Integral casting construction process of dry quenching furnace

A technology of integral pouring and CDQ, which is used in coke ovens, petroleum industry, heating of coke ovens, etc., can solve problems such as CDQ repairs that have not been reported, and achieve low cost, good integrity and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

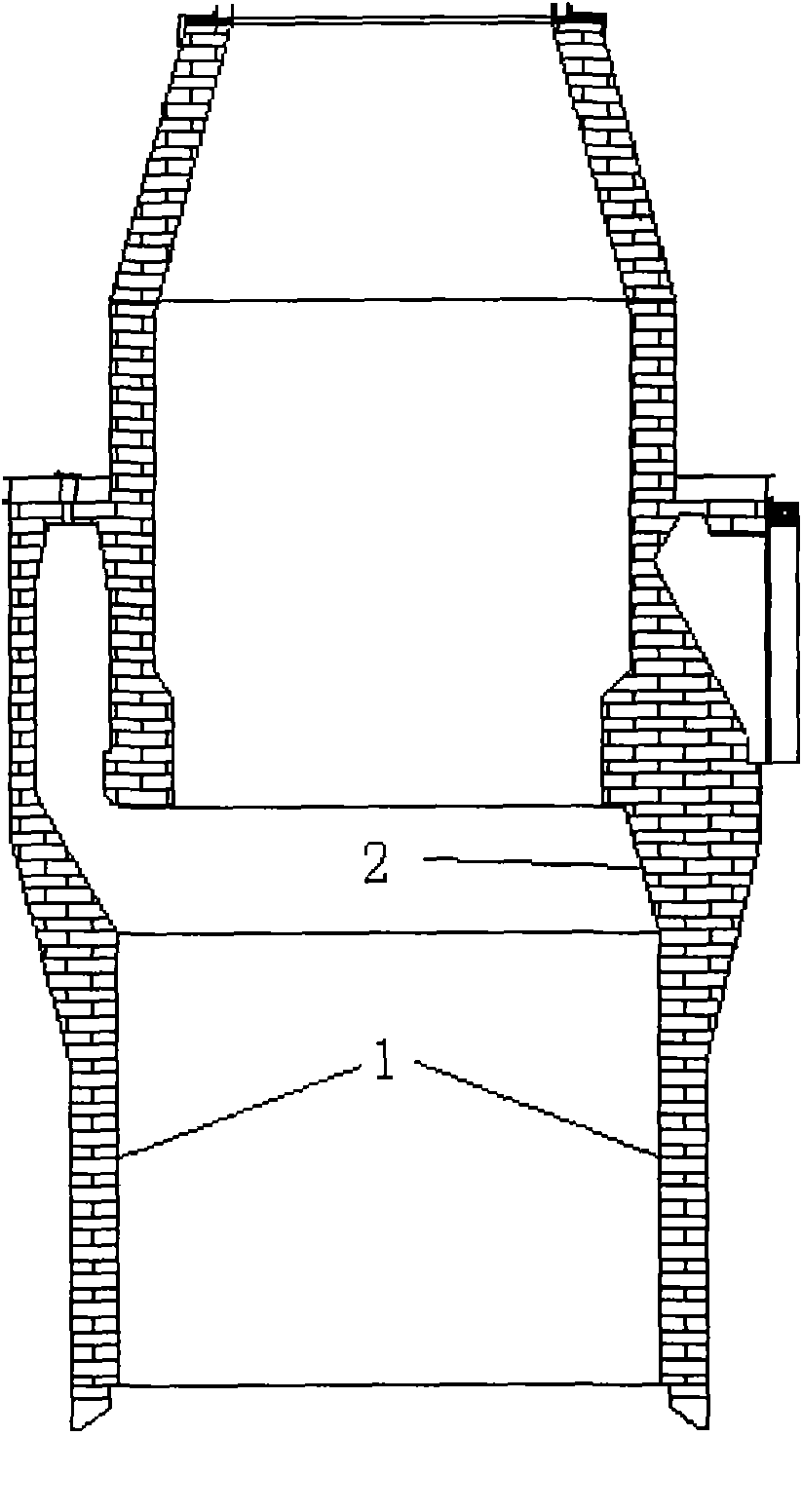

[0029] Embodiment: The overall structure of the dry quenching furnace is as follows figure 1 shown.

