An energy-absorbing connecting structure and an automobile seat connecting structure

A technology that can connect and connect holes, applied in vehicle seats, vehicle parts, transportation and packaging, etc., can solve the problems of no impact force buffering effect, poor connection reliability, etc., to achieve high connection reliability and buffer impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

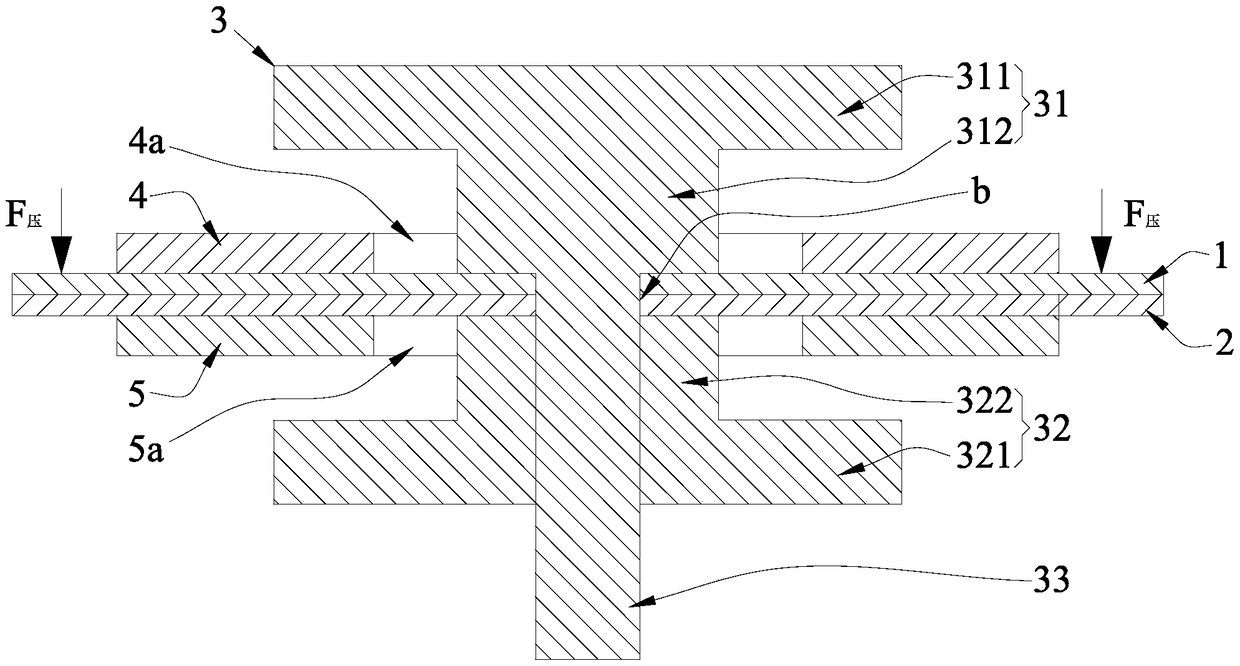

[0046] Such as Figure 1 to Figure 3 As shown, this embodiment one discloses an energy-absorbing connection structure for connecting the first plate 1 and the second plate 2; the energy-absorbing connection structure is provided with a connecting piece 3, which has a first The end head 31 , the second end head 32 and the rod portion 33 connected between the first end head 31 and the second end head 32 .

[0047] The first plate material 1 and the second plate material 2 are respectively provided with a first through hole 1a and a second through hole 2a, and the first plate material 1 and the second plate material 2 are attached so that the first through hole 1a and the second through hole 2a The two through holes 2a communicate to form a connection hole b, and the rod portion 33 of the connector 3 passes through the connection hole b, so that the first plate 1 and the second plate 2 are clamped on the first plate of the connector 3 . Between the end 31 and the second end 32 ....

