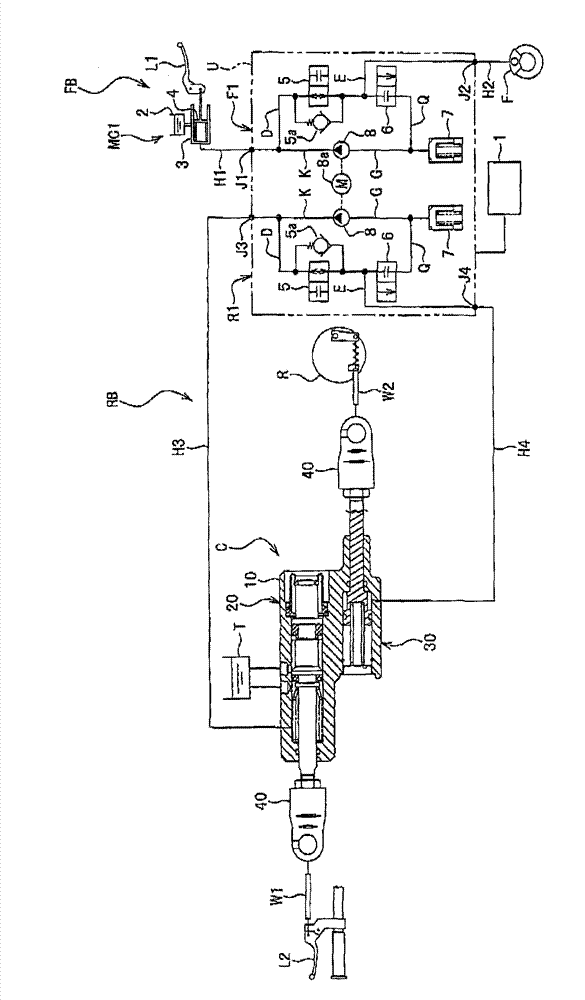

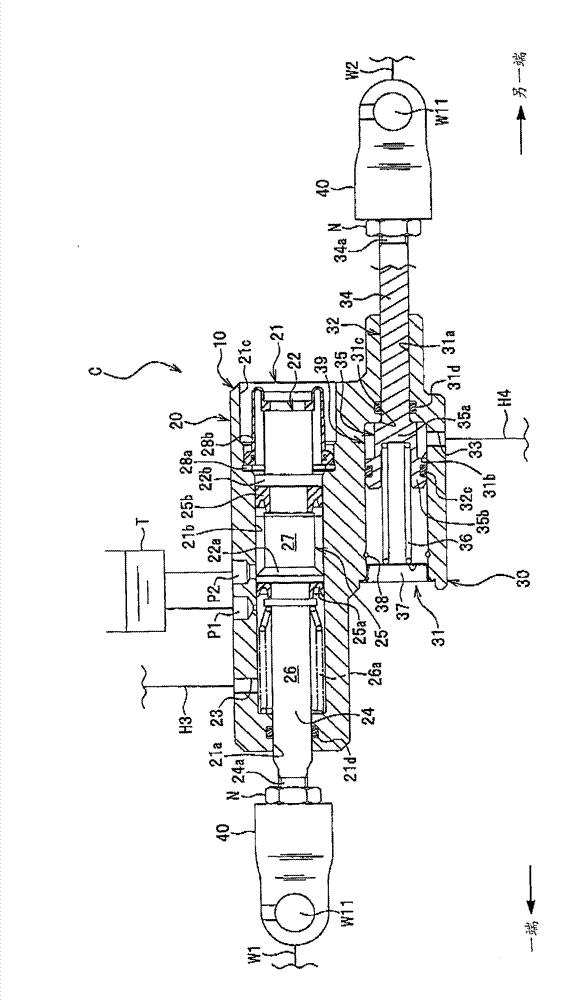

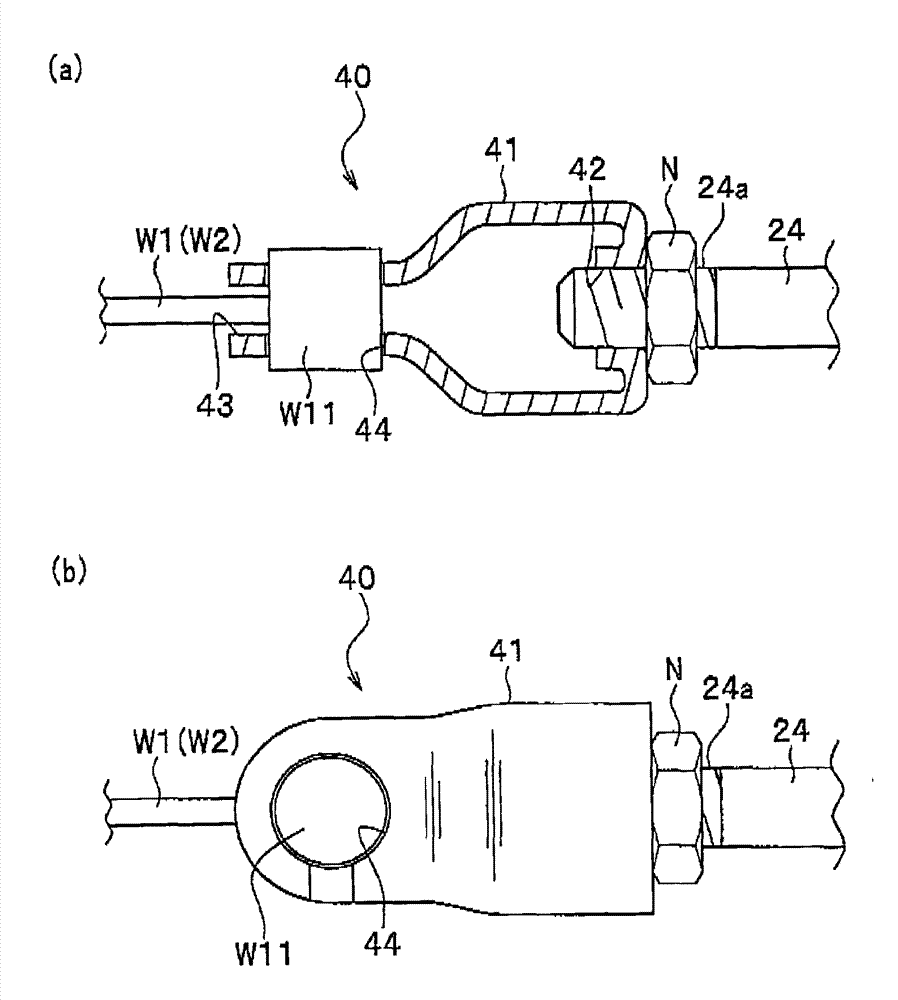

ActiveCN103171730ADoes not damage the designExcellent application versatilityFluid braking transmissionCycle brakesMaster cylinderCoupling

According to the invention there is provided a brake control apparatus for a bar-handle-type vehicle, which does not affect the design around a bar-handle while can be put on the bar-handle-type vehicle. At least one wheel brake forms a mechanical brake driven and operated by a coupling device (C), the coupling device comprises an operating member coupling device and a wheel brake side coupling device, wherein the operating member coupling device is equipped with a first dragging part dragged by a braking operating member, a primary cylinder unit (20) acting by the driving of the first driving part to generate a hydraulic pressure and provide the hydraulic pressure to a control unit, and the wheel brake side coupling device is equipped with a cylinder unit (30) which acts by utilizing the hydraulic pressure outputted by the control unit and a second dragging part linked with the action of the cylinder unit to drag the mechanical brake. The control unit (U), the braking primary cylinder unit (20) and the cylinder unit (30) are arranged in a vehicle body and beyond the bar-handle.

