Twin roller crusher

A technology of roller mill and pulverizer, which is applied in grain processing and other directions, can solve the problems of large final particle size and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

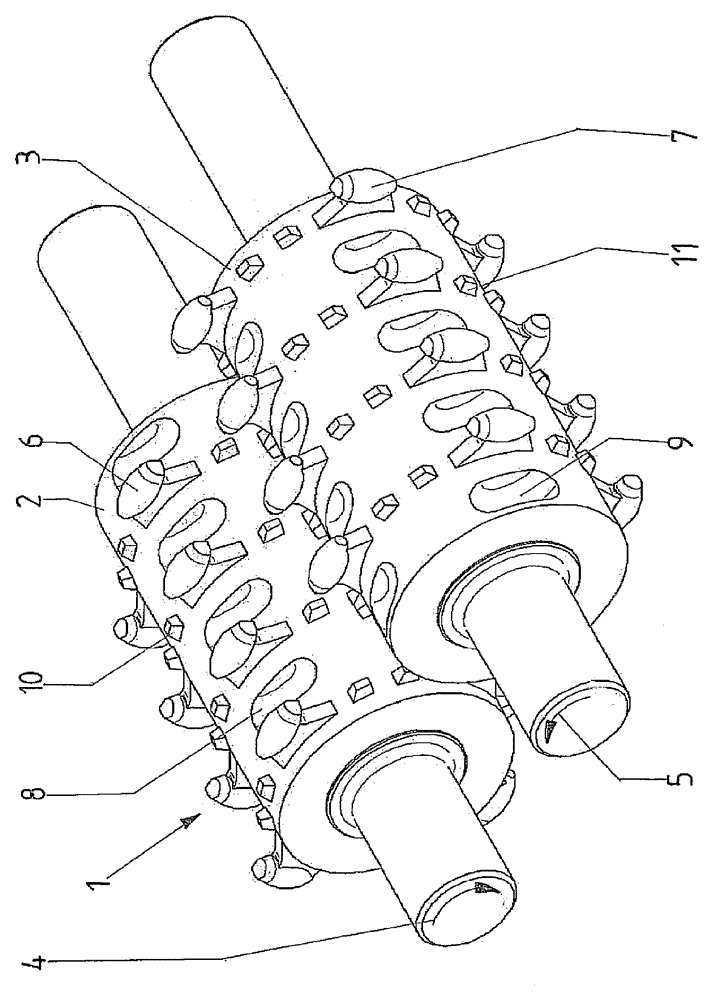

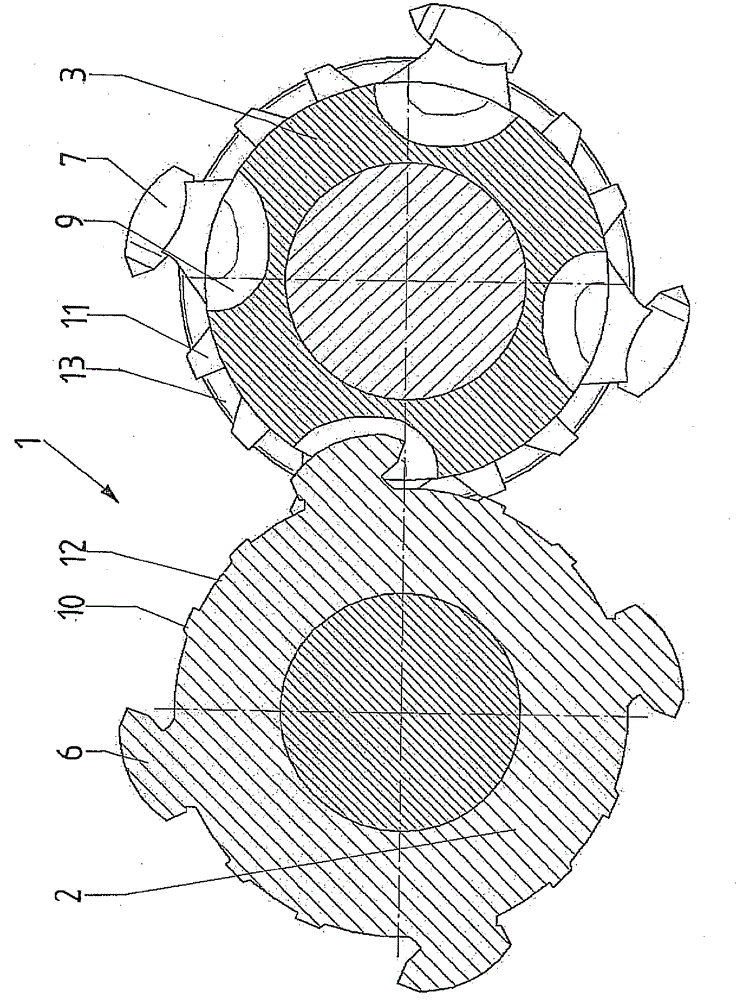

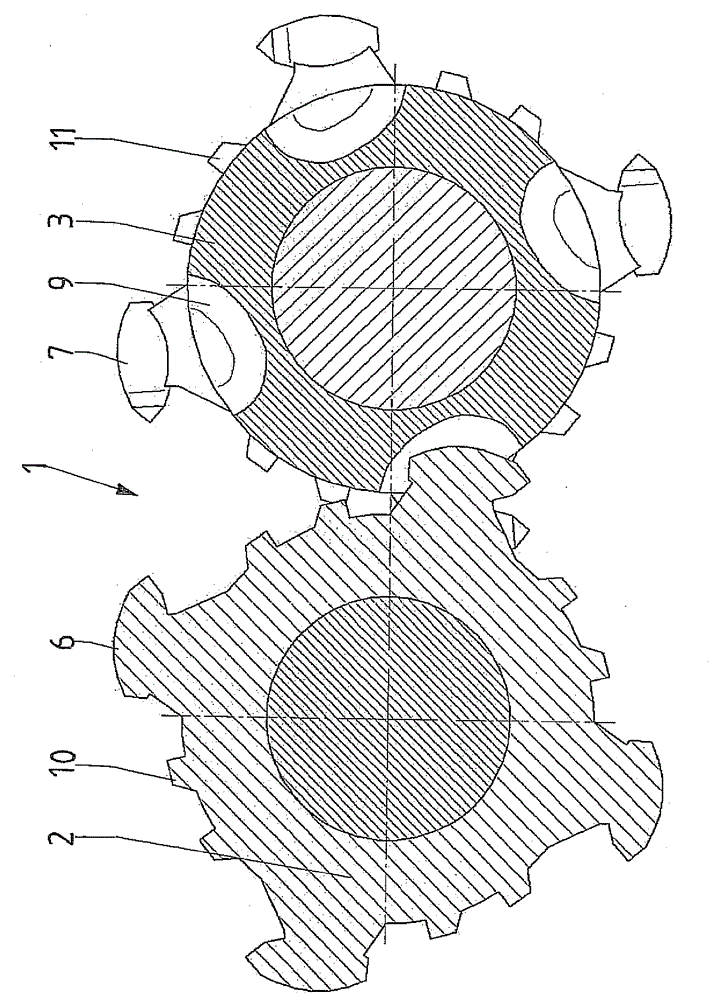

[0026] The elements of the main twin-roll mill 1 of the invention are shown in the drawings. This twin-roller mill has two rotatably mounted rollers 2 , 3 which are synchronously counter-driven by a motor. In this exemplary embodiment, the rollers 2 , 3 have on their end faces shaft ends which are mounted in the respective shredder housing and which correspond synchronously and oppositely to each other by means of a suitable drive in the form of a motor. Movement arrows 4, 5 are driven. The center axes of the two rollers 2 , 3 are aligned parallel to one another. Typically, such twin-roll mills are equipped with horizontally oriented rollers 2, 3, wherein the material to be crushed is brought in and introduced into the roller gap between the rollers 2, 3 from above, while the crushed Material is output from below.

[0027] Arranged on the surrounding surfaces of the rollers 2 , 3 are comminuting teeth 6 , 7 in the form of individual elements, which protrude radially in each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com