Carburization processing method

A carburizing treatment and treatment method technology, which is applied in the field of carburizing treatment, can solve the problems of reduced service life of workpieces, reduction of microhardness of workpieces, failure to improve surface hardness, etc., and achieve the effect of improving surface hardness and macroscopic hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

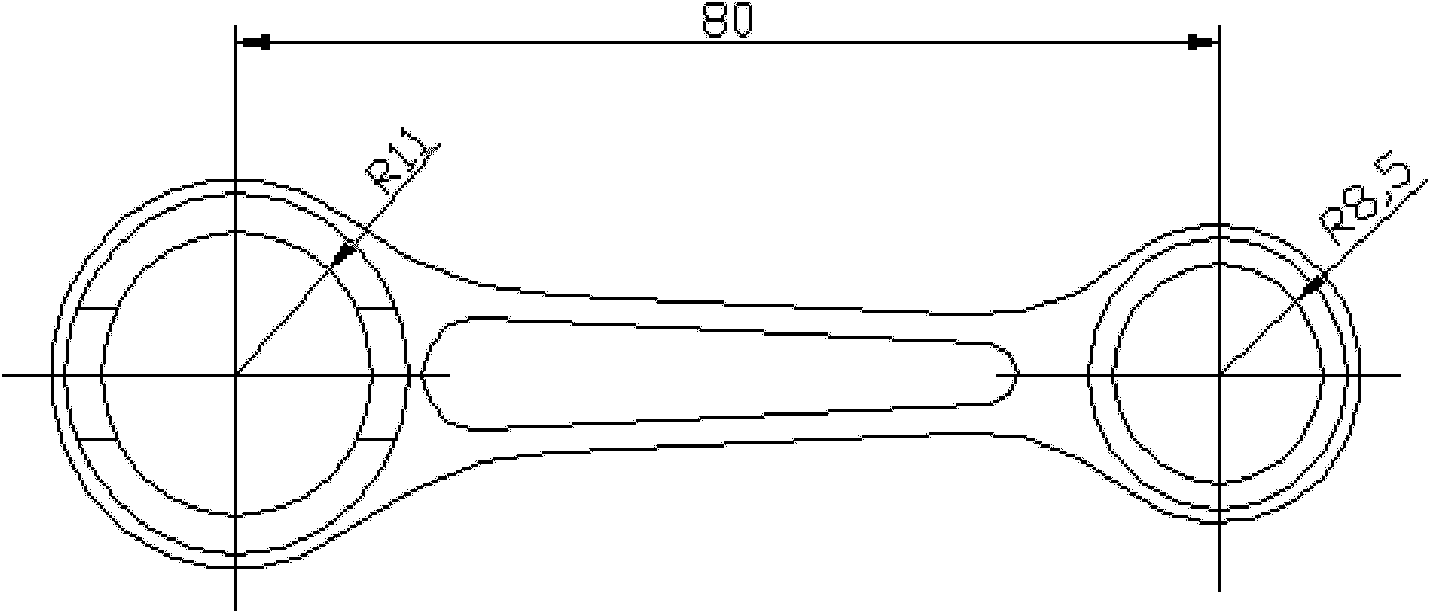

[0069] Use the UBE-600 multi-purpose furnace for example figure 1 The motorcycle crankshaft engine connecting rod shown is carburized.