Owner:HITACHI ASTEMO LTD

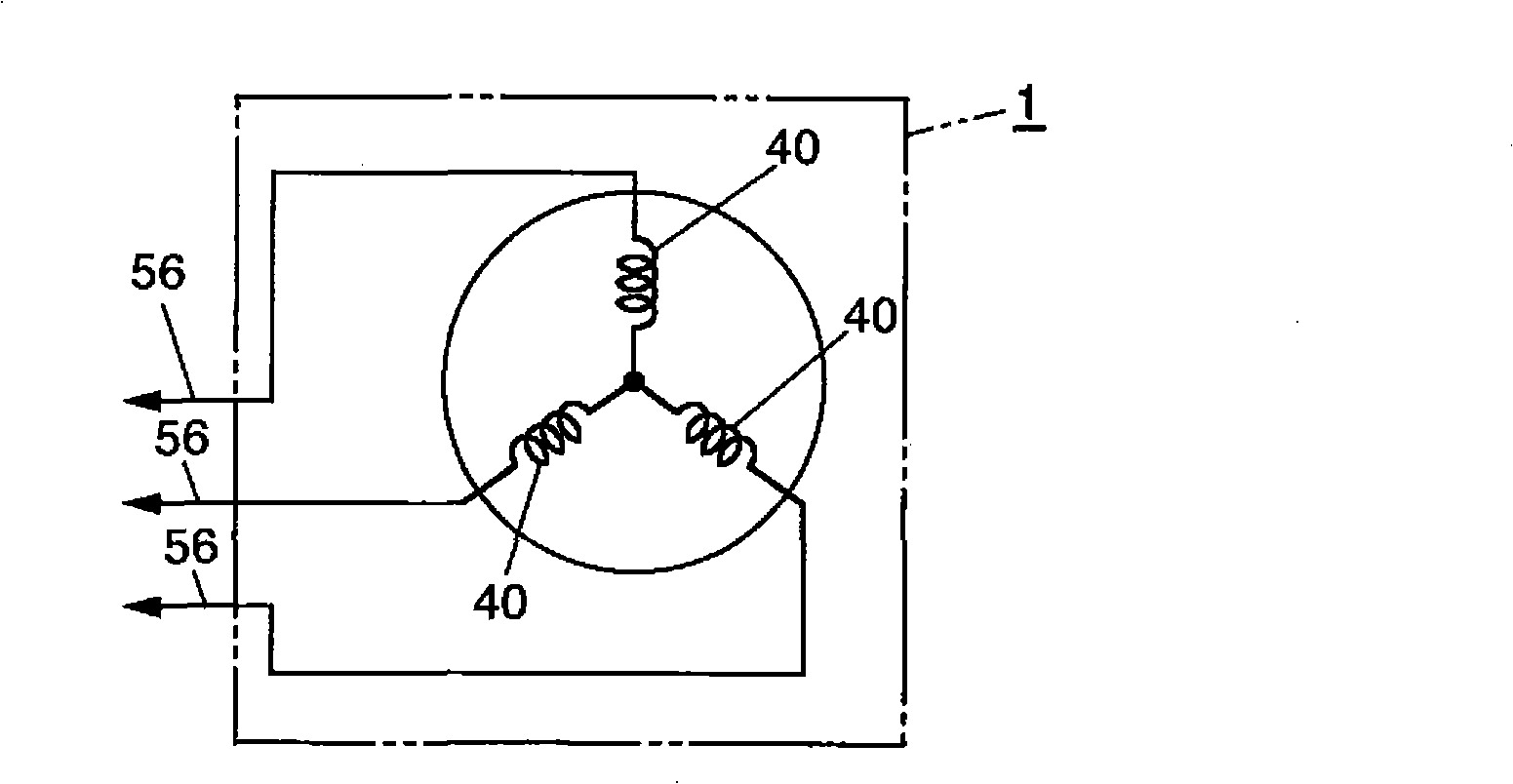

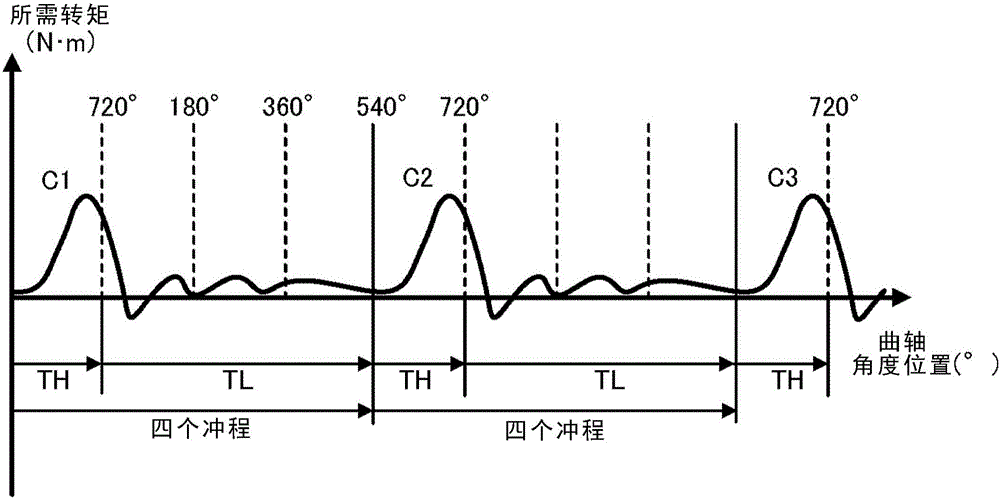

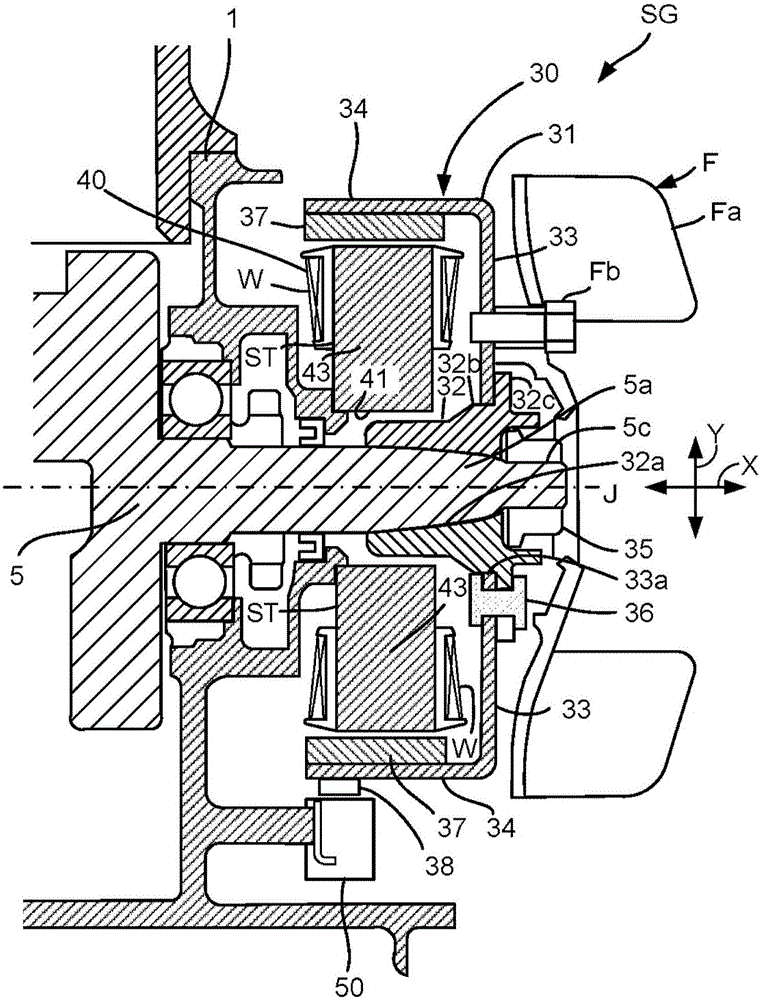

Engine unit and vehicle

ActiveCN105705771AGood loadabilityShorten the timeElectrical controlElectric motor startersBrushless motorsCombustion

