A kind of halloysite nanotube/quaternary ammonium salt composite antibacterial particle and its preparation method and application

A halloysite nanotube, composite antibacterial technology, applied in the directions of botanical equipment and methods, applications, fungicides, etc., can solve problems such as poor anti-bleeding performance, and achieve increased interlayer spacing, increased lumen volume, and good performance. The effect of antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

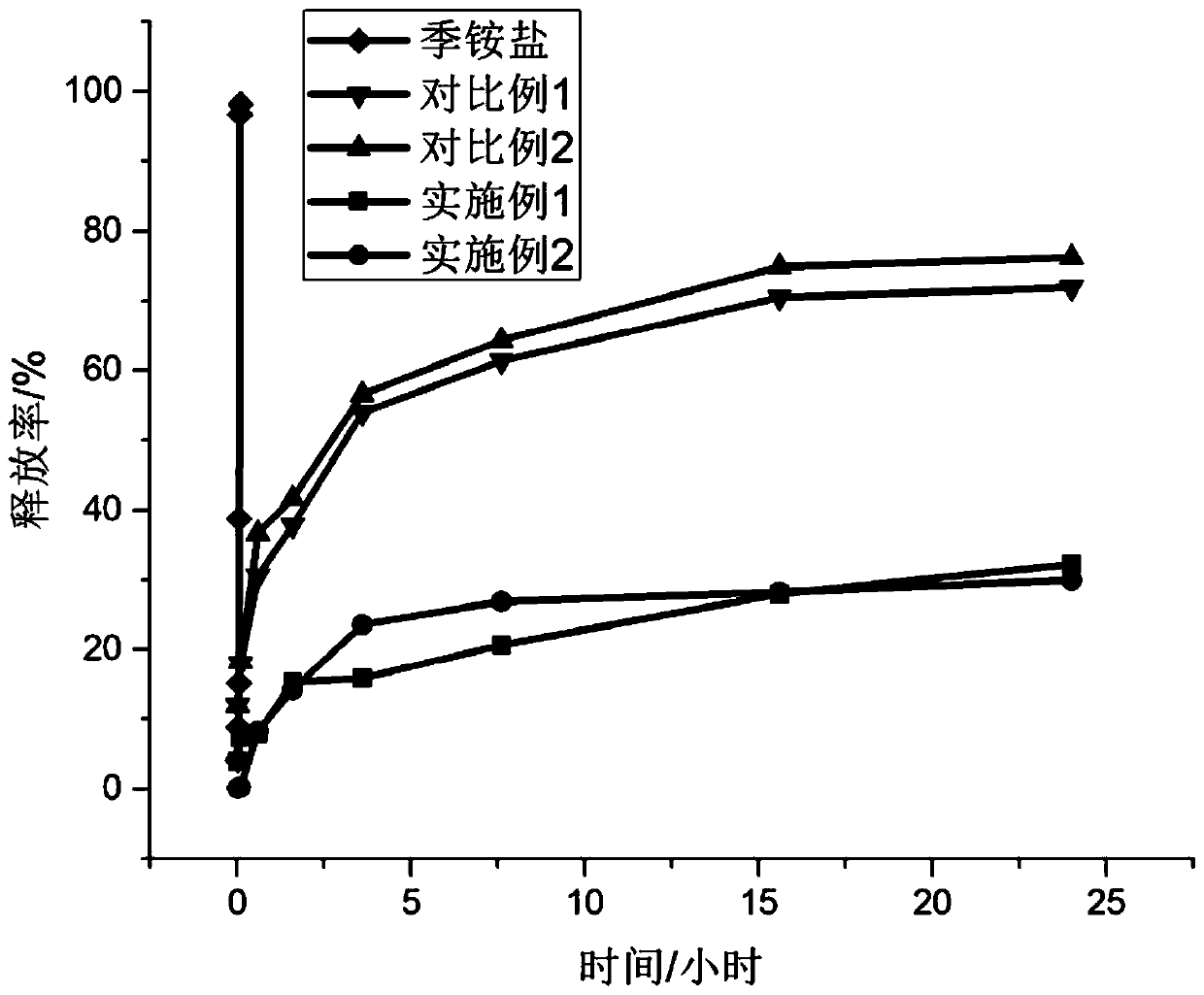

Embodiment 1

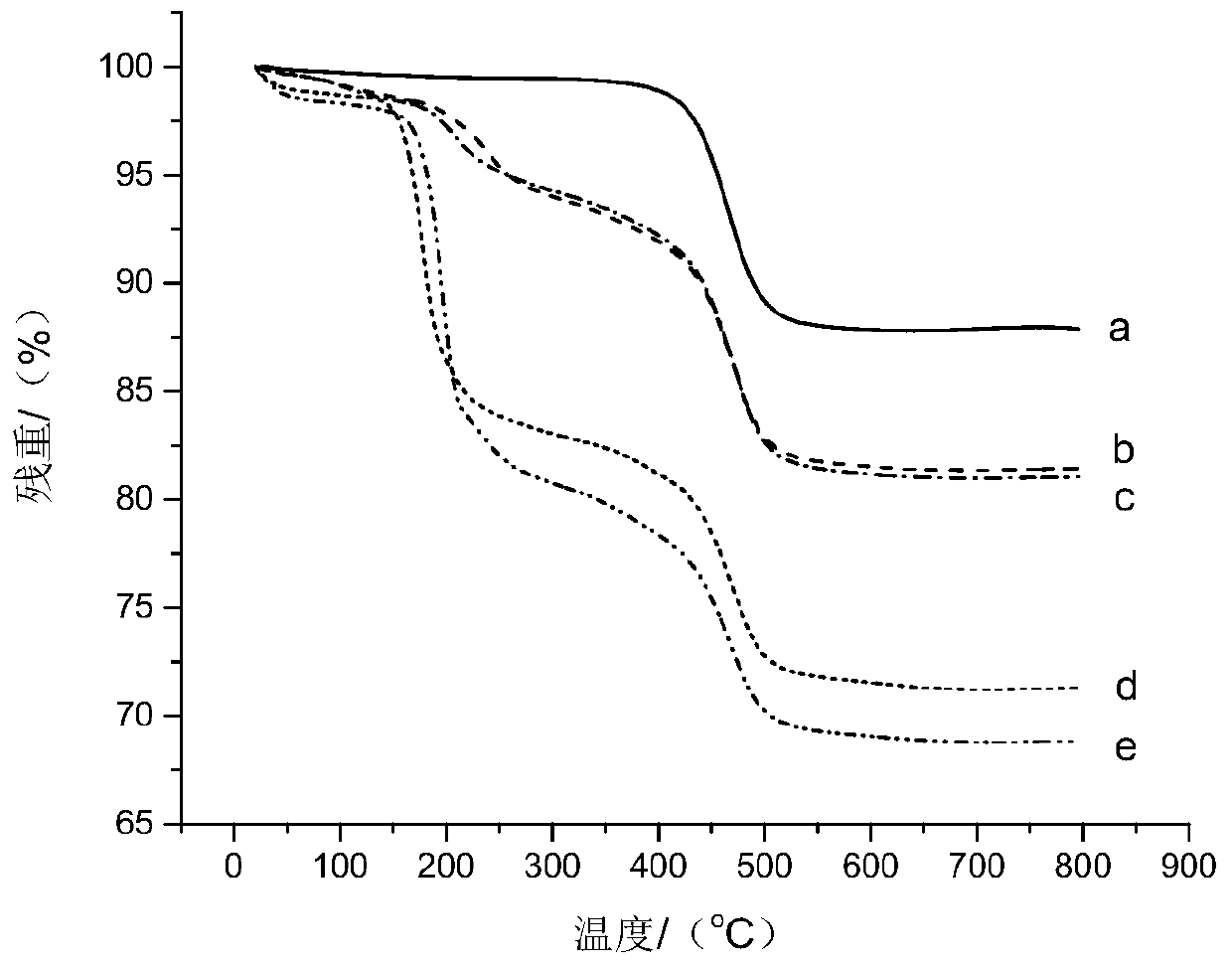

[0035] (1) Acid etching of halloysite

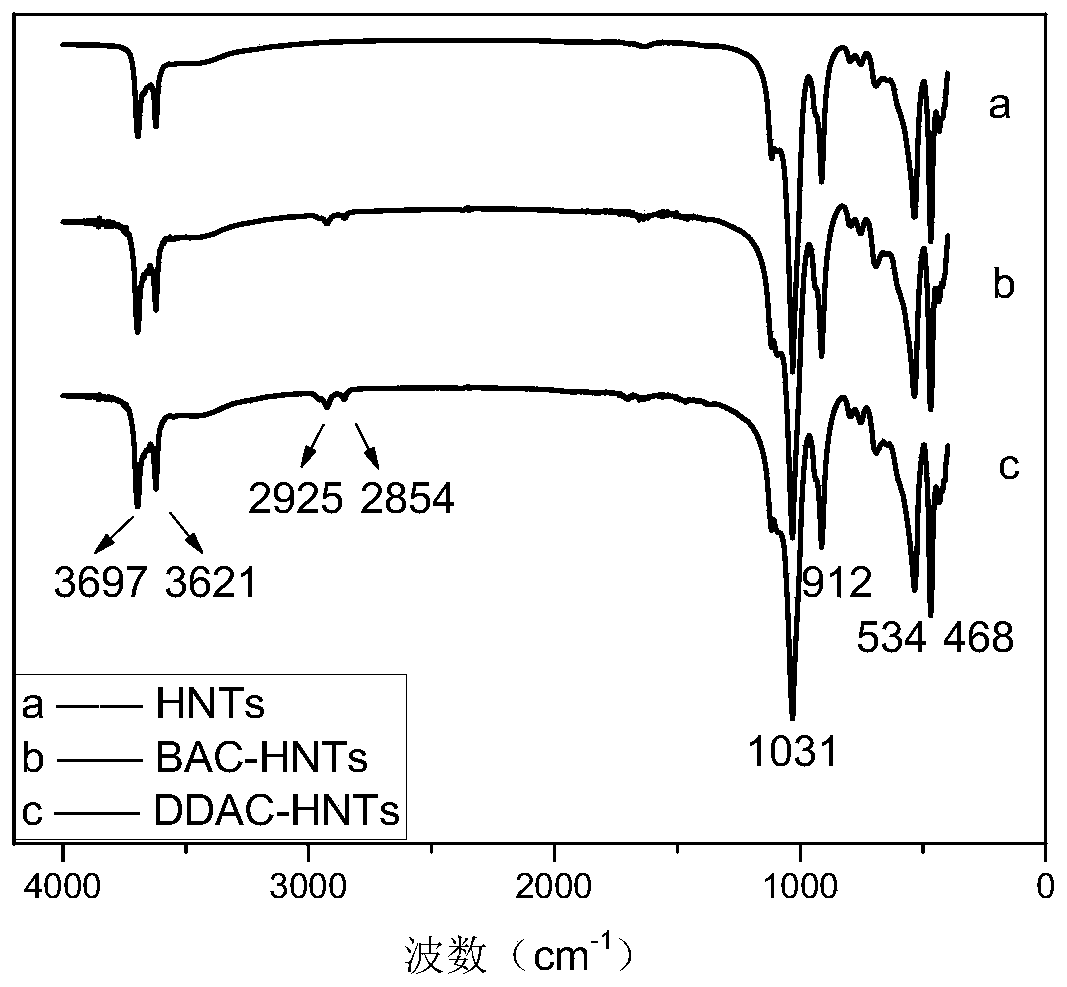

[0036] Take 5g of halloysite nanotube powder and disperse it in 100mL of 3mol / L hydrochloric acid solution, ultrasonically disperse for 30min, place it at 80°C for 8h under magnetic stirring, wash it with deionized water to be neutral, and dry it in vacuum at 60°C to get Acid etching modified halloysite nanotube powder.

[0037] (2) Activation of acid-etched halloysite nanotubes

[0038] Take 5 g of the acid-etched modified halloysite nanotube powder and disperse it in 100 mL of 70% dimethyl sulfoxide (DMSO) solution, ultrasonically disperse, stir at 80°C for 6 h, and centrifuge with deionized water Washed 3 times, dried under vacuum at 60°C to obtain activated halloysite nanotubes.

