Integral pouring molding construction method for reinforced concrete column

A technology of reinforced concrete columns and construction methods, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of heavy weight, long construction period, and many steps in transportation and hoisting and installation, and achieve a simplified on-site construction process and good integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

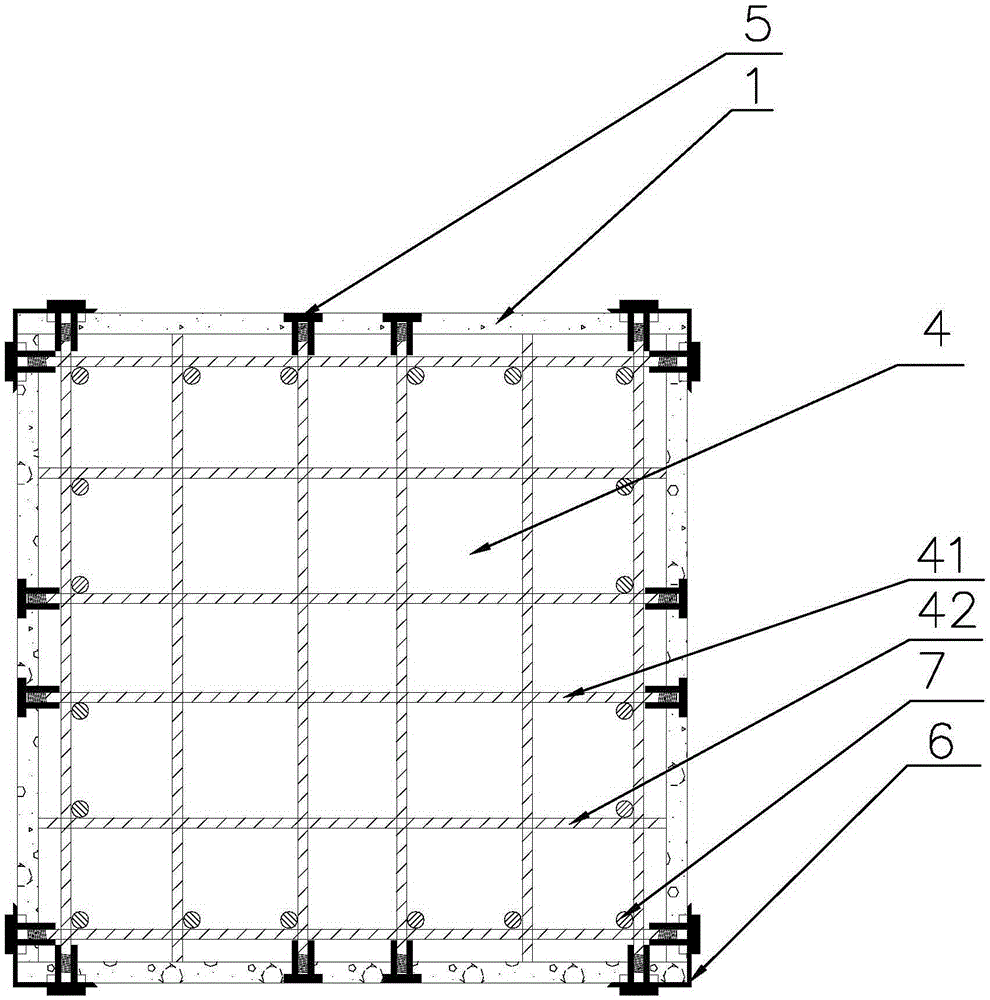

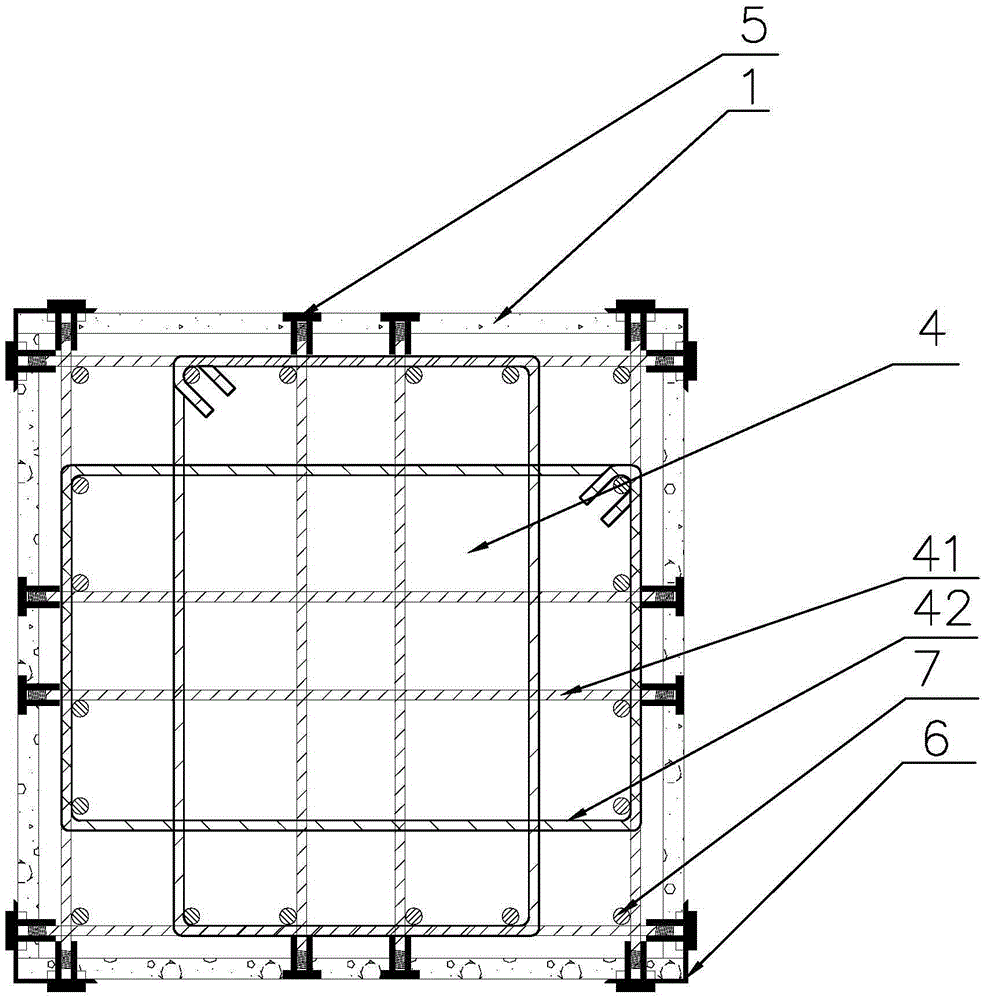

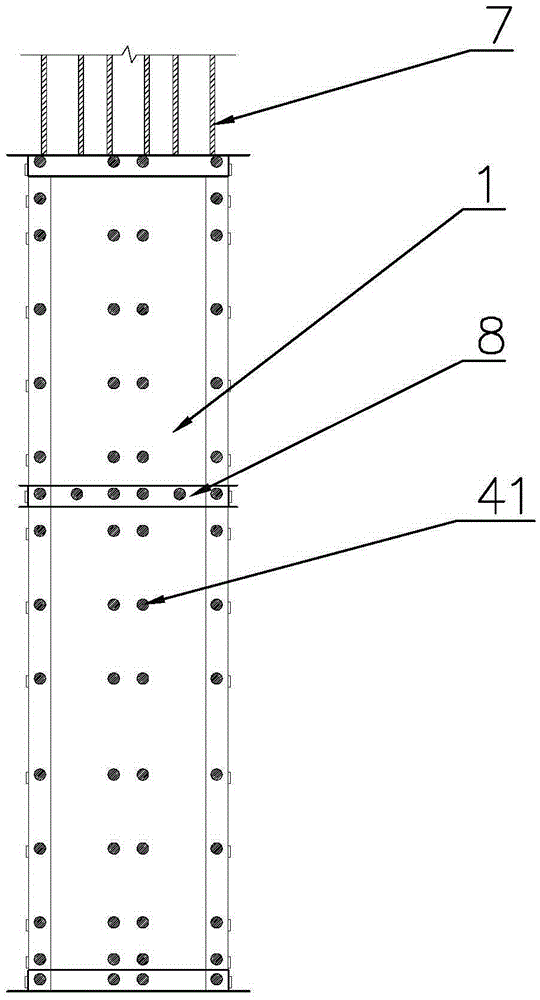

[0031] refer to Figure 1 to Figure 5 , the present invention is a kind of integrated pouring forming construction method of a reinforced concrete column, comprising the following steps:

[0032] 1. Make column reinforcement cage and integral formwork assembly structure;

[0033] a) A number of column reinforcement cages are arranged along the length direction of the concrete column. The vertical reinforcement 7 connects several stirrups 4 arranged parallel to each other along the length direction of the concrete column to form a column reinforcement cage. Each stirrup 4 is provided with two ends protruding outward. And the skeleton steel bar 41 with external thread;

[0034] b) Install a number of templates along the length direction of the concrete column on the periphery of the column reinforcement cage. Each template is fixed through the external thread connection of the nut 5 penetrated from the outside and the skeleton reinforcement 41. The vertical reinforcement 7 of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com