The present invention provides an engine unit and the like that has a high-load region and a low-load region, and after a combustion halt instruction, can achieve both a reduction in the time until restarting and mountability to a vehicle. The engine unit is provided with a four-stroke engine body, a three-phase brushless motor, an inverter, and a control device. After the combustion operation of the four-stroke engine body and the positive rotation of a crankshaft have halted, the control device controls a plurality of switching units of the inverter in the state of the combustion operation of the four-stroke engine body and the positive rotation of a crankshaft being halted and there being no input of a startup instruction, and as a result the voltage from the battery imposed on the three-phase brushless motor is controlled, and the crankshaft is caused to rotate in the positive direction from a stopped position until the compression stroke of the four strokes. When there has been the input of a startup instruction, the control device causes the positive rotation of the crankshaft from the position of the crankshaft at the point in time the startup instruction has been input.

Owner:YAMAHA MOTOR CO LTD

Image forming apparatus

InactiveUS8515327B2Prevent evaporationImprove feedabilityElectrographic process apparatusEvaporationImage formation

The invention provides an image forming apparatus capable of preventing a ripple or curling of the sheet and stabilizing feedability or loadability of the sheet. The image forming apparatus includes an aqueous solution applying portion that applies the aqueous solution containing the deliquescent material for hindering evaporation of moisture to the sheet where the toner image has been thermally fixed by the fixing portion, and a controller that controls so that a concentration of the deliquescent material of the aqueous solution applied to the sheet using the aqueous solution applying portion is changed depending on the basis weight of the sheet.

Owner:CANON KK

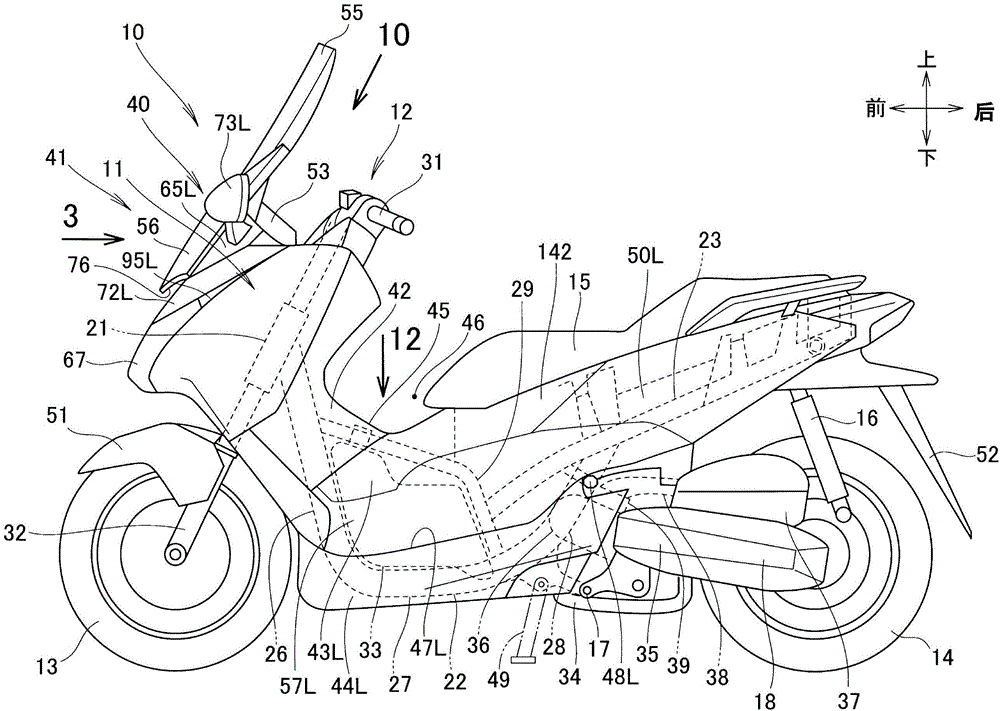

Motorcycle Storage box

ActiveCN104925189AImproved loadabilityIncrease storage spaceWeather guardsMotorcyclesEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

Inductively Coupled Radio Frequency Identification (RFID) Transponder

InactiveUS20120048947A1Cost-effective and simple and flexible to manufactureMechanically robustRecord carriers used with machinesFerrite powderRadio frequency

An RFID transponder comprising a housing for mounting on or in a workpiece having a metallic surface, where the RFID transponder is provided for inductive coupling to an RFID reader, where that side of the RFID transponder which is to face the metallic surface is provided with a ferrite component for guiding the magnetic flux from and to a side of the RFID transponder which is to face away from the metallic surface, and where the ferrite component comprises a composite material composed of a first plastic and ferrite powder and forms a first part of the housing, which is to face the metallic surface. Such an RFID transponder is small and robust and additionally simple to produce.

