Centrifugal fan with low noise

a centrifugal fan and low noise technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of huge power consumption, inability to work normally, and delicate and complicated fabrication of integrated circuits, so as to reduce transmission and noise, the effect of low nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

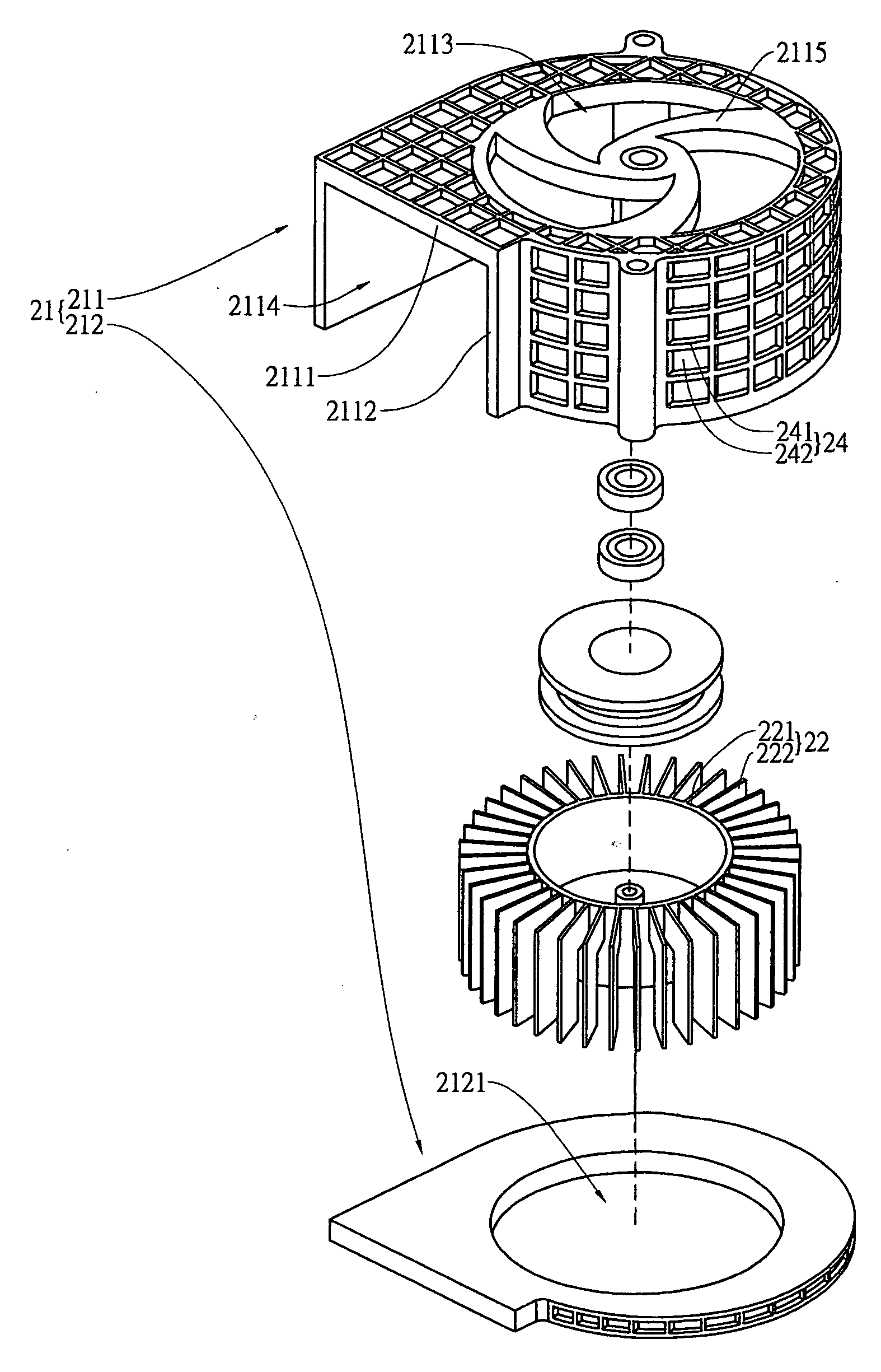

[0025] Referring to FIGS. 4 to 6, the preferred embodiment of a centrifugal fan with low noise according to the present invention includes a housing 21 and a fan wheel 22. The fan wheel 22 provides a hub 221 and a plurality of fan blades 222 surrounding the hub 21 and extending outward radially from the hub 221. The housing 21 has a housing base 211 and a lid member 212 and the housing base 211 has a bottom plate 2111 with a side plate 2112 extending along the bottom plate 2111. A first inlet 2113 is provided at the bottom plate 2111 and an outlet 2114 is provided at the side plate 2112. A plurality of auxiliary ribs 2115 are arranged in the first inlet 2113 and a second inlet 2121 is provided at the lid member 212 to define a chamber 23 with the bottom plate 2111 and the side plate 2112. The chamber 23 communicates with the outlet 2114.

[0026] Both the bottom plate 2111 and the lid member 212 of the housing 21 provides at least a recess unit 24 at the surfaces thereof and the reces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com