A kind of integrated pouring forming construction method of reinforced concrete shear wall

A technology of reinforced concrete and construction method, which is applied in the construction, building structure, processing of building materials, etc., can solve the problems of complex process, many steps, poor structural mechanical performance and integrity, etc., to simplify the construction process, Overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

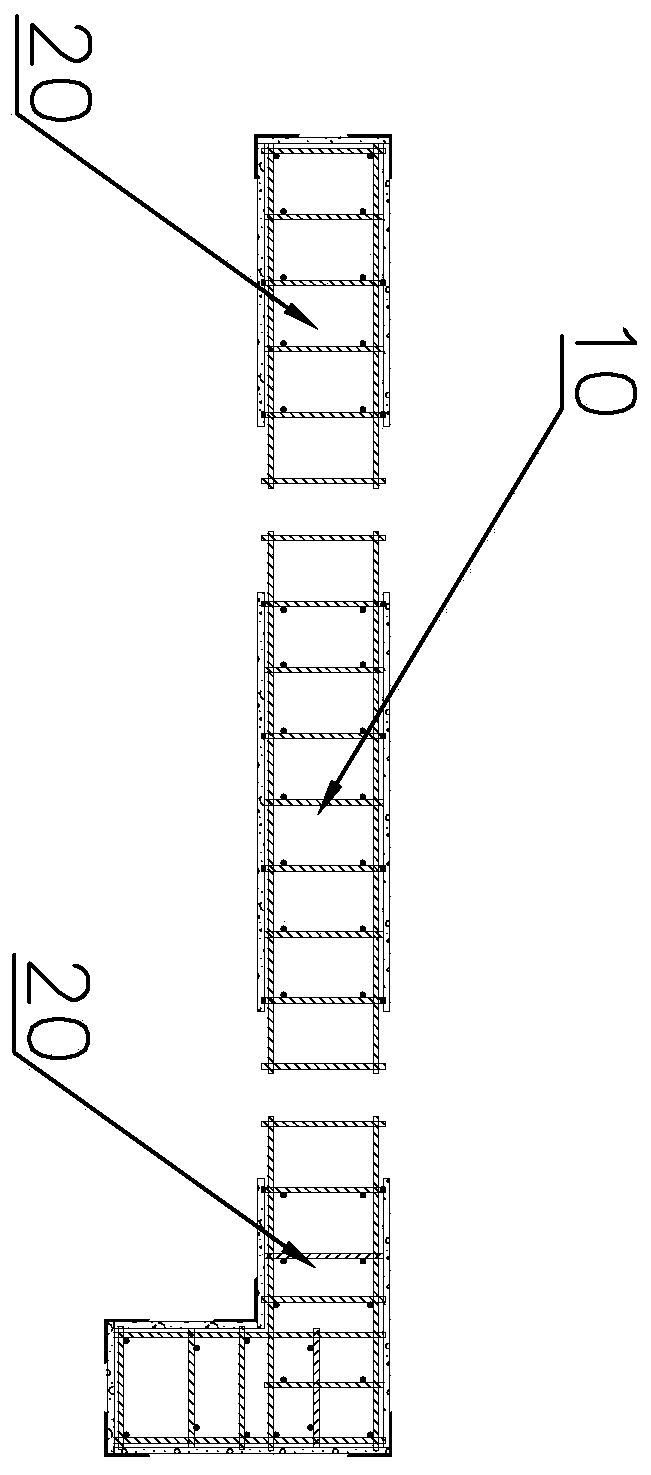

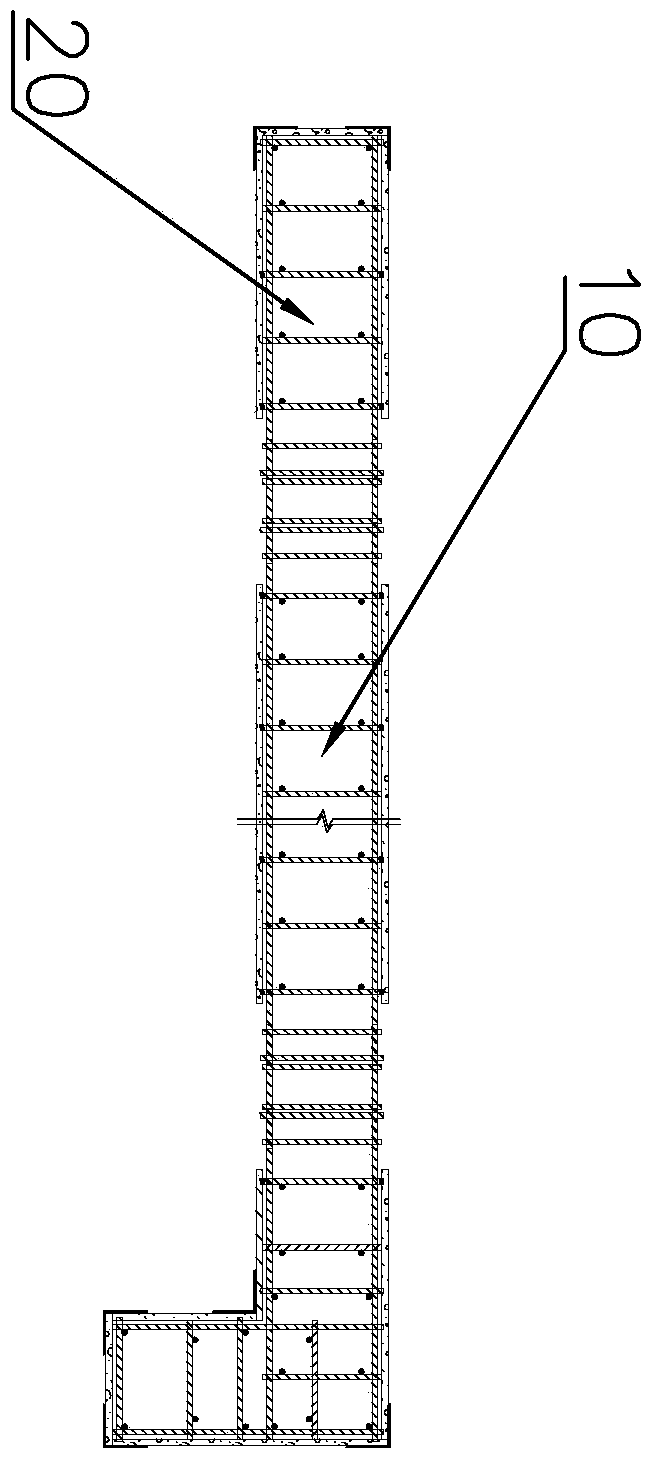

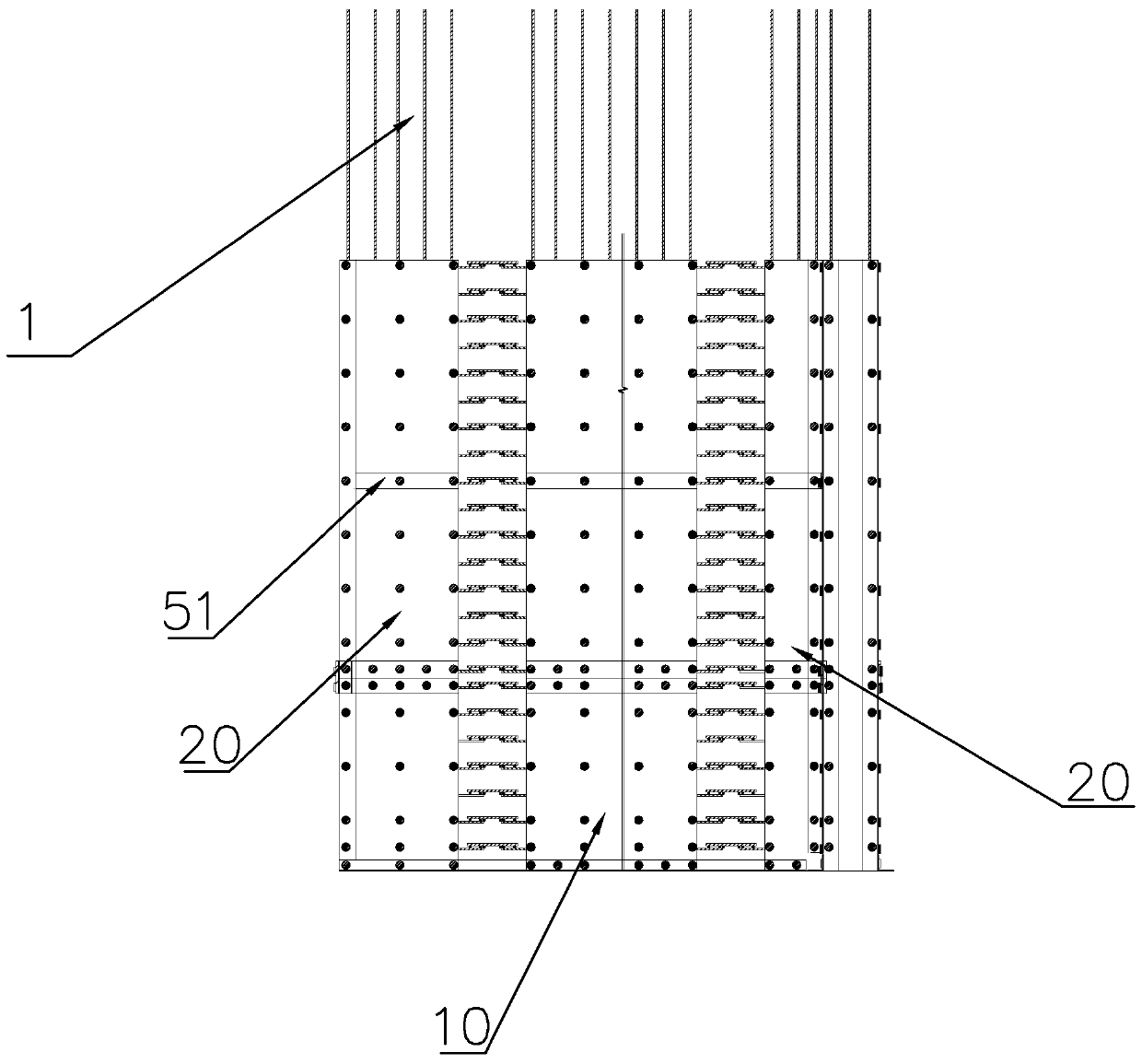

[0038] Refer to 1~ Figure 10 , the present invention is a kind of integral pouring molding construction method of reinforced concrete shear wall, shear wall comprises the wall body section that is positioned at the middle part and the end column section that is positioned at both sides of wall body section, is characterized in that, comprises the following steps:

[0039] 1) A number of reinforcement cage main bars 1 are arranged vertically along the shear wall to connect a number of stirrups 2 arranged parallel to each other vertically along the shear wall to respectively form a reinforcement cage 10 for the wall body section and a reinforcement cage 20 for the end column section. Both ends are provided with skeleton steel bars 22 protruding outward;

[0040] 2), install some templates 3 arranged vertically along the shear wall on both sides and end surfaces of the reinforcement cage 20 of the end column section, and each template 3 is fixed by connecting nuts penetrated fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com