Owner:SIEMENS AG

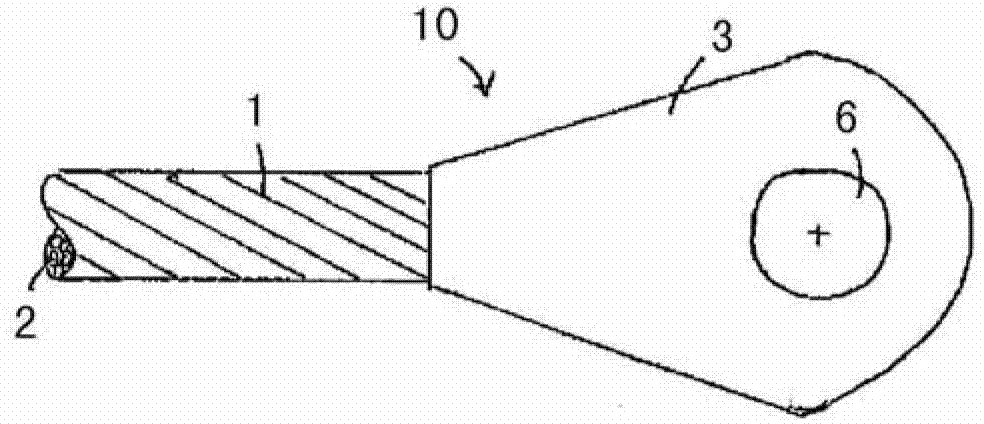

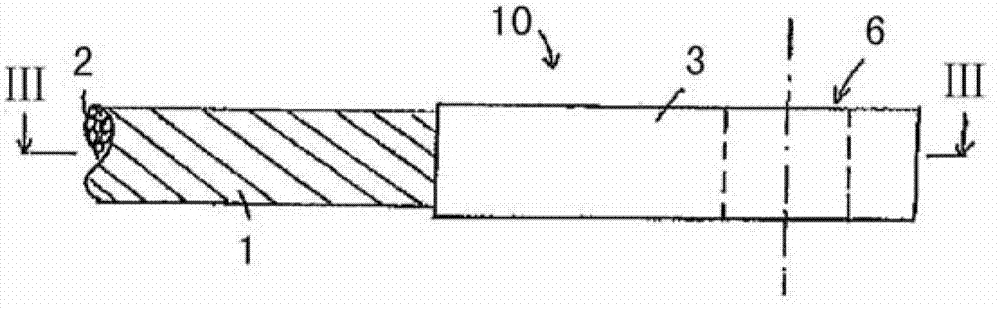

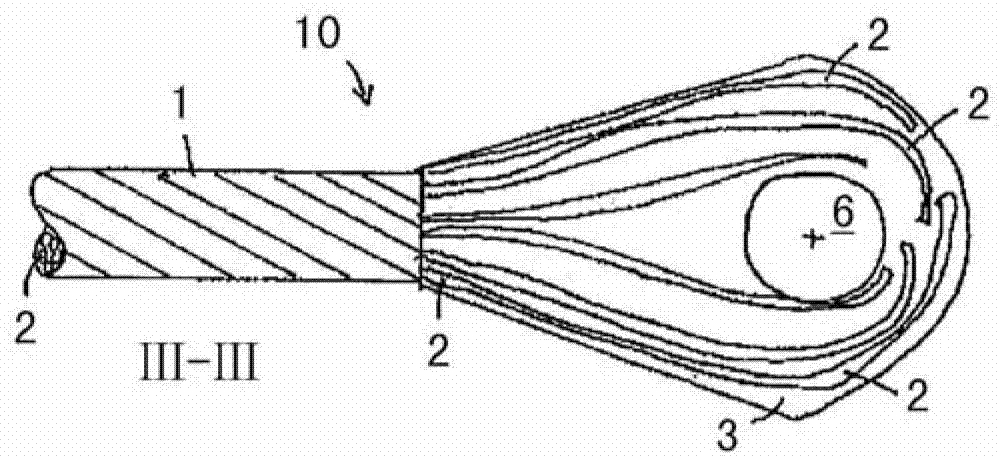

Cable end connection

ActiveCN102893056AHigh strengthIncreased durabilityRopes and cables for vehicles/pulleyHaberdasheryEngineeringInjection moulding

A cable end connection (10) for a cable (1) which is constructed from a plurality of intertwined filaments (2), wherein an end part (3) is provided for installing or supporting the cable (1), said end part being fastened to one end of the cable, wherein the cable end connection is characterized in that the end part (3) is a part which is fitted without a sleeve and is made from a castable, curable material, and in that the end part (3) is connected without additional mechanical connecting elements in a form-fitting manner to the filaments (2) solely by being cast therearound or moulded thereon. The filaments (2) are advantageously fanned out in the material of the end part (3) and are in particular substantially completely embedded therein. The filaments (2) are released from the original stranding assembly in the region of the end part (3) and distributed substantially uniformly. The end part (3) is produced in a casting mould by the injection moulding of synthetic resin, and the filaments (2) are embedded in and cast in a form-fitting manner around the material of the end part (3) under prestress.

