Carburizing method for wind power gear used for wind power generation

A technology for gears and wind power, which is applied in the carburizing field of wind power gears. It can solve the problems of poor uniformity, deepening of internal oxidation, and affecting the performance of wind power gears, etc., and achieve the effects of improving surface strength, improving affinity, and speeding up carburizing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] An embodiment of a carburizing method for a wind power gear used in wind power generation provided by the present invention includes:

[0033] Perform the first carburizing treatment on the wind power gear to be treated in an atmosphere with a carbon potential of 0.8% to 1.1%, and the first carburizing treatment time is 30 hours to 40 hours;

[0034] performing the first quenching treatment on the wind power gear after the first carburizing treatment;

[0035] raising the temperature of the wind power gear after the first quenching treatment to 600° C. to 660° C. for the first tempering treatment;

[0036] Raising the temperature of the wind power gear after the first tempering treatment and performing a second carburizing treatment in an atmosphere with a carbon potential of 0.8% to 1.0%, and the second carburizing treatment time is 1 hour to 4 hours;

[0037] performing a second quenching treatment on the wind power gear after the second carburizing treatment;

[00...

Embodiment 1

[0058] The test piece is a cylinder with a diameter of 160mm×length 100mm. After machining, conventional heat treatment: first quenching 880°C×2 hours, oil cooling; second quenching 800°C, oil cooling; tempering 180°C×1 hour, air cooling .

[0059] Heat the test piece after conventional heat treatment to 430°C in a controlled atmosphere carburizing furnace, and keep it warm for 2.5 hours in an air atmosphere for pre-oxidation treatment;

[0060] Carburize the test piece after pre-oxidation treatment for the first time, including:

[0061] a) carburizing at 920°C for 22 hours in an atmosphere with a carbon potential of 1.1%;

[0062] b) keep the temperature constant, the carbon potential drops to 1%, and carburize for 5 hours;

[0063] c) keep the temperature constant, the carbon potential drops to 0.8%, and carburize for 8 hours;

[0064] After the first carburizing treatment, the carbon potential is kept at 0.8%, the temperature is lowered to 850°C for 2 hours, and the que...

