Three-dimensional soft tactile sensor array

A tactile sensor, flexible technology, applied in the measurement of the property force of piezoelectric resistance materials, manipulators, manufacturing tools, etc., can solve the problems of high algorithm requirements, long decoupling time, unfavorable real-time force detection, etc., to achieve Ease of use, good adaptability, and reduced decoupling difficulty and time complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

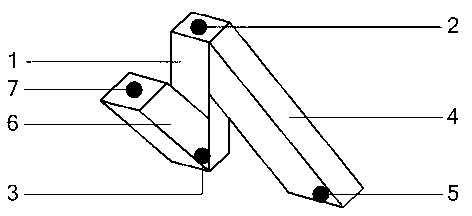

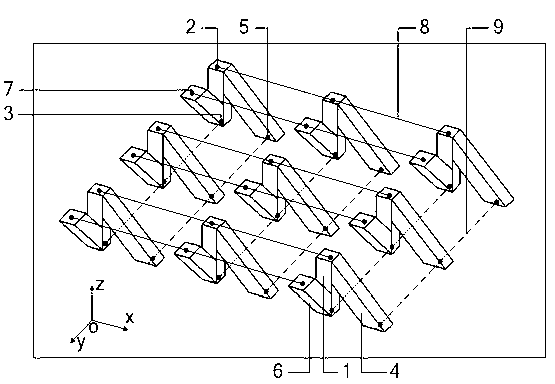

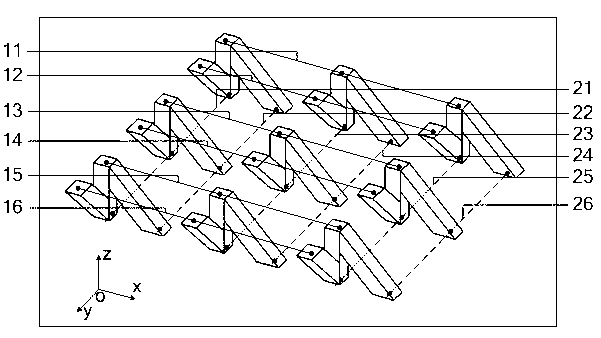

[0016] see figure 1 , the cylinders of this microstructure are all square cylinders, the first section of cylinder 1 is placed vertically, the center of its upper end surface has an electrical contact 2, the center of its lower end surface has an electrical contact 3, and the upper end surface of the second section of cylinder 4 It is inclined at 45° to its axis, and the end face is bonded to the upper part of one side of the first cylindrical body, so that the second cylindrical body 4 intersects with the first cylindrical body 1 to form a 45° connection, and there is an electrical contact 5 in the center of the lower end surface , the lower end surface is on the same plane as the lower end surface of the first columnar body. The lower end surface of the third section of the cylindrical body 6 is inclined at 45° to its axis, and the end surface is bonded to the lower part of the other side of the first section of the cylindrical body, so that the third section of the cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com