Owner:UNIV STUTTGART

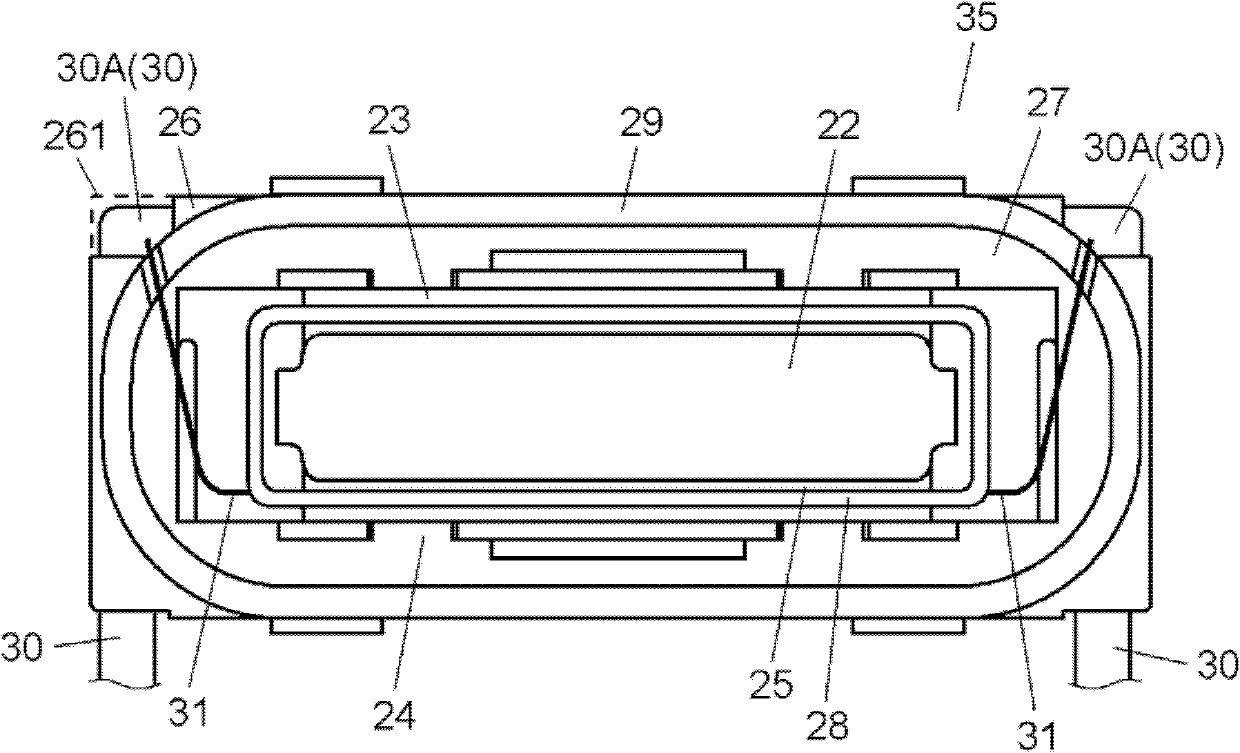

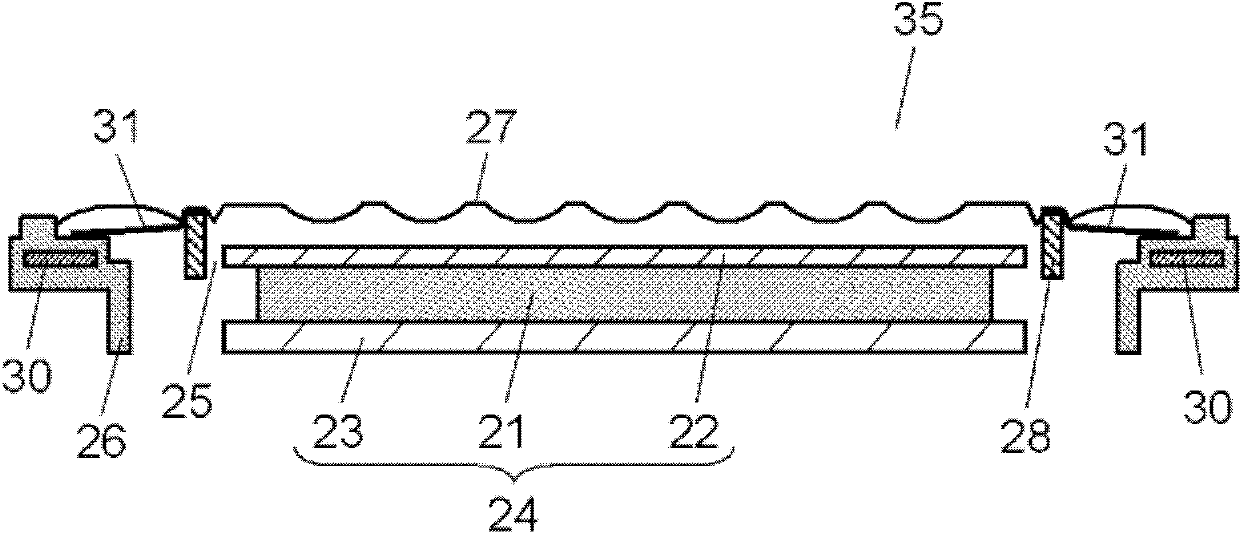

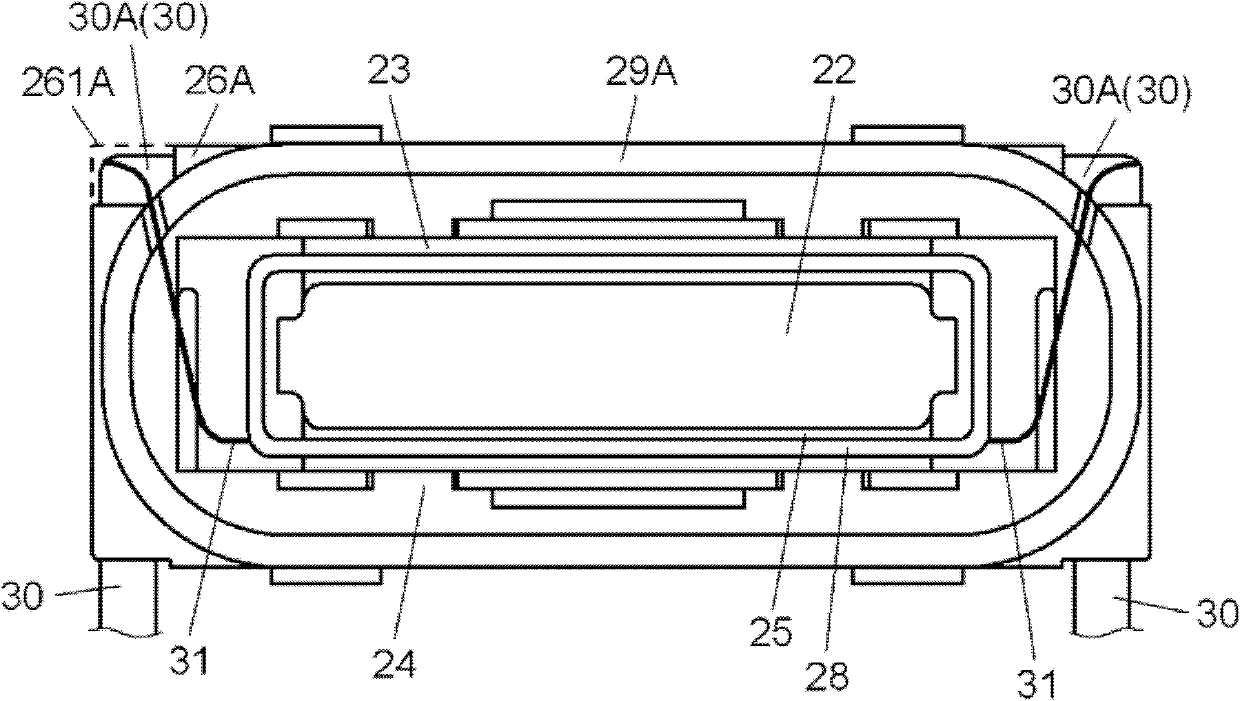

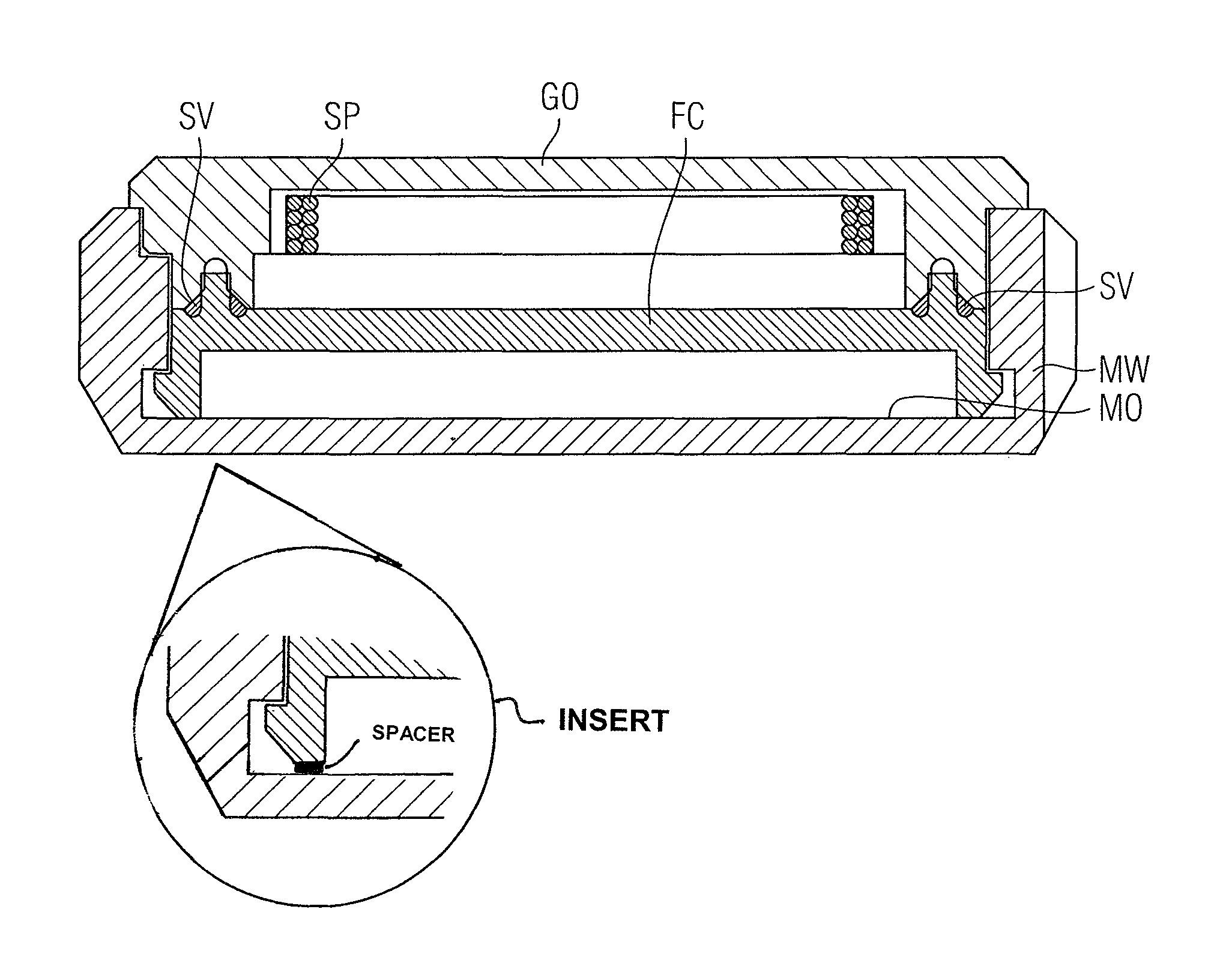

Speaker, and electronic apparatus and cellular phone using the speaker

ActiveCN102598711AThe amount of thinningGood loadabilityNon-planar diaphragms/conesPlane diaphragmsLoudspeakerVoice coil

Disclosed is a speaker having a magnetic circuit, a frame, a diaphragm, a voice coil, and a terminal. The frame has an opening, is connected to the magnetic circuit, and includes a resin portion. The diaphragm is connected to the circumferential edge of the opening of the frame. The voice coil has a lead line, is connected to the diaphragm, and has a part of the voice coil disposed in the magnetic gap of the magnetic circuit. The terminal is connected to the frame by means of insert molding. The outer shape configured by means of the frame and the terminal is rectangular or square, and chipped sections are provided at the corners of the outer shape of the resin portion of the frame. The terminal has a protruding portion that protrudes from each chipped section, and the lead line of the voice coil is connected to the protruding portion.