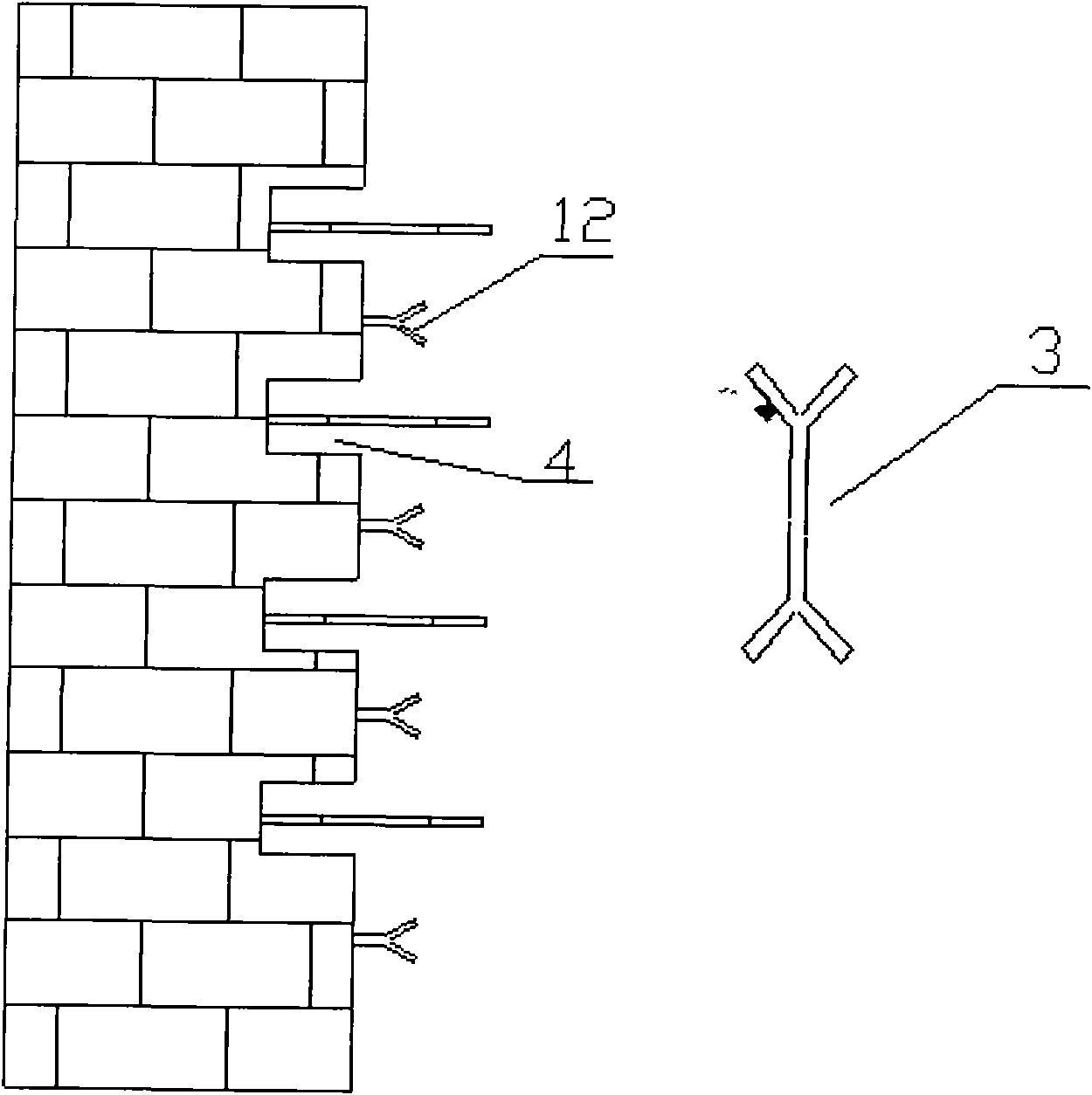

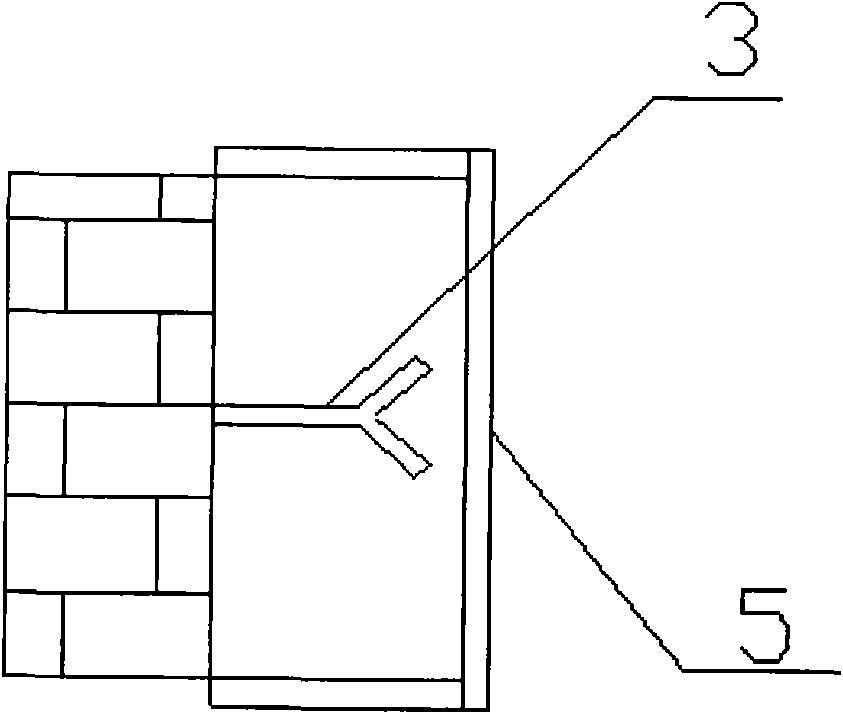

[0030] 1. The cooling section 1 of the CDQ furnace is integrally poured with castables. Before pouring, the wall is first cleaned with compressed air, and then cleaned with a cleaning agent. Finally, by applying a layer of high-temperature interface adhesive, installing fork-shaped anchors 3, and interspersing anchor grooves 4 in the wall, the adhesion of the castable is increased. To improve its strength, self-flowing castables are used for overall pouring after the formwork is supported 5 times. The annular height of the cooling section along the furnace wall is 1.2 meters for each pouring. After one day of solidification, the formwork is removed and continued to pour upwards. To withstand the wear of coke, thermal stress spalling and gas impact, protect the structural stability of the inclined flue, and achieve the purpose of prolonging the service life of CDQ. Cooling se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com