Flat type brushless electric pump and electric water pump group for vehicle using the same

A brushless motor, flat type technology, applied in electric components, components of pumping devices for elastic fluids, synchronous motors with stationary armatures and rotating magnets, etc., can solve unsolvable space waste, fluid retention , Increase the number of shielding sleeve parts, etc., to achieve the effect of improving the characteristics of the motor, extending the friction coefficient, and reducing the axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Hereinafter, embodiments of the present invention will be described based on the drawings.

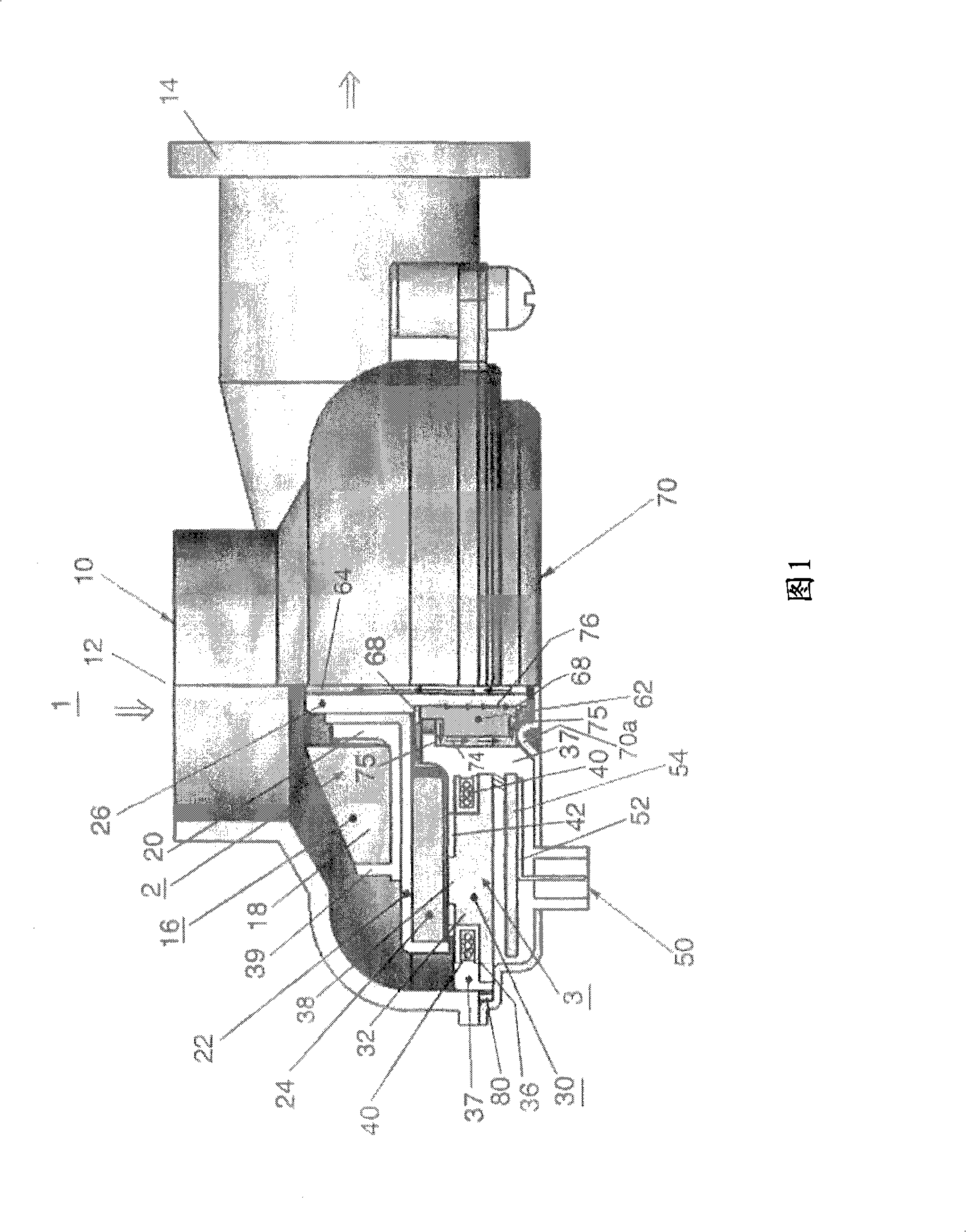

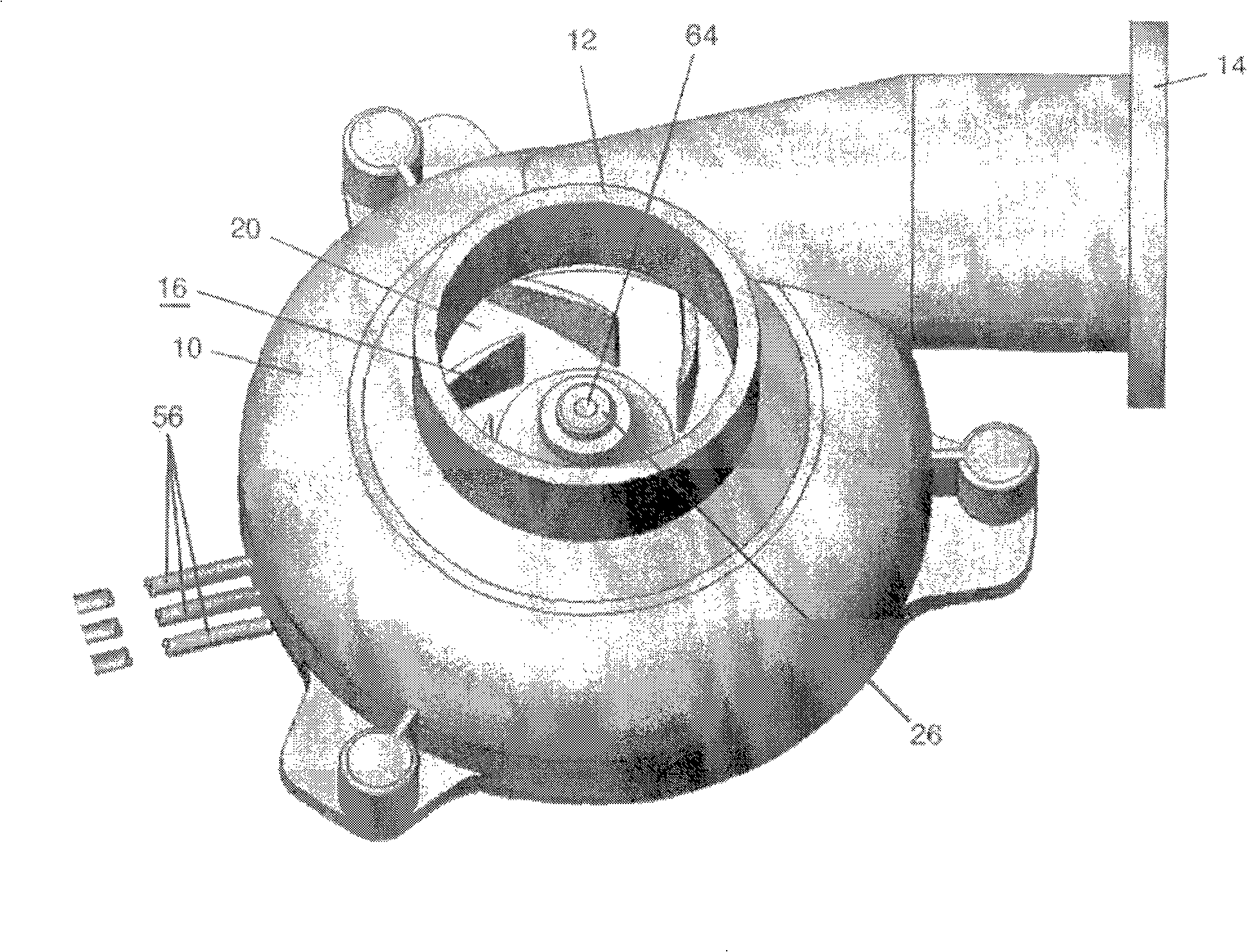

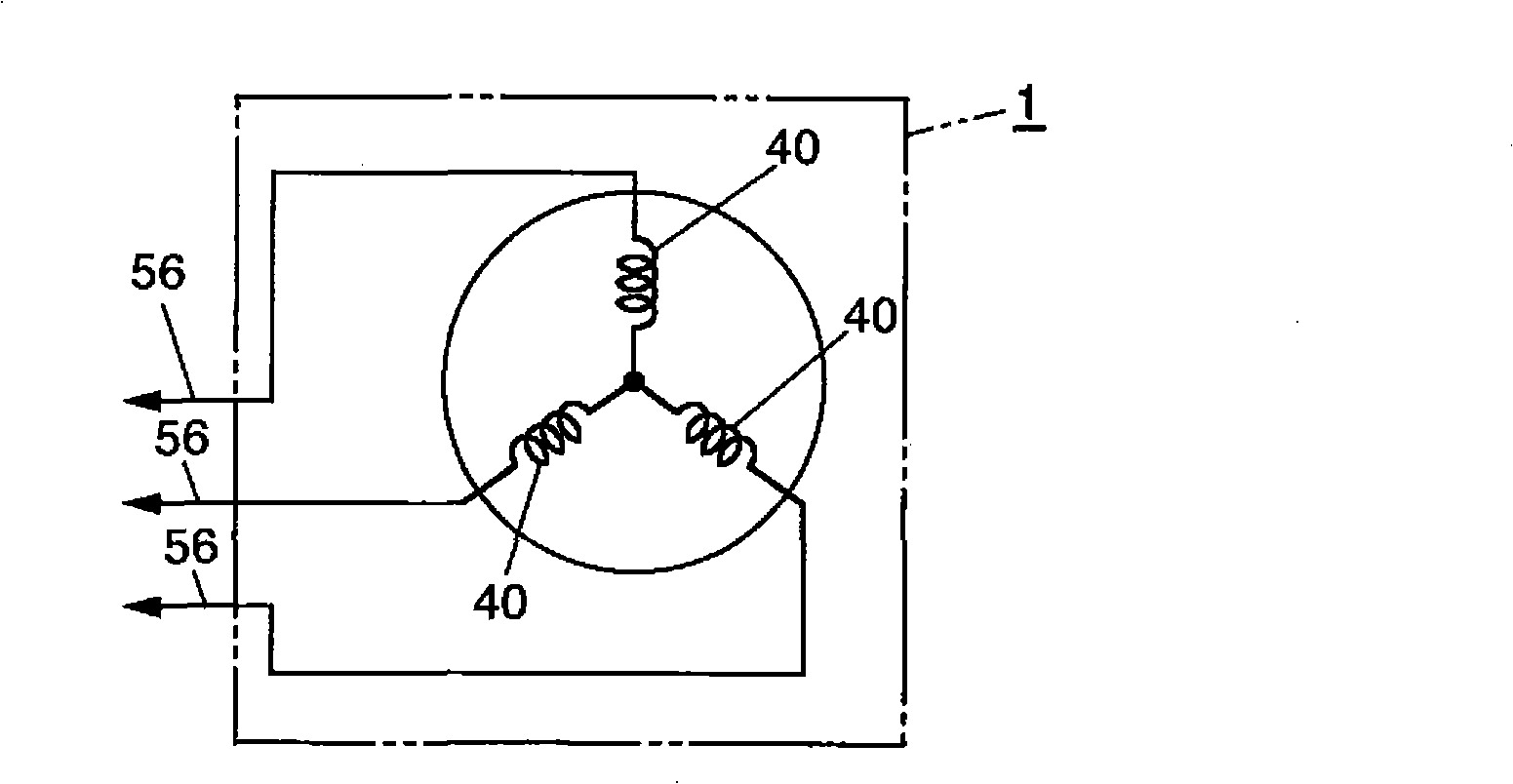

[0052] Fig. 1 is a partial sectional view showing the side of an embodiment of the brushless electric pump of the present invention and its partial internal structure, Figure 2A is the three-dimensional view of its appearance, Figure 2B is its equivalent circuit diagram.

[0053] Reference numeral 10 in FIG. 1 is the housing (pump body) of the brushless electric pump 1, and 12 and 14 are respectively the suction port of the fluid and the discharge port of the fluid provided on the housing 10. By rotating the impeller (blade) 16, The fluid is sucked from the suction port 12 and detoured (flowed) toward the discharge port 14 to be discharged from the discharge port 14 . The impeller 16 is formed by arranging a plurality of plates 18 radially on a bushing 20 , and is fixed to a motor rotor (rotor) yoke 22 to rotate integrally with the rotor yoke 22 .

[0054] The impeller 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com