Embodiment 2

[0061] On the basis of the first embodiment above, the second embodiment also adopts the following preferred structure:

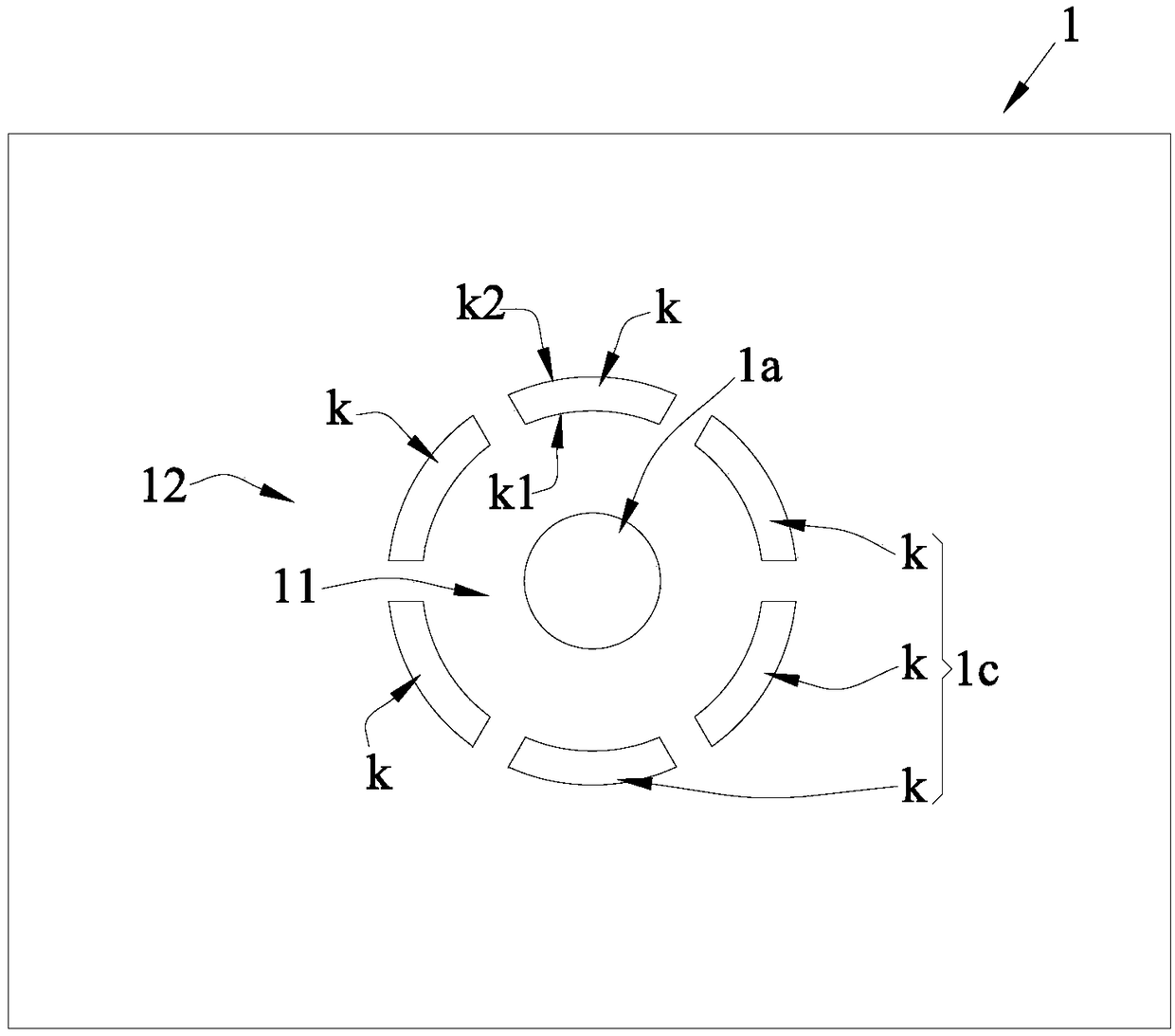

[0062] The first rigidity weakening structure 1c is an intermittent annular groove structure;

[0063] Wherein, the intermittent annular groove structure includes a plurality of slots k, and each of the slots k is evenly spaced around the through holes on the plate where the slots k are used to form the connecting holes b;

[0064] Such as figure 2 As shown, for the second embodiment, that is, the slots k of the first weakening structure 1 c are evenly spaced around the first through hole 1 a of the first board 1 .

