Halloysite nanotube/quaternary ammonium salt composite antibacterial particle and preparation method and application thereof

A halloysite nanotube, composite antibacterial technology, applied in the directions of botanical equipment and methods, applications, fungicides, etc., can solve problems such as poor anti-bleeding performance, and achieve increased interlayer spacing, increased loading, and good antibacterial activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Acid etching of halloysite

[0036] Take 5g of halloysite nanotube powder and disperse it in 100mL 3mol / L hydrochloric acid solution, ultrasonically disperse for 30min, place it under 80℃ and magnetically stir for 8h, centrifuge with deionized water until it is neutral, and vacuum dry at 60℃ to obtain Acid etch modified halloysite nanotube powder.

[0037] (2) Activation of acid-etched halloysite nanotubes

[0038] Take the above 5g acid-etched modified halloysite nanotube powder and disperse it in 100mL of 70% dimethyl sulfoxide (DMSO) solution, ultrasonically disperse, stir at 80℃ for 6h, centrifuge with deionized water Washed three times, dried in vacuum at 60°C to obtain activated halloysite nanotubes.

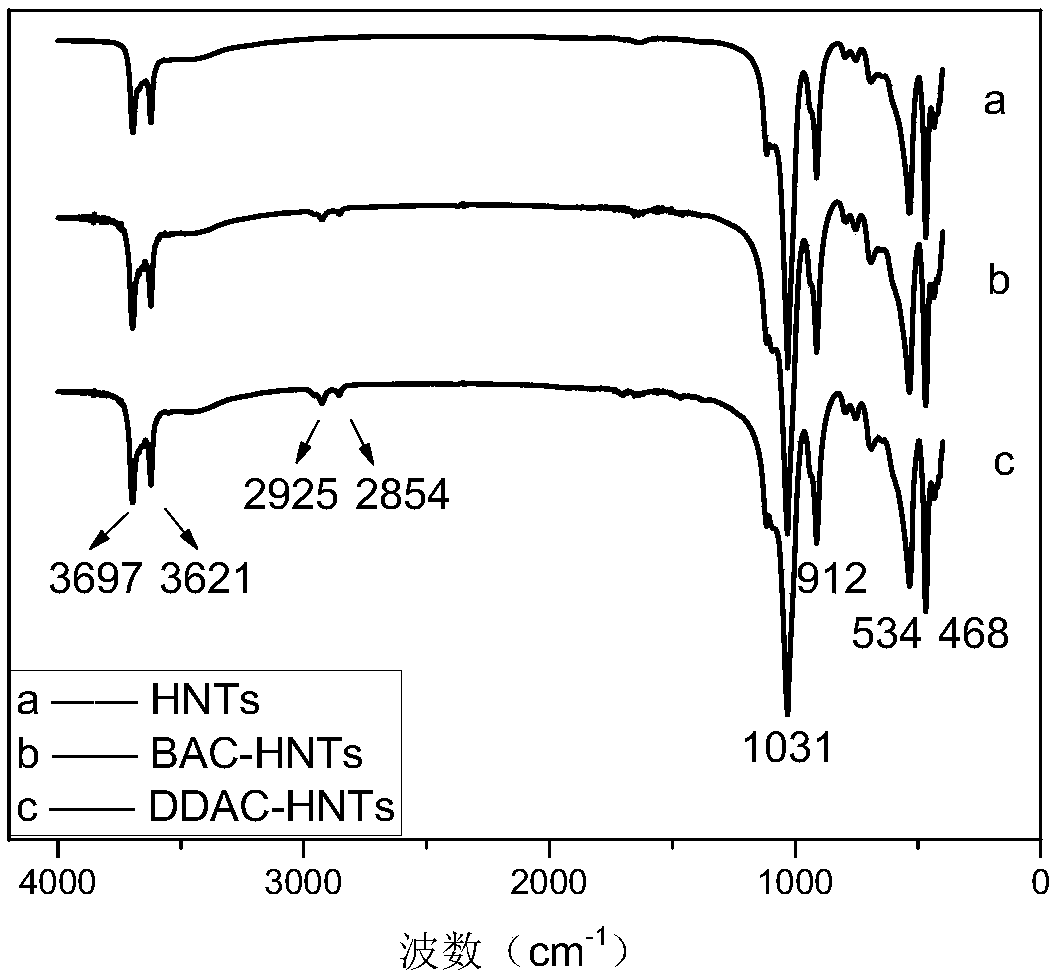

[0039] (3) Load of Didecyl Dimethyl Ammonium Chloride (DDAC)

[0040] Dissolve 10g diddecyldimethylammonium chloride (DDAC) in 100ml deionized water, add 2g activated halloysite nanotubes, ultrasonically disperse, put the mixed solution in a vacuum environment for 30 mi...

Embodiment 2

[0042] (1) Acid etching of halloysite

[0043] Take 5g of halloysite nanotube powder and disperse it in 100mL 3mol / L hydrochloric acid solution, ultrasonically disperse for 30min, place it under 80℃ and magnetically stir for 8h, centrifuge with deionized water until it is neutral, and vacuum dry at 60℃ to obtain Acid etch modified halloysite nanotube powder.

[0044] (2) Activation of acid-etched halloysite nanotubes

[0045] Take the above 5g acid-etched modified halloysite nanotube powder and disperse it in 80mL of 80% dimethyl sulfoxide (DMSO) solution, ultrasonically disperse, stir at 80℃ for 6h, centrifuge with deionized water Washed three times, dried in vacuum at 60°C to obtain activated halloysite nanotubes.

[0046] (3) Load of dodecyl dimethyl benzyl ammonium chloride (BAC)

[0047] Take 10g of dodecyldimethylbenzylammonium chloride (BAC) dissolved in 100ml of deionized water, add 2g of activated halloysite nanotubes, ultrasonically disperse, put the mixed solution in a vacu...

Embodiment 3

[0049] (1) Acid etching of halloysite

[0050] Take 5g halloysite nanotube powder and disperse it in 140mL 3mol / L hydrochloric acid solution, ultrasonically disperse for 30min, place it under 60℃ and magnetically stir for 8h, centrifuge with deionized water until it is neutral, and dry it under vacuum at 60℃ to obtain Acid etch modified halloysite nanotube powder.

[0051] (2) Activation of acid-etched halloysite nanotubes

[0052] Take the above 5g acid-etched modified halloysite nanotube powder and disperse it in 70mL 90% dimethyl sulfoxide (DMSO) solution, ultrasonically disperse, stir at 80℃ for 6h, centrifuge with deionized water Washed three times, dried in vacuum at 60°C to obtain activated halloysite nanotubes.

[0053] (3) Load of Didecyl Dimethyl Ammonium Chloride (DDAC)

[0054] Dissolve 10g diddecyldimethylammonium chloride (DDAC) in 100ml deionized water, add 2g activated halloysite nanotubes, ultrasonically disperse, put the mixed solution in a vacuum environment for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com