Embodiment 2- Embodiment 5

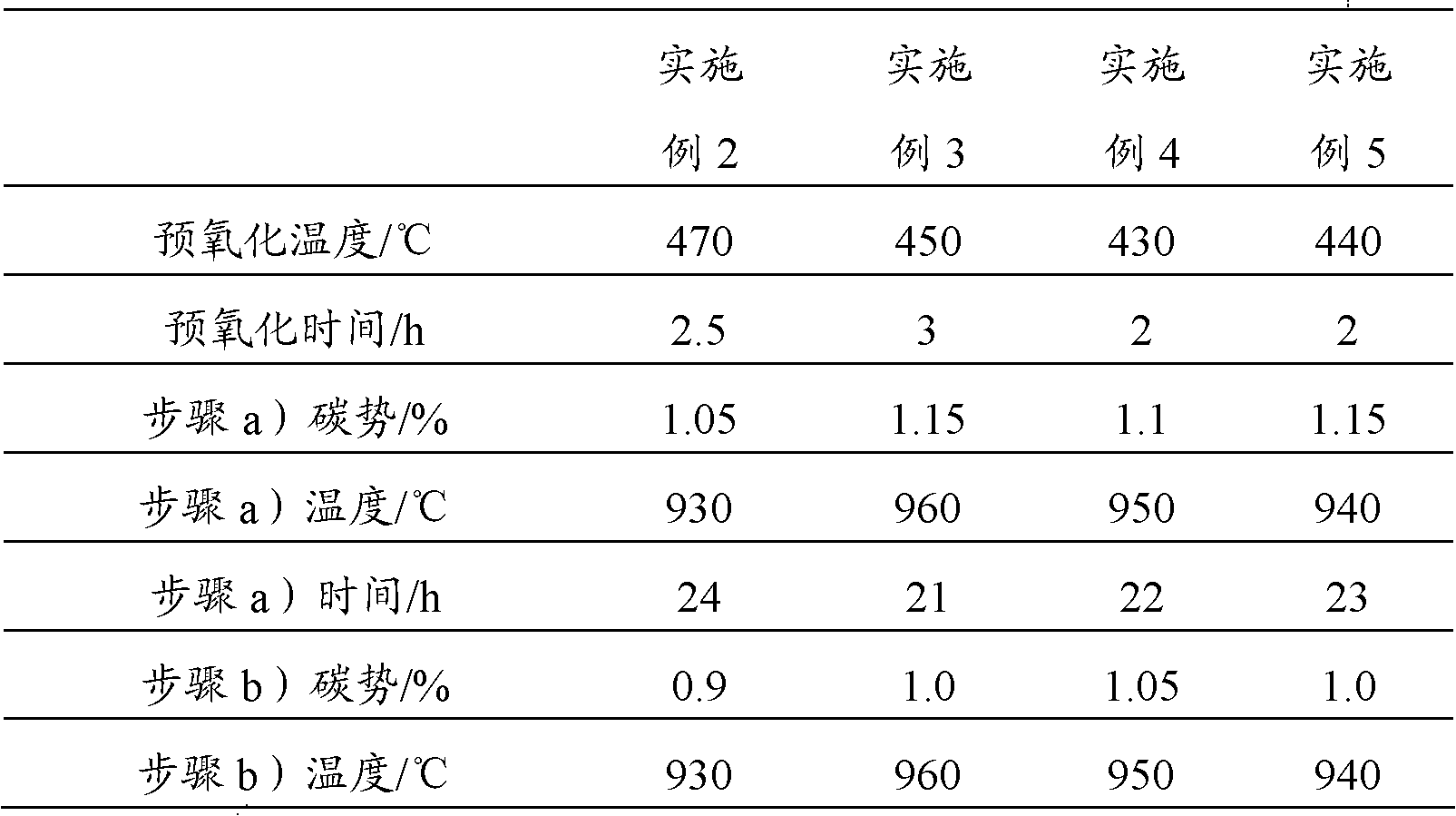

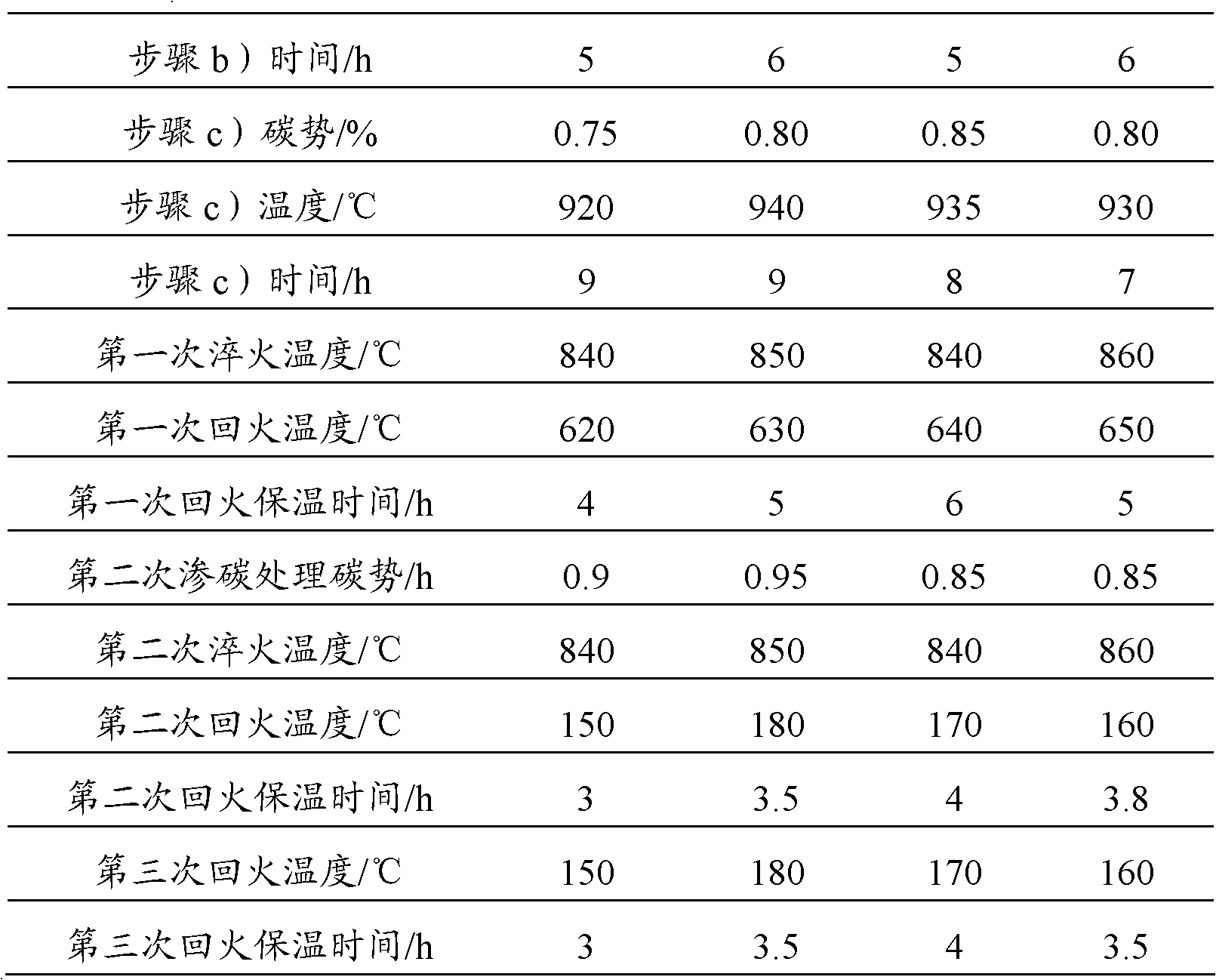

[0071] Mainly changed pre-oxidation conditions and carburizing conditions, other conditions are the same as in Example 1, and