Directional wood-plastic composite plate and manufacturing method thereof

A composite board, wood-plastic technology, applied in the direction of wood laminate products, wood veneer bonding, chemical instruments and methods, etc., can solve the problems of difficult mixing, small size of wood raw materials, surface cracking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

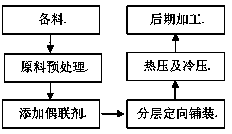

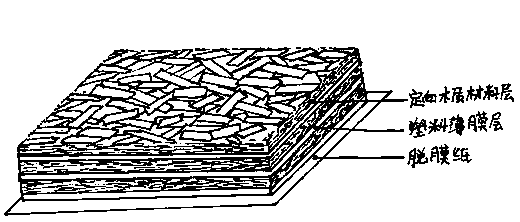

Method used

Image

Examples

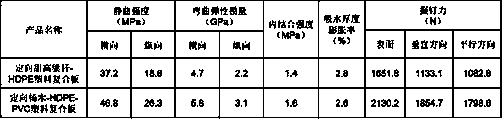

Embodiment 1

[0028] In this example, the oriented sweet sorghum stalk-high-density polyethylene plastic composite board is prepared, and the process steps are as follows:

[0029] (1) Raw material preparation: remove the leaves of sweet sorghum stalks after harvesting, and roll the sweet sorghum stalks into thinner pieces and cut them off by roller compaction, while the sugar juice in the sweet sorghum stalks is squeezed out. After rolling, fine residues are removed by mechanical screening to obtain sweet sorghum stalk fibers with a length of 20-80 mm, a width of 5-15 mm, and a thickness of 1-2 mm.

[0030] (2) Raw material pretreatment: Put the sweet sorghum stalk fibers into a drying oven at 140°C for heat treatment for 2 hours, and the moisture content will be reduced to below 3%.

[0031] (3) Adding coupling agent: liquid polydiphenylmethane diisocyanate (pMDI) was used as coupling agent, and the amount of coupling agent added was 2% of the weight of sweet sorgh...

Embodiment 2

[0036] In this embodiment, the oriented poplar-high-density polyethylene-polyvinyl chloride plastic composite board is prepared, and the process steps are:

[0037](1) Material preparation: The poplar logs were sawed into 13mm thick boards with a woodworking band saw, and then cut into 150mm lengths and sent to a directional planer to make thin wood chips with a size of 150×13×0.4mm.

[0038] (2) Raw material pretreatment: heat-treat poplar veneer in a drying oven at 140°C for 2 hours, and the moisture content will drop below 3%.

[0039] (3) Add coupling agent: use liquid polydiphenylmethane diisocyanate (pMDI) as coupling agent, and the amount of coupling agent added is 2% of the wood weight. By the size of the target product (length: 800mm, width: 700mm, thickness: 15mm), density (800kg / m 3 ) and raw material loss rate (10%) to calculate the weight of the slab, and then calculate the weight of poplar veneer and pMDI respectively according to the total weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com