Embodiment 3

[0066] On the basis of the first embodiment above, the third embodiment also adopts the following preferred structure:

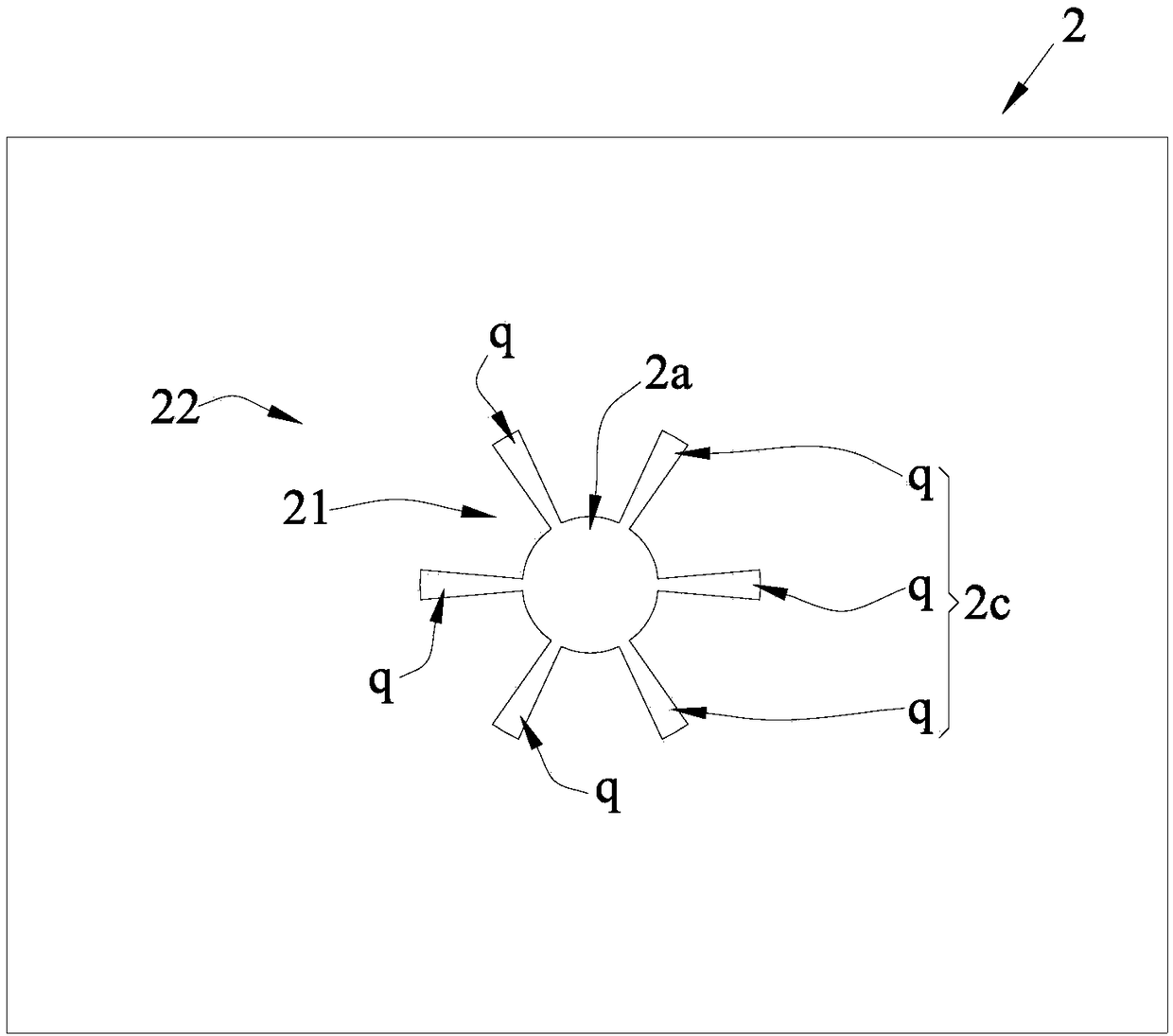

[0067] The first rigidity weakening structure 1c is a star-shaped notch structure;

[0068] Wherein, the star-shaped notch structure includes a plurality of notches q, and each notch q communicates with a through hole on the plate where it is located for forming the connecting hole b and extends along the radial direction of the through hole, and each of the notches q The notches q are evenly spaced around the through-holes on the plate where they are used to form the connection holes b (the arrangement of the notches q relative to the through-holes can be found in image 3 ).

[0069] For the third embodiment, that is: each of the notches q of the first weakening structure 1c communicates with the first through hole 1a of the first plate 1 and extends along the radial direction of the first through hole 1a, and each The notches q are evenly spaced around ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com