Owner:PANASONIC CORP

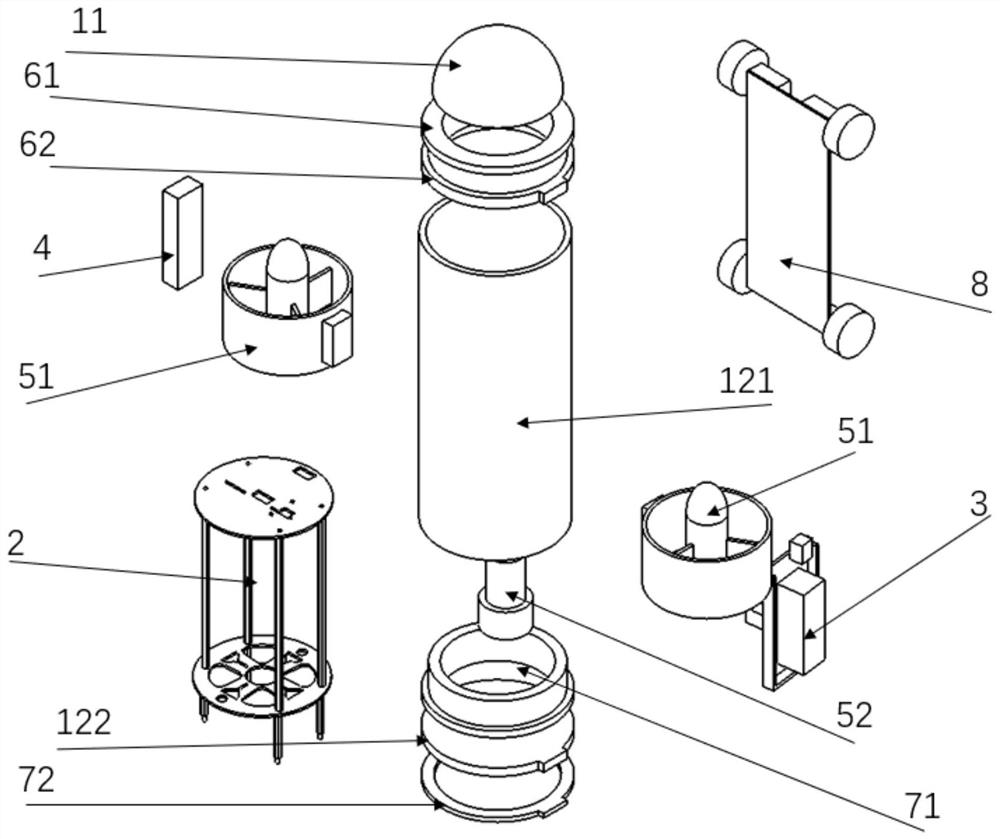

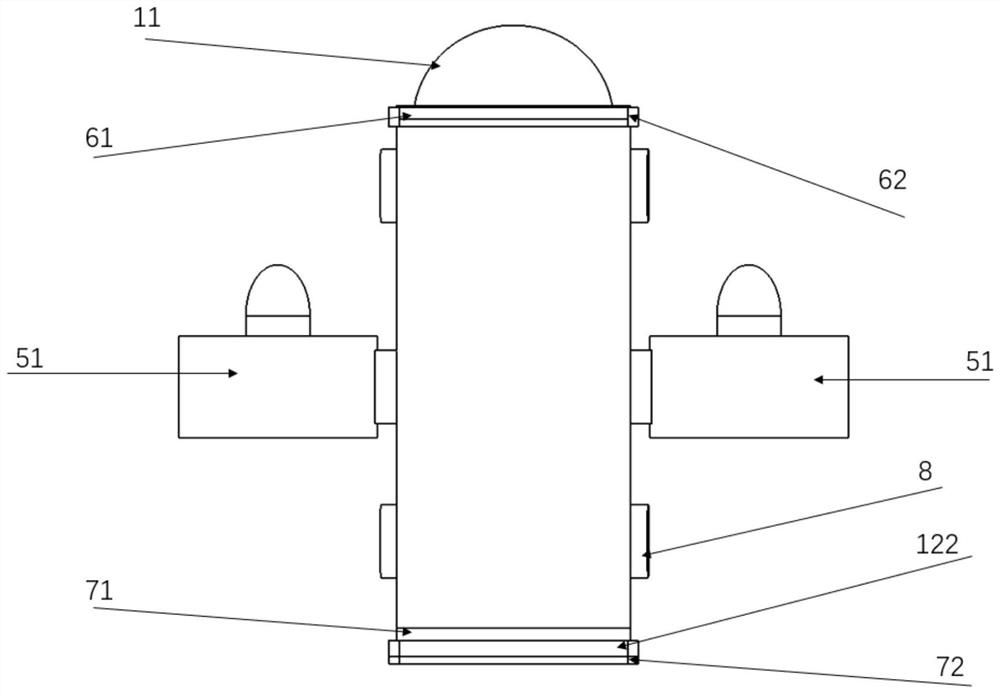

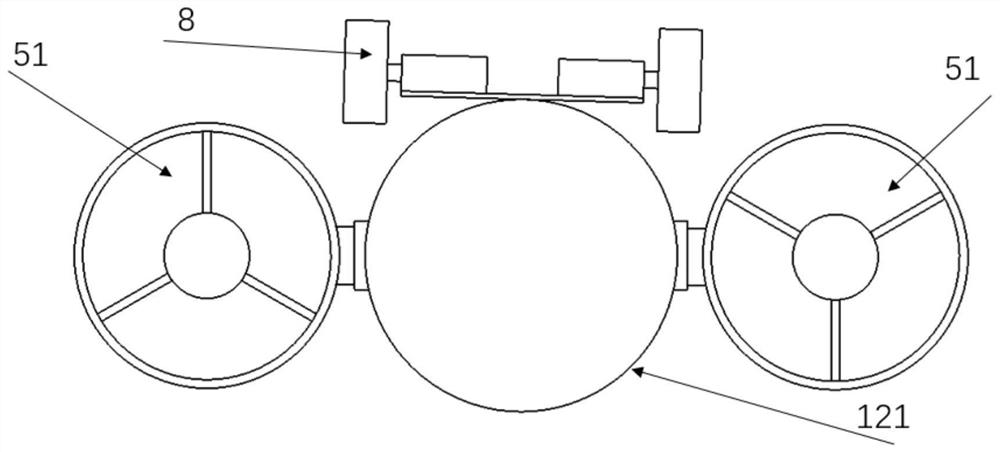

Benthic floating hybrid underwater mobile detection platform and detection method thereof

PendingCN113189670ACompact structureHighly integratedGeological measurementsUnderwater equipmentPropellerMechanical engineering

The invention relates to a benthic floating hybrid underwater mobile detection platform and a detection method thereof in the technical field of ocean robots. The benthic floating hybrid underwater mobile detection platform comprises a pressure-resistant cabin, a controller, a power supply and a driving mechanism, the pressure-resistant cabin comprises a cone section and a cylinder section, the cone section is hermetically connected with the cylinder section, a heavy frame is fixed in the cylinder section, and the controller and the power supply are mounted in the cylinder section; the driving mechanism comprises propellers, a pumping and draining pump and a gravity bag, the propellers are symmetrically installed on the side face of the cylinder section, the gravity bag is fixed in the cylinder section, one end of the pumping and draining pump enters the cylinder section and communicates with the gravity bag, and the other end of the pumping and draining pump is located outside the cylinder section; the controller is electrically connected with the power supply, the propellers are electrically connected with the controller and the power supply, and the pumping and draining pump is electrically connected with the controller and the power supply. The benthic floating hybrid underwater mobile detection platform is compact in structure, is high in integration level, and is easy to carry, assemble, arrange and recover.