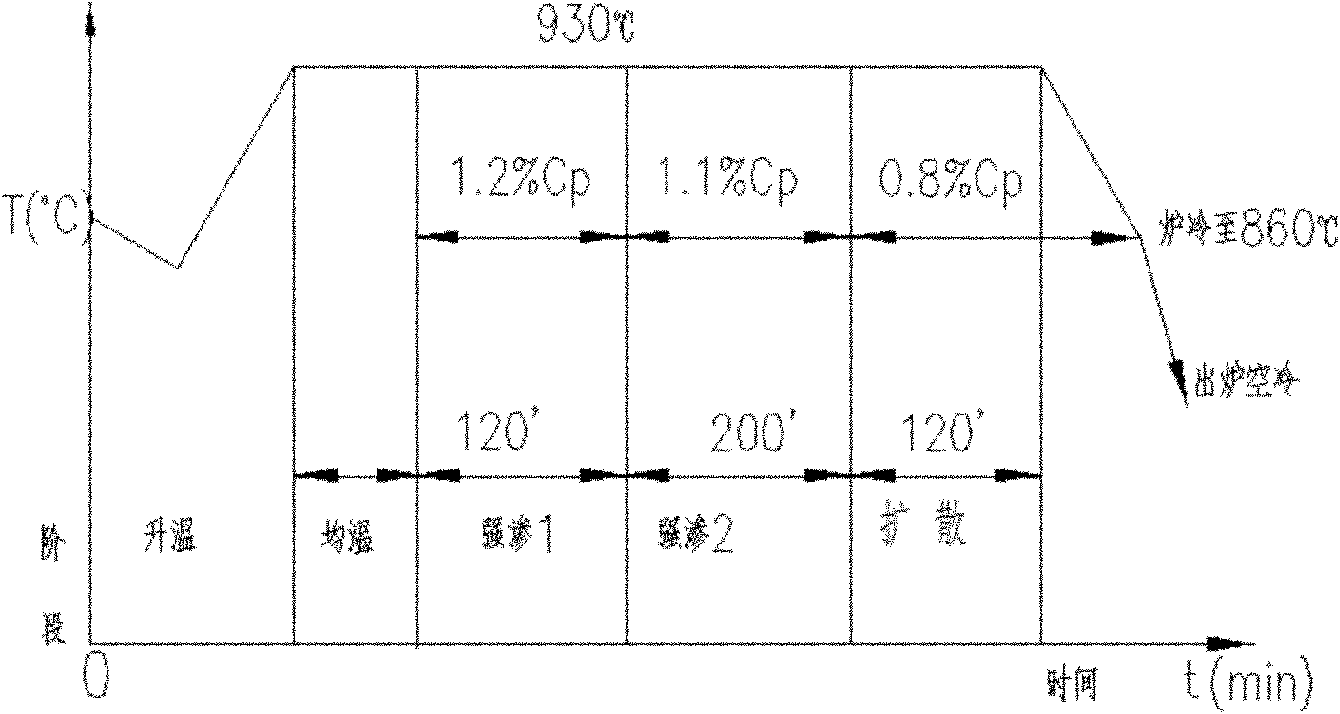

[0070] Step a) as figure 2 As shown, the workpiece is placed in a mixed gas of methane and hydrogen at a carburizing temperature of 930 ° C for 30 minutes, and is kept at a carbon potential of 1.2% for 120 minutes, and then kept at a carbon potential of 1.1% for 200 Minutes, then diffused under 0.8% carbon potential for 120 minutes, and finally cooled to 860°C with the UBE-600 multi-purpose furnace, and cooled in the front chamber of the heating furnace for 120 minutes;

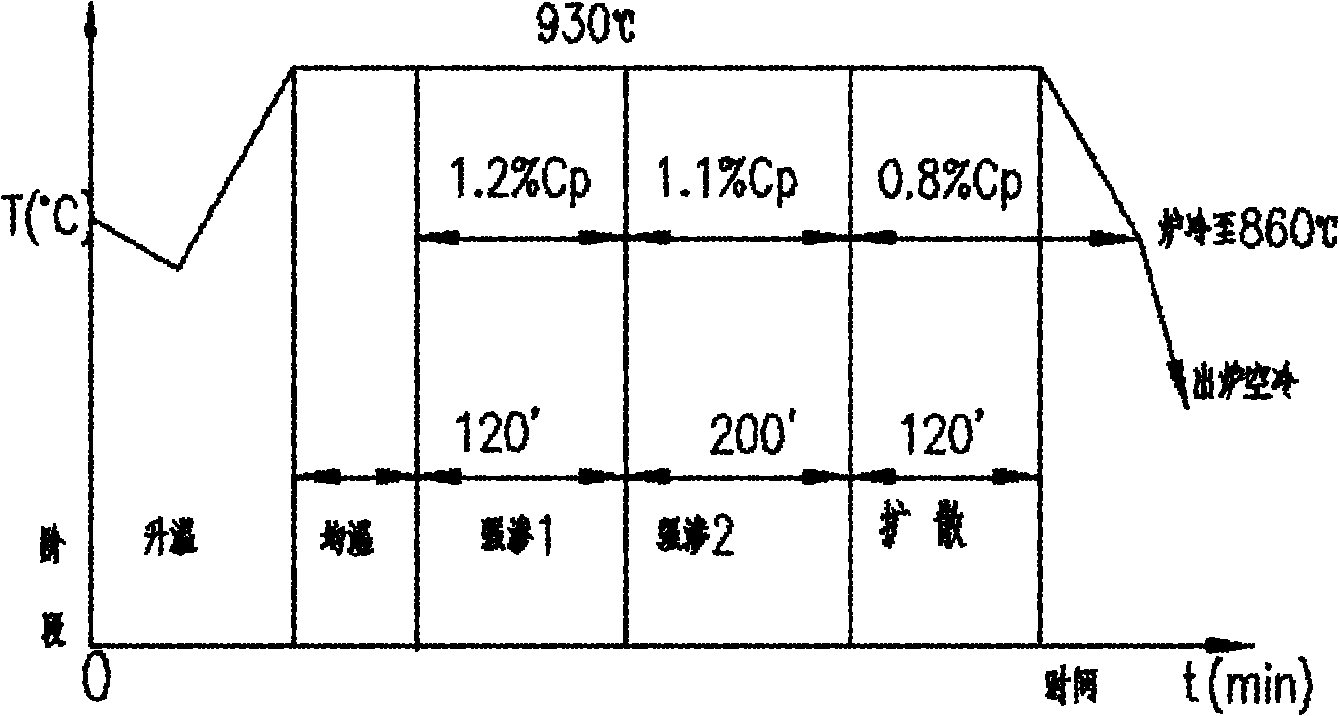

[0071] Step b) if image 3 As shown, the workpiece treated in step a) is placed in a mixed gas of methane and hydrogen after 30 minutes of uniform temperature at a carburizing temperature of 930 ° C, kept at a 1.2% carbon potential for 90 minutes, and then Insulate for 60 minutes under a carbon potential of 0.8%, then diffuse for 60 minutes under a 0.8% carbon potential,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com