[0039] (3) Load of Didecyl Dimethyl Ammonium Chloride (DDAC)

[0040] Dissolve 10 g of didecyl dimethyl ammonium chloride (DDAC) in 100 ml of deionized water, add 2 g of activated halloysite nanotubes, and ultrasonically disperse, place the mixed solutio...

Embodiment 2

[0042] (1) Acid etching of halloysite

[0043] Take 5g of halloysite nanotube powder and disperse it in 100mL of 3mol / L hydrochloric acid solution, ultrasonically disperse for 30min, place it at 80°C for 8h under magnetic stirring, wash it with deionized water to be neutral, and dry it in vacuum at 60°C to obtain Acid etching modified halloysite nanotube powder.

[0044] (2) Activation of acid-etched halloysite nanotubes

[0045] Disperse 5 g of the above-mentioned acid etched modified halloysite nanotube powder in 80 mL of 80% dimethyl sulfoxide (DMSO) solution, ultrasonically disperse, stir at 80 ° C for 6 h, and centrifuge with deionized water Washed 3 times, dried under vacuum at 60°C to obtain activated halloysite nanotubes.

[0046] (3) Loading of dodecyl dimethyl benzyl ammonium chloride (BAC)

[0047] Take 10g of dodecyldimethylbenzyl ammonium chloride (BAC) and dissolve it in 100ml of deionized water, add 2g of activated halloysite nanotubes, disperse by ultrasonic...

Embodiment 3

[0049] (1) Acid etching of halloysite

[0050] Take 5g of halloysite nanotube powder and disperse it in 140mL of 3mol / L hydrochloric acid solution, ultrasonically disperse for 30min, place it under the condition of 60°C for 8h under magnetic stirring, wash it with deionized water to be neutral, and dry it under vacuum at 60°C to obtain Acid etching modified halloysite nanotube powder.

[0051] (2) Activation of acid-etched halloysite nanotubes

[0052] Take 5 g of the acid-etched modified halloysite nanotube powder and disperse it in 70 mL of 90% dimethyl sulfoxide (DMSO) solution, ultrasonically disperse, stir at 80°C for 6 h, and centrifuge with deionized water Washed 3 times, dried under vacuum at 60°C to obtain activated halloysite nanotubes.

[0053] (3) Load of Didecyl Dimethyl Ammonium Chloride (DDAC)

[0054] Dissolve 10 g of didecyl dimethyl ammonium chloride (DDAC) in 100 ml of deionized water, add 2 g of activated halloysite nanotubes, and ultrasonically disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com