the carburizing process parameters are as shown in Table 1:

[0072] Table 1 Example 2-Example 5 carburizing process parameters

[0073]

[0074]

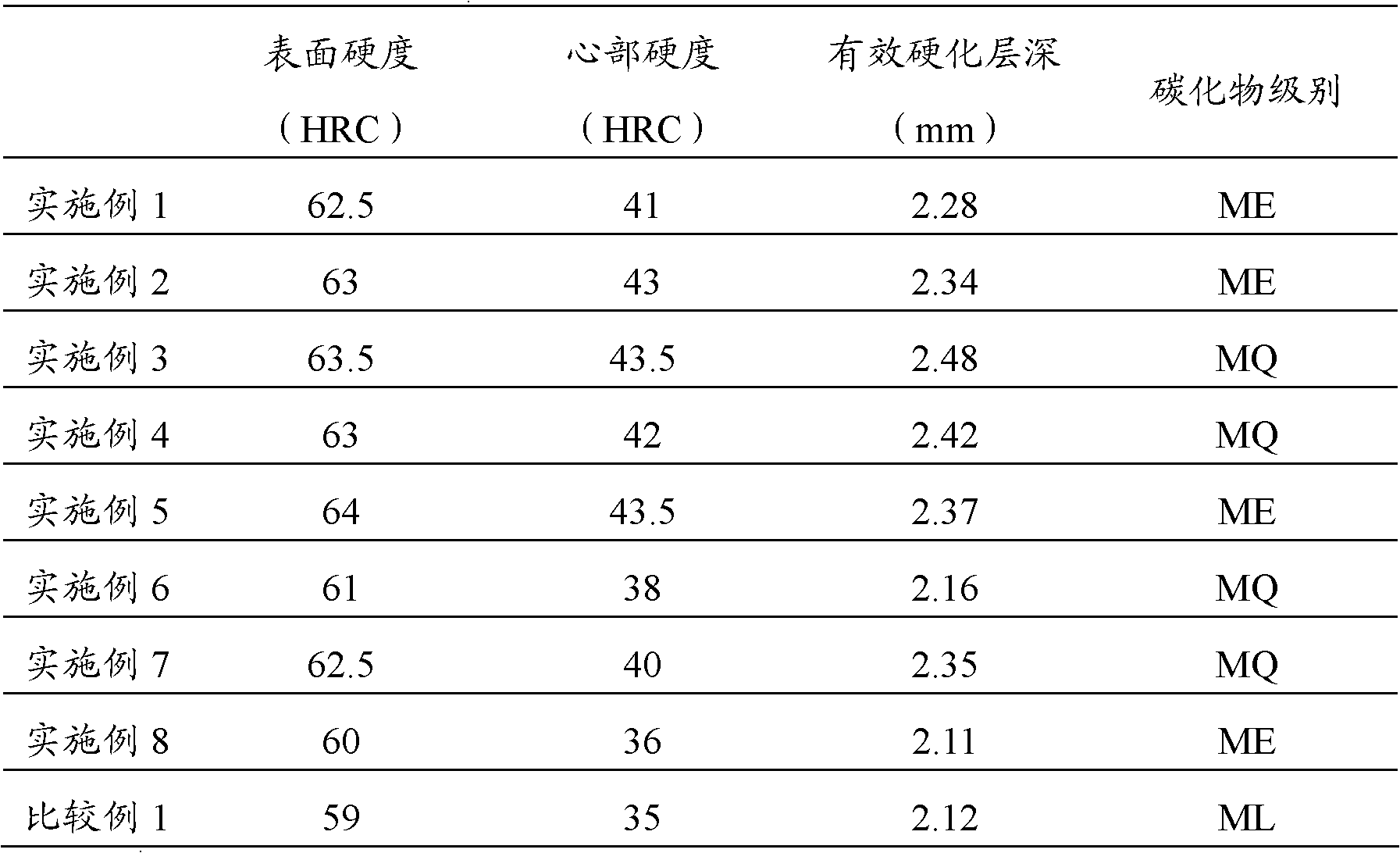

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com