A method for assembling upper and lower interior walls and floor slabs

An assembly method and an interior wall technology, which are applied in the direction of construction and building construction, can solve the problems of lack of effective detection means for the density of grouting materials, waste of steel reinforcement materials, and high cost of grouting materials, so as to avoid the difficulty of effective detection of grouting quality and avoid Difficult installation and reduced wet work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

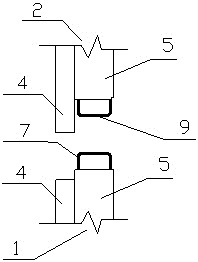

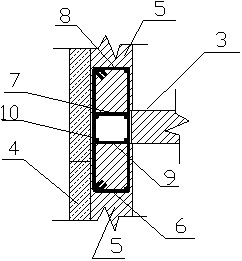

[0071] see figure 1 and figure 2 As shown, the assembly nodes of the exterior wall shear wall and the floor slab in this embodiment include the first shear wall 1 , the second shear wall 2 and the floor slab 3 . Both the first shear wall 1 and the second shear wall 2 include an outer thermal insulation layer 4 and an inner load-bearing layer 5 connected as one, and the bottom side of the thermal insulation layer 4 is longer than the load-bearing layer 5, and the top side is lower than the load-bearing layer 5; the load-bearing layer 5 is provided with steel mesh (not drawn among the figure). The top side and the bottom side of the load-bearing layer 5 are provided with prefabricated connecting beams, and connecting steel bars are arranged in the prefabricated connecting beams. In this embodiment, the connecting steel bars are stirrups; The beam 6 is provided with a first stirrup 7; the bottom side of the load-bearing layer 5 of the second shear wall 2 is a second prefabrica...

Embodiment 2

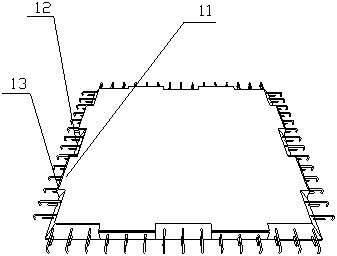

[0078] refer to Figure 5 As shown, the assembly nodes of the exterior wall shear wall and the floor slab in this embodiment include the first shear wall 1, the second shear wall 2 and the floor 3, and the first shear wall 1 and the second shear wall 2 are both Including insulation layer 4 and load-bearing layer 5; insulation layer 4 and load-bearing layer 5 are connected into one body, insulation layer 4 is a fiber cement insulation board, the two sides are wider than load-bearing layer 5, the lower part is longer than load-bearing layer 5, and the upper part is lower than load-bearing layer 5 . The load-bearing layer 5 is provided with a double-sided steel mesh (not marked in the figure), and the double-sided steel mesh is formed by cross-connecting longitudinal rectangular steel rings and vertical rectangular steel rings 14 .

[0079] see Figure 4 The vertical section of the external wall shear wall shows the distribution of vertical rectangular reinforcement rings in the ...

Embodiment 3

[0087] Such as Figure 4 , Figure 7 , Figure 8 As shown, the assembly nodes of the exterior wall shear wall and the floor slab in this embodiment include the first shear wall 1, the second shear wall 2 and the floor slab 3, and the structure of the connection node is roughly the same as that in the second embodiment, the specific difference is that the vertical The positions of the reinforcing bars 10 are different, and the specific description is as follows:

[0088] see Figure 7 As shown, in this embodiment, the longitudinal steel bar 10 is arranged inside the rectangular steel bar anchor ring 15 and is close to the surface of the load-bearing layer 5, that is, the rectangular steel bar protruding from the top side of the load-bearing layer 5 of the first shear wall 1 In the anchor ring 15, two first longitudinal steel bars 19 are arranged close to the surface of the load-bearing layer 5, and in the rectangular reinforcement anchor ring 15 protruding from the bottom si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com