Transfer material

A technology of transfer printing materials and lamination, which is applied in the direction of decorative art and the process for producing decorative surface effects, etc. It can solve the problems of insufficient surface strength and limited thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

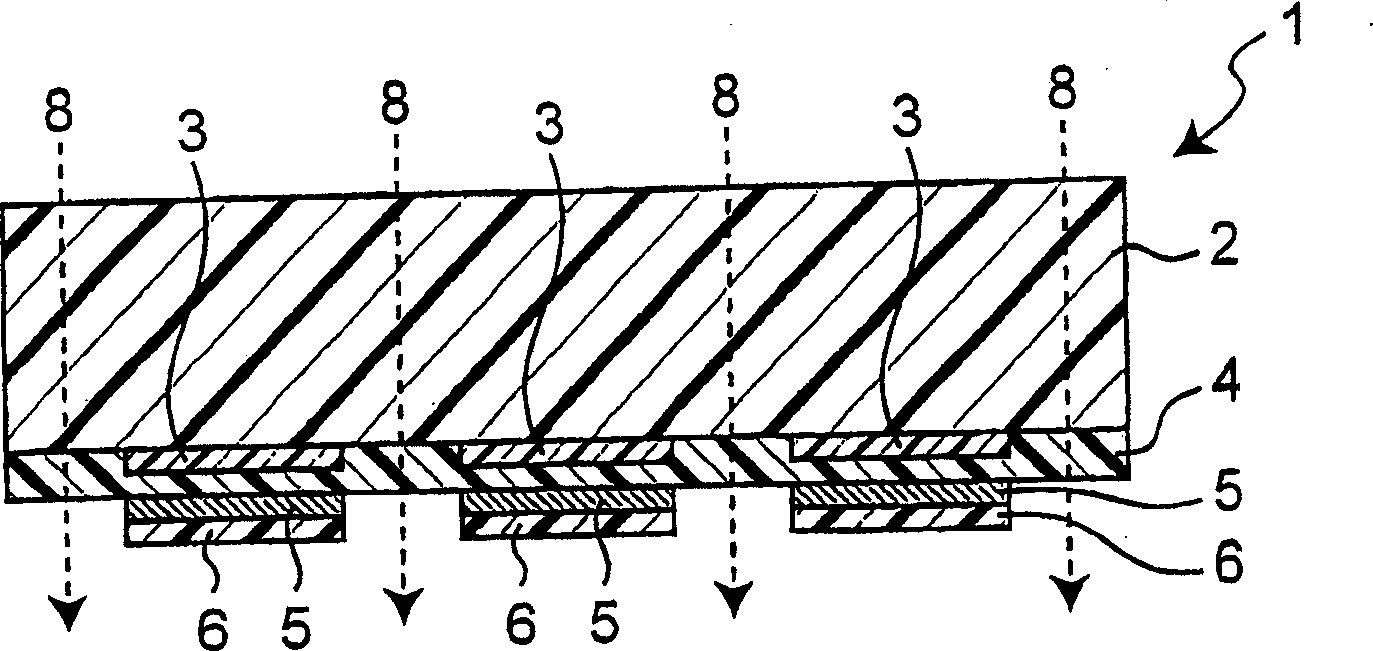

[0070] Using a polyethylene terephthalate film with a thickness of 38 μm as the substrate, coat the release layer in a strip pattern and allow it to fully cure, then form an ionizing radiation curing layer on the entire surface, and then form the release layer in sequence A reinforcement layer, a pattern layer, and an adhesive layer are partially formed on the parts to obtain a transfer material.

[0071] Using the transfer material obtained in this way, when acrylic resin is used as the molding resin for decoration and simultaneous molding, the sprue that is in contact with the part where the release layer is not provided can be smoothly peeled off from the transfer material and has high surface strength. Formed products.