Owner:SHANGHAI JIAO TONG UNIV

Inductively coupled radio frequency identification (RFID) transponder

InactiveUS8387887B2Cost-effective and simple and flexible to manufactureMechanically robustRecord carriers used with machinesFerrite powderEngineering

An RFID transponder comprising a housing for mounting on or in a workpiece having a metallic surface, where the RFID transponder is provided for inductive coupling to an RFID reader, where that side of the RFID transponder which is to face the metallic surface is provided with a ferrite component for guiding the magnetic flux from and to a side of the RFID transponder which is to face away from the metallic surface, and where the ferrite component comprises a composite material composed of a first plastic and ferrite powder and forms a first part of the housing, which is to face the metallic surface. Such an RFID transponder is small and robust and additionally simple to produce.

Owner:SIEMENS AG

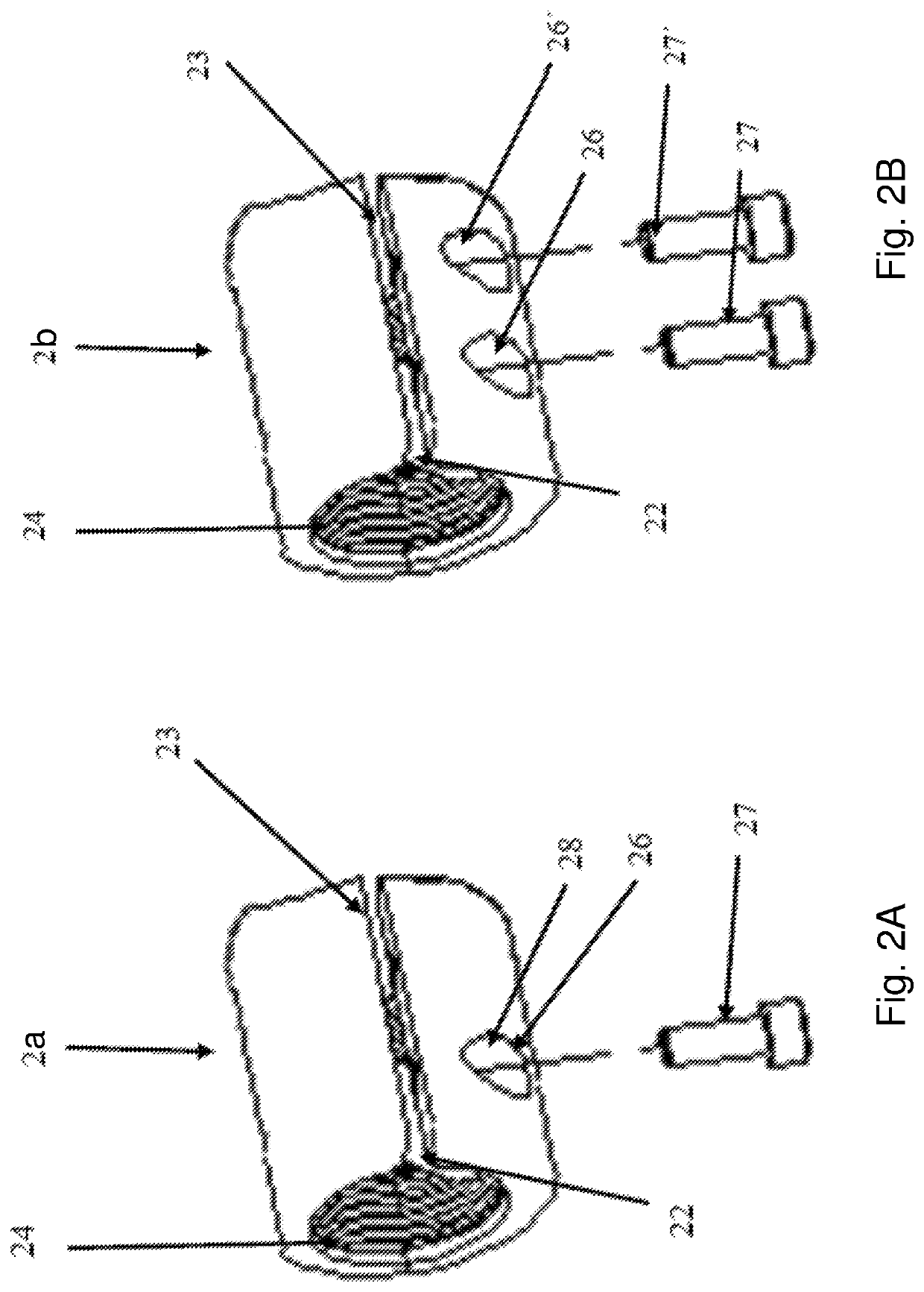

Mounting unit, caster wheel assembly and wheelchair

ActiveUS11331231B2Small sizeReduce weightCastorsWheelchairs/patient conveyanceMating connectionWheelchair

A mounting unit for adjustably mounting an add-on piece to a frame, in particular of a wheelchair, includes at least one drum receiving unit having at least one aperture and female thread. The drum receiving unit is an integral part of the frame or adapted to be attached to the frame. At least one drum assembly has at least one hole and a male thread. At least one bolt is part of the add-on piece or adapted to be mounted therewith to hold the add-on piece. The drum receiving unit is adapted to receive the drum assembly. The female thread mates with the male thread and allows an alignment of the position of the hole with respect to the aperture, such that the bolt can be inserted through the aperture at least partly into the hole. The drum receiving unit with the drum assembly and / or the drum assembly with the bolt comprises a detachable form fit connection. At least one of the drum receiving unit, the drum assembly and / or the bolt comprises a detachable force fit connection with respective mating component.

