Preparation method and application of hydrophobic modified guar gum

A technology of hydrophobic modification and guar gum, applied in the direction of adding water repellents, etc., can solve the problems of reduced molecular weight of guar gum, complicated modification process, etc., and achieve the effect of improving water solubility, good hydrophobic performance, and not easy to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

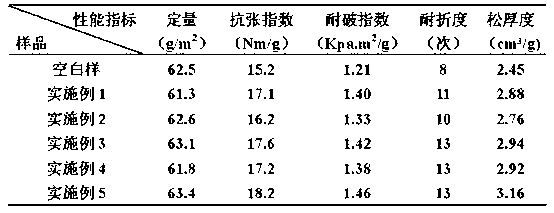

Examples

Embodiment 1

[0042] 50 gram guar gums are dispersed in 100 gram 1-butyl-3-methylimidazolium chloride salt ionic liquids, stir, obtain the suspension that does not stratify; Add the tetramethyl ammonium hydroxide of 10 gram concentration 25%, Stir evenly, seal and place in an ice-water bath at 20°C for alkalization for 30 minutes; add nitrogen gas, heat the water bath to raise the temperature of the water bath to 35°C, add 5 grams of dodecenyl succinic anhydride within 30 minutes, and continue stirring for 4 hours; Add 2.0 grams of acetic acid to adjust the pH of the material to 7, soak and wash with ethanol several times, filter, first recover the ethanol with a rotary evaporator, and then recover the ionic liquid, and vacuum-dry the obtained filter cake at 60°C to obtain hydrophobically modified guar gum .

[0043] It was determined that the degree of substitution of the hydrophobic guar gum was 0.22. The viscosity of the 1% solution was 3200mpa.s.

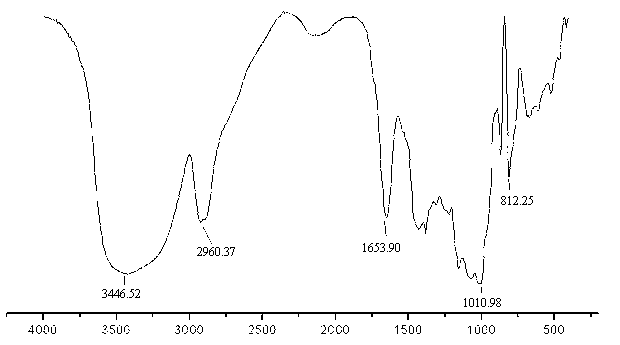

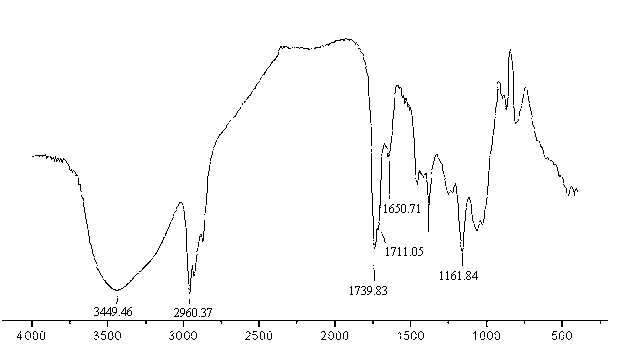

[0044] Adopt infrared spectrometer to...

Embodiment 2

[0046] 50 gram guar gums are dispersed in 450 gram 1-butyl-3-methylimidazolium chloride salt ionic liquids, stir, obtain the suspension that does not stratify; Add the tetramethylammonium hydroxide of 25 gram concentration 25%, Stir evenly, seal and place in an ice-water bath at 10°C for alkalization for 10 minutes; add nitrogen gas, heat the water bath to raise the temperature of the water bath to 80°C, add 30 grams of octenyl succinic anhydride within 60 minutes, and continue stirring for 4 hours; add Adjust the pH of the material to 6 with 8.0 grams of formic acid, soak and wash with ethanol several times, filter, first recover ethanol with a rotary evaporator, and then recover the ionic liquid, and vacuum-dry the obtained filter cake at 60°C to obtain hydrophobically modified guar gum.

[0047] It was determined that the degree of substitution of the hydrophobic guar gum was 2.15. The viscosity of the 1% solution was 2000mpa.s.

Embodiment 3

[0049] Disperse 50 grams of guar gum in 75 grams of 1-allyl-3-methylimidazolium ionic liquid, stir to obtain a non-layered suspension; add 2.5 grams of tetramethylammonium hydroxide with a concentration of 25%, stir Uniform, sealed and placed in 40°C ice-water bath, alkalized for 10 minutes; nitrogen gas was introduced, the water bath was heated to raise the temperature of the water bath to 65°C, 2.5 g of octadecenyl succinic anhydride was added within 10 minutes, and the stirring reaction was continued for 1 hour; Adjust the pH of the material to 5 with 1.0 g of acetic acid, soak and wash with ethanol several times, filter, first recover the ethanol and then the ionic liquid with a rotary evaporator, and vacuum-dry the obtained filter cake at 60°C to obtain hydrophobically modified guar gum.

[0050] After determination, the degree of substitution of the hydrophobic guar gum is 0.14. The viscosity of 1% solution is 2500mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com