Embodiment 2

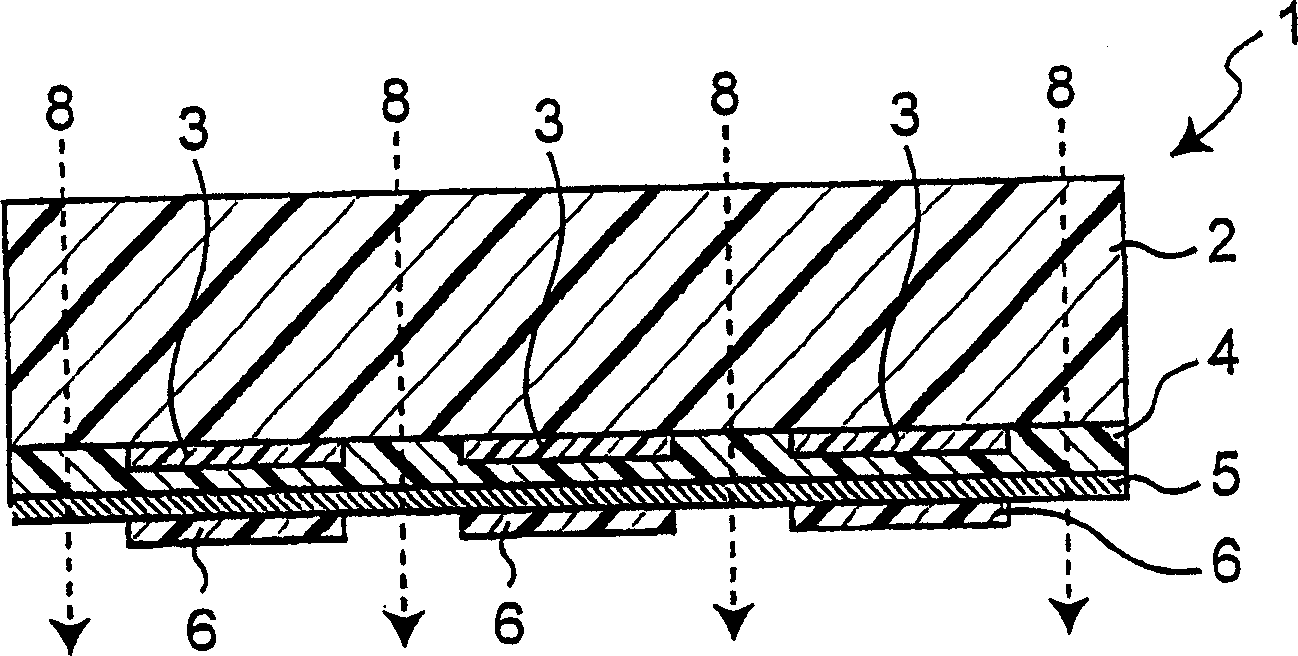

[0073] Using a polyethylene terephthalate film with a thickness of 38 μm as the substrate, coat the release layer in a strip pattern and allow it to be fully cured, then form an ionizing radiation curing layer and a reinforcement layer in sequence, and then in turn A pattern layer and an adhesive layer were partially formed on the site where the mold release layer was formed, and a transfer material was obtained.

[0074] Using the transfer material obtained in this way, when acrylic resin is used as the molding resin for decoration and simultaneous molding, the sprue that is in contact with the part where the release layer is not provided can be smoothly peeled off from the transfer material and has high surface strength. Formed products.

[0075] Since the present invention is composed of the above configurations, it has the following effects.

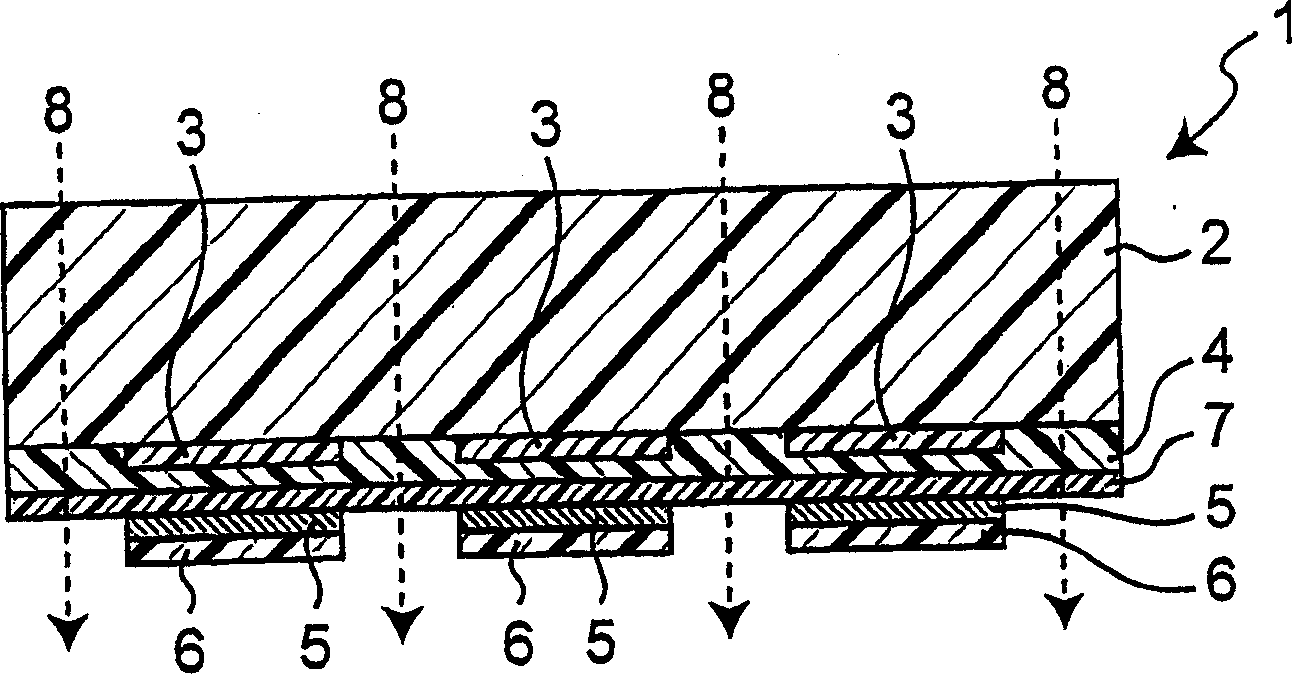

[0076] In the transfer printing material of the present invention, since the strip-shaped pattern release layer is laminated on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com