Owner:SUNRISE MEDICAL (US) LLC

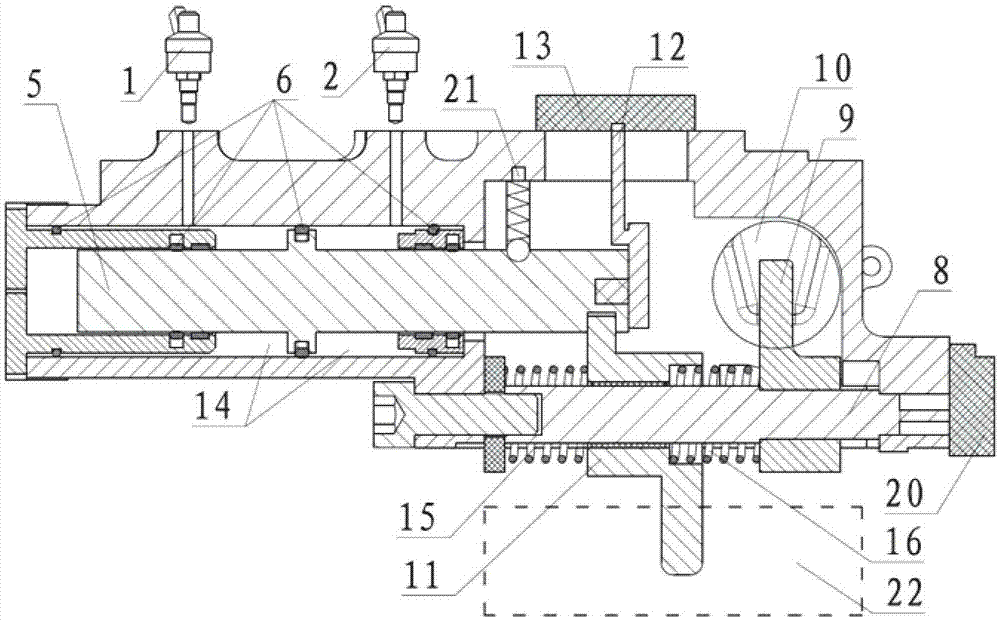

Mechanical automatic transmission selector shift actuator

The invention relates to a gear-selecting and shifting actuating mechanism for an automatic mechanical transmission case and belongs to the field of automobile components. The gear selecting-shifting actuating mechanism comprises a gear-selecting mechanism and a gear-shifting mechanism; a gear-selecting piston is arranged in a gear-selecting operating oil cylinder in the gear-selecting mechanism and is connected with a gear selecting-shifting shifting head in a matching manner; the gear selecting-shifting shifting head is sleeved on a gear-selecting and shifting shaft; gear-shifting piston rods are arranged in a left cylinder and a right cylinder of a gear-shifting operating oil cylinder in the gear-shifting mechanism; a first piston sleeve is arranged in the left cylinder of the gear-shifting operating oil cylinder; a second piston sleeve is arranged in the right cylinder of the gear-shifting operating oil cylinder; the sum of the areas of the left end parts of the gear-shifting piston rods and the working surface of the first piston sleeve in the left cylinder of the operating oil cylinder is equal to that of areas of the right end parts of the gear-shifting piston rods and the working surface of the second piston sleeve in the right cylinder of the operating oil cylinder; the middle bottoms of the gear-shifting piston rods are hinged with a gear-shifting shifting block; and the gear-shifting shifting block is sleeved on the gear-selecting and shifting shaft. The gear-selecting and shifting actuating mechanism has the benefit that the gear-selecting and shifting action can be frequently performed within a short time, so that the operation strength of a driver is greatly reduced.

Owner:DONGFENG MOTOR CORP HUBEI

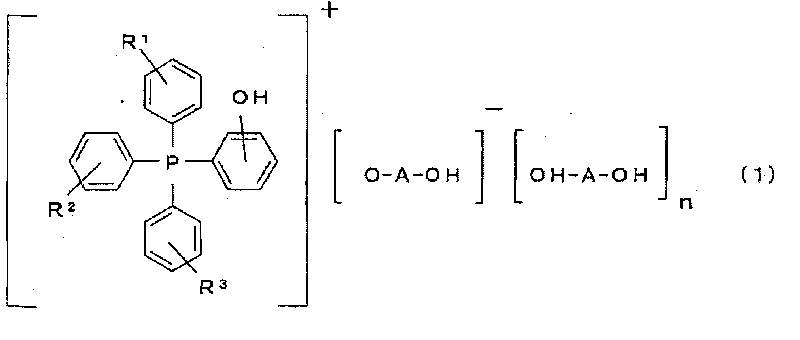

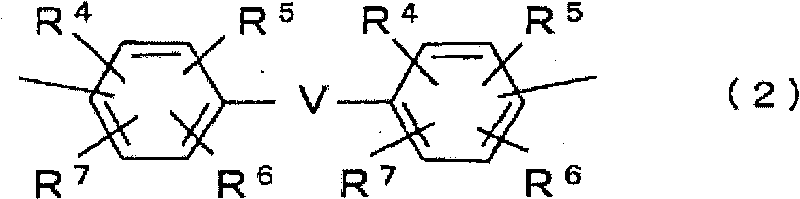

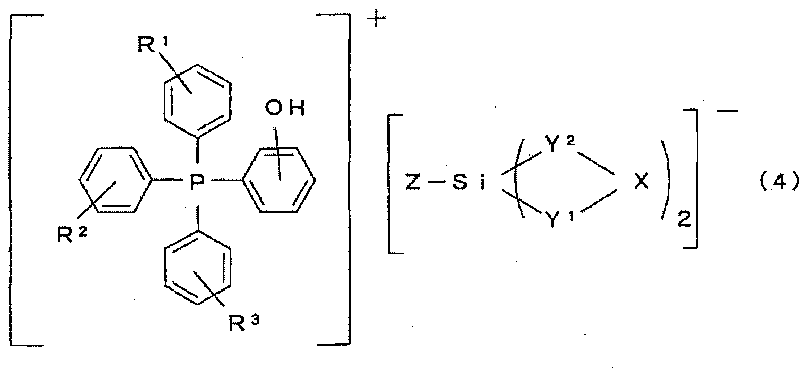

Liquid resin composition for adhesive, semiconductor device, and process for producing semiconductor device

InactiveCN101765646AExcellent continuous printingGood loadabilityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxyAdhesive

A liquid resin composition for adhesives which comprises a solvent (A), an epoxy resin (B) having two or more epoxy groups per molecule, an epoxy resin hardener (C) having two or more phenolic hydroxy groups per molecule, and a hardening accelerator (D). It is characterized in that the epoxy resin (B) and the epoxy resin hardener (C) have dissolved in the solvent (A) and the hardening accelerator (D), in the temperature range of from ordinary temperature to a temperature to be used in vaporizing the solvent (A), is present as particles of a visually observable size in a varnish (W), i.e., a solution of the epoxy resin (B) and the epoxy resin hardener (C) in the solvent (A), and in an adhesive layer obtained by removing the solvent (A) from the varnish (W) by vaporization, and the hardening accelerator (D), in the temperature range of from a temperature higher than that temperature to be used in vaporizing the solvent (A) to a curing temperature, becomes particles of a size not observable visually or dissolves in the adhesive layer. The liquid resin composition for adhesives has excellent suitability for continuous printing. After solvent removal by vaporization, the resin composition has satisfactory suitability for semiconductor element mounting thereon and, despite this, is nontacky at room temperature.

Owner:SUMITOMO BAKELITE CO LTD

Cutting tool with adjustable structure

ActiveCN113182541AImprove mobilityDecreased machinabilityTurning toolsTool bitStructural engineering

The invention discloses a cutting tool with the adjustable structure. The cutting tool comprises a tool apron, wherein a fixing seat is fixedly connected to the surface of the bottom of the tool apron, a cavity is formed in the surface of the fixing seat, an open groove is formed in the bottom of an inner cavity of the fixing seat, and a cross assembly is slidably connected to the surface of a cross groove of an inner cavity of a top cover and an inner cavity of a mounting cylinder; and a cutting tool bit is fixedly connected to the bottom end of the cross assembly. The invention relates to the technical field of cutting tools. According to the cutting tool with the adjustable structure, after a tool breaking accident happens to an existing cutting tool with the adjustable structure, all broken cutting edges can be taken out at the first time, convenient and simple adjustment can be carried out on the premise of adjustment, adjustment of the cutting tool is simpler, mobility is higher, and the cutting tool is more convenient to use. On the premise that the conditions are met, good bearing performance is achieved, the situation that the cutting performance of the cutting tool is reduced due to the fact that too many functions are added is avoided, and people can use the cutting tool conveniently.

Owner:河源市蓝海米克模具刀具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com