Coaxial coupling driving system of double planetary gear systems and double motors

A technology of planetary gear train and coaxial coupling, applied in the field of double planetary gear train dual motor coaxial coupling drive system, can solve the problems of difficult optimization of efficiency, difficult use requirements, high manufacturing cost, etc., to reduce the frequency of combination and separation , realize the synchronous combination of speed and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

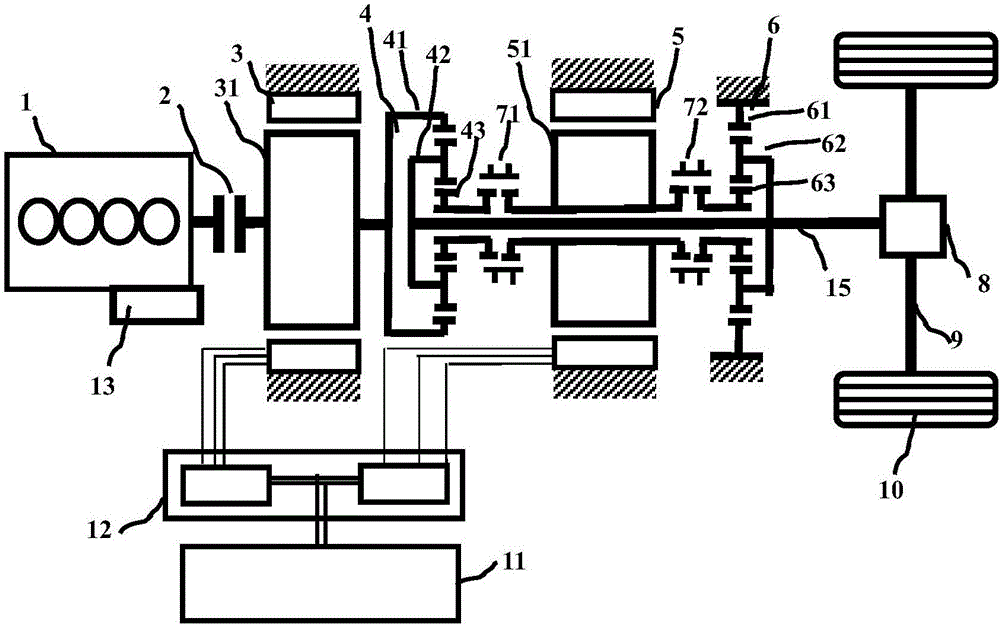

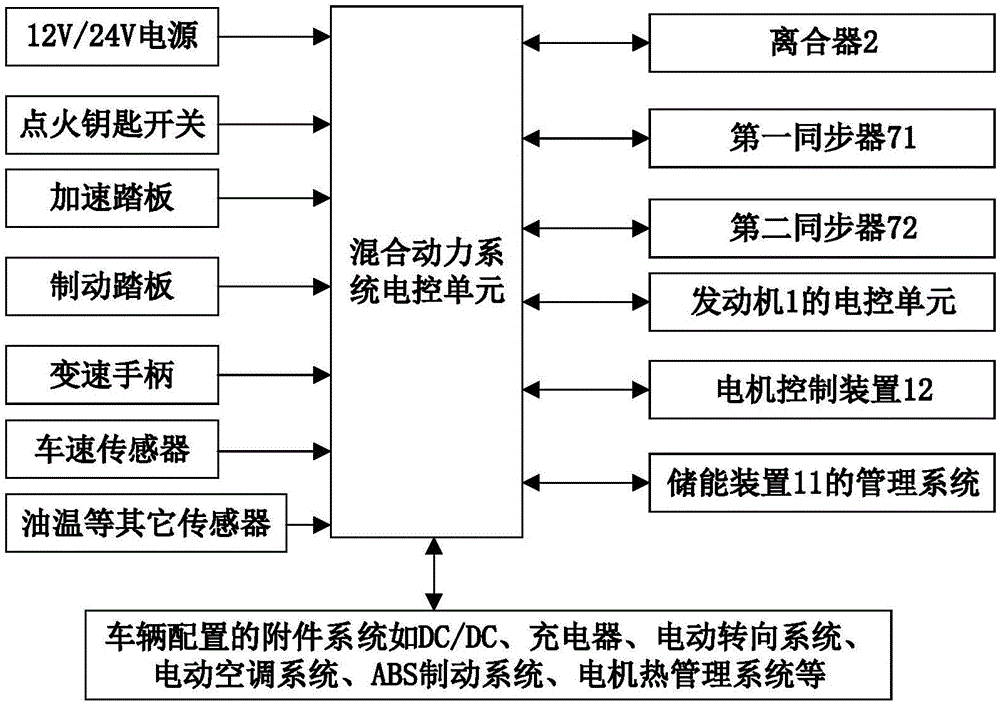

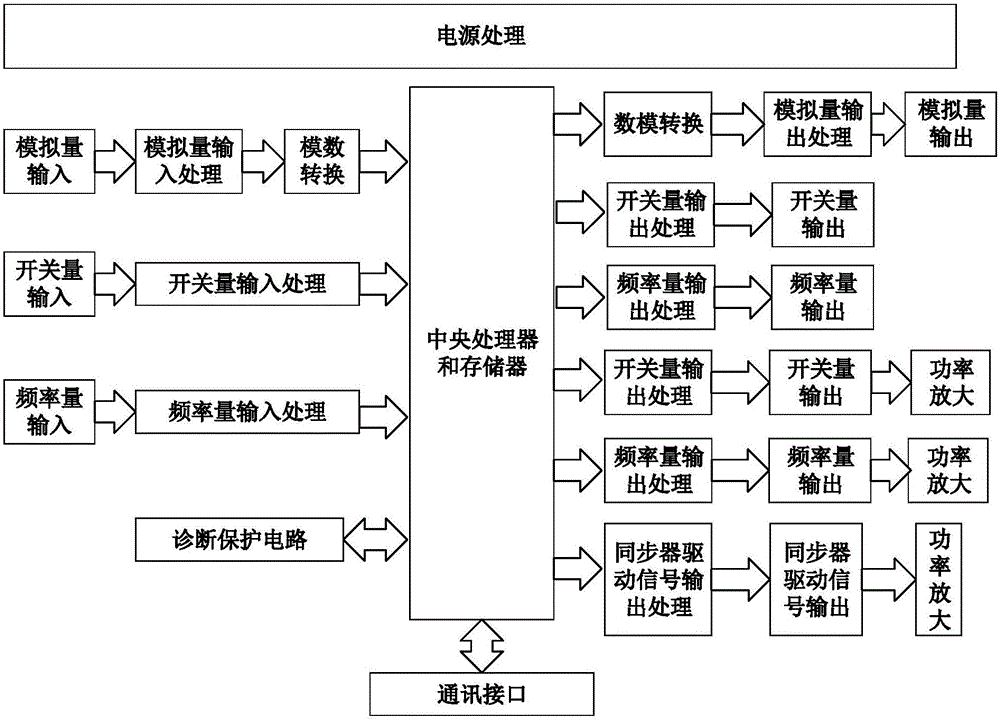

[0065] like figure 1 As shown, the four-mode dual-planetary gear coaxially coupled continuously variable hybrid hybrid drive system (Embodiment 1) of the present invention includes: an engine 1, a clutch 2, a first motor 3, a first planetary gear train 4, a second A synchronizer 71, a second motor 5, a second synchronizer 72, a second planetary gear train 6, an output shaft 15, an energy storage device 11 and a motor control device 12, the first planetary gear train includes an inner ring gear, a planetary gear carrier and sun gear, the second planetary gear train includes an inner ring gear, a planet carrier and a sun gear, the engine 1 is connected with the rotor 31 of the first motor 2 through the clutch 2, and the rotor 31 of the first motor is connected with the first planetary gear The rotor 51 of the second motor is connected to the sun gear 43 of the first planetary gear train through the first synchronizer 71, and the sun gear of the second planetary gear train throug...

Embodiment 2

[0085] like Figure 5 As shown, the second embodiment (five-mode dual-planetary gear train coaxially coupled continuously variable speed hybrid hybrid drive system) is basically the same as the first embodiment, the difference is that the five-mode dual-planetary gear of the second embodiment In order to further realize the direct drive mode of the engine 1, the gear train coaxially coupled continuously variable hybrid drive system further includes a brake locking device 14, and the brake locking device 14 is used for the sun protection of the first planetary gear train 4. The wheel 43 performs control of brake lock and brake lock release, and one end of the brake lock device 14 is connected to the sun gear 43 of the planetary gear train 4 and the other end is connected to the case. The hybrid power system electronic control unit set in the second embodiment, on the basis of the hybrid power system electronic control unit described in the second embodiment, adds a control circ...

Embodiment 3

[0089] like Image 6 As shown, the third embodiment (double-mode double-planetary gear train double-motor coaxially coupled pure electric drive system) is realized by canceling the connection between the engine 1, the clutch 2, and the clutch 2 and the first motor 3 in the first example. of. With the single-motor pure electric drive mode and the dual-motor pure electric drive mode in the first embodiment, the beneficial effects are:

[0090] (1) Avoid long-term high-speed operation of the second motor 5, which can improve the reliability of the system;

[0091] (2) Through the coupling and stepless speed change of the first planetary gear train 4, the overall operating efficiency of the first motor 3 and the second motor 5 can be optimized;

[0092] (3) Due to the automatic switching of the different states of the first synchronizer 71 and the second synchronizer 72, the first motor 1 and the second motor 5 use smaller torques, and can also achieve power performance equivale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com